Professional Documents

Culture Documents

Properties of Thermoplastic Composites Based On Wheat Straw Lignocellulosic Fillers

Properties of Thermoplastic Composites Based On Wheat Straw Lignocellulosic Fillers

Uploaded by

Nory Elago CagatinCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Dr. Premamoy Ghosh - Polymer Science and Technology - Plastics, Rubber, Blends and Composites-McGraw-Hill Education (2011)Document594 pagesDr. Premamoy Ghosh - Polymer Science and Technology - Plastics, Rubber, Blends and Composites-McGraw-Hill Education (2011)Dildeep Jayadevan100% (1)

- GB 4806.11-2016 (Food Migration)Document17 pagesGB 4806.11-2016 (Food Migration)Adel AdielaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Polymer Lab ReportDocument5 pagesPolymer Lab ReportSanzidaNo ratings yet

- Effects of Molecular Weight On Melt Spinning and Mechanical Properties of High Performance PET FibersDocument8 pagesEffects of Molecular Weight On Melt Spinning and Mechanical Properties of High Performance PET FibersMarcus NguyễnNo ratings yet

- Rubber IndiaDocument6 pagesRubber IndiaBizvin OpsNo ratings yet

- Nylon 66Document5 pagesNylon 66Novelia Ananda FitrilaNo ratings yet

- Compression Molding: Neslihan Yağmur 11/12/2012Document17 pagesCompression Molding: Neslihan Yağmur 11/12/2012Karthick PrasadNo ratings yet

- Synthetic Fibres & Plastics Class 8Document3 pagesSynthetic Fibres & Plastics Class 8Pushpa KumariNo ratings yet

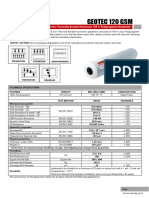

- Geotec 120Document2 pagesGeotec 120hazelNo ratings yet

- Pu ElastomerDocument34 pagesPu ElastomerSuyash TrivediNo ratings yet

- (HEMA) Technical Data Sheet BisomerDocument2 pages(HEMA) Technical Data Sheet BisomerOsmar ContrerasNo ratings yet

- Polyvinyl Acetate - Polyvinyl AlcoholDocument15 pagesPolyvinyl Acetate - Polyvinyl AlcoholUtkarsh Singh100% (1)

- The Burn Test To Identify Textile FibersDocument2 pagesThe Burn Test To Identify Textile FibersRonak JoshiNo ratings yet

- Acronal MB 6476Document3 pagesAcronal MB 6476jose mondacaNo ratings yet

- Development A5Document33 pagesDevelopment A5api-279282047No ratings yet

- Plastic Wiki 5Document2 pagesPlastic Wiki 5WolfMensch1216No ratings yet

- Synthetic Fibre - WorksheetDocument3 pagesSynthetic Fibre - WorksheetALWIN BOBYNo ratings yet

- Liquid Resins & Additives: Europe, Middle East & AfricaDocument30 pagesLiquid Resins & Additives: Europe, Middle East & Africatrường phạmNo ratings yet

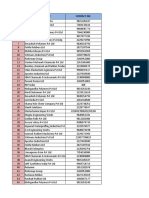

- CON1070 - Lot 11 PricingDocument648 pagesCON1070 - Lot 11 PricingSHiroGBNo ratings yet

- QueriesDocument4 pagesQuerieskommaNo ratings yet

- PolymersDocument34 pagesPolymersJerryco AlviarNo ratings yet

- Tds e DF740Document1 pageTds e DF740尹燕祥No ratings yet

- Indian StandardDocument13 pagesIndian StandardRitesh kumarNo ratings yet

- Liquid Thermoplastic Resinfor Tougher CompositesDocument6 pagesLiquid Thermoplastic Resinfor Tougher Compositeshaolanwang.ac96gNo ratings yet

- Tutorial 1 Solution For PolymerDocument4 pagesTutorial 1 Solution For PolymerdvianNo ratings yet

- Polymer-Matrix Composites (PMC) : General FeaturesDocument27 pagesPolymer-Matrix Composites (PMC) : General FeaturesMahender NagramNo ratings yet

- Unit 2 PlasticsDocument18 pagesUnit 2 PlasticsNivedhaNo ratings yet

- TEXTILE MATERIAL PRACTICAL FIleDocument29 pagesTEXTILE MATERIAL PRACTICAL FIleshivam kumNo ratings yet

- Reactive ExtrusionDocument19 pagesReactive ExtrusionEetu SatosalmiNo ratings yet

- Rubber SyntheticsDocument25 pagesRubber SyntheticsAlif SabilaNo ratings yet

Properties of Thermoplastic Composites Based On Wheat Straw Lignocellulosic Fillers

Properties of Thermoplastic Composites Based On Wheat Straw Lignocellulosic Fillers

Uploaded by

Nory Elago CagatinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Properties of Thermoplastic Composites Based On Wheat Straw Lignocellulosic Fillers

Properties of Thermoplastic Composites Based On Wheat Straw Lignocellulosic Fillers

Uploaded by

Nory Elago CagatinCopyright:

Available Formats

Properties of Thermoplastic Composites Based on Wheat-Straw Lignocellulosic Fillers

F. Le Digabel,1 N. Boquillon,2 P. Dole,3 B. Monties,3 L. Averous4

Unite Mixte de Recherche (UMR), Institut National de la Recherche Agronomique (INRA)/Universite de Reims Champagne-Ardenne (URCA), Ecole Superieure dIngenieurs en Emballage et Conditionnement (ESIEC), Boite Postal (BP) 1029, 51686 Reims Cedex 2, France 2 Agro-Industrie Recherche et Developpement (ARD), Route de Bazancourt, 51110 Pomacle, France 3 UMR INRA/URCA, Centre de Recherche en Agronomie (CRA), BP 1039, 51687 Reims Cedex 2, France 4 Ecole Europeenne en Chimie, Polymeres et Materiaux (ECPM) [Laboratoire dIngenierie des Polymeres pour les Hautes ` ` Technologies (LIPHT)], 25 Rue Becquerel, 67087 Strasbourg Cedex 2, France

Received 3 June 2003; accepted 14 January 2004 DOI 10.1002/app.20426 Published online in Wiley InterScience (www.interscience.wiley.com). ABSTRACT: Lignocellulosic fractions from wheat straw were used as natural llers in composites of a polyolen (a copolymer of polyethylene and polypropylene) and a biodegradable polyester [poly(butylene adipate-co-terephthalate)]. The mechanical properties of these injected composites were investigated with tensile and impact testing. A reinforcing effect of wheat-straw residues was found for both types of composites. Compared with the polyesterbased composites, the polyolen composites were more brittle. The addition of compatibilizing agents ( -methacryloxypropyltrimethoxysilane, maleic anhydride modied polypropylene, and stearic acid) did not improve the properties of the polyolen composites. The surface properties were studied with contact-angle measurements, and poor interfacial adhesion was found between the hydrophilic lignocellulosic ller and the hydrophobic polyolen matrix. Thermal characterization revealed the formation of low intermolecular bonds between the polyester matrix and the lignocellulosic ller, in agreement with the surface tensions results and scanning electron microscopy observations.

2004 Wiley Periodicals, Inc. J Appl Polym Sci 93: 428 436, 2004

1

Key words: composites; biodegradable; polyesters; biobers; interfaces

INTRODUCTION For several years, natural bers have been used as reinforcing additives for polymers. Wood bers have been commonly combined with thermoplastic17 or thermoset8 matrices to enhance mechanical properties such as the stiffness and impact strength. In recent years, annual crop bers have been increased in value through their incorporation into various polymers. Agricultural waste can originate from different sources, such as sisal, jute, coconut, and ax,9 28 and it has signicant potential as a source of low-cost reinforcements for polymers, particularly polyolens such as polyethylene (PE) or polypropylene. However, polyolens are not the most appropriate matrices for natural bers because of their nonpolar character and the polar properties of agricultural waste. Several solutions have been proposed to improve interfacial compatibility, such as chemical or physical treatment of the bers. Different coupling or compatibilizing

Correspondence to: L. Averous (averousl@ecpm.ustrasbg. fr). Contract grant sponsor: EuropolAgro (Reims, France). Journal of Applied Polymer Science, Vol. 93, 428 436 (2004) 2004 Wiley Periodicals, Inc.

agents have been widely used to modify the surface tension of bers.2129 Another alternative for obtaining good compatibility between natural bers and a matrix is to use more polar thermoplastic matrices such as poly(methyl methacrylate), polyacrylate, poly(vinyl chloride), and biodegradable polyesters.30 38 Wheat-straw waste is a natural byproduct of the industrial fractionation of wheat straw. To enhance the value of this residue, we propose its incorporation into thermoplastic polymers. Two matrices and different polarities have been tested. Composites based on a hydrophobic matrix such as a polypropylenepolyethylene copolymer require chemical modication, whereas composites based on a more hydrophilic matrix such as a biodegradable polyester are likely to present better interfacial compatibility. The mechanical and thermal properties of these wheat-strawwaste-based composites have been investigated. The crucial importance of interfacial interactions has been studied. EXPERIMENTAL Materials Two thermoplastic matrices were used. The polypropylenepolyethylene (6%) copolymer was supplied by

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Dr. Premamoy Ghosh - Polymer Science and Technology - Plastics, Rubber, Blends and Composites-McGraw-Hill Education (2011)Document594 pagesDr. Premamoy Ghosh - Polymer Science and Technology - Plastics, Rubber, Blends and Composites-McGraw-Hill Education (2011)Dildeep Jayadevan100% (1)

- GB 4806.11-2016 (Food Migration)Document17 pagesGB 4806.11-2016 (Food Migration)Adel AdielaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Polymer Lab ReportDocument5 pagesPolymer Lab ReportSanzidaNo ratings yet

- Effects of Molecular Weight On Melt Spinning and Mechanical Properties of High Performance PET FibersDocument8 pagesEffects of Molecular Weight On Melt Spinning and Mechanical Properties of High Performance PET FibersMarcus NguyễnNo ratings yet

- Rubber IndiaDocument6 pagesRubber IndiaBizvin OpsNo ratings yet

- Nylon 66Document5 pagesNylon 66Novelia Ananda FitrilaNo ratings yet

- Compression Molding: Neslihan Yağmur 11/12/2012Document17 pagesCompression Molding: Neslihan Yağmur 11/12/2012Karthick PrasadNo ratings yet

- Synthetic Fibres & Plastics Class 8Document3 pagesSynthetic Fibres & Plastics Class 8Pushpa KumariNo ratings yet

- Geotec 120Document2 pagesGeotec 120hazelNo ratings yet

- Pu ElastomerDocument34 pagesPu ElastomerSuyash TrivediNo ratings yet

- (HEMA) Technical Data Sheet BisomerDocument2 pages(HEMA) Technical Data Sheet BisomerOsmar ContrerasNo ratings yet

- Polyvinyl Acetate - Polyvinyl AlcoholDocument15 pagesPolyvinyl Acetate - Polyvinyl AlcoholUtkarsh Singh100% (1)

- The Burn Test To Identify Textile FibersDocument2 pagesThe Burn Test To Identify Textile FibersRonak JoshiNo ratings yet

- Acronal MB 6476Document3 pagesAcronal MB 6476jose mondacaNo ratings yet

- Development A5Document33 pagesDevelopment A5api-279282047No ratings yet

- Plastic Wiki 5Document2 pagesPlastic Wiki 5WolfMensch1216No ratings yet

- Synthetic Fibre - WorksheetDocument3 pagesSynthetic Fibre - WorksheetALWIN BOBYNo ratings yet

- Liquid Resins & Additives: Europe, Middle East & AfricaDocument30 pagesLiquid Resins & Additives: Europe, Middle East & Africatrường phạmNo ratings yet

- CON1070 - Lot 11 PricingDocument648 pagesCON1070 - Lot 11 PricingSHiroGBNo ratings yet

- QueriesDocument4 pagesQuerieskommaNo ratings yet

- PolymersDocument34 pagesPolymersJerryco AlviarNo ratings yet

- Tds e DF740Document1 pageTds e DF740尹燕祥No ratings yet

- Indian StandardDocument13 pagesIndian StandardRitesh kumarNo ratings yet

- Liquid Thermoplastic Resinfor Tougher CompositesDocument6 pagesLiquid Thermoplastic Resinfor Tougher Compositeshaolanwang.ac96gNo ratings yet

- Tutorial 1 Solution For PolymerDocument4 pagesTutorial 1 Solution For PolymerdvianNo ratings yet

- Polymer-Matrix Composites (PMC) : General FeaturesDocument27 pagesPolymer-Matrix Composites (PMC) : General FeaturesMahender NagramNo ratings yet

- Unit 2 PlasticsDocument18 pagesUnit 2 PlasticsNivedhaNo ratings yet

- TEXTILE MATERIAL PRACTICAL FIleDocument29 pagesTEXTILE MATERIAL PRACTICAL FIleshivam kumNo ratings yet

- Reactive ExtrusionDocument19 pagesReactive ExtrusionEetu SatosalmiNo ratings yet

- Rubber SyntheticsDocument25 pagesRubber SyntheticsAlif SabilaNo ratings yet