Professional Documents

Culture Documents

Structure of Ceramics

Structure of Ceramics

Uploaded by

Dong Tri Nguyen ThiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structure of Ceramics

Structure of Ceramics

Uploaded by

Dong Tri Nguyen ThiCopyright:

Available Formats

3-1

Structure of Ceramics

! !

Ceramics have ionic or covalent bonding Crystal structure is strongly influenced by bonding This influences mechanical and physical properties. e.g.

! !

most ceramics are not electrical conductors; little ductility at room temperature

Introduction to Ceramics: 3: Bonding, structure and strength

3-2

Ionic Bonding

!

Crystals of opposite charged ions held together by nondirectional electrostatic forces Anions (-) are larger than Cations (+) Minimum energy anions and cations as close as possible with highest co-ordination number butAnions must not touch.

+ +

+ +

Introduction to Ceramics: 3: Bonding, structure and strength

3-3

Magnesium Oxide - Ideal Ionic Structure

MgO Ionic

Cubic 6:6 co-ordination Rock-salt structure

Oxygen Magnesium

Introduction to Ceramics: 3: Bonding, structure and strength

3-4

Covalent Bonding

!

Interatomic bonding occurs by shared electrons in orbitals of size and direction governed by quantum mechanics. Structures formed like scaffolds with fixed orientation at joints and fixed bond lengths.

C

104.28

C C C C C

Diamond [Silicon, Silicon carbide similar]

C C

Introduction to Ceramics: 3: Bonding, structure and strength

3-5

Silicon Carbide - Ideal Covalent Structure

SiC Covalent

[ This is SiC (cubic): the (hexagonal) forms are more common.

Silicon Carbon

Gallium arsenide etc. have the same structure ]

Introduction to Ceramics: 3: Bonding, structure and strength

3-6

Intermediate and Mixed Bonding

!

Ceramics can have structures intermediate to ionic and covalent and contain different sorts of bonds: e.g:

!

O Si O O

O Si O O Si O

Formula Unit

O O

silicate ceramics are made up of tetrahedral covalent SiO4 units (bonding >50% covalent) which share corners Pure SiO2 (quartz) is a network of these tetrahedral units clays, etc., contain silicate sheets linked by ionic forces

Shared Oxygen ions

2-D slice of quartz crystal showing linked tetrahedra

Introduction to Ceramics: 3: Bonding, structure and strength

3-7

Silicates

!

The SiO4 tetrahedron would be an ion if none of the O were shared (SiO4)4 -. Can get compounds such as Ca2SiO4 - calcium orthosilicate. Can form extended ions by sharing some of the O to make sheets or chains and satisfying the spare negative charge on each unattached O by the presence of balancing ions.

"

It is possible to share sufficient ions to make chains or sheets of silicates, e.g. MgSi2O5

Mg

Mg

Mg

Mg

Mg

Mg

Mg

Mg

Mg

Mg

Mg

Mg

Introduction to Ceramics: 3: Bonding, structure and strength

3-8

Natural Ceramics

!

Many natural ceramics are based on silicates Other oxides also form shared corner structures based on tetrahedra, octahedra or cube coordination Can form mixed oxides by sharing corners of different structural tetrahedra

These more complex materials can also contain balancing cations where there is no corner sharing Thus many chemical compositions can be accommodated in a range of mineral crystal structures

Introduction to Ceramics: 3: Bonding, structure and strength

3-9

Structure of Glasses

!

Most important glasses are based on silica Structure is amorphous but the same joining rules apply as with silicates Structure is a random network of cornersharing tetrahedra

Other oxides can be admitted into the structure, obeying similar rules to in silicates Some oxides join in the network with their own co-ordination solids Others sit as discrete ions next to terminating oxygens

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 10

Structure of Glasses (2)

Other oxides can be incorporated into a glassy SiO2 network in several ways: Network formers are oxides which intrinsically form glassy structures Network modifiers terminate networks by requiring fewer oxygens to balance valency Network intermediates can join in glassy networks but cannot themselves form glasses

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 11

Structure of Glasses

Can tune mechanical properties by varying composition. Other oxides can be incorporated into a glassy SiO2 network in several ways: Network modifiers: MgO, CaO, Na2O, K2O, PbO terminate networks by requiring fewer oxygens to balance valency Network formers: B2O3, P2O3 - oxides which intrinsically form glassy structures Network intermediates: B2O3, Al2O3, PbO can join in glassy networks but cannot themselves form glasses

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 12

Modifiers

! !

Modifiers terminate networks They reduce the mean number of atoms in a chain The covalent Si-O-Si bond has a rotational degree of freedom, thus adding modifiers reduces the total structure rigidity They result in lower melting points (good for processing) and lower elastic moduli.

+ -

+ -

+ -

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 13

Ceramic Phase Diagrams

Mullite (3Al2O3.2SiO2)

Phase diagrams are used to understand the evolution of microstructure much as in metals. However: ! Diffusion is much slower than in metals so equilibrium is rarely reached; ! Phase diagrams are often simplified by using compounds rather than elements.

Al2O3

2000 Temperature (C) 1800 1600 1400 1200 1000 0 SiO2

Liquid

20

40

60

80

wt% Al2O3

Cristobalite (SiO2) Tridymite (SiO2))

100 Al2O3

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 14

Traditional Ceramic Microstructure

Porcelain electrical insulator ! Note complex microstructure with evidence of:

!

largely unmolten phases (Flint SiO2) melting and liquid phase sintering new phases crystallising in frozen melt

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 15

Mechanical Properties

!

Plastic flow by dislocation motion is very difficult in covalent and ionic materials

! !

High yield stress and hardness Very limited plastic flow at crack tips low fracture toughness

Compression: strong (high yield stress); may flow or propagate shear cracks (crushing). Tension: weak (low toughness); always fail by brittle fracture Highly resistant to wear and erosion (compression loading phenomena)

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 16

Dislocations In Ionic Solids

!

+ + + + -

+ + + +

+ + + + -

+ + + +

+ + + + -

+ + + +

+ + + + -

+ + + +

Po

ss

+ + + + -

ib

le

Ionic structures are usually fairly close packed Slip direction and slip plane are constrained by charge e.g. cannot bring like charged ions in contact Dislocation motion is possible but difficult because slip is not on the most close packed planes Often only a limited number of slip systems due to low symmetry of crystal structures

!

+ + + +

Impossible

need 5 for full plasticity in polycrystals

Dislocation motion can be easier at high temperatures

!

easier flow on normal slip systems, new systems may begin to operate.

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 17

Dislocations In Covalent Solids

!

! !

The rigid bond network in covalent solids is very resistant to deformation Dislocations have very high energies Dislocation motion is difficult as bonds must be broken and remade, and bond angle distorted. Very low dislocation mobilities except at very high temperatures (> 0.5 Tm or higher)

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 18

Ceramics: Defect Controlled Strength

Tensile fracture stress F is controlled by the defects present either from fabrication or from damage

Porosity defect in poorlysintered alumina

F =

K Ic

50m

KIc Fracture toughness geometrical factor (~1) a size of biggest crack under stress

Introduction to Ceramics: 3: Bonding, structure and strength

Cross-section through thermallyshocked alumina bar (4mm x 4mm) Dye-penetrant test shows cracks

3 - 19

Toughness, Crack Size and Strength

Tough Metal Example KIc

(MPam1/2)

Brittle Metal Cast Iron 20 13 mm 510 m

Typical Ceramic Alumina, SiC 4 510 m 20 m

Brittle Ceramic Glass, Silicon 1 32 m 1.2 m

Good steel 100 320 mm 13 mm

a for F = 100 MPa a for F = 500 MPa

Introduction to Ceramics: 3: Bonding, structure and strength

3 - 20

Defect-controlled Strength

!

! !

One large crack will lead to failure

Must make ceramics defect free and avoid damage in service

!

Or make tougher ceramic?? even boosting KIc to 15 or 20 MPam1/2 would be useful

In practice, this is dealt with statistically (see later)

Density of cracks

For ceramics, the strength controlling defects can be a few microns or tens of microns in size Below limit of detection of (most) NDT techniques Weakest link problem

When is density low enough that you are sure there are no cracks of this size present ?

Crack size

Introduction to Ceramics: 3: Bonding, structure and strength

You might also like

- 2020 WTS 12 Work, Energy & PowerDocument22 pages2020 WTS 12 Work, Energy & PowerThabelo NgwenyaNo ratings yet

- 2023MSEII Handout9Document12 pages2023MSEII Handout9王竣右No ratings yet

- The Strengthening of Dental PorcelainDocument13 pagesThe Strengthening of Dental PorcelainsankarNo ratings yet

- Traditional CeramicsDocument82 pagesTraditional CeramicsJB HIFINo ratings yet

- EP104 L6aNonMetals (Ceramics) Jul14Document29 pagesEP104 L6aNonMetals (Ceramics) Jul14arvinashNo ratings yet

- Group 14: By: Shafiq Rasila Mag Nova N HasDocument34 pagesGroup 14: By: Shafiq Rasila Mag Nova N HasShafiq HamzahNo ratings yet

- Ceramics: Classification and Properties of Ceramic MaterialsDocument36 pagesCeramics: Classification and Properties of Ceramic MaterialsMadhumita KumarNo ratings yet

- Chapter 1b Ceramics PolymerDocument23 pagesChapter 1b Ceramics PolymermaiNo ratings yet

- Chapter 6 - Ceramics and Carbon MaterialsDocument69 pagesChapter 6 - Ceramics and Carbon MaterialsRicardo Rincon VegaNo ratings yet

- JC 3Document46 pagesJC 3Danielle GravesNo ratings yet

- Glass and Ceramics PDFDocument21 pagesGlass and Ceramics PDFeriic_0425100% (1)

- Segregation and Banding in SteelDocument2 pagesSegregation and Banding in Steelsklux100% (1)

- Materiales CeramicosDocument17 pagesMateriales CeramicosAnaid Lalucky VirgenNo ratings yet

- Composite Material: Composition/Chemical BondingDocument7 pagesComposite Material: Composition/Chemical BondingMc LesterNo ratings yet

- Course KGP003 Structures and Properties of CeramicsDocument22 pagesCourse KGP003 Structures and Properties of CeramicsDaniel GrabovskyNo ratings yet

- Submerged Arc WeldingDocument13 pagesSubmerged Arc WeldingManish MNo ratings yet

- Welding ElectrodesDocument48 pagesWelding ElectrodesPelin Aybay100% (1)

- Cast Steel-Sic Composites As Wear Resistant Materials: Dejan ČikaraDocument5 pagesCast Steel-Sic Composites As Wear Resistant Materials: Dejan ČikaraAna MijatovicNo ratings yet

- Dinkar Kokje ContentDocument8 pagesDinkar Kokje ContentDevashish JoshiNo ratings yet

- Covalent ..MacromoleculeDocument8 pagesCovalent ..Macromoleculekmoiz427No ratings yet

- Introduction of CorrosionDocument23 pagesIntroduction of CorrosionApurva GuptaNo ratings yet

- Lecture 6-Ceramics GlassesDocument39 pagesLecture 6-Ceramics GlassesRUGERO KeslyneNo ratings yet

- Corrosion of Stainless SteelDocument10 pagesCorrosion of Stainless SteelRizky Ilham DescarianNo ratings yet

- CERAMICDocument92 pagesCERAMICRuby Lyn Alcaide LazaNo ratings yet

- Pengban 11 CeramicsDocument122 pagesPengban 11 CeramicstheoNo ratings yet

- Proteksi InggrisDocument9 pagesProteksi Inggrisbo_lankNo ratings yet

- Material Science Term Paper ON: "Importance of Microstructures and Microstructures of Cast Iron"Document15 pagesMaterial Science Term Paper ON: "Importance of Microstructures and Microstructures of Cast Iron"Abhishek AgarwalNo ratings yet

- Technical Note: Corrosion Protection For Tower StructuresDocument4 pagesTechnical Note: Corrosion Protection For Tower Structuresabdulkawi alasharyNo ratings yet

- Manufacturing Science and MetallurgyDocument47 pagesManufacturing Science and MetallurgyAppu bjNo ratings yet

- Revision Guidance and Check List 2022 - 2023Document22 pagesRevision Guidance and Check List 2022 - 2023AlinaHlihorNo ratings yet

- 2 Atomo y Enlace EngDocument29 pages2 Atomo y Enlace EngnikmaxterNo ratings yet

- Engineering Ceramics and GlassesDocument15 pagesEngineering Ceramics and GlassesAqsa BanoNo ratings yet

- KK Chawla Solutions PDFDocument21 pagesKK Chawla Solutions PDFharlow6winfield6adamNo ratings yet

- Lec2-Types of MMCDocument19 pagesLec2-Types of MMCguru prasadNo ratings yet

- Ceramic Pigments and GlassesDocument19 pagesCeramic Pigments and GlassesalbaqueNo ratings yet

- Structure of Silicate GlassesDocument4 pagesStructure of Silicate Glassessujaybhatta2009No ratings yet

- Process Equipment DesignDocument3 pagesProcess Equipment DesignakshaylattimardiNo ratings yet

- Course Content: No. Title Slide NoDocument54 pagesCourse Content: No. Title Slide NoDilip YadavNo ratings yet

- Failure Modes of RBIDocument5 pagesFailure Modes of RBIMuhammad OmarNo ratings yet

- Unit303 Ceramics Callum Jakub Bronius DeclanDocument21 pagesUnit303 Ceramics Callum Jakub Bronius DeclanbroniusrupainisNo ratings yet

- Tugas Mujijana Glasses (One Bundle)Document12 pagesTugas Mujijana Glasses (One Bundle)Tyo SlametNo ratings yet

- Chapter 5 Polymers, Ceramics, Composites-2Document44 pagesChapter 5 Polymers, Ceramics, Composites-2Mojery MohauNo ratings yet

- Ceramic MaterialsDocument34 pagesCeramic MaterialsRaza AliNo ratings yet

- On Types of Corrosion, Reasons and Prescribed Repairs 29.07.2015 Ver 01Document57 pagesOn Types of Corrosion, Reasons and Prescribed Repairs 29.07.2015 Ver 01Ankur SinhaNo ratings yet

- Materials and Processes For Agricultural and Biosystems EngineeringDocument35 pagesMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNo ratings yet

- Corrosion, Prevention and ControlDocument60 pagesCorrosion, Prevention and ControlCherry Obias100% (1)

- ENGG108 Polymers and Ceramics and CompositesDocument40 pagesENGG108 Polymers and Ceramics and CompositesIzc WtcNo ratings yet

- Ss Wire Properties / Orthodontic Courses by Indian Dental AcademyDocument79 pagesSs Wire Properties / Orthodontic Courses by Indian Dental Academyindian dental academyNo ratings yet

- UNIT V - Ceramics-Composites-Nano MaterialsDocument59 pagesUNIT V - Ceramics-Composites-Nano MaterialsHarsha MallaNo ratings yet

- Ceramics: 1.0 OverviewDocument9 pagesCeramics: 1.0 OverviewMehmet Can HatibogluNo ratings yet

- Materials and ProcessesDocument21 pagesMaterials and Processessamluvhouse05No ratings yet

- Preferential Corrosion of Welds - 001Document5 pagesPreferential Corrosion of Welds - 001srinivas raoNo ratings yet

- Advanced Structural CeramicsDocument12 pagesAdvanced Structural CeramicsKarthick RamNo ratings yet

- Welcome To A Presentation On: Corrosion Process & Cathodic Protection SystemDocument63 pagesWelcome To A Presentation On: Corrosion Process & Cathodic Protection SystemSrikanth SrikantiNo ratings yet

- Uniform CorrosionDocument33 pagesUniform CorrosionImmalatulhusnaNo ratings yet

- CORROSION Uniform CorrosionDocument101 pagesCORROSION Uniform Corrosionhal_nasik_planning5657100% (11)

- Lecture 4: Slag in Steelmaking ContentsDocument5 pagesLecture 4: Slag in Steelmaking ContentsAbhijeet BhagavatulaNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Mole Concept Solution Practice Set ObjectiveDocument3 pagesMole Concept Solution Practice Set ObjectiveGagandeep SinghNo ratings yet

- Calculating Productivity - Student Worksheet.137132843Document2 pagesCalculating Productivity - Student Worksheet.137132843Eric WeirNo ratings yet

- January 2014 MS - Paper 1C Edexcel Chemistry IGCSEDocument24 pagesJanuary 2014 MS - Paper 1C Edexcel Chemistry IGCSEVideesha AmunugamaNo ratings yet

- HCL, CL Corrosion DataDocument8 pagesHCL, CL Corrosion DataShah RajendraNo ratings yet

- Investigation of Geothermal Using Magnetotelluric Method in Babakan Bogor, Bengkulu Province, IndonesiaDocument11 pagesInvestigation of Geothermal Using Magnetotelluric Method in Babakan Bogor, Bengkulu Province, IndonesiaAZKY RAMANIYA SUKARDINo ratings yet

- God From Quantum MechanicsDocument4 pagesGod From Quantum MechanicsAnonymous GAiU7gHNo ratings yet

- PDF Balanced Plant Nutrition Manual Min PDF DDDocument58 pagesPDF Balanced Plant Nutrition Manual Min PDF DDVineeth Balaji K SNo ratings yet

- Cell MetabolismDocument6 pagesCell MetabolismelsayidNo ratings yet

- Assignment AC U6 Final eDocument26 pagesAssignment AC U6 Final eYuenHei Kwok0% (1)

- Ans 1Document12 pagesAns 1euphysics2025No ratings yet

- AVR 1500 Audio/Video Receiver: Service ManualDocument74 pagesAVR 1500 Audio/Video Receiver: Service ManualMartel QuirozNo ratings yet

- Mukund Lahoti Review Paper On Geopolymer at High TempDocument13 pagesMukund Lahoti Review Paper On Geopolymer at High TempShaik HussainNo ratings yet

- 2003SP MicrowaveOpticsDocument34 pages2003SP MicrowaveOpticsOmar HraouiNo ratings yet

- Seminar ReportDocument13 pagesSeminar Reportketan chauhan100% (1)

- KP House CombinationDocument5 pagesKP House CombinationBalinder Renu100% (4)

- Physics Notes PDFDocument82 pagesPhysics Notes PDFnatsdorf100% (4)

- MasterSeal P 698 MSDS - EN-23.11.2022-Rev1.2Document11 pagesMasterSeal P 698 MSDS - EN-23.11.2022-Rev1.2recep kablanNo ratings yet

- Norma TestDocument3 pagesNorma TestIvan Huilcapaz MoraNo ratings yet

- Activity Resources (Teacher's Edition) - 2 YearsDocument100 pagesActivity Resources (Teacher's Edition) - 2 YearsYenny Tiga100% (1)

- Department of Education: I. II. Iii. IV. A. BDocument2 pagesDepartment of Education: I. II. Iii. IV. A. BLuz Marie CorveraNo ratings yet

- Vector Calculus Applications in Electricity and MagnetismDocument6 pagesVector Calculus Applications in Electricity and MagnetismSadeep MadhushanNo ratings yet

- GopinathDocument9 pagesGopinathAnand MurugananthamNo ratings yet

- Electricity and Magne/sm II: Gri Ths Chapter 11 Radia/on Clicker Ques/onsDocument17 pagesElectricity and Magne/sm II: Gri Ths Chapter 11 Radia/on Clicker Ques/onsYan YurikoNo ratings yet

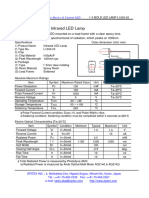

- Led L1200-03Document1 pageLed L1200-03Fabio Augusto GentilinNo ratings yet

- Cyanide FactsDocument8 pagesCyanide FactsAzman TaibNo ratings yet

- Chemical Safety SymbolsDocument2 pagesChemical Safety SymbolsMary Rose MendozaNo ratings yet

- Toxicology Procedures ManualDocument227 pagesToxicology Procedures ManualBenjel AndayaNo ratings yet

- EDC - MATERIAL - Final - 26.07.2014Document139 pagesEDC - MATERIAL - Final - 26.07.2014Sucharita PriyadarshiniNo ratings yet

- Clever Pathway Havells Motors SuppliersDocument12 pagesClever Pathway Havells Motors SuppliersClever Chemicals Ltd.No ratings yet