Professional Documents

Culture Documents

B4 G3 3

B4 G3 3

Uploaded by

Mohit AroraCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aashto T 119Document6 pagesAashto T 119Regen BasiñoNo ratings yet

- Aboveground Welded Steel Storage Tanks - Design and ConstructionDocument44 pagesAboveground Welded Steel Storage Tanks - Design and Constructionم.ذكى فضل ذكىNo ratings yet

- 96-97 FedEx Express Body Parts ManualDocument88 pages96-97 FedEx Express Body Parts ManualTasfin Habib0% (1)

- Oil Interceptor Type: SWOBK 100/ 500: Owership: Material: PolyethyleneDocument1 pageOil Interceptor Type: SWOBK 100/ 500: Owership: Material: PolyethyleneAldea CatalinNo ratings yet

- ANFEXDocument4 pagesANFEXGuillermo Esteban Ferraz SantanderNo ratings yet

- Unit - 6Document22 pagesUnit - 6N Dhanunjaya Rao BorraNo ratings yet

- Catalytic HydrodearomatizationDocument42 pagesCatalytic Hydrodearomatizational3x4n9No ratings yet

- Is 13920 1993Document24 pagesIs 13920 1993SirajMalikNo ratings yet

- Katrina M. Estrada 12 STEM-E9: V V V VDocument3 pagesKatrina M. Estrada 12 STEM-E9: V V V VJOHN RAVEN BUCAONo ratings yet

- DW21 27Document4 pagesDW21 27Mehwish MansoorNo ratings yet

- Investigation and Analysis of Tamarix Aphylla (Ghaz Wood) and Populus Caspica (Poplar Wood) Used As Raw Materials For Manufacturing of Medium Density FiDocument9 pagesInvestigation and Analysis of Tamarix Aphylla (Ghaz Wood) and Populus Caspica (Poplar Wood) Used As Raw Materials For Manufacturing of Medium Density FiAlexander Reategui GarciaNo ratings yet

- Special Considerations in Marine Pile Design and ConstructionDocument3 pagesSpecial Considerations in Marine Pile Design and ConstructionNitinShepurNo ratings yet

- SQUIRT ML 092220651Document8 pagesSQUIRT ML 092220651Roman KrautschneiderNo ratings yet

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosNo ratings yet

- PlasticsDocument48 pagesPlasticsPavan MehataNo ratings yet

- Policyandregulations NairobiDocument28 pagesPolicyandregulations NairobiLo LossNo ratings yet

- Architecture Portfolio - Architect Nicola DoglieroDocument60 pagesArchitecture Portfolio - Architect Nicola Doglieronicola doglieroNo ratings yet

- Experiment 4 - Level MeasurementDocument16 pagesExperiment 4 - Level MeasurementHafizuddin AdzharNo ratings yet

- 12 Samss 018Document4 pages12 Samss 018Dhaval PatelNo ratings yet

- Chapter 6 Electrochemistry SPMDocument62 pagesChapter 6 Electrochemistry SPMhanifzainol100% (1)

- Requirement For Fatigue AssessmentDocument3 pagesRequirement For Fatigue AssessmentyogacruiseNo ratings yet

- Mold Design - Injection MoldingDocument4 pagesMold Design - Injection Moldinganil chejaraNo ratings yet

- AC Tutor1Document4 pagesAC Tutor1Jady chess24No ratings yet

- SCI Stainless ForgedDocument12 pagesSCI Stainless ForgedBrandon TrocNo ratings yet

- Marv Air Door Pace CuDocument2 pagesMarv Air Door Pace Cunj23dublinNo ratings yet

- Lecture Notes Unit 1Document23 pagesLecture Notes Unit 1Akshay SrivastavaNo ratings yet

- Emergency Manual Stations MS-403U/404U: FeaturesDocument2 pagesEmergency Manual Stations MS-403U/404U: FeaturesJMAC SupplyNo ratings yet

- Rs419 Ring Scanner Spec SheetDocument3 pagesRs419 Ring Scanner Spec SheetJames HowardNo ratings yet

- PreviewDocument53 pagesPreviewCikorostore0% (1)

- Bomba Serie 90 100Document98 pagesBomba Serie 90 100lizbethdioses100% (3)

B4 G3 3

B4 G3 3

Uploaded by

Mohit AroraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B4 G3 3

B4 G3 3

Uploaded by

Mohit AroraCopyright:

Available Formats

EXPERIMENT III By : - Lalit Prakash Vatsal, Karanbir Kajal, Injarapu Udaysankar TITLE Four Probe Experiment OBJECTIVE To measure

e resistivity of a given sample crystal EXPERIMENT SETUP AND PROCEDURE Apparatus required: 1. 4- Probe arrangement: It has 4 individually spring loaded probes. The probes are collinear and equally spaced. The probes are provided insulated by mounting on a Teflon bush. A stand holds the probes, sample plate and RTD sensor. Leads are provided for voltage and current measurements. 2. Sample: Germanium crystal in the form of a chip. 3. Oven: small oven to vary temperature of the sample from room temperature to 2000C. 4. Measuring Unit for 4 probe setup: contains 3 subunits (i) Oven Controller, (ii) Digital Multi range Voltmeter, (iii) Constant Current Generator. Experimental Procedures: 1. Place sample in the middle of the base plate of the 4 probe arrangement. Apply a very gentle pressure (as the Germanium crystal is very brittle hence there is always a risk of its breaking) on the probes and check the continuity of the probes for proper electrical contacts, and tighten the pipe holding the probes at this position. 2. Connect the outer pair of probe leads (red/black) to the constant current generator supply and inner pair of probes leads (green/yellow) to the voltmeter.

3. Place the 4 probe arrangement in the oven and connect the sensor leads to the RTD connector on the panel. 4. Turn on the mains supply of the 4 probe setup and put the digital panel meter in the current measuring mode so that LED facing mA would glow, and set the current to a desired value (we have taken it as 5mA). 5. Put the digital panel meter in the voltage measuring mode so that LED facing mV would glow to read the voltage between the probes. 6. Switch ON the temperature controller and adjust the temperature to the maximum temperature you want to measure (T should not exceed 410 K) and then turn OFF the temperature controller and measure the potential with falling temperature from a max. value after equal intervals of temperature (say after every 5K) take the readings upto about room temperature.

THEORY The general conventional methods that we use generally for measuring the potential difference between two point such as voltmeters, potentiometers etc are not such efficient or satisfactory in the case of the semiconductors as semiconductors are known to form rectifying contacts (Schottky contacts) with metals. Hence, there is always an error associated with them. There is also a minority carrier injection through some of the current carrying contacts which may lead to an erroneous voltage measurement thereby resistivity will also contain an error. The method of 4 probe overcomes the difficulties mentioned above. It also has some advantages over general conventional methods as it can be used to measure resistivity of samples of different shapes, it can also be employed to measure resistivity of small region within bigger samples. In this manner resistivity of both sides of a p n junction can be measured precisely before material is cut into bars to make devices.

In this method of measuring the resistivity the 4 sharp probes are placed on the flat surface of the material of which the resistivity is to be measured, a current is passed though the two outermost electrodes (probes) and the middle two electrodes (probes) are used to measure the floating potential across them. If the flat surface on which the probes are rest is adequately large and the crystal is big then the semiconductor sample may be considered to be of semi infinite volume. To prevent the minority carrier injection through the contacts, the surface on which the probes are rest is mechanically lapped.

For using the 4 probe method to measure the resistivity, the following assumptions are made: 1. The resistivity of the material is uniform in the area of measurement 2. Minority carriers, if injected by electrodes recombines near the electrodes leaving no contribution to conductivity (i.e. measurement should made on the surfaces having high recombination rate e.g. mechanically lapsed surfaces). 3. Surface on which the probes rest if flat with no surface leakage. 4. 4 probes contacts lie in a straight line. 5. Diameter of contact between the metallic probe and semiconductor should be smaller than the distance between the probes. 6. The boundry between the current carrying electrodes and the bulk material is hemispherical and small in diameter.

OBSERVATION & CALCULATION Given parameters: s = distance between probes = 2mm, w = thickness of crystal = .5mm Now, 0 = where, I = 5mA

And, = [ = =

( ) ( )

Using the above expression we can get the value of (resistivity) at a particular voltage keeping current constant.

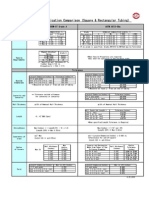

TEMPERATURE(K) VOLTAGE(V) 400 0.46 395 0.55 390 0.6 385 0.68 380 0.77 375 0.88 370 0.99 365 1.14 360 1.28 355 1.43 350 1.62 345 1.78 340 1.99 335 2.11 330 2.25 325 2.34 320 2.42 315 2.43 310 2.43 305 2.4 300 2.36

0.2085 0.24928 0.27194 0.3082 0.34899 0.39885 0.4487 0.51669 0.58014 0.64813 0.734242 0.80676 0.90194 0.95633 1.01978 1.060572 1.09683 1.10136348 1.10136348 1.0877664 1.06963696

(1/T)1000 log() 2.5 -0.6809 2.53 -0.6033 2.5641 -0.5655 2.5974 -0.5112 2.6316 -0.4572 2.6667 -0.3992 2.7027 -0.348 2.739763 -0.2868 2.7778 -0.2365 2.8169 -0.1883 2.857143 -0.1342 2.898551 -0.0933 2.9412 -0.0448 2.9851 -0.0194 3.0303 0.00851 3.0769 0.0255 3.125 0.04014 3.1746 0.0419 3.22581 0.041930671 3.2787 0.036536 3.333 0.02924

Using the values of resistivity and temperature, here is the graph between log() and inverse of temperature.

X axis = (1000/T) Y axis = log10

Since,

( )

( ) or log10 = log10(e).(Eg/2kT) log10K where K =

( )

some constant Therefore, slope = Hence, Eg = ( ( ) ( ) ) ( ( ) =

( ) ( )

= 1.3582

( )) = 0.539eV = 8.6357410-20J

Error in calculation of Eg = ((0.67 0.539)/0.67)*100 = 19.5 Hence, by calculating the slope of the log() vs 1/T curve we can find the Eg of the sample material.

RESULT We have found out the resistivity and temperature relationship of a Germanium sample crystal by a graph plotted between log() and inverse of temperature. We also calculated out the energy band gap of the Germanium sample crystal (0.539eV with an error of 19.5 ).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aashto T 119Document6 pagesAashto T 119Regen BasiñoNo ratings yet

- Aboveground Welded Steel Storage Tanks - Design and ConstructionDocument44 pagesAboveground Welded Steel Storage Tanks - Design and Constructionم.ذكى فضل ذكىNo ratings yet

- 96-97 FedEx Express Body Parts ManualDocument88 pages96-97 FedEx Express Body Parts ManualTasfin Habib0% (1)

- Oil Interceptor Type: SWOBK 100/ 500: Owership: Material: PolyethyleneDocument1 pageOil Interceptor Type: SWOBK 100/ 500: Owership: Material: PolyethyleneAldea CatalinNo ratings yet

- ANFEXDocument4 pagesANFEXGuillermo Esteban Ferraz SantanderNo ratings yet

- Unit - 6Document22 pagesUnit - 6N Dhanunjaya Rao BorraNo ratings yet

- Catalytic HydrodearomatizationDocument42 pagesCatalytic Hydrodearomatizational3x4n9No ratings yet

- Is 13920 1993Document24 pagesIs 13920 1993SirajMalikNo ratings yet

- Katrina M. Estrada 12 STEM-E9: V V V VDocument3 pagesKatrina M. Estrada 12 STEM-E9: V V V VJOHN RAVEN BUCAONo ratings yet

- DW21 27Document4 pagesDW21 27Mehwish MansoorNo ratings yet

- Investigation and Analysis of Tamarix Aphylla (Ghaz Wood) and Populus Caspica (Poplar Wood) Used As Raw Materials For Manufacturing of Medium Density FiDocument9 pagesInvestigation and Analysis of Tamarix Aphylla (Ghaz Wood) and Populus Caspica (Poplar Wood) Used As Raw Materials For Manufacturing of Medium Density FiAlexander Reategui GarciaNo ratings yet

- Special Considerations in Marine Pile Design and ConstructionDocument3 pagesSpecial Considerations in Marine Pile Design and ConstructionNitinShepurNo ratings yet

- SQUIRT ML 092220651Document8 pagesSQUIRT ML 092220651Roman KrautschneiderNo ratings yet

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosNo ratings yet

- PlasticsDocument48 pagesPlasticsPavan MehataNo ratings yet

- Policyandregulations NairobiDocument28 pagesPolicyandregulations NairobiLo LossNo ratings yet

- Architecture Portfolio - Architect Nicola DoglieroDocument60 pagesArchitecture Portfolio - Architect Nicola Doglieronicola doglieroNo ratings yet

- Experiment 4 - Level MeasurementDocument16 pagesExperiment 4 - Level MeasurementHafizuddin AdzharNo ratings yet

- 12 Samss 018Document4 pages12 Samss 018Dhaval PatelNo ratings yet

- Chapter 6 Electrochemistry SPMDocument62 pagesChapter 6 Electrochemistry SPMhanifzainol100% (1)

- Requirement For Fatigue AssessmentDocument3 pagesRequirement For Fatigue AssessmentyogacruiseNo ratings yet

- Mold Design - Injection MoldingDocument4 pagesMold Design - Injection Moldinganil chejaraNo ratings yet

- AC Tutor1Document4 pagesAC Tutor1Jady chess24No ratings yet

- SCI Stainless ForgedDocument12 pagesSCI Stainless ForgedBrandon TrocNo ratings yet

- Marv Air Door Pace CuDocument2 pagesMarv Air Door Pace Cunj23dublinNo ratings yet

- Lecture Notes Unit 1Document23 pagesLecture Notes Unit 1Akshay SrivastavaNo ratings yet

- Emergency Manual Stations MS-403U/404U: FeaturesDocument2 pagesEmergency Manual Stations MS-403U/404U: FeaturesJMAC SupplyNo ratings yet

- Rs419 Ring Scanner Spec SheetDocument3 pagesRs419 Ring Scanner Spec SheetJames HowardNo ratings yet

- PreviewDocument53 pagesPreviewCikorostore0% (1)

- Bomba Serie 90 100Document98 pagesBomba Serie 90 100lizbethdioses100% (3)