Professional Documents

Culture Documents

Trex 08028

Trex 08028

Uploaded by

OSDocs2012Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trex 08028

Trex 08028

Uploaded by

OSDocs2012Copyright:

Available Formats

Exhibit No. Worldwide Courf lnc.

L

t x,Jd

turt IJrilJiry

\a'or d Co-.

ss,or o'

lF Bo DFeprdrer Fo,rlor O'rSo drc Ol\1o,e Dfilhnq

There are a few possibleexplanationsfor why the crew did neither: . First, they may not have recognizedthe severity of the situation, though that seems unlikely given th amount of mud that spewdfiom the rig floor. Second,they did not have much time to act. The explosion occurred roughly six to ight minutes after mud first emergedonto the rig floor Finalll., and perhapsmost significantly, the rig crew had not been trained adequately how to respond to such an emergencysituation. In the future, well-control training should include simulations and drills for such emergencies-inciuding the momentous decisionto engagethe blind shear rams or trigger the EDS

'

The Root Causes: Failures in lndustry and Government Overarching Management Failures Industry by

Whatevcr irreducible uncertainty may persist regarding the precisecontribution to the blowout of eachof sweral potentially immediate causes,no such uncertainty exists about the blowout's root causes.The blowout was not the product of a seriesof aberrational decisionsmade by rogue industry or government officials that cor.rldnot hav been anticipated or er?ectedto occur again. Rather,the root causesare systemic and, absent significant reform in both industry practicesand government policies,might well rcur The misstepswere rooted in systemic failures by industry managemmt (extendingbeyond BP to contractors that servemany in the industry), and also by failures of government to providceffective reguldtoryoversightoI offshoredrilling The most significant failure at Macondo and the clear rool causeof th blowout-was a failure of industry management Most, if not ail, of the failures at Macondo can be traced back lo r.rnderlyingfailures of managemcnt and communication. Better management of within RP and other companies,better communication within decisionmakingprocesses and between BP and its contractors, and efTective training of key engineeringand rig personnelwould have preventcdthe Macondo incident. BP and other operators must have effectivesystems in place for integrating the various corporate cLrltures,internal procedures,and decisionmakingprotocols of the many different contractors involved in drilling a deepwaterwell. RP .r DtanagcnitntIt (rL'cs,; Dt)tarhqrntct' idctrtity ot addrcss ri;ks ct catctl by latc diLl .lnDges to wdl dtsigu tltd prot edr/ftr. BP did not have adequatecontrols in place to ensur that key decisionsin the months leading up to the blowout were safeor sound from an engineeringperspective. While initial well design decisionsundergo a serious peerrwiew processr'5and changesto wll design are subsequently srrbjectto a management of change (MOC) process,rs6 changesto drilling procduresin the weeks and days before implementation are typically 1?r)tsubjct any such peer-reviewor MOC process At to Macondo, such decisionsappear to have been made by the BP Macondo team in ad hrrr-

fashion without any formal risk analysis or internal expert review.rsT This appearsto have beena key causal factor of the blowout. A few obvious e\amples, such as the last-minute confusion regarding whether to run six or 21 centralizers,hawealready been highlighted Another clear example is provided by the temporary abandonment procedureused at Macondo. As discussed earlier,that procedure changeddramatically and repeatedlyduring the week leading up to the blowout. As of April 12, the plan was to set the cement plug in seawaterless than l,OOOfeet below the mud line after setting the lockdown slewe. 1i,vodays latet Morel sent an e rnail in which the procedurewas to set th cement plug in mud before displacing the riser with seawater By April 20, the plan had morphd into the one set forth in the "Ops Note"r the crw would remove 3,300 feet of mud from below the mud line and set the cement plug after the riser had beendisplaced. There is no readily discerniblereasonwhy these temporary abandonment procedurescould not have been more thoroughly and rigorously vetted earlier in the design process.rs3 lt does not appear that the changesio the temporary abandonmnt procedureswent through any sort of formal review at all. jlallibtD'ton and Bl>'s t:nar'tagrruttit pr(rr'c-slrs rrrrf clsrt-!: th,lt rctlicnt r,'a5 a.lcquatclv drd tc-rLJ. Halliburton had insufficient controls in place to ensurethat laboratory testing was performed in a timely fashion or that test results were vetted rigorously in-house or with the client. In fact, it appearsthat Halliburton did not evn have testing results in its possession showing the Macondo slurry was stable until allcr thejob had beenpumped. It is difficult to imagine a clearerfailure of management or communication. The story of the foam stability tests may illuminate management problems within BPas well. By early April, BP team members had recognizedthe importance of timely cement testing.r5! Ar.rdby mid-April, BP's team had identified conccrns regarding the timeliness of Halliburton's testing processr'r' But despitetheir recognition that final changesto the cement design (made to accommodatetheir concernsabout lost returns) might increasethe risks of foam instability,r6r BP personncl do not appar to have insisted that Ilalliburton complete its foam stability tsts-let alone rport the rsults to BP for review-before ordcringprimdry ccmentingto hcgin BI n.1r1soccttt, and HalliburtoD Ltil*l to t'tttt ttutictttc adcqrlattlJ:.Information appearsto have been sxcessively compartmentalized at Macondo as a rcsult of poor communication BP did not sharimportant information rvith its contractors, or sometimesinternally even with members of its own team. Contractors did not share important information with BP or eachothr. As a result, individuals often Found themselvesmaking critical decisions without a full appreciation for the context in u/hich they were being made (or even without recognition that the decisions n,c.rc critical). For example,many BP and Halliburton employeeswere aware of the difficulty of the primary cementjob. But those issueswere for the most part n()t communicated to the rig crew that conductedthe negative-pressure test and monitored the well. It appearsthat

You might also like

- Plan of ConstructionDocument23 pagesPlan of ConstructionPeter MNo ratings yet

- This Is Not A Test - Scenario - Kickstart The Wasteland!Document28 pagesThis Is Not A Test - Scenario - Kickstart The Wasteland!dumi dumi100% (4)

- Vishnu Sahasranamam - TeluguDocument20 pagesVishnu Sahasranamam - TeluguIndrani Gorti100% (2)

- Business Continuity Management in A Dynamic Environment - Lessons From MacondoDocument8 pagesBusiness Continuity Management in A Dynamic Environment - Lessons From MacondoPetroNews100% (1)

- 1969 Body Armor For Aircrewmen - Natick PDFDocument29 pages1969 Body Armor For Aircrewmen - Natick PDFCarter TatumNo ratings yet

- Service Parts Supply Status List For Discontinued Models As of 15 Nov 2012Document3 pagesService Parts Supply Status List For Discontinued Models As of 15 Nov 2012Afrizal SetiawanNo ratings yet

- Manas Publications: New & Bestselling Books byDocument37 pagesManas Publications: New & Bestselling Books bydupeshNo ratings yet

- Trex 06384Document8 pagesTrex 06384OSDocs2012No ratings yet

- Deepwater Horizon - Summary of Critical Events, Human Factors Issues and ImplicationsDocument11 pagesDeepwater Horizon - Summary of Critical Events, Human Factors Issues and ImplicationschalakaaNo ratings yet

- BLOW OUT Report 3Document3 pagesBLOW OUT Report 3HELPPPPPNo ratings yet

- Deepwater DST Planning and Operations From A DP VesselDocument3 pagesDeepwater DST Planning and Operations From A DP VesselD. Nathan MeehanNo ratings yet

- Transocean Report Blaming BP For Deepwater Horizon DisasterDocument218 pagesTransocean Report Blaming BP For Deepwater Horizon Disasterjediparalegal100% (2)

- Groundwater Control For Design & Construction: PDH Course C587 (2 PDH)Document11 pagesGroundwater Control For Design & Construction: PDH Course C587 (2 PDH)T. E. MCLAUGHLIN, P.E.No ratings yet

- Spe 212925Document12 pagesSpe 212925Renzo LópezNo ratings yet

- Impact of The BP Macondo Blowout On ME Operations: Gas Arabia 2011Document25 pagesImpact of The BP Macondo Blowout On ME Operations: Gas Arabia 2011userscribd2011No ratings yet

- Possible Questions of NPBAC To CAP ADDDocument14 pagesPossible Questions of NPBAC To CAP ADDgian jorgioNo ratings yet

- Chapter 1Document54 pagesChapter 1m90abdelwahabNo ratings yet

- Deepstarsatellite DS151198Document17 pagesDeepstarsatellite DS151198umidNo ratings yet

- Why Systemic Management Failures in Well ControlDocument43 pagesWhy Systemic Management Failures in Well Controlivan8villegas8buschNo ratings yet

- Well Plug and AbandonmentDocument2 pagesWell Plug and Abandonmentfaraj100% (2)

- Three Cases - Study: IBP2165 - 12 Improving Well Integrity Throughout Its Life CycleDocument5 pagesThree Cases - Study: IBP2165 - 12 Improving Well Integrity Throughout Its Life CycleMarcelo Varejão CasarinNo ratings yet

- TH THDocument9 pagesTH THP.MannaNo ratings yet

- Rapport: Deepwater Horizon-Ulykken: Årsaker, Lærepunkter Og Forbedrings-Tiltak For Norsk SokkelDocument11 pagesRapport: Deepwater Horizon-Ulykken: Årsaker, Lærepunkter Og Forbedrings-Tiltak For Norsk SokkelAlexander Rueda OrduzNo ratings yet

- Iadc CementingDocument2 pagesIadc CementingMauricio Sanchez BNo ratings yet

- Root Causes-Failures That Casuse The Macondo Well ExplosionDocument28 pagesRoot Causes-Failures That Casuse The Macondo Well Explosionnissefar007100% (1)

- IChemE - LPB 117-1994 - Flixborough 20 Years OnDocument3 pagesIChemE - LPB 117-1994 - Flixborough 20 Years Onsl1828100% (1)

- Offshore Corrosion Integrity ManagementDocument24 pagesOffshore Corrosion Integrity ManagementJanneth Herrera FloresNo ratings yet

- Case Study of British Petroleum and The Deepwater Horizon Disaster of 2010Document6 pagesCase Study of British Petroleum and The Deepwater Horizon Disaster of 2010Abdul Muhaymin MahdiNo ratings yet

- 20101220-Fracking Stocks - The Top Growth Sector For Investors in 2011Document5 pages20101220-Fracking Stocks - The Top Growth Sector For Investors in 2011SchaliegasNo ratings yet

- Decommission and Removal of Offshore O Amp G Facilities 1997Document68 pagesDecommission and Removal of Offshore O Amp G Facilities 1997Linh TranNo ratings yet

- HPHT Well Construction With Closed-Loop Cementing (C-LC) TechnologyDocument16 pagesHPHT Well Construction With Closed-Loop Cementing (C-LC) TechnologyRafael_F_Antunes100% (1)

- FPSO Lessons LearntDocument21 pagesFPSO Lessons LearntAnant Arvind Kulkarni100% (6)

- Trex 04697Document42 pagesTrex 04697OSDocs2012No ratings yet

- A Comprehensive Review On The Loss of Wellbore Integrity Due To Cement Failure and Available Remedial MethodsDocument16 pagesA Comprehensive Review On The Loss of Wellbore Integrity Due To Cement Failure and Available Remedial MethodsXuning WuNo ratings yet

- En 1093 1 1011Document11 pagesEn 1093 1 1011bed passNo ratings yet

- Chatar 2016Document13 pagesChatar 2016GERARDO TORRES RUIZNo ratings yet

- Spring 2012 Oilfield Review PDFDocument60 pagesSpring 2012 Oilfield Review PDFBolsec14No ratings yet

- Assignment 02 POMDocument3 pagesAssignment 02 POMSajal KhanNo ratings yet

- 13-5335-KEO-ST-RPT-0003 - 01 - 150615 Structural Report For Annual Tunnel Audit - 27jul15 PDFDocument162 pages13-5335-KEO-ST-RPT-0003 - 01 - 150615 Structural Report For Annual Tunnel Audit - 27jul15 PDFAnonymous 2wNNl0ULENo ratings yet

- Macondo Report 20042011Document33 pagesMacondo Report 20042011Dr K GallowglaichNo ratings yet

- North Sea Offshore Authorities Forum: Page 1 of 18Document18 pagesNorth Sea Offshore Authorities Forum: Page 1 of 18Saeed MalikNo ratings yet

- Tech Review - TO - 22Document12 pagesTech Review - TO - 22rohanZorbaNo ratings yet

- Process Safety Learning From Disasters: #10 Texas City Refinery ExplosionDocument4 pagesProcess Safety Learning From Disasters: #10 Texas City Refinery ExplosionCarlos Alberto Ferreira FilhoNo ratings yet

- Drilling Optimization TechnologiesDocument9 pagesDrilling Optimization TechnologiesSergio RamirezNo ratings yet

- Otc-31004-Superior Performance Shell BrazilDocument15 pagesOtc-31004-Superior Performance Shell Brazilmbkh7117No ratings yet

- KODIGO For Presentation To NPBACrev2Document11 pagesKODIGO For Presentation To NPBACrev2gian jorgioNo ratings yet

- Trex 06166Document82 pagesTrex 06166OSDocs2012No ratings yet

- Em - 1110 2 3506Document159 pagesEm - 1110 2 3506dannychacon27No ratings yet

- Real Time Drilling OptimizationDocument3 pagesReal Time Drilling OptimizationSergio RamirezNo ratings yet

- Contingency Planning: Chapter TenDocument4 pagesContingency Planning: Chapter TenApukiNo ratings yet

- 2019 017 PDFDocument4 pages2019 017 PDFLarizza TesicoNo ratings yet

- MPWMD Agenda Item 17 Exh 17a 03-18-13Document7 pagesMPWMD Agenda Item 17 Exh 17a 03-18-13L. A. PatersonNo ratings yet

- Ihs PDFDocument8 pagesIhs PDFMarcos SobreiroNo ratings yet

- Garmony Environmental Statement Rev B App BDocument15 pagesGarmony Environmental Statement Rev B App BTAHER AMMARNo ratings yet

- Draft For: Flood Penetration Seal Performance at Nuclear Power PlantsDocument26 pagesDraft For: Flood Penetration Seal Performance at Nuclear Power PlantsAdil ButtNo ratings yet

- The Latent Causes of Rework in Floating Production Storage and Offloading ProjectsDocument15 pagesThe Latent Causes of Rework in Floating Production Storage and Offloading ProjectsDanish KhandelwalNo ratings yet

- Otc19607 About API RP 2skDocument12 pagesOtc19607 About API RP 2skBinh PhamNo ratings yet

- Causes of The Deepwater Horizon Blowout PDFDocument9 pagesCauses of The Deepwater Horizon Blowout PDFBen EdwardsNo ratings yet

- Trex 07324Document52 pagesTrex 07324OSDocs2012No ratings yet

- Exhibit: Page 1 of 1Document14 pagesExhibit: Page 1 of 1OSDocs2012No ratings yet

- Method Statement For Bending and Installation of Downspout For Toll PlazaDocument14 pagesMethod Statement For Bending and Installation of Downspout For Toll PlazaJoseph Aroc AllauiganNo ratings yet

- Riopipeline2019 1086 RPC 1086 19 SCC Management Rev PDFDocument10 pagesRiopipeline2019 1086 RPC 1086 19 SCC Management Rev PDFMarcelo Varejão CasarinNo ratings yet

- Risk Management For Deepwater Oil DrillingDocument4 pagesRisk Management For Deepwater Oil Drillingvarunmunjal245No ratings yet

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- USAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)Document121 pagesUSAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)OSDocs2012No ratings yet

- To's Proposed FOF and COLDocument326 pagesTo's Proposed FOF and COLOSDocs2012No ratings yet

- BP's Post-Trial BriefDocument72 pagesBP's Post-Trial BriefOSDocs2012No ratings yet

- BP's Proposed Findings - Combined FileDocument1,303 pagesBP's Proposed Findings - Combined FileOSDocs2012No ratings yet

- PSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013Document72 pagesPSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013OSDocs2012100% (1)

- DOJ Pre-Trial Statement On QuantificationDocument14 pagesDOJ Pre-Trial Statement On QuantificationwhitremerNo ratings yet

- Macondo Bod (Basis of Design)Document23 pagesMacondo Bod (Basis of Design)OSDocs2012No ratings yet

- HESI's Proposed FOF and COLDocument335 pagesHESI's Proposed FOF and COLOSDocs2012No ratings yet

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Document199 pagesPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012No ratings yet

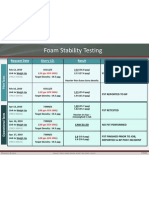

- Foam Stability Testing: Request Date Slurry I.D. Result CommentsDocument1 pageFoam Stability Testing: Request Date Slurry I.D. Result CommentsOSDocs2012No ratings yet

- Driller HITEC Display CCTV Camera System: Source: TREX 4248 8153Document1 pageDriller HITEC Display CCTV Camera System: Source: TREX 4248 8153OSDocs2012No ratings yet

- DR Gene: CloggedDocument1 pageDR Gene: CloggedOSDocs2012No ratings yet

- April 20, BLOWOUT: BP Misreads Logs Does Not IdentifyDocument22 pagesApril 20, BLOWOUT: BP Misreads Logs Does Not IdentifyOSDocs2012No ratings yet

- Lloyd's Report - Appendix C: Deepwater Horizon Summary ReportDocument1 pageLloyd's Report - Appendix C: Deepwater Horizon Summary ReportOSDocs2012No ratings yet

- Production Interval: 14.1-14.2 PPG M57B Gas Brine GasDocument1 pageProduction Interval: 14.1-14.2 PPG M57B Gas Brine GasOSDocs2012No ratings yet

- Exterior: Circa 2003Document1 pageExterior: Circa 2003OSDocs2012No ratings yet

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Document5 pagesArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012No ratings yet

- Circa 2003Document1 pageCirca 2003OSDocs2012No ratings yet

- Webster:: Trial Transcript at 4015:14-16Document1 pageWebster:: Trial Transcript at 4015:14-16OSDocs2012No ratings yet

- Laboratory Results Cement Program Material Transfer TicketDocument13 pagesLaboratory Results Cement Program Material Transfer TicketOSDocs2012No ratings yet

- Webster:: Trial Transcript at 3975:2-4Document1 pageWebster:: Trial Transcript at 3975:2-4OSDocs2012No ratings yet

- Webster:: Trial Transcript at 4136:17-18Document1 pageWebster:: Trial Transcript at 4136:17-18OSDocs2012No ratings yet

- End of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateDocument1 pageEnd of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateOSDocs2012No ratings yet

- BP Is The OperatorDocument1 pageBP Is The OperatorOSDocs2012No ratings yet

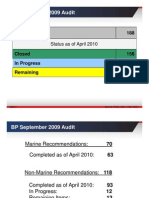

- BP September 2009 Audit: Total Items 188Document3 pagesBP September 2009 Audit: Total Items 188OSDocs2012No ratings yet

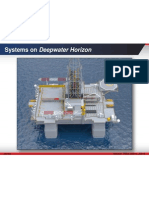

- Systems On Deepwater Horizon: Source: TREX-30014, 30015 D6753Document1 pageSystems On Deepwater Horizon: Source: TREX-30014, 30015 D6753OSDocs2012No ratings yet

- Engines: Electrical Power Generation (ELPG) Emergency Shutdown System (ESD)Document1 pageEngines: Electrical Power Generation (ELPG) Emergency Shutdown System (ESD)OSDocs2012No ratings yet

- Thrusters: Propulsion (PROP)Document1 pageThrusters: Propulsion (PROP)OSDocs2012No ratings yet

- Major DWH Maintenance Timeline: April 20, 2010 Rig in ServiceDocument7 pagesMajor DWH Maintenance Timeline: April 20, 2010 Rig in ServiceOSDocs2012No ratings yet

- Transocean 2009 Annual Report: D6732 Source: TREX-5649Document3 pagesTransocean 2009 Annual Report: D6732 Source: TREX-5649OSDocs2012No ratings yet

- Is0100c SM PDFDocument160 pagesIs0100c SM PDFAaron PaulNo ratings yet

- AT Kubark - PT - 2 Price PDFDocument6 pagesAT Kubark - PT - 2 Price PDFvickieNo ratings yet

- Wwii Unit PlanDocument4 pagesWwii Unit Planapi-279024854No ratings yet

- Seawall, Bulkheads, Quaywall (Retaining Wall & Anchorage)Document86 pagesSeawall, Bulkheads, Quaywall (Retaining Wall & Anchorage)Gaston ChinNo ratings yet

- Military Map Reading: Version 2.0 Dated December 2010Document44 pagesMilitary Map Reading: Version 2.0 Dated December 2010Ron FisherNo ratings yet

- A Call To Action - Lessons From Ukraine For The Future ForceDocument13 pagesA Call To Action - Lessons From Ukraine For The Future ForceTodd DiNettaNo ratings yet

- The Habsburg-Ottoman WarsDocument2 pagesThe Habsburg-Ottoman WarsSára UhercsákNo ratings yet

- Perilous ProspectsDocument405 pagesPerilous ProspectsKenneth Lee0% (1)

- War Thunder Community Magazine Issue 5 PDFDocument86 pagesWar Thunder Community Magazine Issue 5 PDFstevelate73100% (3)

- The Philippine RevolutionDocument32 pagesThe Philippine RevolutionBeejay Raymundo100% (1)

- 0129 Life Is Not Ours - UPDATE 3Document31 pages0129 Life Is Not Ours - UPDATE 3S. M. Hasan ZidnyNo ratings yet

- Who Was Vedius Pollio?Document9 pagesWho Was Vedius Pollio?Kumar SinghNo ratings yet

- Universidad Técnica de Ambato Facultad de Ingeniería Civil Y Mecánica Carrera de Ingeniería Civil Agua Potable ProyectoDocument1 pageUniversidad Técnica de Ambato Facultad de Ingeniería Civil Y Mecánica Carrera de Ingeniería Civil Agua Potable ProyectoJairo ArmasNo ratings yet

- Flags at WaterlooDocument12 pagesFlags at WaterlooJoshua Reyes90% (10)

- War in PeaceDocument10 pagesWar in PeacePaoloViarengoNo ratings yet

- War Diary - Oct. 1942 PDFDocument161 pagesWar Diary - Oct. 1942 PDFSeaforth WebmasterNo ratings yet

- Russia's Spheres of Interest, Not Influence: Dmitri TreninDocument20 pagesRussia's Spheres of Interest, Not Influence: Dmitri TreninJavier BeticoNo ratings yet

- Delta Squadron - Sep 2009Document9 pagesDelta Squadron - Sep 2009CAP Unit NewslettersNo ratings yet

- Will Allow You To Do The FollowingDocument5 pagesWill Allow You To Do The FollowingAlysszandraNo ratings yet

- Task 1. Read The Text and Choose The Best Summary.: A Skill B ChanceDocument3 pagesTask 1. Read The Text and Choose The Best Summary.: A Skill B ChanceBeatrice JanauskaiteNo ratings yet

- Gun Trade World June 2017Document68 pagesGun Trade World June 2017Elizardo MartinezNo ratings yet

- Zillur A Liberation War HeroDocument1 pageZillur A Liberation War HeroYousuf AliNo ratings yet

- Major Causes of The British Empire DeclineDocument2 pagesMajor Causes of The British Empire Declineعمر الخيامNo ratings yet

- The First Battle of GroznyDocument71 pagesThe First Battle of GroznyScimitar Mcmlxv100% (1)

- Aircraft CompanyDocument2 pagesAircraft CompanyBobbyD.ResjaNo ratings yet