Professional Documents

Culture Documents

Trex 01193

Trex 01193

Uploaded by

OSDocs2012Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trex 01193

Trex 01193

Uploaded by

OSDocs2012Copyright:

Available Formats

Task

lro,.ll

K1g move vvorK LISt r-eoruaury "u1u

1 2 Ooy 4

Meoo Blue MUX cables 3

!Replace #50 solenoid coli on Yellow POD 2

I Romove J.Box on #2 tonsloner 1

March

I PRS PM's due In March 3

UPS 11 & 12 1<

hnstall In MCC 7 (total MCC for Thruster 2) 14

I grounds 6

Total 44

I MooQ Blue MUX

-

I Replace #50 "" li on "

!change PBOF cablo ()n Yellow Pod flow meter 2

rl

t and repair Low Puroe air alarm and check Qreen IIQht under DCP panel 2

on #2 tonsloner

!Reset Process Stations 6

-..

Rewire wlre'MRU and Gyro

Work with TOI 1 on Iron ZMS (as penm1t)

6

Reolace batteries In UPS 11 & 12 12

lnstalf-bSCkb03rds"ln MCC 7 (total MCC for Thruster 2) 10

I "'ooard grounds 6

'uoornde (NOV tech

50

FWD Replace hoses that are susoect fas operatJons perrrul) 10

AFT PRS -Prs Replace hoses that are suspect c;;;- permll) 22

movo 18

365 DavPMon Mud Pump# 1 24

365 Day PM on Mud Pump# 2 24

Tot;! 98

IDrllUng

IRIQ Down 4

!Replace Tensloner #2 36

!Assist with DWHC 24

as noodod with roplacolnQ 2 RAMS 16

Assist as needed with TDS PM's 3

Assist as needed with PRS PM's 3

I Assist with PRS hose I 32

lchanae out drill line 24

Change out drill line roller >check) 3

Total 147

lllatlne

Arivol T ostlna 24

Transit 10

SeaT ex- 4 DOGPSuPQr.:>do9 4o EXHIBIT1113.d._

Total 74

WIT:

Subsea

- J

WORK TO BE PERFORMED ON BOP

-

I 1. Wash down BOP with high pressure wand to remove ollck sludge. 3

12. Full function test from both oods to checl< all an. 'charqodl 8

13. While function testino. check all hoses for leaks 6

[4. Drv fire EDS 1 and 2. check data logger for proper functions 2

Is. Chanoe out WH Conn with DWHC 24

Is. Inspect stack bore for kov seating 1

[7. Grease all failsafe volvos. 16

[8. Chance out Uooer and Middle VSR'S with 18

19. AdJust Procharqe In 80 gal 6

<nD.

1as many 112" hoses as possible on LMRP 6

1 1 .Install 6 518' test joint and make full pressure test. With all :Ch8raed 8

r12.1nstall manual riser tool and test all valves 8

I13.Perform full function test with both pods. (Post Service) 8

<D

1 low pressure test on Wellhead Conn. 2

15.1nsbll new AX posket In 1

[inooct lot ond 5k onnulor $1rlpplnp olomont. Ch>nQo Wla1kld tOStltlq, thon ro-t ltom11 ond thon oroeood 12. 13. 14 or<S 15. 30

Totnl

..... ORK TOBE

1 T.

t leak on Test Rams 2

l2. Chonpe DOd suooiY. allot filtern. and 4

[3. Drain and fill Ambient chambor on LMRP 1

4. Ensure all manual regulators are properly sot 2

5. Adjust precharqe In 60 gal. 3

6. Adjust precharqe in all ; on both pods 4

. Chanoe Pod Manifold Rooulator. 1

8. Pressure up both oods and check for leaks. 2

9. lnsoect Inside pods 1 tools. or leaks 1

10. Replace all 1 .5" control hoses for both annulars

261

WORK TO BE

I 1. Visually Inspect and replace outer poly oak seals In riser [This Is done by the Drilling Dept and con be I at their discretion

[2. At same time Inspect all thrust collars for loose parls or broken bolts 12 [This Is done by the Drilling Dept and can be I at their discretion

[3. VIsually Inspect and replace seals In ri ser adaptor 1 [This is done by the Drilling Dopt and can be I at thei r discretion

Total 25

[WORK TO BE I ON

-

[1. Change out Riser Tensloner #2 I 3sl

2. Chance out "Tens. Vent" and APV vent on I 41

Toblii

Additional work

I 1. lnsoect and chance as noodod all seals on dlvorter. 2

!2. Chango out suction and discharge filters on HPU 3

I Install now 208' Mud boost drape hose( drill aow to preform task) 10

Total 5

Overall Total 656

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- ZULF 29 ProgramDocument60 pagesZULF 29 ProgramJan Nico TorresNo ratings yet

- Modelling of Shale, Tight Oil and Gas Reservoirs - PRESENTATIONDocument70 pagesModelling of Shale, Tight Oil and Gas Reservoirs - PRESENTATIONsparda94No ratings yet

- Kettle ReboilersDocument4 pagesKettle ReboilersMuhammad Usman100% (1)

- GATE Chemical Engineering 2002Document10 pagesGATE Chemical Engineering 2002rahulsaini855No ratings yet

- Unit Ra o (S) : Chut''Document10 pagesUnit Ra o (S) : Chut''SAGAR PAVANENo ratings yet

- (:jjliti: T:I/I:Tll&/1'L (!N Hca'.FllDocument23 pages(:jjliti: T:I/I:Tll&/1'L (!N Hca'.FllGaurav AggarwalNo ratings yet

- Fermilab d0 en 124Document12 pagesFermilab d0 en 124charleselitb92No ratings yet

- Mechanical Engineering Objective Questions Part 1Document13 pagesMechanical Engineering Objective Questions Part 1sansagithNo ratings yet

- Trex 00185Document12 pagesTrex 00185OSDocs2012No ratings yet

- Instruction Manual FOR Brushless A.C. Generaior Tilodel TWYDocument17 pagesInstruction Manual FOR Brushless A.C. Generaior Tilodel TWYTahan Lodewyk Butar ButarNo ratings yet

- Electrical EngineeringDocument105 pagesElectrical Engineeringfakrul_is100% (5)

- Îndrumar Proiect M.A.I.Document182 pagesÎndrumar Proiect M.A.I.Regele ArthurNo ratings yet

- Hot Startup Checklist1Document6 pagesHot Startup Checklist1Selva ManianNo ratings yet

- EMB Centrifugal PumpDocument9 pagesEMB Centrifugal PumpFaiqah AzmirNo ratings yet

- Boiler Foster WheelerDocument48 pagesBoiler Foster WheelersprotkarNo ratings yet

- Burst and Pressure - Full ReportDocument18 pagesBurst and Pressure - Full ReportEspion BenNo ratings yet

- Trex 01194Document136 pagesTrex 01194OSDocs2012No ratings yet

- Table of ContentDocument17 pagesTable of ContentOh DausNo ratings yet

- Basics of Non-Ideal Flow April 2012Document37 pagesBasics of Non-Ideal Flow April 2012Syukri ShahNo ratings yet

- Bombas Volute Centrifugas0001Document7 pagesBombas Volute Centrifugas0001caovadio88No ratings yet

- Alcatel MDP-5010 Turbo Drag Pump ManualDocument28 pagesAlcatel MDP-5010 Turbo Drag Pump ManualAmir SohailNo ratings yet

- Silo Unloading PanelDocument9 pagesSilo Unloading PanelNikhil PariharNo ratings yet

- A Purpose:-: Ntpc/Tstps Operation Department Operating Instruction For Management of Turbine DrainsDocument13 pagesA Purpose:-: Ntpc/Tstps Operation Department Operating Instruction For Management of Turbine Drainsnetygen175% (4)

- Boe Thermal PaperDocument31 pagesBoe Thermal PaperAnand Swami100% (9)

- Itacklifej: Instruction ManualDocument73 pagesItacklifej: Instruction Manualwxhp5s66jgNo ratings yet

- Experiment No: 3: ObjectivesDocument14 pagesExperiment No: 3: ObjectivesAlimah Azeli100% (1)

- Boiler Operator Exam Preparation Guide-TheodoreDocument334 pagesBoiler Operator Exam Preparation Guide-TheodoreSyam PrasadNo ratings yet

- Boiler Operator Exam Preparation Guide pdf-1 PDFDocument27 pagesBoiler Operator Exam Preparation Guide pdf-1 PDFEmmanuel Jesus Marquez Rea100% (1)

- TCP Perforating ProgrammeDocument3 pagesTCP Perforating ProgrammeYougchu LuanNo ratings yet

- Lambretta 175 TV - Owners Manual - #3676Document32 pagesLambretta 175 TV - Owners Manual - #3676Mariano KokoNo ratings yet

- C C C C C C C C C C C C C C C C C C C C C C C C C: C C C CDocument4 pagesC C C C C C C C C C C C C C C C C C C C C C C C C: C C C CdelhivenkatramdasNo ratings yet

- Power Transformer Pre Commisioning ChecklistDocument26 pagesPower Transformer Pre Commisioning ChecklistRajesh TK100% (2)

- OwsDocument10 pagesOwsAnte BudimirNo ratings yet

- CJ FSM 84to86Document1,303 pagesCJ FSM 84to86Kevin StatzNo ratings yet

- P-51 Flight Manual 1944Document31 pagesP-51 Flight Manual 1944andrei_pirauNo ratings yet

- Hydraulic DataDocument32 pagesHydraulic Datafahirin100% (1)

- GATE Chemical Engineering 2003Document12 pagesGATE Chemical Engineering 2003anand singhNo ratings yet

- Standard Operating Procedures For FS EquipmentsDocument24 pagesStandard Operating Procedures For FS EquipmentsAnonymous LFgO4WbIDNo ratings yet

- Maintenance Check ListDocument6 pagesMaintenance Check ListGunadevan ChandrasekaranNo ratings yet

- BP America Gomx Deepwater Drilling MC 562 #1 Drilling Progra For 14-3/4"X16" By-PassDocument17 pagesBP America Gomx Deepwater Drilling MC 562 #1 Drilling Progra For 14-3/4"X16" By-PassOSDocs2012No ratings yet

- Refu Rbish Ment Proced Urc For Camelon Solenoid Valves Part No. 223290-15 and Part No. 223290-83Document14 pagesRefu Rbish Ment Proced Urc For Camelon Solenoid Valves Part No. 223290-15 and Part No. 223290-83OSDocs2012No ratings yet

- Adobe Scan 21 Oct. 2022Document1 pageAdobe Scan 21 Oct. 2022Juan Ariel BogadoNo ratings yet

- PETE 411: Well DrillingDocument36 pagesPETE 411: Well DrillingandrewNo ratings yet

- Culvert DesignDocument41 pagesCulvert Designkolopen andrewNo ratings yet

- GATE Chemical Engineering 1991Document7 pagesGATE Chemical Engineering 1991rahulNo ratings yet

- Deck Crane EL Control Box Mainetanance & Spare PartsDocument5 pagesDeck Crane EL Control Box Mainetanance & Spare PartsJayant AradwadNo ratings yet

- Total Company Process Eng Design ManuallDocument312 pagesTotal Company Process Eng Design ManuallChetan PatelNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- BP's Proposed Findings - Combined FileDocument1,303 pagesBP's Proposed Findings - Combined FileOSDocs2012No ratings yet

- DOJ Pre-Trial Statement On QuantificationDocument14 pagesDOJ Pre-Trial Statement On QuantificationwhitremerNo ratings yet

- To's Proposed FOF and COLDocument326 pagesTo's Proposed FOF and COLOSDocs2012No ratings yet

- BP's Post-Trial BriefDocument72 pagesBP's Post-Trial BriefOSDocs2012No ratings yet

- USAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)Document121 pagesUSAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)OSDocs2012No ratings yet

- Foam Stability Testing: Request Date Slurry I.D. Result CommentsDocument1 pageFoam Stability Testing: Request Date Slurry I.D. Result CommentsOSDocs2012No ratings yet

- HESI's Proposed FOF and COLDocument335 pagesHESI's Proposed FOF and COLOSDocs2012No ratings yet

- Webster:: Trial Transcript at 3975:2-4Document1 pageWebster:: Trial Transcript at 3975:2-4OSDocs2012No ratings yet

- PSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013Document72 pagesPSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013OSDocs2012100% (1)

- Exterior: Circa 2003Document1 pageExterior: Circa 2003OSDocs2012No ratings yet

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Document199 pagesPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012No ratings yet

- Macondo Bod (Basis of Design)Document23 pagesMacondo Bod (Basis of Design)OSDocs2012No ratings yet

- April 20, BLOWOUT: BP Misreads Logs Does Not IdentifyDocument22 pagesApril 20, BLOWOUT: BP Misreads Logs Does Not IdentifyOSDocs2012No ratings yet

- Driller HITEC Display CCTV Camera System: Source: TREX 4248 8153Document1 pageDriller HITEC Display CCTV Camera System: Source: TREX 4248 8153OSDocs2012No ratings yet

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Document5 pagesArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012No ratings yet

- Circa 2003Document1 pageCirca 2003OSDocs2012No ratings yet

- DR Gene: CloggedDocument1 pageDR Gene: CloggedOSDocs2012No ratings yet

- Production Interval: 14.1-14.2 PPG M57B Gas Brine GasDocument1 pageProduction Interval: 14.1-14.2 PPG M57B Gas Brine GasOSDocs2012No ratings yet

- End of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateDocument1 pageEnd of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateOSDocs2012No ratings yet

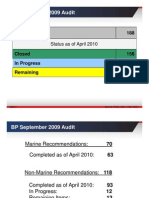

- BP September 2009 Audit: Total Items 188Document3 pagesBP September 2009 Audit: Total Items 188OSDocs2012No ratings yet

- Laboratory Results Cement Program Material Transfer TicketDocument13 pagesLaboratory Results Cement Program Material Transfer TicketOSDocs2012No ratings yet

- Engines: Electrical Power Generation (ELPG) Emergency Shutdown System (ESD)Document1 pageEngines: Electrical Power Generation (ELPG) Emergency Shutdown System (ESD)OSDocs2012No ratings yet

- Webster:: Trial Transcript at 4015:14-16Document1 pageWebster:: Trial Transcript at 4015:14-16OSDocs2012No ratings yet

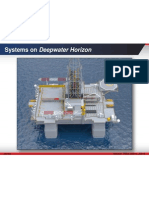

- Systems On Deepwater Horizon: Source: TREX-30014, 30015 D6753Document1 pageSystems On Deepwater Horizon: Source: TREX-30014, 30015 D6753OSDocs2012No ratings yet

- Thrusters: Propulsion (PROP)Document1 pageThrusters: Propulsion (PROP)OSDocs2012No ratings yet

- Webster:: Trial Transcript at 4136:17-18Document1 pageWebster:: Trial Transcript at 4136:17-18OSDocs2012No ratings yet

- Major DWH Maintenance Timeline: April 20, 2010 Rig in ServiceDocument7 pagesMajor DWH Maintenance Timeline: April 20, 2010 Rig in ServiceOSDocs2012No ratings yet

- Lloyd's Report - Appendix C: Deepwater Horizon Summary ReportDocument1 pageLloyd's Report - Appendix C: Deepwater Horizon Summary ReportOSDocs2012No ratings yet

- BP Is The OperatorDocument1 pageBP Is The OperatorOSDocs2012No ratings yet

- Transocean 2009 Annual Report: D6732 Source: TREX-5649Document3 pagesTransocean 2009 Annual Report: D6732 Source: TREX-5649OSDocs2012No ratings yet

- EMCDocument3 pagesEMCAnshikha NautiyalNo ratings yet

- Ideal Turbofan Cycle: Total Thrust Is Generated by Both Cold and Hot Jets.Document25 pagesIdeal Turbofan Cycle: Total Thrust Is Generated by Both Cold and Hot Jets.Elakkiya KarthicNo ratings yet

- ASME Code Safety Valve Rules-A Review and DiscussionDocument11 pagesASME Code Safety Valve Rules-A Review and DiscussionM WaleedNo ratings yet

- 299HDocument20 pages299HJulian Esteban Arnaiz VargasNo ratings yet

- Dow Therm J SpecificationsDocument28 pagesDow Therm J SpecificationsClintronicNo ratings yet

- Presentation On Centrifugal CompressorsDocument17 pagesPresentation On Centrifugal CompressorsakshayupadhyayNo ratings yet

- Air CompressorsDocument2 pagesAir CompressorsBrandy Ponting SusonNo ratings yet

- Dos and DontsDocument4 pagesDos and DontsArun GuptaNo ratings yet

- Syllabus - AO409 Wind Tunnel TechniquesDocument2 pagesSyllabus - AO409 Wind Tunnel TechniquesJohnNo ratings yet

- 6D Series Pump: Three-Screw Pumps Standard Product SpecificationsDocument2 pages6D Series Pump: Three-Screw Pumps Standard Product SpecificationsOreolNo ratings yet

- DT Series-Catalog 3800 - SectionE PDFDocument5 pagesDT Series-Catalog 3800 - SectionE PDFImran HashmiNo ratings yet

- GT Data Sheet 9FA PDFDocument6 pagesGT Data Sheet 9FA PDFZaki nouiNo ratings yet

- Practice ProblemsDocument5 pagesPractice ProblemsKaliyaperumal KalamegamNo ratings yet

- Design and Simulate An Aerodynamic Urban Concept Car Body For The Shell Eco-MarathonDocument76 pagesDesign and Simulate An Aerodynamic Urban Concept Car Body For The Shell Eco-Marathonanhelllo100% (1)

- Lox PDFDocument38 pagesLox PDFRobertNo ratings yet

- AEON® 9000TH: Synthetic Lubricant & Coolant For Rotary Screw Air CompressorsDocument2 pagesAEON® 9000TH: Synthetic Lubricant & Coolant For Rotary Screw Air CompressorsivanNo ratings yet

- CSE CatalogDocument1 pageCSE CatalogNhut PipingNo ratings yet

- Selecting Offshore LNG Processes: Engineering ForumDocument3 pagesSelecting Offshore LNG Processes: Engineering ForummohamedNo ratings yet

- Calculating The True Cost of SteamDocument2 pagesCalculating The True Cost of Steamisquare77No ratings yet

- Week 7Document6 pagesWeek 7shmyeNo ratings yet

- F110 e 1 001Document39 pagesF110 e 1 001ameen hassanNo ratings yet

- Report - Experimental Performance Evaluation of Vortex Tube RefrigeratorDocument68 pagesReport - Experimental Performance Evaluation of Vortex Tube RefrigeratorPakshyaNo ratings yet

- Halocarbon Compound: Presented By: Santos, John Merwin S. Pagdanganan, John Del C. Sanchez, Ronn Andrew EDocument10 pagesHalocarbon Compound: Presented By: Santos, John Merwin S. Pagdanganan, John Del C. Sanchez, Ronn Andrew ERalph Bernard Dela RosaNo ratings yet

- API Flush Plan 54Document2 pagesAPI Flush Plan 54hurrikenNo ratings yet

- Heat Pump Water HeatersDocument13 pagesHeat Pump Water Heatersdarthvader_1388No ratings yet

- Stanco Slaker - Brochure - Low Res ProofDocument2 pagesStanco Slaker - Brochure - Low Res ProofGuglielmo CancelliNo ratings yet

- Andrews' ExperimentsDocument3 pagesAndrews' ExperimentsRSLNo ratings yet

- States of MatterDocument6 pagesStates of MatterSetiawan TanadiNo ratings yet