Professional Documents

Culture Documents

Sheet 6

Sheet 6

Uploaded by

Abdalla Mohamed AbdallaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet 6

Sheet 6

Uploaded by

Abdalla Mohamed AbdallaCopyright:

Available Formats

BENHA UNIVERSITY BANHA FACULTY OF ENGINEERING MECHANICAL ENGINEERING DEPARTMENT

M578 HYDRAULIC POWER SYSTEMS 5 YEAR PRODUCTION ENGINEERING DR. H. EL-BATSH | ENG. ABDALLA MOHAMED

TH

SHEET6: HYDRAULIC SYSTEM DESIGN

PROPLEMS 1. Design a hydraulic circuit to lift a guided load of 4 tones vertically for a stroke of 0.5 m. The retract speed of the load is 6 m/min. The hydraulic cylinder is mounted by its front flange and the piston rod is rigidly fixed. The system pressure is limited to 300 bar. a) Construct the hydraulic circuit with its accessories and explain the function of each element. b) Design the actuator. c) Estimate the pump type, its flow rate in liter per minute, and the extending speed. d) If you connect a hydraulic motor instead of the hydraulic cylinder, calculate the torque produced if the load will be driven with 30 rpm. (Hint: take into your consideration the volumetric and mechanical efficiencies) 2. It is required to design a big hydraulic crane is used to lift a mechanical load of about 10 tons vertically for a distance of 1 meter with a speed 3 m/min. The system must provide locking for the cylinder position in any position, and gives 8 different speeds. a) Draw the hydraulic circuit with its accessories and explain the function of each component. b) Design the hydraulic actuator i. Select its type. (Write your reasons) ii. Find its dimensions. iii. Estimate the best method for mounting. (Draw a free-hand sketch for it) c) Select the hydraulic power unit i. Select the pump type. (write your reasons) ii. Which type of displacement is it? iii. Calculate the input power required at the pump shaft in kilowatts.

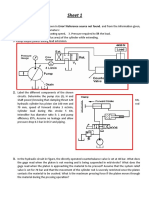

3. In a given hydraulic system, the hydraulic cylinder is 12 cm inner diameter which drives a load of 200 kN with a speed of 8 cm/s. The pump overall efficiency is 0.85. Determine a) The pump exit pressure and the pump flow rate. b) The power and the torque required to drive the pump if the pump is driven by an electric motor with speed of 3000 rpm. c) The maximum possible cylinder load and corresponding pump driving power if the relief valve is adjusted at 30 MPa. 4. A hydraulic cylinder is to compress a car body down to a bale size in 10 seconds. The operation requires 13.05 m stroke and 35520 N force. If a 68 bar pump has been selected and assuming the cylinder is 100% efficient, find the following: a) The required piston area. b) The necessary pump flow rate. c) The hydraulic power delivered to the cylinder. d) Solve parts a, b, and c assuming frictional force of 444 N and a leakage of 0.776 lpm. Then determine the efficiency of the cylinder with the given friction force and leakage. 5. A sequence valve is used in a hydraulic press with two cylinders. The first cylinder exerts 10 kN to move and hold the work piece while the other cylinder is used to perform the pressing job with 180 kN. Both cylinders have bore diameter of 150 mm and a 100 rod diameter. Both cylinders have to move at velocity of 5 m/min. Draw the circuit using symbols [2 marks] and then determine: a) Pump pressure during work piece movement. b) Pump pressure during pressing. c) The capacity of the pump. d) Select appropriate pressure to set the sequence valve. 6. A machine tool cylinder gives a rapid approach speed of 10 m/min for a stroke of 1.0 m with a thrust of 2.5 tones. It then switched to give a pressing speed of 0.25 m/min for a 0.5 m with a thrust of 10 tones. The system working pressure should not exceed 200 bar. Draw a hydraulic circuit which can satisfy these requirements and obtain the following: a) Suitable size for the cylinder. b) The pressure setting for switching the circuit. c) The circuit efficiency for rapid approach and for final pressing. 7. The cylinder shown in figure has to apply extend force of 80 kN and retract force of 10 kN. The retract speed should be 5 m/min using full pump flow. The maximum pump pressure is 150 bar and the pressure drops over the filter is 3 bar and over the directional valve (for each path) is 2 bar.

Determine the cylinder size (assuming 2:1 ratio piston area to piston rod area). Determine also the pump size and circuit efficiency during extend and during retract.

8. A sequence valve is used in a hydraulic press with two cylinders. The first cylinder exerts 10 kN to move and hold the work piece while the other cylinder is used to perform the pressing job with 180 kN. Both cylinders have bore diameter of 150 mm and a 100 rod diameter. Both cylinders have to move at velocity of 5 m/min. Draw the circuit using symbols and then determine: a) Pump pressure during work piece movement. b) Pump pressure during pressing. c) The capacity of the pump. d) Select appropriate pressure to set the sequence valve. 9. A hydraulic power system has cylinder piston diameter = 20.3 cm and piston rod diameter = 10.2 cm. the cylinder extending speed is 7.6 cm/s. the external load of the cylinder during extend = 178 kN. The pump mechanical efficiency =90 % and the pump volumetric efficiency = 92%. Pump speed = 1800 rpm. The total pressure drop in the line from pump discharge to the cylinder is 5.2 bars and the pressure drop in the return line from the rodend of the cylinder is 3.5 bar. Draw the circuit using standard symbols and determine the following: a) Pump volumetric displacement. b) Input power to drive the pump. c) Input torque to the pump. d) Circuit efficiency during extend. 10. A press cylinder having a bore of 140 mm and a 100 mm diameter rod is to have an initial approach speed of 5 m/min and final pressing speed of 0.5 m/min. The system pressure for rapid approach is 40 bar and for final pressing 350 bar. Two pumps (high and low) are used in the system. Both pumps may be assumed to have volumetric and mechanical efficiencies of

0.95 and 0.9, respectively. Draw the circuit using symbols and then determine: a) The flow to the cylinder for rapid approach and final processing. b) Suitable deliveries for each pump. c) Each pump displacement if the drive speed is 1800 rpm. d) The pump motor power required during rapid approach and during final pressing. 11. A hydraulic power system has cylinder piston diameter = 20.3 cm and piston rod diameter = 10.2 cm. the cylinder extending speed is 7.6 cm/s. the external load of the cylinder during extend = 178 kN. The pump mechanical efficiency =90 % and the pump volumetric efficiency = 92%. Pump speed = 1800 rpm. The total pressure drop in the line from pump discharge to the cylinder is 5.2 bars and the pressure drop in the return line from the rod-end of the cylinder is 3.5 bar. Draw the circuit using standard symbols and determine the following: a) Pump volumetric displacement. b) Input power to drive the pump. c) Input torque to the pump. d) Circuit efficiency during extend. 12. Shown is the load-lifting mode of a hydraulic system having the following parameters: Pump: a swash plate axial piston pump, with piston diameter = 8 mm, pitch circuit diameter = 3 cm, swash plate inclination angle = 20, mechanical efficiency = 0.9, total efficiency = 0.81, number of pistons = 7, pump speed = 3000 rpm. Relief valve: preset at a relief pressure of 10 MP, with zero override pressure. Hydraulic cylinder: an ideal cylinder, loaded by a constant load of 60kN; the piston and piston rod diameters are 10 cm and 7 cm, respectively. Check valve: of zero cracking pressure. Throttle valve: sharp-edged with a 3 mm2 cross-sectional area. Hydraulic oil: a 850 kg/m3 density. (a) Explain the function of the system. (b) Calculate the piston speed and pump driving power at each of the two positions of the DCV if the pressure in the pump delivery line does not reach the preset relief pressure. Neglect the losses in lines and DCV.

13. For the following system, calculate the pump exit pressure, and the override pressure of the relief valve, given: Pump: pump speed = 1000 rpm, volumetric efficiency = 0.95, and pump displacement = 8 cm3 Relief valve: Pr = 22.5 MPa, andQr = K(Override pressure) ; K = 1013 where Pp is the pump exit pressure and (Pp Pr ) is the override pressure Throttle valve: throttle area a = 1 mm2 and Qm = 0.029a . Hydraulic motor: motor displacement Vm = 80 cm3/rev, total efficiency = 0.68, volumetric efficiency = 0.93, and loading torque = 200 Nm.

14. A 50-kN hydraulic press performs pressing and clamping actions. The clamping cylinder force is 4 kN. The pressing cylinder stroke is 30 cm and its extension speed is 8 cm/s. Design the hydraulic circuits, perform the preliminary calculations, and select the needed hydraulic elements. Then, calculate the different operating modes of the system. Assume, always, reasonable values for any missing data.

DUE DATE: NEXT WEEK | 1,2 DAYS AFTER D.D.: -10% | 3,7: -20% | 8,14: -40% | >15: 0 PLAGIARISM = 0 | A4 PAPERS | NAME, SECTION & SUBJECT ONLY; CLEAR ON THE 1ST PAPER ONLY

You might also like

- Đề thi HK221Document4 pagesĐề thi HK221Hải NguyễnNo ratings yet

- Tutorial 3 (Pump Power Efficiency)Document2 pagesTutorial 3 (Pump Power Efficiency)lamaNo ratings yet

- 2 (Pumps)Document2 pages2 (Pumps)arsenic_94100% (1)

- ME2135E Fluid Mechanics II Tutorial 1Document3 pagesME2135E Fluid Mechanics II Tutorial 1Law Zhan Hong0% (1)

- Sheet 4Document5 pagesSheet 4Abdalla Mohamed AbdallaNo ratings yet

- New Sheet - CorrectedDocument19 pagesNew Sheet - CorrectedklashincoviskyNo ratings yet

- Fluid Power Systems - Sheet 2Document4 pagesFluid Power Systems - Sheet 2Mohamed Maher100% (1)

- TutorialDocument27 pagesTutorialbassemNo ratings yet

- Sheet 4 New PDFDocument3 pagesSheet 4 New PDFMahmoud GaballaNo ratings yet

- 2135 Tutorial 1Document4 pages2135 Tutorial 1Eezhar JumadiNo ratings yet

- TM 7me4a Question Bank Mid Term IDocument1 pageTM 7me4a Question Bank Mid Term IVijay SharmaNo ratings yet

- Hydraulic Sheet7 - ActuatorsDocument3 pagesHydraulic Sheet7 - ActuatorsAmany SobhyNo ratings yet

- Assignemnt 05Document3 pagesAssignemnt 05Abdalrhman SayedNo ratings yet

- Fluid Power AutomationquestonsDocument3 pagesFluid Power AutomationquestonsSriram Nanjangud SubramanyaNo ratings yet

- Steam EnginesDocument6 pagesSteam Engineschat2adiNo ratings yet

- HDM360S Tutorial 2-2024 - Hydraulic PumpsDocument5 pagesHDM360S Tutorial 2-2024 - Hydraulic Pumpssmisosphamandla30No ratings yet

- SumsDocument3 pagesSumssp2532658.1970No ratings yet

- Turbo Machinery Tutorial - Jan-Feb 2012Document3 pagesTurbo Machinery Tutorial - Jan-Feb 2012Suchithra RamanNo ratings yet

- Application of 3/2 DCV For Controlling A Single-Acting CylinderDocument2 pagesApplication of 3/2 DCV For Controlling A Single-Acting Cylindernarasimha rao100% (1)

- Fluid Machinery II Seme2 2006Document2 pagesFluid Machinery II Seme2 2006Arindam MisraNo ratings yet

- Sheet5-Centrifugal PumpDocument5 pagesSheet5-Centrifugal Pumpyousef mohamedNo ratings yet

- Assignment 6Document3 pagesAssignment 6Muhammad Jawad IsmaeelNo ratings yet

- Problem Set 1Document15 pagesProblem Set 1Silva, Joe Mari T.No ratings yet

- Tutorial 2Document2 pagesTutorial 2zul hilmiNo ratings yet

- Sheet No2Document7 pagesSheet No2Ismail SakrNo ratings yet

- Hydraulic Components and SystemsDocument31 pagesHydraulic Components and SystemsPrasad ChamarajanagarNo ratings yet

- ExChapter7 HydraulicActuator2-QDocument2 pagesExChapter7 HydraulicActuator2-QMr. A.ENo ratings yet

- Sheet 2Document3 pagesSheet 2Abdalla Mohamed AbdallaNo ratings yet

- 9A01308 Fluid Mechanics and Hydraulic MachineryDocument4 pages9A01308 Fluid Mechanics and Hydraulic MachinerysivabharathamurthyNo ratings yet

- MidtermExam Sample ME561Document1 pageMidtermExam Sample ME561Sushil ChoudharyNo ratings yet

- Fundamentals of FluidesDocument2 pagesFundamentals of FluidesAbderrahman ZINE EL ABIDINENo ratings yet

- Week Two Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek Two Homework Problems: Fundamentals of ! Fluid PowerhellfireNo ratings yet

- Week Two Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek Two Homework Problems: Fundamentals of ! Fluid Powermustafa1011No ratings yet

- Week Two Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek Two Homework Problems: Fundamentals of ! Fluid PowerhellfireNo ratings yet

- Week Two Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek Two Homework Problems: Fundamentals of ! Fluid PowerhellfireNo ratings yet

- Structural Calculation EOTDocument2 pagesStructural Calculation EOTAmarnath0% (1)

- Assigment IIDocument4 pagesAssigment IIMurtesa KumaNo ratings yet

- Worksheet 1Document5 pagesWorksheet 1DANIEL WELDAYNo ratings yet

- DPBC Question BankDocument10 pagesDPBC Question BankshubhamNo ratings yet

- Muzeyin FocusDocument3 pagesMuzeyin FocuseyobNo ratings yet

- SQ - 4.7 - Pumps (Table Format)Document5 pagesSQ - 4.7 - Pumps (Table Format)Amitav MishraNo ratings yet

- Hydarulic SheetsDocument11 pagesHydarulic Sheetsأحمد عبدالجليلNo ratings yet

- Final Exam - Hydraulic - Tanta UniversityDocument4 pagesFinal Exam - Hydraulic - Tanta UniversityGehad MohamedNo ratings yet

- Assignment and WorksheetDocument2 pagesAssignment and WorksheetAbebe AyingdaNo ratings yet

- Ex Chapter 7 - HydraulicActuatorDocument2 pagesEx Chapter 7 - HydraulicActuatorMr. A.ENo ratings yet

- 1.trial On Gear PumpDocument6 pages1.trial On Gear PumpAlmas 1710No ratings yet

- 1.trial On Gear PumpDocument6 pages1.trial On Gear PumpAlmas 1710No ratings yet

- UNIT 5 HydraulicsDocument31 pagesUNIT 5 Hydraulicsnandu20No ratings yet

- Assignemnt 04Document2 pagesAssignemnt 04Abdalrhman SayedNo ratings yet

- Taller 5 FluidosDocument5 pagesTaller 5 FluidosManuel OlayaNo ratings yet

- r5310302 Hydraulic Machinery and SystemsDocument4 pagesr5310302 Hydraulic Machinery and SystemswirelessandlessNo ratings yet

- Problem Set ADocument3 pagesProblem Set AAldrich BaldonadoNo ratings yet

- Ajay Kumar Garg Engineering College, Ghaziabad: Department of Mechanical EngineeringDocument3 pagesAjay Kumar Garg Engineering College, Ghaziabad: Department of Mechanical EngineeringMradul GuptaNo ratings yet

- Quetions Turbo.................Document4 pagesQuetions Turbo.................DICKSON SIMUTAMINo ratings yet

- Assignment-Fluid MechanicsDocument2 pagesAssignment-Fluid MechanicsTarani TharanNo ratings yet

- Assighnment On Chapter 3 and 4Document2 pagesAssighnment On Chapter 3 and 4Samuel WozabNo ratings yet

- MEC 4106 Pumps Tutorial SheetDocument6 pagesMEC 4106 Pumps Tutorial SheetleitchNo ratings yet

- Sheet 4Document5 pagesSheet 4vector mosesNo ratings yet

- OAFISjLOEeiP Qrke KVoA Setting A Sales Goal AOSDocument1 pageOAFISjLOEeiP Qrke KVoA Setting A Sales Goal AOSAbdalla Mohamed AbdallaNo ratings yet

- Engineering From Home: White PaperDocument7 pagesEngineering From Home: White PaperAbdalla Mohamed AbdallaNo ratings yet

- Hydraulics and Conveyor Systems: TrainingDocument3 pagesHydraulics and Conveyor Systems: TrainingAbdalla Mohamed AbdallaNo ratings yet

- Optimization of Polysulfone / Graphene Oxide / Polyethylene Glycol / Triaminopyrimidine by Using Response Surface MethodologyDocument8 pagesOptimization of Polysulfone / Graphene Oxide / Polyethylene Glycol / Triaminopyrimidine by Using Response Surface MethodologyAbdalla Mohamed AbdallaNo ratings yet

- Investigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyDocument12 pagesInvestigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyAbdalla Mohamed AbdallaNo ratings yet

- Dd422i Specification Sheet EnglishDocument4 pagesDd422i Specification Sheet EnglishAbdalla Mohamed AbdallaNo ratings yet

- Research Grant Donors: ItidaDocument5 pagesResearch Grant Donors: ItidaAbdalla Mohamed AbdallaNo ratings yet

- PublicationDocument1 pagePublicationAbdalla Mohamed AbdallaNo ratings yet

- #Aimenjobs: R&D Senior Researcher in Advanced Materials: Polymer and CompositesDocument2 pages#Aimenjobs: R&D Senior Researcher in Advanced Materials: Polymer and CompositesAbdalla Mohamed AbdallaNo ratings yet

- W 4 Yte 54 SyDocument2 pagesW 4 Yte 54 SyAbdalla Mohamed AbdallaNo ratings yet

- Teaching Statement: Roberto Silveira Silva FilhoDocument2 pagesTeaching Statement: Roberto Silveira Silva FilhoAbdalla Mohamed AbdallaNo ratings yet

- Creating Effective Scientific Figures For PublicationDocument24 pagesCreating Effective Scientific Figures For PublicationAbdalla Mohamed AbdallaNo ratings yet

- ﻝﺎﻤﻟﺍ ﺓﺪﻳﺮﺟ ﺭﺎﺒﺧﺃ ﻢﻫﺃ (Alltopstories - 1.Aspx/) : ﻙﻮـــﻨﺑ (Section/12/1/بنـــوك/)Document9 pagesﻝﺎﻤﻟﺍ ﺓﺪﻳﺮﺟ ﺭﺎﺒﺧﺃ ﻢﻫﺃ (Alltopstories - 1.Aspx/) : ﻙﻮـــﻨﺑ (Section/12/1/بنـــوك/)Abdalla Mohamed AbdallaNo ratings yet

- CourseworkFEA CAD 2015Document4 pagesCourseworkFEA CAD 2015Abdalla Mohamed AbdallaNo ratings yet

- Stress Analysis AssignmentDocument1 pageStress Analysis AssignmentAbdalla Mohamed AbdallaNo ratings yet

- Formal Supervision Meeting Record Template - PGR-PROG-04Document2 pagesFormal Supervision Meeting Record Template - PGR-PROG-04Abdalla Mohamed AbdallaNo ratings yet

- CADE Technologybrochure AccumulatorsDocument24 pagesCADE Technologybrochure AccumulatorsJose francisco Lazo castroNo ratings yet

- Check Valves 2003Document14 pagesCheck Valves 2003Cesar Augusto Navarro ChirinosNo ratings yet

- ENGINEERING - DESIGN - GUIDELINES Control Valve Sizing and SelectionDocument28 pagesENGINEERING - DESIGN - GUIDELINES Control Valve Sizing and SelectionAlberto Enrique De Santa Anna Campderá100% (1)

- Expansion BellowsDocument97 pagesExpansion BellowsShrikant100% (1)

- Product Loading - Marine Loading ArmDocument9 pagesProduct Loading - Marine Loading Arminvilink87No ratings yet

- DarshanDocument21 pagesDarshanMandar Ambi100% (1)

- Specification: Filter Regulator+LubricatorDocument2 pagesSpecification: Filter Regulator+LubricatorLuiggi Javier Juliano BarraNo ratings yet

- 006 API610 PumpsDocument110 pages006 API610 Pumpskaveh fadaeiNo ratings yet

- Site Part Number Customer SCM PL Abcq ASP (Local) Dec-18Document3 pagesSite Part Number Customer SCM PL Abcq ASP (Local) Dec-18Ajay SinghNo ratings yet

- PEDDocument2 pagesPEDAjay KumarNo ratings yet

- OTC Rigless Completions: A Spoolable Coiled-Tubing Gas-Lift SystemDocument6 pagesOTC Rigless Completions: A Spoolable Coiled-Tubing Gas-Lift SystemyesicaNo ratings yet

- First Checking: Mass Balance Checking in TurbineDocument17 pagesFirst Checking: Mass Balance Checking in TurbineTrisha Mae BelmonteNo ratings yet

- TM - Midea - Creator - Rooftop Package - T1 - 50Hz - Heat Pump - 20200603 - V6 (6) 1Document100 pagesTM - Midea - Creator - Rooftop Package - T1 - 50Hz - Heat Pump - 20200603 - V6 (6) 1Nahuel DezilaNo ratings yet

- Technical Spec Movable Bridge Kap 50 Ton Taipa PaluDocument2 pagesTechnical Spec Movable Bridge Kap 50 Ton Taipa PaluSiprianus GamurNo ratings yet

- Spare Parts - EquipmentsDocument12 pagesSpare Parts - EquipmentsCesar Rojas MonteroNo ratings yet

- Price List Spare Part Tdar 2522: No CodeDocument2 pagesPrice List Spare Part Tdar 2522: No Codemacis garisNo ratings yet

- T80520en Samson DatasheetDocument12 pagesT80520en Samson Datasheetbruno devinckNo ratings yet

- Libo GS: Document / Drawing Submission Status Proyek Penyesuaian Pompa RokanDocument5 pagesLibo GS: Document / Drawing Submission Status Proyek Penyesuaian Pompa RokanekyyyNo ratings yet

- Catalogue en 50hz PDFDocument643 pagesCatalogue en 50hz PDFMECHANICAL ENGINEERINGNo ratings yet

- Ecovar Product Portfolio - N2Document17 pagesEcovar Product Portfolio - N2Jesus ChristNo ratings yet

- ABB Turbocharging: Tps - . - D / EDocument8 pagesABB Turbocharging: Tps - . - D / ETibor AngeloNo ratings yet

- BopDocument80 pagesBopcrni rokoNo ratings yet

- AE01Document5 pagesAE01jawadalurdaniNo ratings yet

- Water Transmission and Distribution SystemsDocument71 pagesWater Transmission and Distribution SystemsDr. Akepati Sivarami Reddy100% (6)

- Cylinder Head: N103.4H3 Tractor (N3 Series)Document2 pagesCylinder Head: N103.4H3 Tractor (N3 Series)Patrick LandinNo ratings yet

- Laddomat 21 ManualDocument8 pagesLaddomat 21 ManualAlonso CoradoNo ratings yet

- Hydraulics (: Laboratory ManualDocument27 pagesHydraulics (: Laboratory ManualRyan Christopher0% (1)

- 09 - Ball ValvesDocument10 pages09 - Ball ValvesacildeNo ratings yet

- (Package-2-Mech Works) : Clean Fuels ProjectDocument17 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet