Professional Documents

Culture Documents

Estatica Pesagem

Estatica Pesagem

Uploaded by

Daniele CavanellasCopyright:

Available Formats

You might also like

- Complete History of The UniverseDocument179 pagesComplete History of The UniverseSivapriya100% (7)

- Electric Machines - D. P. Kothari and I. J. Nagrath PDFDocument170 pagesElectric Machines - D. P. Kothari and I. J. Nagrath PDFRamar Murugasen33% (3)

- The Science Behind SiCoatDocument5 pagesThe Science Behind SiCoatStephen BridgesNo ratings yet

- Mutual Inductance and Transformer Circuits With Ltspice IvDocument4 pagesMutual Inductance and Transformer Circuits With Ltspice IvSteinerNo ratings yet

- Eng Article2Document4 pagesEng Article2Michael Perfinan FlavianoNo ratings yet

- Air Ionization TheoryDocument16 pagesAir Ionization TheoryPieter RobaeysNo ratings yet

- Static ElectricityDocument50 pagesStatic ElectricityrohmanhidyahNo ratings yet

- On DustDocument13 pagesOn DustManu SharmaNo ratings yet

- Causes of Static ElectricityDocument14 pagesCauses of Static ElectricityArj RajshahiNo ratings yet

- 3.1.17 Static Electricity. An Electric Charge That IsDocument7 pages3.1.17 Static Electricity. An Electric Charge That IsfahmiulaNo ratings yet

- Simple Understanding of Static ElectricityDocument6 pagesSimple Understanding of Static ElectricityBRLSwamyNo ratings yet

- Particulate or Dust Emission Control For IndustryDocument6 pagesParticulate or Dust Emission Control For IndustryHii Wang SingNo ratings yet

- 9B47584EC5B3BCA75F98809B9B6454BDocument3 pages9B47584EC5B3BCA75F98809B9B6454Bamro emadNo ratings yet

- Anti Static TreatmentsDocument12 pagesAnti Static TreatmentsIndhu Indhhuu100% (1)

- Danger and Control of Static Electricity BuildupDocument5 pagesDanger and Control of Static Electricity BuildupUsman Mustafa SyedNo ratings yet

- SputteringDocument17 pagesSputteringTonmoy PaulNo ratings yet

- Effect of Dust On Solar CellDocument27 pagesEffect of Dust On Solar Cellboyka gNo ratings yet

- Ans ApceDocument18 pagesAns ApcekalpNo ratings yet

- Self Cleaning TextileDocument15 pagesSelf Cleaning TextilevinayarenNo ratings yet

- Final Report Smoke PrecipitatorDocument7 pagesFinal Report Smoke PrecipitatorSiti Anis IzzatieNo ratings yet

- Static ElectricityDocument47 pagesStatic Electricitykaushalacharya100% (3)

- Preventing Electrostatic DischargeDocument6 pagesPreventing Electrostatic DischargeJhonny CastilloNo ratings yet

- Applications of ElectricityDocument7 pagesApplications of ElectricityCrystal DavidsonNo ratings yet

- ElectrostaticsDocument6 pagesElectrostaticsLaud FumhandaNo ratings yet

- Lec#6 MS - Electrostatic SeparationDocument26 pagesLec#6 MS - Electrostatic Separationss-leaksNo ratings yet

- Silicone White Paper 2Document8 pagesSilicone White Paper 2VinzoKeiNo ratings yet

- Static Electricity in Textile.Document15 pagesStatic Electricity in Textile.Anik Talukder67% (3)

- Antistatic FinishDocument3 pagesAntistatic Finishnahidulbutex002No ratings yet

- From Wikipedia, The Free Encyclopedia: Electrostatic Precipitator of A Biomass Heating System With A Heat Power of 2 MWDocument17 pagesFrom Wikipedia, The Free Encyclopedia: Electrostatic Precipitator of A Biomass Heating System With A Heat Power of 2 MWPrabhumk07No ratings yet

- Electrostatics and Everyday LifeDocument1 pageElectrostatics and Everyday LifeSri MurthyNo ratings yet

- Enercon Hidden Problems in Surface TreatmentDocument4 pagesEnercon Hidden Problems in Surface TreatmentcavekeNo ratings yet

- 1.1. BackgroundDocument10 pages1.1. BackgroundSiva KumarNo ratings yet

- Unit 4 Mechanical SeparationDocument23 pagesUnit 4 Mechanical SeparationSk jahidul IslamNo ratings yet

- E I (EC 323) : Lectrical NstallationsDocument69 pagesE I (EC 323) : Lectrical NstallationsMalith DeemanthaNo ratings yet

- Review of Self-Cleaning Method For Solar Cell ArraDocument6 pagesReview of Self-Cleaning Method For Solar Cell ArraYounes MouhoubNo ratings yet

- Bannari Amman Institute of Technology: G.NalankilliDocument75 pagesBannari Amman Institute of Technology: G.NalankilliAbirami SubramaniamNo ratings yet

- Static ElectricityDocument2 pagesStatic ElectricitytusharNo ratings yet

- PrecautionsDocument15 pagesPrecautionsyajur_nagiNo ratings yet

- 6007-32-1: The New Standard On Avoidance of Electrostatic HazardsDocument12 pages6007-32-1: The New Standard On Avoidance of Electrostatic Hazardsnavi_0403No ratings yet

- Static ElectricityDocument10 pagesStatic ElectricityJohn MillerNo ratings yet

- Sputter Deposition DCHDocument15 pagesSputter Deposition DCHTrần Huỳnh Hoàng KhangNo ratings yet

- Static ElectricityDocument4 pagesStatic ElectricityMD. Sharifuzzaman JoyNo ratings yet

- CoronaDocument51 pagesCoronaNavdeep KaurNo ratings yet

- PhotoLitho and SputteringDocument2 pagesPhotoLitho and SputteringAndre KostroNo ratings yet

- Corona Treatment: Why Is It Necessary?Document6 pagesCorona Treatment: Why Is It Necessary?Taufiq RidhoNo ratings yet

- Semiconductor Fabrication Lecture NotesDocument11 pagesSemiconductor Fabrication Lecture NotesJoanna Fabricante100% (1)

- Electrostatic PrecipitatorDocument10 pagesElectrostatic Precipitatorsuthandira.malarNo ratings yet

- Hot Wall: in The Former Reactor, The Reactor Tube Is Surrounded by A Tube Furnace Making TheDocument4 pagesHot Wall: in The Former Reactor, The Reactor Tube Is Surrounded by A Tube Furnace Making Thesandeep_surya432No ratings yet

- How Semiconductors Are MadeDocument7 pagesHow Semiconductors Are MadeAshner NovillaNo ratings yet

- NLNG Division: Electrostatic SprayingDocument8 pagesNLNG Division: Electrostatic Sprayingsaleh67msNo ratings yet

- Antistatic AgentsDocument4 pagesAntistatic AgentsEndang Asih SafitriNo ratings yet

- Static ElectricityDocument5 pagesStatic Electricitydunhamc100% (2)

- Static Electricity - Shocks & How To Avoid ThemDocument4 pagesStatic Electricity - Shocks & How To Avoid ThemDerek OngNo ratings yet

- Esd Protection While Handling Leds: Application NoteDocument21 pagesEsd Protection While Handling Leds: Application NoteOrbán Norbert100% (1)

- ESDS BasicsDocument12 pagesESDS BasicspontooNo ratings yet

- Static ElectricityDocument28 pagesStatic ElectricityDeepak GuptaNo ratings yet

- © OMICRON Academy 01 - IntroductionDocument29 pages© OMICRON Academy 01 - IntroductionJackson Berganza100% (1)

- Coagulation and FiltrationDocument49 pagesCoagulation and Filtrationmuhammednumaan235No ratings yet

- INSTALL YOUR OWN Photovoltaic System: Hybrid, Stand Alone and Battery StorageFrom EverandINSTALL YOUR OWN Photovoltaic System: Hybrid, Stand Alone and Battery StorageNo ratings yet

- Isolated - Foundation Design ES en 2015Document10 pagesIsolated - Foundation Design ES en 2015Dino AbdelaNo ratings yet

- 01 Formulae, Equations and Amount of SubstanceDocument39 pages01 Formulae, Equations and Amount of SubstanceNandi100% (1)

- Baker Campbell Hausdorf TheoremDocument13 pagesBaker Campbell Hausdorf TheoremArooj RazaNo ratings yet

- Properties of Insulating Materials PDFDocument66 pagesProperties of Insulating Materials PDFLincoln Cesar100% (2)

- Applied Phy Civil Petroleum 1yearDocument1 pageApplied Phy Civil Petroleum 1yearBilalNo ratings yet

- Printed Pages-4 (10×2 20) : (Sem. V) Odd Semester Theory EXAMINATION 2013-14Document2 pagesPrinted Pages-4 (10×2 20) : (Sem. V) Odd Semester Theory EXAMINATION 2013-14Syam RajuNo ratings yet

- Thermal Properties of Matter - 3Document16 pagesThermal Properties of Matter - 3Nik AshrafNo ratings yet

- Physics Form 4 Yearly Lesson Plan 2010Document26 pagesPhysics Form 4 Yearly Lesson Plan 2010Mohd Khairul AnuarNo ratings yet

- The Problem of Time in Quantum Gravity: Edward AndersonDocument26 pagesThe Problem of Time in Quantum Gravity: Edward AndersonÁdám T. BogárNo ratings yet

- Plasma Separation Review PPT 5Document42 pagesPlasma Separation Review PPT 5NhhjNo ratings yet

- Mass Transfer LiquidDocument7 pagesMass Transfer LiquidDhiyafiraNo ratings yet

- Fundamentals of Compressible Flows in Pipelines: Dr. Ahmed Elmekawy Fall 2018Document74 pagesFundamentals of Compressible Flows in Pipelines: Dr. Ahmed Elmekawy Fall 2018Tamunoiboumie ElijahNo ratings yet

- Die Design and Dough Expansion in Low Moisture Extrusion-Cooking ProcessDocument14 pagesDie Design and Dough Expansion in Low Moisture Extrusion-Cooking ProcessMuhammad HammadNo ratings yet

- LIBRO - Encapsulados y Alimentos en Polvo PDFDocument11 pagesLIBRO - Encapsulados y Alimentos en Polvo PDFMALELA70No ratings yet

- Introduction To Ee New 1Document220 pagesIntroduction To Ee New 1Valentine K.No ratings yet

- Development of Micro Power Generators - A ReviewDocument16 pagesDevelopment of Micro Power Generators - A Reviewherdi sutanto adiguna100% (1)

- Abiotic Oil - J F KenneyDocument6 pagesAbiotic Oil - J F KenneyzaroiaNo ratings yet

- Tutorial 2Document2 pagesTutorial 2rustam effendyNo ratings yet

- FST-35 (20-04-2023) PaperDocument55 pagesFST-35 (20-04-2023) Papermailrahul1994No ratings yet

- Sheet 4 - ME 211TDocument3 pagesSheet 4 - ME 211Tsophia haniNo ratings yet

- Proposed Scheme For Plugging Three-Phase Induction Motor: Haroutuon A. Hairik, Wissam A. KadhemDocument5 pagesProposed Scheme For Plugging Three-Phase Induction Motor: Haroutuon A. Hairik, Wissam A. KadhemBilal HBNo ratings yet

- MATH3968 Lecture 1: DR Emma Carberry 28 July 2009Document5 pagesMATH3968 Lecture 1: DR Emma Carberry 28 July 2009TOM DAVISNo ratings yet

- Chapter 2: Coulomb's Law and Electric Field IntensityDocument2 pagesChapter 2: Coulomb's Law and Electric Field IntensityvpkvikasNo ratings yet

- Tools - For - Problem - Solving (Appendix B), R.K. Malik's Newton Classes PDFDocument48 pagesTools - For - Problem - Solving (Appendix B), R.K. Malik's Newton Classes PDFMoindavis DavisNo ratings yet

- 10" ARRAY 2560 M: Fabulous Series by ACR - 10 Inch - WooferDocument2 pages10" ARRAY 2560 M: Fabulous Series by ACR - 10 Inch - WooferIrsyadi 86No ratings yet

- Model Steam Turbine Gov System PDFDocument60 pagesModel Steam Turbine Gov System PDFAyush GuptaNo ratings yet

- Analytical Fourbar - Pps4barDocument15 pagesAnalytical Fourbar - Pps4barEl JulaibibNo ratings yet

Estatica Pesagem

Estatica Pesagem

Uploaded by

Daniele CavanellasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estatica Pesagem

Estatica Pesagem

Uploaded by

Daniele CavanellasCopyright:

Available Formats

CAHN -Technical Note Copyright Text Courtesy of Orion Research, Inc.

STATIC CONTROL FOR BALANCES by Jerry Weil One of the major problems when using a sensitive balance is "static". Some of the more technical names for this phenomenon are static electricity, electrostatic, triboelectric charge and static charge. In order to control the effects of static, an understanding of the causes and the methods of treatment are needed. CAUSES OF STATIC Static is the accumulation of electrical charges on the surface of a non-conductive material. The surface will have a negative charge when it has an excess of electrons, and will be positive when the surface has a deficiency of electrons. A surface that has an excess or deficiency of one electron in every 100,000 atoms is very strongly charged and may have several thousand volts potential compared to a conducting surface. The most common method of generating static is to rub two different non-conducting surfaces together. In this process, the material in the higher position of the Triboelectric Series Table (see page 4) will give electrons to the material beneath it in the Table. For example, if Nylon and Polyethylene are rubbed together, the Nylon will become positively charged and the Polyethylene will carry the negative charge. The further apart the materials are located within the series, the easier it is to generate a static charge. However, rubbing is not the sole means of creating static. Strong static charges can be generated by simply separating the surfaces of the two materials. The stronger the two materials are pressed together, the stronger will be the static charge when the materials are separated. This is how static is created even when great care is taken not to rub the two surfaces together. Static can also be induced onto a surface from another surface that is strongly charged. An example of this "induced charge" occurs when a person wearing a strongly charged Nylon jacket approaches a balance. The charge on the Nylon jacket sets up an electrical field that reaches out for several feet. This field will induce a strong attractive charge on the material on the weighing pan causing very erratic readings. The human body itself can induce a strong static charge on a non-conductive surface. The body can become charged as it walks due to the separation of surfaces between the shoes and the floor. Since the body is an excellent conductor, the charge will quickly migrate to surfaces having the least radius of curvature, namely the fingers and toes. When the fingers touch a non-conductive surface, the charge will be transferred. When the fingers touch a conductive surface, the transfer can be shocking. In a static prone environment, touching a door knob first with the palm of the hand will reduce shock. Clean, dry gases flowing through glass tubing, will not generate static. However, if the gases contain any moisture or particles, they will generate significant amounts of static.

EFFECTS OF STATIC Like charges repel each other and unlike charges attract. These forces can be very strong if the static charges are intense. A negatively charged sample on the balance weighing pan can be strongly effected by a positively charged glass chamber window or glass hangdown tube, resulting in erroneous and unstable weight readings. Samples like membrane filters and dry powders are particularly susceptible to static and, therefore, are difficult to weigh. Charged samples are difficult to handle and portions of them may be lost in the transfer process. STATIC can also degrade a sample by attracting contaminating particulates. CONDUCTIVE SURFACES One of the methods of removing static is to conduct the static charge off the surface. Since the surface is originally non-conducting, it must be coated with a conducting material that will remain on the surface long enough to remove the static charge. On humid days, a moisture layer may form on the surface with sufficient conductivity to drain the static charge. However, the moisture coating is not dependable. The surface coated with a metal foil or compound offers the best solution to static problems. Silver and tin oxide coatings are the most popular for this purpose. However, metal coatings sometimes are difficult to bond to the surfaces and obscure visibility in glass vessels. A conductive surface can be created with anti-static solutions. The type of anti-static solution used will depend on the surface material, permanency of protection needed, and environmental conditions. There is a wide variety of solutions available that will provide conducting surfaces for many laboratory needs. The Cahn #2027 Anti-Static Solution is intended for static control for use with balances. It has a water base and is not toxic by oral ingestion or inhalation and is not a skin irritant, but it is an eye irritant. It has long life on nonconductive surfaces and can be used up to about 400 degrees C. Both the inside and outside glass and/or plastic surfaces of the balance weighing chamber should be coated with this solution. After the coating has completely dried, the surfaces will remain conductive for several months, even with repeated handling. The solution should not be used on the inside of sample containers since the coating can contaminate the contents. Since the human body is such a large source of static, efforts should be made to conduct static charges off of the body and clothing. Most computer supply catalogs now offer static control floor mats and work-station mats that will drain the static charges from the body through the feet and fingers respeclively. These mats have conductive surfaces that are grounded. Conducting static off clothing is a more difricult problem. Natural fibers usually hold less static than man-made fibers because they will absorb more moisture. Anti-static compounds introduced either in the washing or drying cycles of the laundry are not generally effective in controlling static in severe conditions. For these cases, there are several good anti-static sprays available specifically designed for clothing. IONIZING UNITS Usually, the sample that is to be weighed can not be coated with a conductive surface to remove the static charge. The best method of eliminating this static is to neutralize the static

charges. This means that positively charged surfaces are exposed to negatively charged air molecules. The opposile is true for negatively charged surfaces. Airborne moisture, ionized by the sun's ultraviolet radiation, acts as an abundant reservoir of available ions. Under normal environmental conditions, with relative humidities above 60%, the moisture will neutralize static charges as they occur. As the humidity drops below 60%, the lack of ionized moisture will allow static charges to build and become more objectionable. When the air does not normally have enough ions to neutralize the charged surface, additional ions can be created with radioactive or electrical ionizers. The most popular radioactive units for the laboratory emit alpha particles. These particles are the largest of all the nuclear radiated particles and consist of two protons and two neutrons. Alpha particles travel at extreme speeds (10,000 miles/sec) but, because of their size, very short distances. In air, they travel only a few centimeters before colliding with a gas molecule. This collision will ionize gas molecules, which are now available to neutralize a static charge. The most common source of alpha particles for static control is Polonium 210 as manufactured by the 3M Co. The Cahn #1269 Ionizing Unit is an example of a static control device using this 3M Polonium source. This device is extremely safe and neither State or U.S. Nuclear Regulatory Commission specific licenses are required to possess these ionizing units. Tlhe Polonium is absorbed into ceramic micro-spheres which are then heated to very high temperatures. This results in shrinkage and loss of porosity so that a solid, almost completely insoluble sphere is obtained. An acid wash is used to remove any surface activity and a nickel coating is applied to provide additional integrity. The microspheres are bonded to a thin aluminum substrate with a radiation resistant binder. Finally, the aluminum strips are cemented into a protective grid which prevents direct contact with the surface of the Polonium source. The microspheres are inert, so if dislodged and ingested, the Polonium would not be absorbed by the body. The average diameter of the spheres is 30 microns which is considered non-respirable. An alpha particle can not penetrate the dead layer of skin on the human body to reach live cells. For all these reasons, this device is a safe method of creating ionized air for static control.

The Cahn Ionizing Units are supplied with 500 microcuries of radioactivity. Since Polonium 210 has a half life of 138 days and the device loses its effectiveness when the activity is below about 100 microcuries, the ionizing units will be effective for about one year from date of manufacture. This date is stamped on the back of the device. The effective life of the device will also depend on ambient humidity and the type of non-conductive surface containing the static charge. To use the Ionizing Unit, bring it to within one-half inch of the surface or material containing the static charge. Only a couple of seconds are required to neutralize the surface. After being neutralized, handle the material carefully to prevent the static charge being formed again. The Ionizing Unit can be left in the weighing chamber near the pan to provide a source of ionized air around the sample. Because of the relatively short life of Polonium 210, Radium 226 is sometimes used as an alpha particle source. Though it has a half life of 1600 years, it also emits some gamma radiation and must be used under careful control and requires a license. Beta emitters, like Thorium 233 and Nickel 63 are also used for special conditions. The other method of creating additional ions is with electrical ionizers. Though these units have been available for 80 years and are extensively used on production lines, they are now first being used in the laboratory. These devices have a 5000 ACvolt emitter point recessed in a grounded collar. This high voltage ionizes the air passing through the field. Compared to radioactive units, the electrical ionizers do not require a license, will not deteriorate with time, and are often more effective. For the lab, the air gun is the most convenient configuration of the electrical units. The Chapman 33575-001 Air Gun plus 10798 Power Supply is a good example. The gun is shockless, weighs about 1/2 pounds, supplied with a three meter cable and has a pistol grip. The gun and the power supply must all be reliably grounded. With a 10 to 20 psi dry air supply, the gun is held 1 to 2 feet from the surface and is useful for removing static from containers and enclosures. Without the air supply, the tip of the gun is still effective from 1/2 to 1 inch from the surface and is useful for removing static from powdered samples. Pass the Run slowly and evenly across the surface. AVOIDING STATIC The most effective method of controlling static is by not generating it in the first place. Plan your work such that the touching of the surfaces is kept to a minimum. Handle the surfaces with moist cotton gloves. Obviously, do not rub two surfaces together. If friction from rubbing is difficult to avoid, there are anti-static liquids that lubricate the surface in order to reduce the static generated. Use grounded floor mats and workstation mats to reduce the charge being carried on your body. Make sure that any piece of equipment with moving or rotating parts is grounded. Wear clothing that has been sprayed with an anti-static compound. If possible, use sample containers that have a conductive surface. Humidifiers can be very effective in reducing the overall static problems in a work area. However, the best way of avoiding static problems is to understand the causes and the methods of treatment.

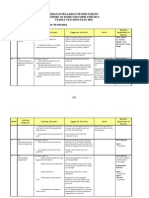

TRIBOELECTRIC SERIES TABLE

(Positive)

(Negative)

Asbestos Rabbit fur Glass Mica Human hair Nylon Wool Fur Lead Silk Aluminum Paper Cotton Steel Wood Amber Sealing wax Hard rubber Nickel copper Brass silver Gold platinum Sulfur Acetate rayon Polyester Celluloid Orlon Saran Polyurethane Polyethylene Polypropylene PVC (vinyl) Kelf Silicon Teflon Silicone rubber

REFERENCES: "Static Electricity 1983", National Fire Protection Association, Quincy, Mass. "Electrostatic Effects in Microbalances", Robert E. Hawley and Colin J. Williams, J. Vac. Sci. Technol., Jan/Feb 1974. "Topical Antistatic Primer", Stephen A. Halperin, Evaluation Engineering Sept/Oct 1979. "Bulletin #210", Nuclear Products. "Conductive versus static-free plastics", Ralph L Mondano, Safety Engineering, June, 1968. Chemistry and Physics Handbook. 62nd ed. CRC Press, Inc. Harper Encyclopedia of Science, edited by James R Newman, Harper & Row Pub., 1967. Application Note 13", Chapman Corp., P.O. Box 10700, Portland, Maine 04104 Tel: 207-773-4726

CAHN INSTRUMENTS, INC. 16207 S. Carmenita Road, Cerritos, CA 90701 USA Phone (213) 926-3378, FAX (213) 926-6969, TLX 3724174.

You might also like

- Complete History of The UniverseDocument179 pagesComplete History of The UniverseSivapriya100% (7)

- Electric Machines - D. P. Kothari and I. J. Nagrath PDFDocument170 pagesElectric Machines - D. P. Kothari and I. J. Nagrath PDFRamar Murugasen33% (3)

- The Science Behind SiCoatDocument5 pagesThe Science Behind SiCoatStephen BridgesNo ratings yet

- Mutual Inductance and Transformer Circuits With Ltspice IvDocument4 pagesMutual Inductance and Transformer Circuits With Ltspice IvSteinerNo ratings yet

- Eng Article2Document4 pagesEng Article2Michael Perfinan FlavianoNo ratings yet

- Air Ionization TheoryDocument16 pagesAir Ionization TheoryPieter RobaeysNo ratings yet

- Static ElectricityDocument50 pagesStatic ElectricityrohmanhidyahNo ratings yet

- On DustDocument13 pagesOn DustManu SharmaNo ratings yet

- Causes of Static ElectricityDocument14 pagesCauses of Static ElectricityArj RajshahiNo ratings yet

- 3.1.17 Static Electricity. An Electric Charge That IsDocument7 pages3.1.17 Static Electricity. An Electric Charge That IsfahmiulaNo ratings yet

- Simple Understanding of Static ElectricityDocument6 pagesSimple Understanding of Static ElectricityBRLSwamyNo ratings yet

- Particulate or Dust Emission Control For IndustryDocument6 pagesParticulate or Dust Emission Control For IndustryHii Wang SingNo ratings yet

- 9B47584EC5B3BCA75F98809B9B6454BDocument3 pages9B47584EC5B3BCA75F98809B9B6454Bamro emadNo ratings yet

- Anti Static TreatmentsDocument12 pagesAnti Static TreatmentsIndhu Indhhuu100% (1)

- Danger and Control of Static Electricity BuildupDocument5 pagesDanger and Control of Static Electricity BuildupUsman Mustafa SyedNo ratings yet

- SputteringDocument17 pagesSputteringTonmoy PaulNo ratings yet

- Effect of Dust On Solar CellDocument27 pagesEffect of Dust On Solar Cellboyka gNo ratings yet

- Ans ApceDocument18 pagesAns ApcekalpNo ratings yet

- Self Cleaning TextileDocument15 pagesSelf Cleaning TextilevinayarenNo ratings yet

- Final Report Smoke PrecipitatorDocument7 pagesFinal Report Smoke PrecipitatorSiti Anis IzzatieNo ratings yet

- Static ElectricityDocument47 pagesStatic Electricitykaushalacharya100% (3)

- Preventing Electrostatic DischargeDocument6 pagesPreventing Electrostatic DischargeJhonny CastilloNo ratings yet

- Applications of ElectricityDocument7 pagesApplications of ElectricityCrystal DavidsonNo ratings yet

- ElectrostaticsDocument6 pagesElectrostaticsLaud FumhandaNo ratings yet

- Lec#6 MS - Electrostatic SeparationDocument26 pagesLec#6 MS - Electrostatic Separationss-leaksNo ratings yet

- Silicone White Paper 2Document8 pagesSilicone White Paper 2VinzoKeiNo ratings yet

- Static Electricity in Textile.Document15 pagesStatic Electricity in Textile.Anik Talukder67% (3)

- Antistatic FinishDocument3 pagesAntistatic Finishnahidulbutex002No ratings yet

- From Wikipedia, The Free Encyclopedia: Electrostatic Precipitator of A Biomass Heating System With A Heat Power of 2 MWDocument17 pagesFrom Wikipedia, The Free Encyclopedia: Electrostatic Precipitator of A Biomass Heating System With A Heat Power of 2 MWPrabhumk07No ratings yet

- Electrostatics and Everyday LifeDocument1 pageElectrostatics and Everyday LifeSri MurthyNo ratings yet

- Enercon Hidden Problems in Surface TreatmentDocument4 pagesEnercon Hidden Problems in Surface TreatmentcavekeNo ratings yet

- 1.1. BackgroundDocument10 pages1.1. BackgroundSiva KumarNo ratings yet

- Unit 4 Mechanical SeparationDocument23 pagesUnit 4 Mechanical SeparationSk jahidul IslamNo ratings yet

- E I (EC 323) : Lectrical NstallationsDocument69 pagesE I (EC 323) : Lectrical NstallationsMalith DeemanthaNo ratings yet

- Review of Self-Cleaning Method For Solar Cell ArraDocument6 pagesReview of Self-Cleaning Method For Solar Cell ArraYounes MouhoubNo ratings yet

- Bannari Amman Institute of Technology: G.NalankilliDocument75 pagesBannari Amman Institute of Technology: G.NalankilliAbirami SubramaniamNo ratings yet

- Static ElectricityDocument2 pagesStatic ElectricitytusharNo ratings yet

- PrecautionsDocument15 pagesPrecautionsyajur_nagiNo ratings yet

- 6007-32-1: The New Standard On Avoidance of Electrostatic HazardsDocument12 pages6007-32-1: The New Standard On Avoidance of Electrostatic Hazardsnavi_0403No ratings yet

- Static ElectricityDocument10 pagesStatic ElectricityJohn MillerNo ratings yet

- Sputter Deposition DCHDocument15 pagesSputter Deposition DCHTrần Huỳnh Hoàng KhangNo ratings yet

- Static ElectricityDocument4 pagesStatic ElectricityMD. Sharifuzzaman JoyNo ratings yet

- CoronaDocument51 pagesCoronaNavdeep KaurNo ratings yet

- PhotoLitho and SputteringDocument2 pagesPhotoLitho and SputteringAndre KostroNo ratings yet

- Corona Treatment: Why Is It Necessary?Document6 pagesCorona Treatment: Why Is It Necessary?Taufiq RidhoNo ratings yet

- Semiconductor Fabrication Lecture NotesDocument11 pagesSemiconductor Fabrication Lecture NotesJoanna Fabricante100% (1)

- Electrostatic PrecipitatorDocument10 pagesElectrostatic Precipitatorsuthandira.malarNo ratings yet

- Hot Wall: in The Former Reactor, The Reactor Tube Is Surrounded by A Tube Furnace Making TheDocument4 pagesHot Wall: in The Former Reactor, The Reactor Tube Is Surrounded by A Tube Furnace Making Thesandeep_surya432No ratings yet

- How Semiconductors Are MadeDocument7 pagesHow Semiconductors Are MadeAshner NovillaNo ratings yet

- NLNG Division: Electrostatic SprayingDocument8 pagesNLNG Division: Electrostatic Sprayingsaleh67msNo ratings yet

- Antistatic AgentsDocument4 pagesAntistatic AgentsEndang Asih SafitriNo ratings yet

- Static ElectricityDocument5 pagesStatic Electricitydunhamc100% (2)

- Static Electricity - Shocks & How To Avoid ThemDocument4 pagesStatic Electricity - Shocks & How To Avoid ThemDerek OngNo ratings yet

- Esd Protection While Handling Leds: Application NoteDocument21 pagesEsd Protection While Handling Leds: Application NoteOrbán Norbert100% (1)

- ESDS BasicsDocument12 pagesESDS BasicspontooNo ratings yet

- Static ElectricityDocument28 pagesStatic ElectricityDeepak GuptaNo ratings yet

- © OMICRON Academy 01 - IntroductionDocument29 pages© OMICRON Academy 01 - IntroductionJackson Berganza100% (1)

- Coagulation and FiltrationDocument49 pagesCoagulation and Filtrationmuhammednumaan235No ratings yet

- INSTALL YOUR OWN Photovoltaic System: Hybrid, Stand Alone and Battery StorageFrom EverandINSTALL YOUR OWN Photovoltaic System: Hybrid, Stand Alone and Battery StorageNo ratings yet

- Isolated - Foundation Design ES en 2015Document10 pagesIsolated - Foundation Design ES en 2015Dino AbdelaNo ratings yet

- 01 Formulae, Equations and Amount of SubstanceDocument39 pages01 Formulae, Equations and Amount of SubstanceNandi100% (1)

- Baker Campbell Hausdorf TheoremDocument13 pagesBaker Campbell Hausdorf TheoremArooj RazaNo ratings yet

- Properties of Insulating Materials PDFDocument66 pagesProperties of Insulating Materials PDFLincoln Cesar100% (2)

- Applied Phy Civil Petroleum 1yearDocument1 pageApplied Phy Civil Petroleum 1yearBilalNo ratings yet

- Printed Pages-4 (10×2 20) : (Sem. V) Odd Semester Theory EXAMINATION 2013-14Document2 pagesPrinted Pages-4 (10×2 20) : (Sem. V) Odd Semester Theory EXAMINATION 2013-14Syam RajuNo ratings yet

- Thermal Properties of Matter - 3Document16 pagesThermal Properties of Matter - 3Nik AshrafNo ratings yet

- Physics Form 4 Yearly Lesson Plan 2010Document26 pagesPhysics Form 4 Yearly Lesson Plan 2010Mohd Khairul AnuarNo ratings yet

- The Problem of Time in Quantum Gravity: Edward AndersonDocument26 pagesThe Problem of Time in Quantum Gravity: Edward AndersonÁdám T. BogárNo ratings yet

- Plasma Separation Review PPT 5Document42 pagesPlasma Separation Review PPT 5NhhjNo ratings yet

- Mass Transfer LiquidDocument7 pagesMass Transfer LiquidDhiyafiraNo ratings yet

- Fundamentals of Compressible Flows in Pipelines: Dr. Ahmed Elmekawy Fall 2018Document74 pagesFundamentals of Compressible Flows in Pipelines: Dr. Ahmed Elmekawy Fall 2018Tamunoiboumie ElijahNo ratings yet

- Die Design and Dough Expansion in Low Moisture Extrusion-Cooking ProcessDocument14 pagesDie Design and Dough Expansion in Low Moisture Extrusion-Cooking ProcessMuhammad HammadNo ratings yet

- LIBRO - Encapsulados y Alimentos en Polvo PDFDocument11 pagesLIBRO - Encapsulados y Alimentos en Polvo PDFMALELA70No ratings yet

- Introduction To Ee New 1Document220 pagesIntroduction To Ee New 1Valentine K.No ratings yet

- Development of Micro Power Generators - A ReviewDocument16 pagesDevelopment of Micro Power Generators - A Reviewherdi sutanto adiguna100% (1)

- Abiotic Oil - J F KenneyDocument6 pagesAbiotic Oil - J F KenneyzaroiaNo ratings yet

- Tutorial 2Document2 pagesTutorial 2rustam effendyNo ratings yet

- FST-35 (20-04-2023) PaperDocument55 pagesFST-35 (20-04-2023) Papermailrahul1994No ratings yet

- Sheet 4 - ME 211TDocument3 pagesSheet 4 - ME 211Tsophia haniNo ratings yet

- Proposed Scheme For Plugging Three-Phase Induction Motor: Haroutuon A. Hairik, Wissam A. KadhemDocument5 pagesProposed Scheme For Plugging Three-Phase Induction Motor: Haroutuon A. Hairik, Wissam A. KadhemBilal HBNo ratings yet

- MATH3968 Lecture 1: DR Emma Carberry 28 July 2009Document5 pagesMATH3968 Lecture 1: DR Emma Carberry 28 July 2009TOM DAVISNo ratings yet

- Chapter 2: Coulomb's Law and Electric Field IntensityDocument2 pagesChapter 2: Coulomb's Law and Electric Field IntensityvpkvikasNo ratings yet

- Tools - For - Problem - Solving (Appendix B), R.K. Malik's Newton Classes PDFDocument48 pagesTools - For - Problem - Solving (Appendix B), R.K. Malik's Newton Classes PDFMoindavis DavisNo ratings yet

- 10" ARRAY 2560 M: Fabulous Series by ACR - 10 Inch - WooferDocument2 pages10" ARRAY 2560 M: Fabulous Series by ACR - 10 Inch - WooferIrsyadi 86No ratings yet

- Model Steam Turbine Gov System PDFDocument60 pagesModel Steam Turbine Gov System PDFAyush GuptaNo ratings yet

- Analytical Fourbar - Pps4barDocument15 pagesAnalytical Fourbar - Pps4barEl JulaibibNo ratings yet