Professional Documents

Culture Documents

H8 f7 Tolerance

H8 f7 Tolerance

Uploaded by

SIPNETCopyright:

Available Formats

You might also like

- XR5 Data SheetDocument7 pagesXR5 Data SheetReeta DuttaNo ratings yet

- SOLIDWORKS Inspection CMM Calypso PDFDocument5 pagesSOLIDWORKS Inspection CMM Calypso PDFJosephRomeraloNo ratings yet

- Buyersguide Asbrandparts PDFDocument237 pagesBuyersguide Asbrandparts PDFADJIMGARNo ratings yet

- Technical Card Ck45 Mechanical PropertiesDocument3 pagesTechnical Card Ck45 Mechanical PropertiesNuno Miguel TorcatoNo ratings yet

- DrillsDocument237 pagesDrillssimon reidNo ratings yet

- Abrasive Water Jet Machining (AWJM) : Sanjeev Sharma Professor, Deptt. of Mech. Engg. CEC, LandranDocument33 pagesAbrasive Water Jet Machining (AWJM) : Sanjeev Sharma Professor, Deptt. of Mech. Engg. CEC, LandranAbhishek KumarNo ratings yet

- Gear Pumps: Product RangeDocument4 pagesGear Pumps: Product RangeEng-Mohammed SalemNo ratings yet

- MultiCam 3000-Series CNC WaterjetDocument12 pagesMultiCam 3000-Series CNC WaterjetDaniel AustinNo ratings yet

- Design and Fabrication of Fixture For Labyrinth RingDocument6 pagesDesign and Fabrication of Fixture For Labyrinth RingAkhilesh KumarNo ratings yet

- Anchor Force CalculationsDocument40 pagesAnchor Force CalculationsImmanuel SNo ratings yet

- Mechanical Engineering FormulaDocument19 pagesMechanical Engineering FormulaHaider AliNo ratings yet

- Diamond Wire Saw Machine - 副本 (350591)Document2 pagesDiamond Wire Saw Machine - 副本 (350591)rohit10mpuatNo ratings yet

- SPECS Diamond Wire Cutting Machine TYROLITDocument2 pagesSPECS Diamond Wire Cutting Machine TYROLITKhyle Laurenz DuroNo ratings yet

- Dimensioning and Tolerances: Mechanical Engineering Graphics MECH 211Document175 pagesDimensioning and Tolerances: Mechanical Engineering Graphics MECH 211SATHISHKUMAR MNo ratings yet

- Hydraulic Filtration Product Guide PDFDocument286 pagesHydraulic Filtration Product Guide PDFCire Lop CastroNo ratings yet

- Silent Tools: Productivity With Slender ToolsDocument12 pagesSilent Tools: Productivity With Slender Toolsxmen norNo ratings yet

- Chapter 5 - Shaft DesignDocument0 pagesChapter 5 - Shaft DesignwanpudinNo ratings yet

- CAD CAM Laboratory ManualDocument227 pagesCAD CAM Laboratory ManualGopinath B L NaiduNo ratings yet

- Gear Manufacturing MethodDocument89 pagesGear Manufacturing MethodRamalingam AlagarajaNo ratings yet

- CNC Mill Machine PICODocument4 pagesCNC Mill Machine PICOVlastimir PejićNo ratings yet

- Water Jet CutterDocument16 pagesWater Jet CutterRex Delon50% (2)

- Water Jet Machining: Recent DevelopmentDocument36 pagesWater Jet Machining: Recent Developmentrmehfuz60% (5)

- Chapter 9 Design For Sheet Metal1Document92 pagesChapter 9 Design For Sheet Metal1VishalNaranjeNo ratings yet

- A-09-02122 Widia ToolingSystems Complete enDocument1,190 pagesA-09-02122 Widia ToolingSystems Complete enLuis LopezNo ratings yet

- Limits of Size-Unified Screw ThreadsDocument7 pagesLimits of Size-Unified Screw Threadsxeron7126No ratings yet

- Dimensioning Practice: Threaded FastenersDocument27 pagesDimensioning Practice: Threaded FastenersAfaq AslamNo ratings yet

- SAW - Tractor 1000Document2 pagesSAW - Tractor 1000Rizaldi Akhmad SungkawaNo ratings yet

- Pierburg-Fuel Pump Product Info PDFDocument52 pagesPierburg-Fuel Pump Product Info PDFGauravPradhanNo ratings yet

- SAW D ManualDocument16 pagesSAW D ManualjlmansillaNo ratings yet

- Analysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisDocument7 pagesAnalysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisEditor IJTSRDNo ratings yet

- Gear Motors: Achieving The Perfect Motor & Gearbox MatchDocument16 pagesGear Motors: Achieving The Perfect Motor & Gearbox MatchJohn LeeNo ratings yet

- Shimpo Circulute 3000 CatalogDocument36 pagesShimpo Circulute 3000 CatalogElectromateNo ratings yet

- Unit 3 Vehicle and Their SpecificationsDocument48 pagesUnit 3 Vehicle and Their Specificationssiddh2805No ratings yet

- Technical Reference OverviewDocument17 pagesTechnical Reference OverviewHery Vázquez JiménezNo ratings yet

- MC Design 2Document71 pagesMC Design 2Upayan Ghatak100% (1)

- Abrasive Jet MachineDocument39 pagesAbrasive Jet MachineMuhammad Suleman100% (1)

- Power Skiving PDFDocument11 pagesPower Skiving PDFmadhavikNo ratings yet

- Surface Finish ChartDocument1 pageSurface Finish ChartMACKAY9999No ratings yet

- 1405 Katalog eDocument232 pages1405 Katalog eAnonymous YdCOaQTNo ratings yet

- Lecture 5 Machine Tool StructureDocument19 pagesLecture 5 Machine Tool StructureMD Al-AminNo ratings yet

- Lect22 Surface RoughnessDocument16 pagesLect22 Surface RoughnessAnshul SharmaNo ratings yet

- Canlin Castings - Cast Iron GradesDocument2 pagesCanlin Castings - Cast Iron GradeshooijschuurNo ratings yet

- Motor Torque Calculation: Lead Screw Drive LoadsDocument5 pagesMotor Torque Calculation: Lead Screw Drive LoadsTruta IonutNo ratings yet

- Design & Development of Multi-Evaporative Refrigeration SystemDocument4 pagesDesign & Development of Multi-Evaporative Refrigeration SystemAnonymous izrFWiQNo ratings yet

- Simufact Sheet Metal Forming 2015Document8 pagesSimufact Sheet Metal Forming 2015MrLanternNo ratings yet

- Machine Drawing Through CadDocument91 pagesMachine Drawing Through CadmjdaleneziNo ratings yet

- Hydraulic Rod Bending MachineDocument14 pagesHydraulic Rod Bending Machinek.santhosh kumar50% (2)

- Pneumatic Sheet Metal Shearing MachineDocument21 pagesPneumatic Sheet Metal Shearing MachineGamerNo ratings yet

- Fluent - Tutorial - Dynamic Mesh - 2D Adiabatic CompressionDocument29 pagesFluent - Tutorial - Dynamic Mesh - 2D Adiabatic Compressionmm0hammadi100% (2)

- Nema 23Document2 pagesNema 23BenjaminSanchezNo ratings yet

- Tolerances 01Document76 pagesTolerances 01minhchien0001100% (1)

- Spur Gearing, Helical Gearing (mm/ISO)Document6 pagesSpur Gearing, Helical Gearing (mm/ISO)oman1148No ratings yet

- Bolt EqualentsDocument1 pageBolt EqualentsvkturkiNo ratings yet

- RESM Angle EncoderDocument8 pagesRESM Angle EncoderJaswinder SinghNo ratings yet

- Service - Specifications Toyota ProboxDocument85 pagesService - Specifications Toyota Proboxcpgmotors83% (6)

- 9 Regular Machining Dimension Tolerance 01Document1 page9 Regular Machining Dimension Tolerance 01OllenkNo ratings yet

- Sanitary TurbinaDocument4 pagesSanitary TurbinaCindy MateusNo ratings yet

- Metric and Inch SystemDocument1 pageMetric and Inch SystemINTRAVEcom Industrial AutomationNo ratings yet

- Summary of Cutting Data For Axial Grooving: Material DetailsDocument4 pagesSummary of Cutting Data For Axial Grooving: Material Detailsunmilionlei931No ratings yet

- En 10029 Quarto Plate TolerancesDocument4 pagesEn 10029 Quarto Plate TolerancesDiyanto AntoNo ratings yet

- Quantel Optimis II Service Manual 51 60Document10 pagesQuantel Optimis II Service Manual 51 60Vladimir LevchenkoNo ratings yet

- DCC2063 Mechanics of Civil Engineering StructuresDocument3 pagesDCC2063 Mechanics of Civil Engineering StructuresShivaranjini0% (1)

- Ulllted States Patent (19) (11) Patent Number: 6,054,488: Oliver Et Al. (45) Date of Patent: Apr. 25, 2000Document8 pagesUlllted States Patent (19) (11) Patent Number: 6,054,488: Oliver Et Al. (45) Date of Patent: Apr. 25, 2000Nia MachyNo ratings yet

- 05 T07.P12 80 PDFDocument1 page05 T07.P12 80 PDFGideão O BarbosaNo ratings yet

- CharterMedical - Cell-FreezeDocument10 pagesCharterMedical - Cell-FreezeCampaign MediaNo ratings yet

- PriyankaDocument2 pagesPriyankaPriyanka AmazonNo ratings yet

- CSE 1004: Network and Communication (L23+L24) Lab - Assignment Mid TermDocument22 pagesCSE 1004: Network and Communication (L23+L24) Lab - Assignment Mid TermMajety S LskshmiNo ratings yet

- Empower 2e B1 Word List GermanDocument102 pagesEmpower 2e B1 Word List GermanOmid SofeNo ratings yet

- Software Agents: - Software Agents: - Software Agents Are A Piece - CharacteristicsDocument6 pagesSoftware Agents: - Software Agents: - Software Agents Are A Piece - CharacteristicsrkagrNo ratings yet

- Digital Astrophotography A Guide To Capturing The Cosmos (PDFDrive)Document236 pagesDigital Astrophotography A Guide To Capturing The Cosmos (PDFDrive)Paolo Fasselli100% (1)

- Bollard Pull CalculationsDocument16 pagesBollard Pull CalculationsLuis Sierra100% (1)

- Tense: Atle Grønn and Arnim Von StechowDocument29 pagesTense: Atle Grønn and Arnim Von StechowCamila SilvestreNo ratings yet

- Untitled FebDocument9 pagesUntitled Febdjz24txj48No ratings yet

- Data Structures Algorithms Mock TestDocument6 pagesData Structures Algorithms Mock Testnehal nasimNo ratings yet

- Francis AssignmentDocument21 pagesFrancis AssignmentAlok YadavNo ratings yet

- Quantum Field Theory - R. Clarkson, D. McKeonDocument266 pagesQuantum Field Theory - R. Clarkson, D. McKeonKepler4246No ratings yet

- From Stupid To Solid CodeDocument50 pagesFrom Stupid To Solid CodeAndrei OlteanuNo ratings yet

- Reviewer in Personal Development 2nd QuarterDocument2 pagesReviewer in Personal Development 2nd QuarterDave Homer Huerto MoralesNo ratings yet

- Edu 222 Educational Administration Lecture Notes Updated and Current 2023Document76 pagesEdu 222 Educational Administration Lecture Notes Updated and Current 2023derrosammaNo ratings yet

- Muet Speaking Past Year QuestionsDocument6 pagesMuet Speaking Past Year Questionsaina sorfina100% (1)

- JSG Decoration Brochure-S3000 - 1Document3 pagesJSG Decoration Brochure-S3000 - 1HuyenNo ratings yet

- Troubleshooting PDFDocument4 pagesTroubleshooting PDFAlexander LondoñoNo ratings yet

- Charles LawDocument3 pagesCharles LawJohn Eliandrei Bañaga IINo ratings yet

- Sociologycbcs PDFDocument71 pagesSociologycbcs PDFPreeti YadavNo ratings yet

- Specification For High-Strength Concrete in Moderate To High Seismic ApplicationsDocument16 pagesSpecification For High-Strength Concrete in Moderate To High Seismic ApplicationsRandy CamaclangNo ratings yet

- Milnor ManualDocument94 pagesMilnor ManualMajid KhanNo ratings yet

- Significant Figure Rules For LogsDocument2 pagesSignificant Figure Rules For Logsmooningearth2No ratings yet

- What Is ABM Strand?: Acquire Basic Industry SkillsDocument6 pagesWhat Is ABM Strand?: Acquire Basic Industry SkillsAngelaNo ratings yet

- Corrosion Prediction and Material Selection For Sulfuric Acid Alkylation UnitsDocument4 pagesCorrosion Prediction and Material Selection For Sulfuric Acid Alkylation Unitssandrine guerinNo ratings yet

- Excel To CATIADocument6 pagesExcel To CATIAdjtj89No ratings yet

H8 f7 Tolerance

H8 f7 Tolerance

Uploaded by

SIPNETOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H8 f7 Tolerance

H8 f7 Tolerance

Uploaded by

SIPNETCopyright:

Available Formats

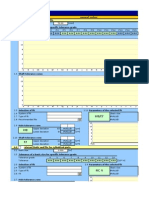

Nzev vpotu Tolerances and fits General section 1.0 ISO system of limits and fits 50.

00 IT1 1.5 IT2 2.5 IT3 4 IT4 7 IT5 11 [mm] [m] IT8 39 IT9 62 IT10 100 IT11 160 IT12 250 IT13 390 IT14 620 IT15 IT16 IT17 IT18 [m]

D E EF F FG G H JS J K M N P R S T U V X Y Z ZA

IT8

ISO 286

1.1 Basic size IT01 0.6 IT0 1

1.2 Tolerance of a basic size for specific tolerance grade IT6 16 IT7 25

1000 1600 2500 3900

1.3 Hole tolerance zones

A 400 300 200 100 0 -100 -200 -300 -400 -500 B C CD ZB

ZC

1.4 Shaft tolerance zones

400 300 200 100 0 -100 -200 -300 -400 a b c cd d e ef f fg g h js j k m n p r s t u v x y z za zb

IT7

[m]

zc

1.5 Selection of fit 1.6 System of fit 1.7 Type of fit 1.8 Recommended fits 1.9 Hole tolerance zone

Hole basis system Clearance fit H8/f7 *

1.11 Parameters of the selected fit

H8/f7

Basic size Maximum clearance Minimum clearance

50 0.089 0.025

Shaft

[mm] [mm] [mm]

Hole 60

H8

Upper deviation Lower deviation

ES EI

f

39 0

7

[m] [m]

40 20 0

39

0 -25 -50

1.10 Shaft tolerance zone

-20

f7

2.0 2.1 Basic size

Upper deviation Lower deviation

es ei 2.000

-25 -50 [in] 6 0.7 7 1.2

[m] [m]

-40 -60

Preferred limits and fits for cylindrical parts

ANSI B4.1

2.2 Tolerance of a basic size for specific tolerance grade Tolerance grade Tolerance 2.3 Selection of fit 2.4 System of fit 2.5 Type of fit 2.6 Fit

Hole basis system Running or sliding clearence fit RC 4 Hole 3

4 0.3

5 0.5

8 1.8

9 3

10 4.5

11 7

12 12

13 18 [10-3 in] 2 0.0042 0.0012

Shaft

2.9 Parameters of the selected fit

RC 4

Basic size Maximum clearance Minimum clearance

[in] [in] [in]

Hole

Shaft 1.8 0 -1.2 -2.4

2.7 Hole tolerance zone

H8

Upper deviation Lower deviation

ES EI

1.8 0

[10-3 in] [10-3 in]

2 1 0

2.8 Shaft tolerance zone

-1

f7

3.0

Upper deviation Lower deviation

es ei

-1.2 -2.4

[10 in] [10-3 in]

-3

-2 -3

General tolerances for linear and angular dimensions without individual tolerance indications Limit deviations for basic size range [mm] over 6 over 30 over 120 over 400 to 30 to 120 to 400 to 1000 0,3 0,2 0,15 0,1 0,2 0,5 1 0,3 0,8 1,5 0,5 1,2 2,5 0,8 2 4

ISO 2768 -1

3.1 Limit deviations for linear dimensions Tolerance class f m c v fine medium coarse very coarse 0.5 to 3 0,05 0,1 0,15 over 3 to 6 0,05 0,1 0,2 0,5 over 1000 to 2000 0,5 1,2 3 6 over 2000 to 4000 2 4 8

3.2 Limit deviations for broken edges (external radii and chamfer heights) Limit deviations for basic size range [mm] Tolerance class 0.5 over 3 to 3 to 6 fine f 0,2 0,5 medium m c v coarse very coarse 0,4 1

over 6 1 2

3.3 Limit deviations for angular dimensions Limit deviations for length range of shorter side of the angle concerned [mm] Tolerance class over 10 over 50 over 120 over 400 to 10 to 50 to 120 to 400 fine f 1 30 ' 20 ' 10 ' 5' medium m c v 4.0 coarse very coarse 1 30 ' 3 1 2 30 ' 1 15 ' 30 ' 10 ' 20 '

Supplements section Design of fit for specific allowance 4.8 Parameters of the selected fit

Hole basis system Clearance fit

4.1 Desired parameters of the fit 4.2 System of fit 4.3 Type of fit 4.4 Basic size 4.5 Maximum clearance 4.6 Minimum clearance 4.7 Design and selection of the fit ID | Quality| Max. clearan.|Min. clearance| Fit

Pref. | 20 | 90 | 15 | H7/g6 -----------------------------------------------------------------------------------1. | 11 | 101 | 15 | H4/g8 2. | 11 | 101 | 15 | H8/g4 3. | 13 | 97 | 15 | H3/g8 4. | 13 | 97 | 15 | H8/g3 5. | 16 | 94 | 15 | H2/g8 6. | 17 | 107 | 15 | H5/g8 7. | 17 | 107 | 15 | H7/g7

H7/g6

200.00 100.0 25.0 [mm] [m] [m] Tolerance zone Upper deviation Lower deviation

Maximum clearance Minimum clearance Hole ES/es EI/ei

Hole

90 15 Shaft -15 -44

Shaft

[m] [m] [m] [m]

46 0

60 40 20 0 -20 -40 -60

46

-15 -44

5.0 Lapping Honing

Relationship of tolerance to surface finish 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Tolerance grade

Superfinishing Cylindrical/centrelees grinding Diamond turning

Plan grinding Broaching Reaming Boring, Turning Sawing Milling Planing, Shaping Extruding Cold Rolling, Drawing Drilling Die Casting Forging Sand Casting Hot rolling, Flame cutting

You might also like

- XR5 Data SheetDocument7 pagesXR5 Data SheetReeta DuttaNo ratings yet

- SOLIDWORKS Inspection CMM Calypso PDFDocument5 pagesSOLIDWORKS Inspection CMM Calypso PDFJosephRomeraloNo ratings yet

- Buyersguide Asbrandparts PDFDocument237 pagesBuyersguide Asbrandparts PDFADJIMGARNo ratings yet

- Technical Card Ck45 Mechanical PropertiesDocument3 pagesTechnical Card Ck45 Mechanical PropertiesNuno Miguel TorcatoNo ratings yet

- DrillsDocument237 pagesDrillssimon reidNo ratings yet

- Abrasive Water Jet Machining (AWJM) : Sanjeev Sharma Professor, Deptt. of Mech. Engg. CEC, LandranDocument33 pagesAbrasive Water Jet Machining (AWJM) : Sanjeev Sharma Professor, Deptt. of Mech. Engg. CEC, LandranAbhishek KumarNo ratings yet

- Gear Pumps: Product RangeDocument4 pagesGear Pumps: Product RangeEng-Mohammed SalemNo ratings yet

- MultiCam 3000-Series CNC WaterjetDocument12 pagesMultiCam 3000-Series CNC WaterjetDaniel AustinNo ratings yet

- Design and Fabrication of Fixture For Labyrinth RingDocument6 pagesDesign and Fabrication of Fixture For Labyrinth RingAkhilesh KumarNo ratings yet

- Anchor Force CalculationsDocument40 pagesAnchor Force CalculationsImmanuel SNo ratings yet

- Mechanical Engineering FormulaDocument19 pagesMechanical Engineering FormulaHaider AliNo ratings yet

- Diamond Wire Saw Machine - 副本 (350591)Document2 pagesDiamond Wire Saw Machine - 副本 (350591)rohit10mpuatNo ratings yet

- SPECS Diamond Wire Cutting Machine TYROLITDocument2 pagesSPECS Diamond Wire Cutting Machine TYROLITKhyle Laurenz DuroNo ratings yet

- Dimensioning and Tolerances: Mechanical Engineering Graphics MECH 211Document175 pagesDimensioning and Tolerances: Mechanical Engineering Graphics MECH 211SATHISHKUMAR MNo ratings yet

- Hydraulic Filtration Product Guide PDFDocument286 pagesHydraulic Filtration Product Guide PDFCire Lop CastroNo ratings yet

- Silent Tools: Productivity With Slender ToolsDocument12 pagesSilent Tools: Productivity With Slender Toolsxmen norNo ratings yet

- Chapter 5 - Shaft DesignDocument0 pagesChapter 5 - Shaft DesignwanpudinNo ratings yet

- CAD CAM Laboratory ManualDocument227 pagesCAD CAM Laboratory ManualGopinath B L NaiduNo ratings yet

- Gear Manufacturing MethodDocument89 pagesGear Manufacturing MethodRamalingam AlagarajaNo ratings yet

- CNC Mill Machine PICODocument4 pagesCNC Mill Machine PICOVlastimir PejićNo ratings yet

- Water Jet CutterDocument16 pagesWater Jet CutterRex Delon50% (2)

- Water Jet Machining: Recent DevelopmentDocument36 pagesWater Jet Machining: Recent Developmentrmehfuz60% (5)

- Chapter 9 Design For Sheet Metal1Document92 pagesChapter 9 Design For Sheet Metal1VishalNaranjeNo ratings yet

- A-09-02122 Widia ToolingSystems Complete enDocument1,190 pagesA-09-02122 Widia ToolingSystems Complete enLuis LopezNo ratings yet

- Limits of Size-Unified Screw ThreadsDocument7 pagesLimits of Size-Unified Screw Threadsxeron7126No ratings yet

- Dimensioning Practice: Threaded FastenersDocument27 pagesDimensioning Practice: Threaded FastenersAfaq AslamNo ratings yet

- SAW - Tractor 1000Document2 pagesSAW - Tractor 1000Rizaldi Akhmad SungkawaNo ratings yet

- Pierburg-Fuel Pump Product Info PDFDocument52 pagesPierburg-Fuel Pump Product Info PDFGauravPradhanNo ratings yet

- SAW D ManualDocument16 pagesSAW D ManualjlmansillaNo ratings yet

- Analysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisDocument7 pagesAnalysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisEditor IJTSRDNo ratings yet

- Gear Motors: Achieving The Perfect Motor & Gearbox MatchDocument16 pagesGear Motors: Achieving The Perfect Motor & Gearbox MatchJohn LeeNo ratings yet

- Shimpo Circulute 3000 CatalogDocument36 pagesShimpo Circulute 3000 CatalogElectromateNo ratings yet

- Unit 3 Vehicle and Their SpecificationsDocument48 pagesUnit 3 Vehicle and Their Specificationssiddh2805No ratings yet

- Technical Reference OverviewDocument17 pagesTechnical Reference OverviewHery Vázquez JiménezNo ratings yet

- MC Design 2Document71 pagesMC Design 2Upayan Ghatak100% (1)

- Abrasive Jet MachineDocument39 pagesAbrasive Jet MachineMuhammad Suleman100% (1)

- Power Skiving PDFDocument11 pagesPower Skiving PDFmadhavikNo ratings yet

- Surface Finish ChartDocument1 pageSurface Finish ChartMACKAY9999No ratings yet

- 1405 Katalog eDocument232 pages1405 Katalog eAnonymous YdCOaQTNo ratings yet

- Lecture 5 Machine Tool StructureDocument19 pagesLecture 5 Machine Tool StructureMD Al-AminNo ratings yet

- Lect22 Surface RoughnessDocument16 pagesLect22 Surface RoughnessAnshul SharmaNo ratings yet

- Canlin Castings - Cast Iron GradesDocument2 pagesCanlin Castings - Cast Iron GradeshooijschuurNo ratings yet

- Motor Torque Calculation: Lead Screw Drive LoadsDocument5 pagesMotor Torque Calculation: Lead Screw Drive LoadsTruta IonutNo ratings yet

- Design & Development of Multi-Evaporative Refrigeration SystemDocument4 pagesDesign & Development of Multi-Evaporative Refrigeration SystemAnonymous izrFWiQNo ratings yet

- Simufact Sheet Metal Forming 2015Document8 pagesSimufact Sheet Metal Forming 2015MrLanternNo ratings yet

- Machine Drawing Through CadDocument91 pagesMachine Drawing Through CadmjdaleneziNo ratings yet

- Hydraulic Rod Bending MachineDocument14 pagesHydraulic Rod Bending Machinek.santhosh kumar50% (2)

- Pneumatic Sheet Metal Shearing MachineDocument21 pagesPneumatic Sheet Metal Shearing MachineGamerNo ratings yet

- Fluent - Tutorial - Dynamic Mesh - 2D Adiabatic CompressionDocument29 pagesFluent - Tutorial - Dynamic Mesh - 2D Adiabatic Compressionmm0hammadi100% (2)

- Nema 23Document2 pagesNema 23BenjaminSanchezNo ratings yet

- Tolerances 01Document76 pagesTolerances 01minhchien0001100% (1)

- Spur Gearing, Helical Gearing (mm/ISO)Document6 pagesSpur Gearing, Helical Gearing (mm/ISO)oman1148No ratings yet

- Bolt EqualentsDocument1 pageBolt EqualentsvkturkiNo ratings yet

- RESM Angle EncoderDocument8 pagesRESM Angle EncoderJaswinder SinghNo ratings yet

- Service - Specifications Toyota ProboxDocument85 pagesService - Specifications Toyota Proboxcpgmotors83% (6)

- 9 Regular Machining Dimension Tolerance 01Document1 page9 Regular Machining Dimension Tolerance 01OllenkNo ratings yet

- Sanitary TurbinaDocument4 pagesSanitary TurbinaCindy MateusNo ratings yet

- Metric and Inch SystemDocument1 pageMetric and Inch SystemINTRAVEcom Industrial AutomationNo ratings yet

- Summary of Cutting Data For Axial Grooving: Material DetailsDocument4 pagesSummary of Cutting Data For Axial Grooving: Material Detailsunmilionlei931No ratings yet

- En 10029 Quarto Plate TolerancesDocument4 pagesEn 10029 Quarto Plate TolerancesDiyanto AntoNo ratings yet

- Quantel Optimis II Service Manual 51 60Document10 pagesQuantel Optimis II Service Manual 51 60Vladimir LevchenkoNo ratings yet

- DCC2063 Mechanics of Civil Engineering StructuresDocument3 pagesDCC2063 Mechanics of Civil Engineering StructuresShivaranjini0% (1)

- Ulllted States Patent (19) (11) Patent Number: 6,054,488: Oliver Et Al. (45) Date of Patent: Apr. 25, 2000Document8 pagesUlllted States Patent (19) (11) Patent Number: 6,054,488: Oliver Et Al. (45) Date of Patent: Apr. 25, 2000Nia MachyNo ratings yet

- 05 T07.P12 80 PDFDocument1 page05 T07.P12 80 PDFGideão O BarbosaNo ratings yet

- CharterMedical - Cell-FreezeDocument10 pagesCharterMedical - Cell-FreezeCampaign MediaNo ratings yet

- PriyankaDocument2 pagesPriyankaPriyanka AmazonNo ratings yet

- CSE 1004: Network and Communication (L23+L24) Lab - Assignment Mid TermDocument22 pagesCSE 1004: Network and Communication (L23+L24) Lab - Assignment Mid TermMajety S LskshmiNo ratings yet

- Empower 2e B1 Word List GermanDocument102 pagesEmpower 2e B1 Word List GermanOmid SofeNo ratings yet

- Software Agents: - Software Agents: - Software Agents Are A Piece - CharacteristicsDocument6 pagesSoftware Agents: - Software Agents: - Software Agents Are A Piece - CharacteristicsrkagrNo ratings yet

- Digital Astrophotography A Guide To Capturing The Cosmos (PDFDrive)Document236 pagesDigital Astrophotography A Guide To Capturing The Cosmos (PDFDrive)Paolo Fasselli100% (1)

- Bollard Pull CalculationsDocument16 pagesBollard Pull CalculationsLuis Sierra100% (1)

- Tense: Atle Grønn and Arnim Von StechowDocument29 pagesTense: Atle Grønn and Arnim Von StechowCamila SilvestreNo ratings yet

- Untitled FebDocument9 pagesUntitled Febdjz24txj48No ratings yet

- Data Structures Algorithms Mock TestDocument6 pagesData Structures Algorithms Mock Testnehal nasimNo ratings yet

- Francis AssignmentDocument21 pagesFrancis AssignmentAlok YadavNo ratings yet

- Quantum Field Theory - R. Clarkson, D. McKeonDocument266 pagesQuantum Field Theory - R. Clarkson, D. McKeonKepler4246No ratings yet

- From Stupid To Solid CodeDocument50 pagesFrom Stupid To Solid CodeAndrei OlteanuNo ratings yet

- Reviewer in Personal Development 2nd QuarterDocument2 pagesReviewer in Personal Development 2nd QuarterDave Homer Huerto MoralesNo ratings yet

- Edu 222 Educational Administration Lecture Notes Updated and Current 2023Document76 pagesEdu 222 Educational Administration Lecture Notes Updated and Current 2023derrosammaNo ratings yet

- Muet Speaking Past Year QuestionsDocument6 pagesMuet Speaking Past Year Questionsaina sorfina100% (1)

- JSG Decoration Brochure-S3000 - 1Document3 pagesJSG Decoration Brochure-S3000 - 1HuyenNo ratings yet

- Troubleshooting PDFDocument4 pagesTroubleshooting PDFAlexander LondoñoNo ratings yet

- Charles LawDocument3 pagesCharles LawJohn Eliandrei Bañaga IINo ratings yet

- Sociologycbcs PDFDocument71 pagesSociologycbcs PDFPreeti YadavNo ratings yet

- Specification For High-Strength Concrete in Moderate To High Seismic ApplicationsDocument16 pagesSpecification For High-Strength Concrete in Moderate To High Seismic ApplicationsRandy CamaclangNo ratings yet

- Milnor ManualDocument94 pagesMilnor ManualMajid KhanNo ratings yet

- Significant Figure Rules For LogsDocument2 pagesSignificant Figure Rules For Logsmooningearth2No ratings yet

- What Is ABM Strand?: Acquire Basic Industry SkillsDocument6 pagesWhat Is ABM Strand?: Acquire Basic Industry SkillsAngelaNo ratings yet

- Corrosion Prediction and Material Selection For Sulfuric Acid Alkylation UnitsDocument4 pagesCorrosion Prediction and Material Selection For Sulfuric Acid Alkylation Unitssandrine guerinNo ratings yet

- Excel To CATIADocument6 pagesExcel To CATIAdjtj89No ratings yet