Professional Documents

Culture Documents

Washing Machine Motor Controller

Washing Machine Motor Controller

Uploaded by

Suneel VenkatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Washing Machine Motor Controller

Washing Machine Motor Controller

Uploaded by

Suneel VenkatCopyright:

Available Formats

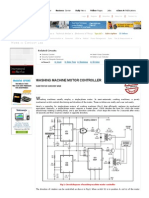

WASHING MACHINE MOTOR CONTROLLER

Abstract by- V.Venkata Suneel(08P61A0262) Washing machines usually employ a single-phase motor. In semi-automatic washing machines, a purely mechanical switch controls the timing and direction of the motor. These switches are costly and wear out easily. Heres a controller for single-phase motors of washing machines that efficiently replaces its mechanical equivalent. Basically, a single-phase motor requires a master timer, which decides the time for which the motor should keep rotating, and a spin direction controller, which stops the motor for 3 seconds after every 10 seconds and then resumes rotation in opposite direction. The direction of rotation can be controlled. When switch S1 is in position A, coil L1 of the motor receives the current directly, whereas coil L2 directly receives current with a phase shift due to capacitor C. so the rotor rotates in clockwise direction. When switch S1 is in position B, the reverse happens and the rotor rotates in anti-clock wise direction. Thus switch S1 can change rotation direction. The motor cannot be reversed instantly. It needs a brief pause between switching directions, or else it may get damaged. For this purpose, another spin direction control timer (IC2) is employed. It is realised with an IC555. This timer gives an alternate on and off time duration of 10 seconds and 3 seconds respectively. So after every 10 seconds of running (either in clockwise or anti-clockwise direction), the motor stops for a brief duration of 3 seconds. The values of R3 and R4 are calculated accordingly. The master timer is realised with mono-stable IC555 (IC1) and its ontime is decided by the resistance of 1megaohm potentiometer VR. A 47-kilo-ohm resistor is added in series so that even when the VR knob is in zero resistance position, the net-series resistance is not zero. The on-off cycle in the master timer should go on only for the set time ( here it is 18 minutes ). Ones the master timer goes off, the cycle should stop. To achieve this the outputs of both the timers are connected to NAND gate N1(IC3), which gives a low output only when both the timers are giving high outputs. The output pin-2 of N1 is connected to relay RL1 via PNP transistor T1, so the relay energises only when the output from NAND gate N1 emerges. As the mains 220 volts line taken through relay RL1, the motor turns off during the 3 second off period after the set time of 10 seconds is over. During on time of spin direction timer IC2, the output off negative edge triggered JK flip-flop at pin2 goes low to energise RL2 and washing machine motor rotates in 1 direction. During the off time of IC2, the output of N1 goes high again to de-energise relay RL1, which cuts off the main supply to RL2 and the motor stops rotating. Floating point trouble may occur at trigger pin2 of IC1. Resistor R8 overcomes this problem by holding pin2 high.

You might also like

- Time Study PresentationDocument16 pagesTime Study PresentationMubasher RajputNo ratings yet

- Sand BlastingDocument1 pageSand BlastingReynaldo PesqueraNo ratings yet

- Honeywell CS10XE Evaporative Air Cooler English - Instructions - ManualDocument21 pagesHoneywell CS10XE Evaporative Air Cooler English - Instructions - Manualaljh71100% (2)

- Tables of R22 Ammonia R134aDocument17 pagesTables of R22 Ammonia R134aStar GlacierNo ratings yet

- Induction MotorDocument74 pagesInduction Motormera nam chinNo ratings yet

- Induction MotorDocument4 pagesInduction MotorPauline JacintoNo ratings yet

- Heaters WaterDocument8 pagesHeaters WaterkittieyNo ratings yet

- AO Smith Commercial Electric Water HeatersDocument84 pagesAO Smith Commercial Electric Water HeatersKathryn WorkmanNo ratings yet

- Low Cost AutomationDocument88 pagesLow Cost AutomationvijisathishNo ratings yet

- 09 ST-Water HeaterDocument56 pages09 ST-Water HeaterMisdehRasmanNo ratings yet

- Air Cooler E-Catalogue SUMMER 2022Document9 pagesAir Cooler E-Catalogue SUMMER 2022ABHISHEK CHAUDHARYNo ratings yet

- Sand Blasting MachineDocument3 pagesSand Blasting MachineCarl Diaz100% (1)

- Godrej InterioDocument33 pagesGodrej InterioTarun MaheshwariNo ratings yet

- ChimneyDocument5 pagesChimneyrajachandaNo ratings yet

- Low Cost Automation DeeDocument16 pagesLow Cost Automation DeeDeekshu 4141likilNo ratings yet

- Line BalancingDocument5 pagesLine Balancingsaravananpg8697No ratings yet

- Studies On Flow Characteristics at High-Pressure Die-CastingDocument6 pagesStudies On Flow Characteristics at High-Pressure Die-CastingRashed KaiserNo ratings yet

- Air Cooler or Air Conditioner Which Is Bestcvhgk PDFDocument2 pagesAir Cooler or Air Conditioner Which Is Bestcvhgk PDFwormocelot4No ratings yet

- Cs071ae Honeywell Portable Air Cooler 7 LiterDocument42 pagesCs071ae Honeywell Portable Air Cooler 7 LiterHenry Avilés ChongNo ratings yet

- Die Casting ResearchDocument10 pagesDie Casting Researchمحمد الخالديNo ratings yet

- Work Study 1Document47 pagesWork Study 1Anonymous phDoExVlNo ratings yet

- Kaff Kitchen AppliancesDocument16 pagesKaff Kitchen Appliancesraj dubeyNo ratings yet

- Work Study Method Study Work MeasurementDocument53 pagesWork Study Method Study Work MeasurementPrabhu VelidindiNo ratings yet

- Line Balancing Problem: 3.4 MinsDocument11 pagesLine Balancing Problem: 3.4 MinsSureshMandwaniNo ratings yet

- LG Refrigerator Repair in HyderabadDocument22 pagesLG Refrigerator Repair in HyderabaddharaniNo ratings yet

- How To Trade The Budget PDFDocument33 pagesHow To Trade The Budget PDFrishab agarwalNo ratings yet

- Line BalancingDocument18 pagesLine BalancingSivakumar K100% (1)

- Work StudyDocument16 pagesWork StudyAkanksha kondaNo ratings yet

- Productivity Improvement by Line Balancing On JacketDocument47 pagesProductivity Improvement by Line Balancing On JacketAmanuel Mulatu Boche100% (1)

- General Introduction of Hydraulic PressDocument2 pagesGeneral Introduction of Hydraulic PressKabil RajNo ratings yet

- Hydraulic Baling PressDocument3 pagesHydraulic Baling Pressajay pandeyNo ratings yet

- Candle Stick EncrptDocument26 pagesCandle Stick EncrptHarish vijayakumarNo ratings yet

- Split AC On RCDocument11 pagesSplit AC On RCSubir Kumar BiswasNo ratings yet

- Design of Mechanical Press PDFDocument8 pagesDesign of Mechanical Press PDFArsl RanaNo ratings yet

- Refrigeration Cycle: COP Q W COP Q WDocument8 pagesRefrigeration Cycle: COP Q W COP Q WZain Ul AbideenNo ratings yet

- Developments in Injection Moulding 3Document331 pagesDevelopments in Injection Moulding 3Salah HammamiNo ratings yet

- GLASSDocument5 pagesGLASSPamela SidicNo ratings yet

- Washing Machine: Case Study: Embedded SystemDocument16 pagesWashing Machine: Case Study: Embedded SystemPreetam KarmakarNo ratings yet

- Low Cost Automation For CNC Machining Center PDFDocument11 pagesLow Cost Automation For CNC Machining Center PDFgsudhanta1604No ratings yet

- Pressure Die CastingDocument5 pagesPressure Die CastingIdrisNo ratings yet

- Types of PlasticsDocument6 pagesTypes of PlasticsFarrukh ShahzadNo ratings yet

- 3phase Induction Motor (Sukhpreet)Document17 pages3phase Induction Motor (Sukhpreet)Ankesh KunwarNo ratings yet

- List of Licences: Data For IS 2082: 1993 (All India)Document21 pagesList of Licences: Data For IS 2082: 1993 (All India)cooolaxeNo ratings yet

- CastingDocument20 pagesCastingCHANDRAJEET AMARNo ratings yet

- Induction Motor: Presented by Pranesh KaDocument26 pagesInduction Motor: Presented by Pranesh KaPranesh KaNo ratings yet

- Design and Analysis of Pressure Die Casting For Door HandleDocument6 pagesDesign and Analysis of Pressure Die Casting For Door HandleEditor IJTSRDNo ratings yet

- Electromagnetic Induction: Sardar Patel Institute of Technology 1Document22 pagesElectromagnetic Induction: Sardar Patel Institute of Technology 1krushiNo ratings yet

- Applications of Ergonomics and Work Study in An Organization (A Case Study)Document9 pagesApplications of Ergonomics and Work Study in An Organization (A Case Study)International Journal of Innovative Science and Research Technology100% (3)

- Induction MotorDocument7 pagesInduction MotoruwaifotonyNo ratings yet

- Figure 1: SMED SystemDocument13 pagesFigure 1: SMED SystemAbdulziz kurdiNo ratings yet

- Glass: Leading The Way in Glass Manufacturing SolutionsDocument12 pagesGlass: Leading The Way in Glass Manufacturing Solutionsshaileshgupta83No ratings yet

- 102 Hydraulic Press-Job ProcedureDocument3 pages102 Hydraulic Press-Job ProcedureShams TabrezNo ratings yet

- Injection MouldingDocument12 pagesInjection MouldingFranzMigNo ratings yet

- V Guard Electric Water Heaters PDFDocument31 pagesV Guard Electric Water Heaters PDFYOGENDER KUMARNo ratings yet

- Assembly Line BalancingDocument19 pagesAssembly Line BalancingMilan MeeraNo ratings yet

- Casting ProcessesDocument42 pagesCasting ProcessesVijay PawarNo ratings yet

- Different Types of GlassesDocument20 pagesDifferent Types of GlassesRatnesh PatelNo ratings yet

- Work StudyDocument55 pagesWork StudyvvvvmNo ratings yet

- Single Phase Motor Controller For Washing Machine ApplicationDocument3 pagesSingle Phase Motor Controller For Washing Machine ApplicationVenkata Rajkumar ChNo ratings yet

- Washing Machine Motor ControllerDocument3 pagesWashing Machine Motor ControllerprabhyodhNo ratings yet

- Electronics Washing Machine ControlDocument4 pagesElectronics Washing Machine ControlMohd ShukriNo ratings yet

- 3 D 91654 Fed 96 C 76 ADocument7 pages3 D 91654 Fed 96 C 76 APhuriwat ChantraworawitNo ratings yet

- SPE-196769-MS - Burdakov, Wolcott - WAG Pilot Design and ResultsDocument15 pagesSPE-196769-MS - Burdakov, Wolcott - WAG Pilot Design and ResultsDonald WolcottNo ratings yet

- Quotation - Transformer Coil Winding MachineDocument5 pagesQuotation - Transformer Coil Winding MachineDavid BernalNo ratings yet

- A Battery Charge and Discharge Device Using PID Genetic Algorithm Based On PWM RectifierDocument4 pagesA Battery Charge and Discharge Device Using PID Genetic Algorithm Based On PWM RectifierAdi MulyadiNo ratings yet

- Jet Fuel Colonial Grade 54 - JP54Document1 pageJet Fuel Colonial Grade 54 - JP54BernhardNo ratings yet

- Electric Illumination McqsDocument48 pagesElectric Illumination McqsEngrAneelKumarAkhani36% (14)

- HVOF Coatings PDFDocument36 pagesHVOF Coatings PDFRadu HaiducuNo ratings yet

- HT MCQ QBDocument41 pagesHT MCQ QBSaurabh ChaudhariNo ratings yet

- Randell 2010Document2 pagesRandell 2010dstout74No ratings yet

- Electronegativity PDFDocument42 pagesElectronegativity PDFNehaNo ratings yet

- Selina Chemistry X Periodic-Table Periodic-PropertiesDocument26 pagesSelina Chemistry X Periodic-Table Periodic-PropertiesSumeet ShindeNo ratings yet

- Processing Station - Part 1 (Mpob HQ 21711)Document56 pagesProcessing Station - Part 1 (Mpob HQ 21711)Ameen Zenn100% (2)

- Jet Fan Exhaust System Layout B-2 Floor: 241 CarsDocument1 pageJet Fan Exhaust System Layout B-2 Floor: 241 CarsUsama TahirNo ratings yet

- Hardware ProjectDocument11 pagesHardware ProjectGirish TayalNo ratings yet

- Phy 2 Military 2024Document7 pagesPhy 2 Military 2024sam2jbegNo ratings yet

- A Project On "Tranformers": JULY 3, 2019Document33 pagesA Project On "Tranformers": JULY 3, 2019Aman SrivastavaNo ratings yet

- Chap1 The Physics of Solar CellsDocument16 pagesChap1 The Physics of Solar Cellsmin_yu_6No ratings yet

- C C 5 56 62 2 C CM M: Description Boundary Layer MicrophoneDocument2 pagesC C 5 56 62 2 C CM M: Description Boundary Layer MicrophoneoikklNo ratings yet

- Work Transfer Authorization (WTA) ProcedureDocument15 pagesWork Transfer Authorization (WTA) ProcedureOkinawa TeakNo ratings yet

- Trans Switching-Power SRX SRV enDocument24 pagesTrans Switching-Power SRX SRV enMoch Abduh AlcantaraNo ratings yet

- R7410207 High Voltage EngineeringDocument4 pagesR7410207 High Voltage EngineeringsivabharathamurthyNo ratings yet

- MULTI V 5 Catalog PDFDocument34 pagesMULTI V 5 Catalog PDFquangNo ratings yet

- Public Speaking Global WarmingDocument2 pagesPublic Speaking Global Warmingمحمد صبحي عبدالرحيم100% (2)

- 61120-0011-2 REV.0 DescriptionDocument19 pages61120-0011-2 REV.0 DescriptionJin HernNo ratings yet

- Bul SAE J2044 PDFDocument8 pagesBul SAE J2044 PDFGenny_ArtiacoNo ratings yet

- Amana Package Terminal Service Instructions PDFDocument95 pagesAmana Package Terminal Service Instructions PDFBillNo ratings yet

- Line Follower Robot Using ArduinoDocument5 pagesLine Follower Robot Using Arduinochockalingam athilingam100% (1)

- D3516C 2500kvaDocument6 pagesD3516C 2500kvaarehman.shahidNo ratings yet

- Lokozo Battery Mangement System Bms LP 15s60aDocument2 pagesLokozo Battery Mangement System Bms LP 15s60aPhani ArvapalliNo ratings yet