Professional Documents

Culture Documents

Rock Excavation Systems

Rock Excavation Systems

Uploaded by

Kerim AydinerCopyright:

Available Formats

You might also like

- MidtermDocument348 pagesMidtermIAMVIBE100% (1)

- Introduction To Drilling Technology PDFDocument37 pagesIntroduction To Drilling Technology PDFgggicutza75% (4)

- Quarrying in Cement IndustryDocument14 pagesQuarrying in Cement IndustryNael100% (2)

- Intro To Fine Art BW Photography PDFDocument165 pagesIntro To Fine Art BW Photography PDFNovandi BariqNo ratings yet

- UtopiaDocument62 pagesUtopiaDamlaNo ratings yet

- SpringBootMicroservicesContent PDFDocument11 pagesSpringBootMicroservicesContent PDFPurushotham reddyNo ratings yet

- Chapter Three: 1 Department of Mining EngineeringDocument24 pagesChapter Three: 1 Department of Mining EngineeringYewuhalashet FisshaNo ratings yet

- DrillingDocument4 pagesDrillingHardik KarkarNo ratings yet

- Prnciples of Drilling and Drill BitDocument20 pagesPrnciples of Drilling and Drill Bitsudishett100% (1)

- Mechanical ExcavationDocument17 pagesMechanical Excavationmohan_manoj43No ratings yet

- RockFrag 070716Document169 pagesRockFrag 070716vongai chimbundeNo ratings yet

- E. Note On Drilling - For Surfcae Mining ApplicationDocument13 pagesE. Note On Drilling - For Surfcae Mining ApplicationEyob FkrNo ratings yet

- 2 class-INTRODUCTION TO MINING-3Document8 pages2 class-INTRODUCTION TO MINING-3Davies EmmanuelNo ratings yet

- Rock Drilling and DrillabilityDocument57 pagesRock Drilling and Drillabilitybishal pradhan0% (1)

- Lec9-Rock Cutting ToolsDocument35 pagesLec9-Rock Cutting ToolsAmraha NoorNo ratings yet

- 324-Chapter 1 Rock Bit Interactions PDFDocument42 pages324-Chapter 1 Rock Bit Interactions PDFBilge KaanNo ratings yet

- UG Mechanical ExcavationDocument116 pagesUG Mechanical ExcavationSaineesh VinjamuriNo ratings yet

- Modeling and Analysis of Rotor Shaft Assembly of Hammer Mill CrusherDocument46 pagesModeling and Analysis of Rotor Shaft Assembly of Hammer Mill CrusherPrudhvi VasagiriNo ratings yet

- Introduction To Drilling TechnologyDocument37 pagesIntroduction To Drilling TechnologySam ShiddoNo ratings yet

- Lec9-Rock Cutting ToolsDocument27 pagesLec9-Rock Cutting ToolsEnchanting EffortNo ratings yet

- Optimizacion de Aceros PDFDocument34 pagesOptimizacion de Aceros PDFKendra RobertsNo ratings yet

- BlastDocument12 pagesBlastemptyqqNo ratings yet

- Drilling by SubhransuDocument29 pagesDrilling by Subhransujusttrailers07No ratings yet

- Introduction To Mechanical Size ReductionDocument35 pagesIntroduction To Mechanical Size ReductionFikrie MuhdNo ratings yet

- Tunnel Boring MachineDocument14 pagesTunnel Boring MachineRohit Sharma100% (1)

- Jaw Crusher: Cam Pitman Lever NutcrackerDocument13 pagesJaw Crusher: Cam Pitman Lever NutcrackerVickram JainNo ratings yet

- Blast Design and Assessment For Surface Mines and QuarriesDocument198 pagesBlast Design and Assessment For Surface Mines and QuarriesOmar Alex Meléndez HuamánNo ratings yet

- Crushing LawsDocument12 pagesCrushing Lawsharishkumar.ravichandranNo ratings yet

- Chapter-6 Comminution - Theory and Plant Practice: Fig-6.1: Particlle Breaking MechanismDocument16 pagesChapter-6 Comminution - Theory and Plant Practice: Fig-6.1: Particlle Breaking MechanismLMNo ratings yet

- Crusher WikipediaDocument8 pagesCrusher WikipediaJaya ChandranNo ratings yet

- FINAL PPT-Aggregate ProductionDocument77 pagesFINAL PPT-Aggregate ProductionLeilani Manalaysay100% (1)

- Percussion DrillingDocument7 pagesPercussion DrillingFahim UllahNo ratings yet

- Quarrying of StonesDocument12 pagesQuarrying of StonesHana HadraNo ratings yet

- Impact Crusher PDFDocument45 pagesImpact Crusher PDFMusheer BashaNo ratings yet

- Stages OF Underground Excavation Method: Presented byDocument14 pagesStages OF Underground Excavation Method: Presented byHimaniNo ratings yet

- Crushing: 1. Jaw CrusherDocument6 pagesCrushing: 1. Jaw Crusherpranav reddyNo ratings yet

- Effect of Depth of Cut On MRR in Surface GrindingDocument7 pagesEffect of Depth of Cut On MRR in Surface GrindingshubhamNo ratings yet

- Crushing and GrindingDocument2 pagesCrushing and GrindingdivNo ratings yet

- 3-Disc, Button, Toothed Cutters - KopyaDocument22 pages3-Disc, Button, Toothed Cutters - KopyaceydaksemrNo ratings yet

- Perforacion de Rocas: Presentado PorDocument26 pagesPerforacion de Rocas: Presentado PorEsteban C. ZubietaNo ratings yet

- 19PWCHE1431Document6 pages19PWCHE1431Khan AaghaNo ratings yet

- HoningDocument4 pagesHoningmiso_mallard5123No ratings yet

- Design and Manufacturing of Small Scale Stone Crusher MachineDocument6 pagesDesign and Manufacturing of Small Scale Stone Crusher Machinetibem100% (1)

- Perforación y Tronadura Unidad I: IntroducciónDocument31 pagesPerforación y Tronadura Unidad I: IntroducciónLaiss FernandaNo ratings yet

- Sampling and Analysis of Drilled CuttingsDocument6 pagesSampling and Analysis of Drilled CuttingsSubrahmanyamNo ratings yet

- Alenowicz Wymagania 2017 1Document5 pagesAlenowicz Wymagania 2017 1robson2015No ratings yet

- Honing of CylindersDocument3 pagesHoning of Cylindersvijay9994No ratings yet

- Assignment For MID Topic: Basics of BlastingDocument65 pagesAssignment For MID Topic: Basics of BlastingUdit kumarNo ratings yet

- Review On Design and Analysis of Jaw Abstract Plate of Jaw-CrusherDocument10 pagesReview On Design and Analysis of Jaw Abstract Plate of Jaw-CrusherCarlos Ediver Arias RestrepoNo ratings yet

- Computer Aided Design of Jaw CrusherDocument50 pagesComputer Aided Design of Jaw Crusherdinesh_ypkNo ratings yet

- General Rock Removal: A Matter of ScaleDocument32 pagesGeneral Rock Removal: A Matter of ScaleJuan Camilo Guerra GNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Geotechnical Investigation: (Drilling Tools)Document17 pagesGeotechnical Investigation: (Drilling Tools)A Bashir AsalaiNo ratings yet

- Mining Rock DrillingDocument19 pagesMining Rock DrillingAdda Rivera100% (1)

- Micro DrillingDocument9 pagesMicro DrillingsubavlNo ratings yet

- Size Reduction: Within The Context of Sample PreparationDocument6 pagesSize Reduction: Within The Context of Sample PreparationEva Valentino CapiliNo ratings yet

- Drilling 1Document33 pagesDrilling 1OUMAIMA OULD SALTANANo ratings yet

- Surface FinishingDocument11 pagesSurface FinishingShashank BhambaleNo ratings yet

- Chapter 3 & 4 by D.ChandraDocument19 pagesChapter 3 & 4 by D.Chandraফয়েজ আহমেদNo ratings yet

- Cte U1l3Document14 pagesCte U1l3Nikhil VishavkramaNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Bridges, Hauber Et Al. 2011 - Conjoint Analysis Applications in Health-A PDFDocument11 pagesBridges, Hauber Et Al. 2011 - Conjoint Analysis Applications in Health-A PDFali rezaNo ratings yet

- Appnote WisprDocument7 pagesAppnote WisprXisco LladóNo ratings yet

- Cambodia Climate Change Report FINAL For Publication JSJMfinal Edit 26sept08Document60 pagesCambodia Climate Change Report FINAL For Publication JSJMfinal Edit 26sept08Som PisethNo ratings yet

- D1875 18737Document2 pagesD1875 18737JEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- Bernard Guenther - Know Thyself PDFDocument4 pagesBernard Guenther - Know Thyself PDFJelena AćaNo ratings yet

- Optics TestDocument2 pagesOptics Testiskenderbey100% (1)

- The Reaction PaperDocument1 pageThe Reaction Papervenus lamadridNo ratings yet

- RRLDocument96 pagesRRLCassandra Alyssa Villaflores100% (1)

- TUGAS BAHASA INGGRIS FEBRI HANDAYANiDocument29 pagesTUGAS BAHASA INGGRIS FEBRI HANDAYANiFebri handayaniNo ratings yet

- Project HR ManagementDocument73 pagesProject HR ManagementgadoradatabaseNo ratings yet

- Process FitnessDocument7 pagesProcess Fitnessapi-3748659No ratings yet

- Competency MappingDocument31 pagesCompetency MappingKirti Sangwan100% (1)

- Tabla de Especificaciones Primer Grado InglésDocument1 pageTabla de Especificaciones Primer Grado InglésRamiro Covarrubias ReséndizNo ratings yet

- Zero To One - MKT523 - Book SummaryDocument3 pagesZero To One - MKT523 - Book SummaryMahmudul Hasan TusharNo ratings yet

- Finite-State Description of Vietnamese ReduplicationDocument7 pagesFinite-State Description of Vietnamese ReduplicationPham Hai YenNo ratings yet

- 27 08 2016-MS-RachnaDocument13 pages27 08 2016-MS-RachnaRachna SelvamaniNo ratings yet

- Laguna Lake Development Authority v. Court of AppealsDocument16 pagesLaguna Lake Development Authority v. Court of Appealsmichee coiNo ratings yet

- English For Specific PurposesDocument7 pagesEnglish For Specific PurposesCarmie Lactaotao DasallaNo ratings yet

- Recreational Fishing: Sustainable Fishing and Health of The Oceans Program Tampa, FloridaDocument36 pagesRecreational Fishing: Sustainable Fishing and Health of The Oceans Program Tampa, FloridaNational Press FoundationNo ratings yet

- Barbara BenderDocument287 pagesBarbara BenderElmer Homero Mi ReyNo ratings yet

- Bryston CodesDocument3 pagesBryston CodesBradley ChilderhoseNo ratings yet

- Materials Selection For Hot Stamped Automotive Body Parts: An Application of The Ashby Approach Based On The Strain Hardening Exponent and Stacking Fault Energy of MaterialsDocument10 pagesMaterials Selection For Hot Stamped Automotive Body Parts: An Application of The Ashby Approach Based On The Strain Hardening Exponent and Stacking Fault Energy of MaterialsJaka Haris MustafaNo ratings yet

- TXTDocument5 pagesTXTproman25-1No ratings yet

- HR Training GD TopicsDocument4 pagesHR Training GD TopicsNiraj KumarNo ratings yet

- PivotTable Tutorial1Document27 pagesPivotTable Tutorial1Sumit RazNo ratings yet

- Ogutu - The Role of National Housing Corporation in The Provision of Housing in KenyaDocument95 pagesOgutu - The Role of National Housing Corporation in The Provision of Housing in KenyaboneylouNo ratings yet

Rock Excavation Systems

Rock Excavation Systems

Uploaded by

Kerim AydinerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rock Excavation Systems

Rock Excavation Systems

Uploaded by

Kerim AydinerCopyright:

Available Formats

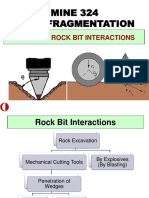

Rock Excavation Systems Mechanical Excavation

Theories of Interaction of Rock Cutting tools

U.Siva Sankar Sr. Under Manager Project Planning Singareni Collieries Company Ltd E-Mail :ulimella@gmail.com or uss_7@yahoo.com Visit at:

www.slideshare.net/sankarsulimella

Rock Breaking Processes

The basic principles of breaking brittle hard rock. The main considerations in breaking rock are the forces required to induce fractures in the rock and the energy consumed in breaking rock. Force is important because it determines the limitation on the type of machinery that can be used to break the rock and on the materials of construction that can be used in the machinery. As the breaking mechanism of the machine changes, so would the energy required to break the rock since the strength of rock varies depending on the type of stress induced on the material. Energy is important because it determines the rate at which rock breaking can be carried out. All machines are limited in the power that can be applied to the rock and hardness of the manufactured components of the machine. Therefore a process that demands substantial energy will result in a slow rock breaking rate. The rock breaking process is classified into three major groups: primary, secondary, and tertiary.

Rock Breaking Processes Primary

This is the application of a force by means of a hard indenter to a free rock face much larger than the indenter. This generates chips which are of a size similar to that of the indenter at the sides of the indenter and a pulverized zone immediately below the indenter.

Primary breakage processes

1. Impact or hammering. Dynamic forces are applied 2. Percussive drilling. Application of a hard indenter to the bottom of a hole. The force is applied from one side only and the bottom of the hole is the free face. The force applied dynamically and after each application the hard indenter is moved slightly to break out more chips on the next application 3. Button type cutters for raise and tunnel borers. The buttons are loaded slowly (quasi-statically) and are moved away to be re-applied elsewhere, that is, indexing occurs by rolling to the next button. Repeated applications over a large surface area maintain the flat face 4. Disc type cutters for raise and tunnel borers. Hard indenter indexed by rolling. Forces at a point in the rock rise very slowly. 5. Drag bit. A hard indenter forced onto the rock and indexed by dragging across the surface. 6. Diamond bits. A very hard surface and very small indenter dragged across the surface. The real breaking is done by the force thrusting the diamonds against the rock. Diamonds produce very small fragments because they are small indenters.

Secondary breakage processes This is the application of forces inside a hole near to the rock face. The forces inside the hole generate tension at the sides of the hole to which produces cracks which ultimately runs to the free surface. Secondary breakage processes includes: 1. Wedging. Wedge driven into a hole which produces crack 2.Blasting. Explosive generates a pulverized zone through compression but the real breaking process is by driving tensile cracks.

Tertiary breakage

1. Breaking boulders by impact or mud blasting 2. Crushing 3. Milling According to theory, the tertiary breakage process is closely related to breaking the rock in tension. From Figure can be seen that loading of a sphere by diametrically opposed forces causes a uniform tensile stress across the diametrical plane. This causes the sphere to split in tension, that is, at a stress very much lower than the uniaxial compressive stress. Tertiary This is the application of forces from more than one side to a free surface.

Tertiary breakage process Fig; Tertiary Breakage a Tensile effect It has been found that the tertiary stress, t, is also dependent on the size of the rock, but not as important as the size of the indenter for primary breakage.

Miscellaneous breakage processes

Several other breakage processes exist, these include: 1. Thermal spalling. This depends on intense heat (flame) being applied to the rock and traversed so that a high temperature gradient is produce in the rock resulting in differential expansion which produces mechanical strains and ultimately breaking of the rock. It is used in taconite and certain quarrying operations, usually in cold climates. Thermal spalling is also used for finishes on rock surfaces and where high forces must be avoided during breakage. (Commonly used ancient technique) 2. Water jets. The water jets create high stagnation pressures against the surface it impinges on. Used for drilling in porous hard rock where water goes into pores and breaks grains out. Water jets are known to be wasteful on energy and are used only for special applications.

Mechanical Excavation Systems Different mechanical excavation systems, like machines with;

Teeth (Dozer, Shovel, Scraper, Bucket wheel excavator, Bucket chain excavator) Ripping tool (Coal Plough, ripper, rock breaker), Pick mounted rotary cutting head/drum (Roadheader, Shearer, Continuous miner, Surface miner) Disc cutters and button bits (rock drill, Mobile tunnel miner, Tunnel boring machine) Auger tool (Continuous Auger Miner, Surface Auger Miner)

Application of Mechanical Systems

Under Ground: Continuous Miners, Bolter miners, Auger Miners and shearers for coal or soft nonmetalics Boom type miners (road headers in soft to medium hard rocks) Rapid excavation equipment (Mobile tunnel miners,Tunner borers, raise borers, and shaft sinking rigs) for soft to medium hard and hard rocks) Surface: Rippers for very compact soil, coal, and weathered or soft rock Bucket wheel and cutting head excavators for soil or coal Augers and highwall miners for coal Mechanical dredges for placers and soil

Mechanical Excavation Systems Classifications of cutting tool based on Cutting Action

Type of tool Drag tool Mode of action Specific tool types Machines using tool Rotary drilling machine Roadheader Continuous miner Shearer Rotary percussive drilling machine Rotary drilling machine Raise borer Tunnel boring machine (TBM) Mobile miner Raise borer

Applies a force Diamond drill bit roughly parallel to the rock Pick surface (point attack and wedge) Applies a force Brazed drill bit normal to the Button drill bit rock surface Tricone Roller drill bit Disc cutter

Indenter

Mechanical Excavation Systems

The main difference between indenters and drag bits is that an indenter breaks rock by applying a force that is predominantly in a direction normal to the rock surface. Comparatively, a sharp drag bit applies the main force in a direction predominantly parallel to the rock surface. The breaking mechanism for both is actually a tensile fracture. Because the drag tool initiates tensile fractures in a more direct manner, with less crushing, it is more efficient than an indenter. However, indenters are by far the most widely used type of tool; why is this? The reason lies in the strength of the tool itself. The materials used for the cutting edge must be hard but, because of this property, they are also brittle. The mode of action of a drag tool induces bending, or tensile stresses in the tool cutting edge and makes catastrophic failure of the tool more likely. An indenter, on the other hand, is loaded mainly by a compressive force along its main axis and the material of which it is made is inherently strong in compression. (Hood and Roxborough 1992.)

Mechanical Excavation Systems

These basic cutting methods, defined in terms of tool type, are and include: 1.Drag bit cutting. 2. Point-attack bit cutting. 3. Disk cutting. 4. Roller cutting. 5. Button cutting.

Indenters Drag type

Fig: Rock Cutting Techniques

Mechanical Excavation Systems

Drag bit cutting and Point-attack bit cutting. The application of both drag bits and point-attack bits is similar. The tools are inserted in tool holders (or boxes), which are integral parts of the cutting head, and may be held in place by a circlip or spring. Point-attack bits are commonly free to rotate in their holders. It has been claimed that this feature promotes more even tool wear (self sharpening) and better overall tool life. During cutting, the bits are pushed into the rock, developing cutting forces parallel to the direction of head rotation and normal forces parallel to the direction of head thrust. As these forces build up to critical values, a macroscopic failure surface develops ahead of the bit, and a piece of rock spalls away. Road headers, Continuous Miners (Bolter Miners & Surface Miners) and Shearers use drag and point-attack bits almost exclusively. These tools also find application on tunnel boring machine (TBM) cutter heads, but in this role they are generally limited to machines operating in weaker formations.

Mechanical Excavation Systems

Disk cutters generally consist of solid steel alloy discs with a tapered cutting edge. The disk is mounted in a bearing and is free to roll in response to applied forces acting parallel to the rock surface. These rolling forces are analogous to the cutting forces applied in drag bit cutting. Thrust and drag forces are applied to the disk through the bearing and act normal and parallel respectively to the rock surface. Thrust forces acting on the cutting head push the cutter into the rock building up stresses which cause local rock failure. Disks used in practice may be of the simple type, or may consist of multi-edge varieties, including types with successively smaller disk diameters giving a tapered or conical arrangement. Frequently these multi-row disks employ carbide inserts with chisel points imbedded nearly flush with the circumference. Simple disk cutters are used primarily on full face TBMs, and multi-row disks on raise boring machines (RBMs).

Breaking Process Under a Disc Cutter

Fig: Model for disk cutting (Roxborough and Phillips, 1975a).

Mechanical Excavation Systems

Roller or mill-tooth cutting is similar to disk cutting except that instead of a tapered disc edge, the tool is equipped with circumferential teeth. As the cutter moves in response to rolling forces, each tooth in turn is pushed into the rock, acting like a wedge, and causing local failure. Button cutters consist of cylindrical or conical tool bodies inset with tungsten carbide buttons. The tool is mounted in a bearing in the same way as disk cutters or roller cutters and is free to roll in response to applied forces acting parallel to the rock surface. Thrust forces cause high stress concentrations beneath each button as they roll across the rock surface, resulting in local failure and pulverization of the rock. The area of influence of each button is small and results in a fine-grained product. Button cutting is used in applications in which high rock strength and abrasivity preclude the use of other methods. These cutters also find application as reaming cutters used for final profiling on RBMs and TBMs.

Pick

Mechanical Excavation Systems

The picks consist of a steel body containing a recess into which a cemented carbide tip is brazed. The cemented carbide tip is the cutting portion of the pick, and consists of two materials, tungsten carbide and cobalt, sintered together to form a matrix of car bide grains within a cement of fused carbon. The most important physical properties of the cemented carbide are hardness and toughness. The value of both these properties can be varied by the amount of cobalt present, as shown in Fig. I. If the carbide is too hard, premature fracturing will occur, and, if it is too soft, the material will wear away too quickly. Thus, for optimum cutting performance, a balance between the two properties is necessary, dependent upon the quality of the coal being cut.

Fig: variation of Toughness and hardness of pick with % of Cobalt

Mechanical Excavation Systems Drag Pick Types

Radial picks Forward attack Picks, and Point attack Picks

Radial and Forward attack Picks (Chisel or Wedge Picks)

Conical or Point Attack Picks

Radial picks Chisel or Wedge pick Mechanical Excavation Systems These tools are designed such that the axis of pick shank is normally parallel to the radial line of cutting head/drum. They are generally suitable for cutting soft and medium-hard rocks and coal. Radial picks generate lower forces than those of point attack tools, when pristine. The normal force is of low magnitude compared to cutting force. Forward attack Picks - Chisel or Wedge pick These picks are also termed tangential picks, together with point attack picks, due to the orientation of their tool axis. The design and the geometry of tool tip is similar to that found on radial picks Chisel or wedge pick may be having either flat bottom surface or round bottomed surface. Point attack picks Conical tip and cylindrical shank. Shank axis is inclined relative to the rock surface. The tool is designed to rotate by the action of cutting to produce even wear and is therefore favoured in abrasive rocks. Often, however, dirt clogs the tool, so that it cannot rotate.

Cutting parameters

Mechanical Excavation Systems

Cutting Geometry of Drag Pick

Schematic Drawing of Forces acting on a Conical Bit

Cutting parameters

Mechanical Excavation Systems

A simple Drag pick with the forces acting on it is illustrated in Figure. The resultant force Pa may be resolved into three mutually perpendicular components: Cutting force (Fc), acting in the direction of cutting; Normal force (FN) perpendicular to the direction of Fc; and Sideways force (Fs) normal to the plane on which Fc and FN lie. Clearance Angle: Clearance angle, which is between the lower surface of pick and a plane parallel to the cutting direction, also has pronounced affects on the pick forces. Investigations have shown that tool forces drop sharply after a value of around 5and stay sensibly constant. To meet the kinematic needs, the clearance angle is generally designed to be around 10 degrees.

10

Mechanical Excavation Systems

Rake Angle: Cutting and normal forces decrease monotonically with increasing rake angle as seen in Figure. Most of the benefit to pick forces has been achieved at a rake angle of 20 , beyond which further marginal improvement is at an increasing penalty to pick strength and its potential to survive. Rake angle can be either +ve or -ve. Rake angles between +20 and +30 degrees can be chosen for weak rocks and coal cutting. High rake angles may not be beneficial since picks with these angles are more susceptible to gross failure.

Mechanical Excavation Systems

Attack Angle The angle of attack which is the angle between the tool axis and the tangent of the cutting path, is another parameter affecting the performance of point attack picks. This angle provides a good contact between the pick and rock and failure to position the pick at its correct angle of attack will significantly alter the effective tool geometry. In order to offset the value of clearance angle, the angle of attack is to be larger, e.g. at 90 degrees cone angle, the angle of attack should be at least 55 degrees. It is also reported that at high rotational speed this angle should not exceed 48 . Tilt angle: It is the angle between cutter axis to the vertical line normal to direction of cutting. Tilt angles of 65 to 70 degrees offered the lower specific energy and relative freedom from vibration problems.

11

Breakout Angle:

Fig. Effect of breakout.

Fig. Breakout between neighbouring Picks

When a pick cuts its way through a material, some of it breaks away at each side of the pick; this is referred to as side splay or breakout Usually the sides of the groove are irregular, but over the total cut length the average slope of the sides, termed the 'breakout angle', can be considered constant for a particular material Efficient cutting is achieved through the maximum use of breakout, and pick lacing patterns should be designed so as to continually repeat the cutting sequence that produces it.

where s = spacing between the tools, d= depth of cut, and = breakout angle. If the breakout angle for a particular material has been determined then s/d can be calculated.

Mechanical Excavation Systems

Wear Angle: The wearflat is almost parallel to the cutting direction; however, it generally tends to incline in the opposite direction and forms a wear angle. This angle is around few degrees and becomes smaller for the hardest and strongest materials. Occurrence of wearflat changes the tool tip geometry and, consequently, results in the generation of higher tool forces. The normal force is the most affected component by the wear, e.g. a wearflat around 1mm can drastically increase Fn/Fc ratio. It is also reported that a large clearance angle relieves the wear effect and provides better overall efficiency even if, as a consequence, a small or slightly negative rake angle is introduced.

Wear Development of Drag Pick

12

Important measures of cutting performance Yield (Q)

Mechanical Excavation Systems

The volume f rock produced by cutting - depends on penetration depth (d), breakout angle () and distance cut work done by the cutting force (F ) to excavate unit Specific Energy The C (SE) volume of yield. Dependent on: Rock strength and toughness Degree of fracturing Machine type and method of operation Tool type and condition Available tool forces (machine size and power) Penetration depth

Specific energy is one of the most important factors in determining the efficiency of cutting systems and defined as the work to excavate a unit volume of rock. Hughes and Mellor demonstrated that specific energy might be formulated as in the following: Where, SE is specific energy, E is secant elasticity modulus from zero to load to failure and Sc is compressive strength of rock.

Detailed rock cutting tests, however, showed that specific energy was not only a function of rock properties but it was also closely related to operational parameters such as rotational speed, cutting power of excavation machines and tool geometry. Roxborough reported that specific energy decreased dramatically to a certain level with increasing depth of cut and decreasing tool angle. The effect of the spacing between cuts and depth of cut (or penetration) on cutting efficiency is explained in Figure. If the line spacing is too close , the cutting is not efficient because the rock is over-crushed; in this region, tool wear is also high due to the high friction between tool and rock.

Fig: General effect of cutter spacing on specific energy.

13

Mechanical Excavation Systems

Pointed Attack Vs Chisel or Wedge or Radial Picks

In terms of pick shape, when operating at the same rake and clearance angles and depth of cut, the pointed pick requires the least cutting and normal force. The chisel pick requires the greatest forces. Due to the increased penetrating capability of the pointed pick, for a given available normal force, pointed picks operate more efficiently than the chisel bit. Pointed picks can but deeper for a given level of force, whereas chisel bit cut more material for a given depth of penetration.

Mechanical Excavation Systems Theoretical and experimental studies on cutting forces

A number of scientists have formulated mathematical models to improve the design of the excavation machines and find the best configuration of the cutting tools for more efficient cutting process. Evans, Evans and Pomeroy extended theoretical works of Evans were used to establish the basic principles of the cutting process and these have been widely used in the efficient design of excavation machines such as shearers, continuous miners and road headers. Evans demonstrated theoretically that tensile strength and compressive strength were dominant rock properties in rock cutting with chisel picks and point attack tools. He also formulated optimum spacing for chisel picks as three to four times the pick width.

Where FC is cutting force, d is depth of cut, w is tool width, is rake angle, t is tensile strength, C is compressive strength and is tip angle.

14

Mechanical Excavation Systems Theoretical and experimental studies on cutting forces

Goktan suggested a modication on Evans cutting theory for point attack tools as indicated in Equation below and concluded that the force values obtained with this equation were close to previously published experimental values and could be of practical value;

Where is friction coefficient between cutting tool and rock Goktan used Evans theories to compare the cutting efficiency of point attack tools and wedgeshaped picks and concluded that the ratio of tensile to compressive strength was the main parameter governing the relative efficiency.

Performance of Disc Cutters

Fig: Model for disk cutting (Roxborough and Phillips, 1975a).

Fig. Interplay between pick width and spacing.

Fig: General effect of cutter spacing on specific energy.

15

Performance of Disc, Button and Pineapple cutters

A ranking of cutting efficiency of tool types, in terms of specific energy, places the steel disk cutter as the most efficient, the disk-button cutter next, and the pineapple cutter as least efficient. However, the wear resistance, and therefore the capability of cutting strong abrasive formations, is the reverse of this efficiency ranking. Consequently, steel disks tend to be used for cutting weaker, less abrasive rocks, and pineapple cutters are used for machining the most abrasive and toughest formations. First, in contrast with drag bits, the efficiency of the rock breakage process does not decrease when disk cutters are used in a groove deepening mode. Second, the value of this optimum spacing depends on the depth of cut taken and on the rock type and with drag bits an optimum s/d value of 2 to 3 and with disk cutters this value is in the range 5 to 10. Third, the efficiency of the rock breakage process is independent of whether the grooves are cut simultaneously, with multiple disks on a single hub, orequentially, with independent disks.

16

You might also like

- MidtermDocument348 pagesMidtermIAMVIBE100% (1)

- Introduction To Drilling Technology PDFDocument37 pagesIntroduction To Drilling Technology PDFgggicutza75% (4)

- Quarrying in Cement IndustryDocument14 pagesQuarrying in Cement IndustryNael100% (2)

- Intro To Fine Art BW Photography PDFDocument165 pagesIntro To Fine Art BW Photography PDFNovandi BariqNo ratings yet

- UtopiaDocument62 pagesUtopiaDamlaNo ratings yet

- SpringBootMicroservicesContent PDFDocument11 pagesSpringBootMicroservicesContent PDFPurushotham reddyNo ratings yet

- Chapter Three: 1 Department of Mining EngineeringDocument24 pagesChapter Three: 1 Department of Mining EngineeringYewuhalashet FisshaNo ratings yet

- DrillingDocument4 pagesDrillingHardik KarkarNo ratings yet

- Prnciples of Drilling and Drill BitDocument20 pagesPrnciples of Drilling and Drill Bitsudishett100% (1)

- Mechanical ExcavationDocument17 pagesMechanical Excavationmohan_manoj43No ratings yet

- RockFrag 070716Document169 pagesRockFrag 070716vongai chimbundeNo ratings yet

- E. Note On Drilling - For Surfcae Mining ApplicationDocument13 pagesE. Note On Drilling - For Surfcae Mining ApplicationEyob FkrNo ratings yet

- 2 class-INTRODUCTION TO MINING-3Document8 pages2 class-INTRODUCTION TO MINING-3Davies EmmanuelNo ratings yet

- Rock Drilling and DrillabilityDocument57 pagesRock Drilling and Drillabilitybishal pradhan0% (1)

- Lec9-Rock Cutting ToolsDocument35 pagesLec9-Rock Cutting ToolsAmraha NoorNo ratings yet

- 324-Chapter 1 Rock Bit Interactions PDFDocument42 pages324-Chapter 1 Rock Bit Interactions PDFBilge KaanNo ratings yet

- UG Mechanical ExcavationDocument116 pagesUG Mechanical ExcavationSaineesh VinjamuriNo ratings yet

- Modeling and Analysis of Rotor Shaft Assembly of Hammer Mill CrusherDocument46 pagesModeling and Analysis of Rotor Shaft Assembly of Hammer Mill CrusherPrudhvi VasagiriNo ratings yet

- Introduction To Drilling TechnologyDocument37 pagesIntroduction To Drilling TechnologySam ShiddoNo ratings yet

- Lec9-Rock Cutting ToolsDocument27 pagesLec9-Rock Cutting ToolsEnchanting EffortNo ratings yet

- Optimizacion de Aceros PDFDocument34 pagesOptimizacion de Aceros PDFKendra RobertsNo ratings yet

- BlastDocument12 pagesBlastemptyqqNo ratings yet

- Drilling by SubhransuDocument29 pagesDrilling by Subhransujusttrailers07No ratings yet

- Introduction To Mechanical Size ReductionDocument35 pagesIntroduction To Mechanical Size ReductionFikrie MuhdNo ratings yet

- Tunnel Boring MachineDocument14 pagesTunnel Boring MachineRohit Sharma100% (1)

- Jaw Crusher: Cam Pitman Lever NutcrackerDocument13 pagesJaw Crusher: Cam Pitman Lever NutcrackerVickram JainNo ratings yet

- Blast Design and Assessment For Surface Mines and QuarriesDocument198 pagesBlast Design and Assessment For Surface Mines and QuarriesOmar Alex Meléndez HuamánNo ratings yet

- Crushing LawsDocument12 pagesCrushing Lawsharishkumar.ravichandranNo ratings yet

- Chapter-6 Comminution - Theory and Plant Practice: Fig-6.1: Particlle Breaking MechanismDocument16 pagesChapter-6 Comminution - Theory and Plant Practice: Fig-6.1: Particlle Breaking MechanismLMNo ratings yet

- Crusher WikipediaDocument8 pagesCrusher WikipediaJaya ChandranNo ratings yet

- FINAL PPT-Aggregate ProductionDocument77 pagesFINAL PPT-Aggregate ProductionLeilani Manalaysay100% (1)

- Percussion DrillingDocument7 pagesPercussion DrillingFahim UllahNo ratings yet

- Quarrying of StonesDocument12 pagesQuarrying of StonesHana HadraNo ratings yet

- Impact Crusher PDFDocument45 pagesImpact Crusher PDFMusheer BashaNo ratings yet

- Stages OF Underground Excavation Method: Presented byDocument14 pagesStages OF Underground Excavation Method: Presented byHimaniNo ratings yet

- Crushing: 1. Jaw CrusherDocument6 pagesCrushing: 1. Jaw Crusherpranav reddyNo ratings yet

- Effect of Depth of Cut On MRR in Surface GrindingDocument7 pagesEffect of Depth of Cut On MRR in Surface GrindingshubhamNo ratings yet

- Crushing and GrindingDocument2 pagesCrushing and GrindingdivNo ratings yet

- 3-Disc, Button, Toothed Cutters - KopyaDocument22 pages3-Disc, Button, Toothed Cutters - KopyaceydaksemrNo ratings yet

- Perforacion de Rocas: Presentado PorDocument26 pagesPerforacion de Rocas: Presentado PorEsteban C. ZubietaNo ratings yet

- 19PWCHE1431Document6 pages19PWCHE1431Khan AaghaNo ratings yet

- HoningDocument4 pagesHoningmiso_mallard5123No ratings yet

- Design and Manufacturing of Small Scale Stone Crusher MachineDocument6 pagesDesign and Manufacturing of Small Scale Stone Crusher Machinetibem100% (1)

- Perforación y Tronadura Unidad I: IntroducciónDocument31 pagesPerforación y Tronadura Unidad I: IntroducciónLaiss FernandaNo ratings yet

- Sampling and Analysis of Drilled CuttingsDocument6 pagesSampling and Analysis of Drilled CuttingsSubrahmanyamNo ratings yet

- Alenowicz Wymagania 2017 1Document5 pagesAlenowicz Wymagania 2017 1robson2015No ratings yet

- Honing of CylindersDocument3 pagesHoning of Cylindersvijay9994No ratings yet

- Assignment For MID Topic: Basics of BlastingDocument65 pagesAssignment For MID Topic: Basics of BlastingUdit kumarNo ratings yet

- Review On Design and Analysis of Jaw Abstract Plate of Jaw-CrusherDocument10 pagesReview On Design and Analysis of Jaw Abstract Plate of Jaw-CrusherCarlos Ediver Arias RestrepoNo ratings yet

- Computer Aided Design of Jaw CrusherDocument50 pagesComputer Aided Design of Jaw Crusherdinesh_ypkNo ratings yet

- General Rock Removal: A Matter of ScaleDocument32 pagesGeneral Rock Removal: A Matter of ScaleJuan Camilo Guerra GNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Geotechnical Investigation: (Drilling Tools)Document17 pagesGeotechnical Investigation: (Drilling Tools)A Bashir AsalaiNo ratings yet

- Mining Rock DrillingDocument19 pagesMining Rock DrillingAdda Rivera100% (1)

- Micro DrillingDocument9 pagesMicro DrillingsubavlNo ratings yet

- Size Reduction: Within The Context of Sample PreparationDocument6 pagesSize Reduction: Within The Context of Sample PreparationEva Valentino CapiliNo ratings yet

- Drilling 1Document33 pagesDrilling 1OUMAIMA OULD SALTANANo ratings yet

- Surface FinishingDocument11 pagesSurface FinishingShashank BhambaleNo ratings yet

- Chapter 3 & 4 by D.ChandraDocument19 pagesChapter 3 & 4 by D.Chandraফয়েজ আহমেদNo ratings yet

- Cte U1l3Document14 pagesCte U1l3Nikhil VishavkramaNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Bridges, Hauber Et Al. 2011 - Conjoint Analysis Applications in Health-A PDFDocument11 pagesBridges, Hauber Et Al. 2011 - Conjoint Analysis Applications in Health-A PDFali rezaNo ratings yet

- Appnote WisprDocument7 pagesAppnote WisprXisco LladóNo ratings yet

- Cambodia Climate Change Report FINAL For Publication JSJMfinal Edit 26sept08Document60 pagesCambodia Climate Change Report FINAL For Publication JSJMfinal Edit 26sept08Som PisethNo ratings yet

- D1875 18737Document2 pagesD1875 18737JEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- Bernard Guenther - Know Thyself PDFDocument4 pagesBernard Guenther - Know Thyself PDFJelena AćaNo ratings yet

- Optics TestDocument2 pagesOptics Testiskenderbey100% (1)

- The Reaction PaperDocument1 pageThe Reaction Papervenus lamadridNo ratings yet

- RRLDocument96 pagesRRLCassandra Alyssa Villaflores100% (1)

- TUGAS BAHASA INGGRIS FEBRI HANDAYANiDocument29 pagesTUGAS BAHASA INGGRIS FEBRI HANDAYANiFebri handayaniNo ratings yet

- Project HR ManagementDocument73 pagesProject HR ManagementgadoradatabaseNo ratings yet

- Process FitnessDocument7 pagesProcess Fitnessapi-3748659No ratings yet

- Competency MappingDocument31 pagesCompetency MappingKirti Sangwan100% (1)

- Tabla de Especificaciones Primer Grado InglésDocument1 pageTabla de Especificaciones Primer Grado InglésRamiro Covarrubias ReséndizNo ratings yet

- Zero To One - MKT523 - Book SummaryDocument3 pagesZero To One - MKT523 - Book SummaryMahmudul Hasan TusharNo ratings yet

- Finite-State Description of Vietnamese ReduplicationDocument7 pagesFinite-State Description of Vietnamese ReduplicationPham Hai YenNo ratings yet

- 27 08 2016-MS-RachnaDocument13 pages27 08 2016-MS-RachnaRachna SelvamaniNo ratings yet

- Laguna Lake Development Authority v. Court of AppealsDocument16 pagesLaguna Lake Development Authority v. Court of Appealsmichee coiNo ratings yet

- English For Specific PurposesDocument7 pagesEnglish For Specific PurposesCarmie Lactaotao DasallaNo ratings yet

- Recreational Fishing: Sustainable Fishing and Health of The Oceans Program Tampa, FloridaDocument36 pagesRecreational Fishing: Sustainable Fishing and Health of The Oceans Program Tampa, FloridaNational Press FoundationNo ratings yet

- Barbara BenderDocument287 pagesBarbara BenderElmer Homero Mi ReyNo ratings yet

- Bryston CodesDocument3 pagesBryston CodesBradley ChilderhoseNo ratings yet

- Materials Selection For Hot Stamped Automotive Body Parts: An Application of The Ashby Approach Based On The Strain Hardening Exponent and Stacking Fault Energy of MaterialsDocument10 pagesMaterials Selection For Hot Stamped Automotive Body Parts: An Application of The Ashby Approach Based On The Strain Hardening Exponent and Stacking Fault Energy of MaterialsJaka Haris MustafaNo ratings yet

- TXTDocument5 pagesTXTproman25-1No ratings yet

- HR Training GD TopicsDocument4 pagesHR Training GD TopicsNiraj KumarNo ratings yet

- PivotTable Tutorial1Document27 pagesPivotTable Tutorial1Sumit RazNo ratings yet

- Ogutu - The Role of National Housing Corporation in The Provision of Housing in KenyaDocument95 pagesOgutu - The Role of National Housing Corporation in The Provision of Housing in KenyaboneylouNo ratings yet