Professional Documents

Culture Documents

Use of SMT

Use of SMT

Uploaded by

Vikas AnandCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Excalibur L Ron Hubbard PDFDocument2 pagesExcalibur L Ron Hubbard PDFRobert0% (8)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- STAR SchemaDocument3 pagesSTAR SchemaVikas AnandNo ratings yet

- Vaishak - AmulDocument22 pagesVaishak - AmulVaishak Nair75% (4)

- CV Daily WageDocument1 pageCV Daily WageVikas AnandNo ratings yet

- Resume Vikas SAP SDDocument2 pagesResume Vikas SAP SDVikas AnandNo ratings yet

- Work DivisionDocument2 pagesWork DivisionVikas AnandNo ratings yet

- VodafoneDocument1 pageVodafoneVikas AnandNo ratings yet

- Hindustan Aeronautics Limited: Vikas AnandDocument12 pagesHindustan Aeronautics Limited: Vikas AnandVikas AnandNo ratings yet

- Test Bank For Biology The Essentials 1st Edition HoefnagelsDocument24 pagesTest Bank For Biology The Essentials 1st Edition Hoefnagelsripenesshallowzfh334No ratings yet

- Assessment Speaking & ListeningDocument26 pagesAssessment Speaking & ListeningSelvita Márquez MontoyaNo ratings yet

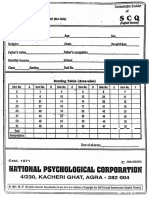

- Response Sheet For SCQDocument7 pagesResponse Sheet For SCQChandresh Gambhir100% (1)

- 24 Samantamukhaparivarta : Technical DetailsDocument13 pages24 Samantamukhaparivarta : Technical Details健二田中No ratings yet

- 4 4MagneticFields-MakingaCompassDocument2 pages4 4MagneticFields-MakingaCompassPrima Diane EdejerNo ratings yet

- HSPA - Network Optimization & Trouble Shooting v1.2Document15 pagesHSPA - Network Optimization & Trouble Shooting v1.2Ch_L_N_Murthy_273No ratings yet

- FlightDocument2 pagesFlightRich BaguiNo ratings yet

- Lebato-Pr2Document6 pagesLebato-Pr2Sir JrNo ratings yet

- SSRN Id2191280 1Document21 pagesSSRN Id2191280 1Andrew TandohNo ratings yet

- 4.-Student Dropout Prediction 2020Document12 pages4.-Student Dropout Prediction 2020Cap Scyte Victor MariscalNo ratings yet

- Admin STRMDocument442 pagesAdmin STRMjeromenlNo ratings yet

- 2020 Competencies Assessment Tool: Ache Healthcare ExecutiveDocument28 pages2020 Competencies Assessment Tool: Ache Healthcare ExecutiveNader ElbokleNo ratings yet

- English 8 Course OutlineDocument7 pagesEnglish 8 Course OutlineYhel LantionNo ratings yet

- 18 Making Math Meaningful For Students With Learning Problems Powerful Teaching Strategies That WorkDocument79 pages18 Making Math Meaningful For Students With Learning Problems Powerful Teaching Strategies That WorkFroilan TinduganNo ratings yet

- Procedures of Experiments and Reading Materials For The Experiments Offer by NN Ghosh in CE II PDFDocument41 pagesProcedures of Experiments and Reading Materials For The Experiments Offer by NN Ghosh in CE II PDFshreyas patelNo ratings yet

- Annual Implementation PlanDocument4 pagesAnnual Implementation PlanNeil Atanacio50% (2)

- GREY BOOK August 2017 66thDocument146 pagesGREY BOOK August 2017 66thxedoyis969No ratings yet

- Acceleration & DecelerationDocument23 pagesAcceleration & Decelerationmrs azizi100% (1)

- The Architects of Islamic CivilizationDocument372 pagesThe Architects of Islamic Civilizationlazut273No ratings yet

- Task 1 (Primera Tarea) : ActualizaciónDocument3 pagesTask 1 (Primera Tarea) : ActualizaciónDiegoMartelVazquezNo ratings yet

- Health Teaching Plan SampleDocument4 pagesHealth Teaching Plan SampleLicha Javier100% (1)

- Filipino DissertationDocument7 pagesFilipino DissertationHelpWritingCollegePapersSavannah100% (1)

- Exclusive Seller Representation Agreement Feb 4Document5 pagesExclusive Seller Representation Agreement Feb 4Md IslamNo ratings yet

- Notes On Religious Knowledge Systems (Part 2)Document4 pagesNotes On Religious Knowledge Systems (Part 2)xNo ratings yet

- AdxDocument7 pagesAdxRishi BansalNo ratings yet

- Using Flexible Clinical Processes in The Unified Protocol For The Treatment of Emotional Disorders in AdolescenceDocument6 pagesUsing Flexible Clinical Processes in The Unified Protocol For The Treatment of Emotional Disorders in AdolescenceLaura SanabriaNo ratings yet

- A Study On Employee's Satisfaction With Special Reference To KKR Group of Companies (Nirapara), Okkal, ErnakulamDocument74 pagesA Study On Employee's Satisfaction With Special Reference To KKR Group of Companies (Nirapara), Okkal, ErnakulamClick Pick100% (1)

- Flamenco FormsDocument3 pagesFlamenco FormsNayvi KirkendallNo ratings yet

Use of SMT

Use of SMT

Uploaded by

Vikas AnandOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Use of SMT

Use of SMT

Uploaded by

Vikas AnandCopyright:

Available Formats

Now the customer on SMT processing industry increasingly high demands, to reduce costs, improve efficiency, reduced manual

operation! Then the face of such situation, production line balancing analysis appears particularly important! First: it is the safeguard of efficiency and foundation, second: it is cost control theory! Balance analysis for the production flow balance and a single production line balance, then we discuss here is a single production line balance, production line balancing is a product of the balance processes, general equilibrium rate is calculated as follows, balance rate = = total / ( bottleneck time * total number) * 100% ( total = the sections work together ). Equilibrium rate analysis of commonly used methods of analysis has the following two kinds: First, time analysis, second, program analysis. Program analysis: two means : 5W2H and ECRS ( i.e.: cancellation, merger, rearrangement, simplify the four principles). Here mainly introduce second methods of analysis! E ( Eliminate ) -- cancelled. In" accomplished what"," if necessary" and" why" questions can be satisfied with the answer person are not necessary, should give cancel, cancel is the best way. The removal of unnecessary procedures, operation or action is not need to invest in an improvement, is the highest principle. ( Combine ) -- with C. For can not be removed without the necessary, to see whether they can merge, to achieve the time the purpose of simplifying. As with some process or action, or by people in different locations in different operations, replaced by a person or a single device. R ( Rearrange ) -- rearrangement. After cancellation, merger, but according to the" who, what, when" three questions for rearrangement, enable it to have the best sequence, remove duplication, work order. S ( Simple ) -- simplified. After cancellation, merger, after rearrangement necessary work, can consider the possibility of using the most simple method and equipment, in order to save manpower, time and cost. Through the" ECRS" four major principles, first consider the removal of unnecessary procedures, operation, operation; for example: the same production line 1895 transfer plate processing components can control the feet, cancel after welding procedure of cutting process. Secondly, some process or action with, to reduce processing procedures; for example, the production of 12291 South and 12185 types of inferior to feeding stations work content is to check the element has less parts and wrong material, reverse, and the furnace position of the operating action is pressed piece placed fixture, through analysis, found on the feeding stations can check in at the same time element pressure, and put good governance, will two station merger, save personnel 1 people

Once again, the work table, the machine as well as the storage layout to adjust, to reduce the transportation distance. Sometimes it may have to change the operation or inspection order, to avoid repetition. The last is the most simple equipment, tools instead of complex equipment, tools, or with a simple, labor-saving, time-saving action instead of heavy action. For example, ANAM production line executive tin Duan Zhixi station transferred between too much, affect the production efficiency, the use of slide, to reduce the transmission of action. In the analysis should also pay attention to the following questions: 1, pay attention to clearly distinguish the object of analysis is the product or the operator. In 2, as a means of improving the purpose, before the start of the first clear analysis purposes. 3, most began to clear scope, don't omit problem. In 4, at the scene and the operators and managers work analysis. In 5, temporary process change is the most basic process as the benchmark analysis. In 6, the analysis process is to think about improving scheme. 7, research solutions, to process overall improvement as a top priority target. Of course, program analysis is a long-term accumulation process, in practice we need engineers carefully to identify problems, solve problems. Everything from the perspective of improving, we will experience program analysis to our happiness.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Excalibur L Ron Hubbard PDFDocument2 pagesExcalibur L Ron Hubbard PDFRobert0% (8)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- STAR SchemaDocument3 pagesSTAR SchemaVikas AnandNo ratings yet

- Vaishak - AmulDocument22 pagesVaishak - AmulVaishak Nair75% (4)

- CV Daily WageDocument1 pageCV Daily WageVikas AnandNo ratings yet

- Resume Vikas SAP SDDocument2 pagesResume Vikas SAP SDVikas AnandNo ratings yet

- Work DivisionDocument2 pagesWork DivisionVikas AnandNo ratings yet

- VodafoneDocument1 pageVodafoneVikas AnandNo ratings yet

- Hindustan Aeronautics Limited: Vikas AnandDocument12 pagesHindustan Aeronautics Limited: Vikas AnandVikas AnandNo ratings yet

- Test Bank For Biology The Essentials 1st Edition HoefnagelsDocument24 pagesTest Bank For Biology The Essentials 1st Edition Hoefnagelsripenesshallowzfh334No ratings yet

- Assessment Speaking & ListeningDocument26 pagesAssessment Speaking & ListeningSelvita Márquez MontoyaNo ratings yet

- Response Sheet For SCQDocument7 pagesResponse Sheet For SCQChandresh Gambhir100% (1)

- 24 Samantamukhaparivarta : Technical DetailsDocument13 pages24 Samantamukhaparivarta : Technical Details健二田中No ratings yet

- 4 4MagneticFields-MakingaCompassDocument2 pages4 4MagneticFields-MakingaCompassPrima Diane EdejerNo ratings yet

- HSPA - Network Optimization & Trouble Shooting v1.2Document15 pagesHSPA - Network Optimization & Trouble Shooting v1.2Ch_L_N_Murthy_273No ratings yet

- FlightDocument2 pagesFlightRich BaguiNo ratings yet

- Lebato-Pr2Document6 pagesLebato-Pr2Sir JrNo ratings yet

- SSRN Id2191280 1Document21 pagesSSRN Id2191280 1Andrew TandohNo ratings yet

- 4.-Student Dropout Prediction 2020Document12 pages4.-Student Dropout Prediction 2020Cap Scyte Victor MariscalNo ratings yet

- Admin STRMDocument442 pagesAdmin STRMjeromenlNo ratings yet

- 2020 Competencies Assessment Tool: Ache Healthcare ExecutiveDocument28 pages2020 Competencies Assessment Tool: Ache Healthcare ExecutiveNader ElbokleNo ratings yet

- English 8 Course OutlineDocument7 pagesEnglish 8 Course OutlineYhel LantionNo ratings yet

- 18 Making Math Meaningful For Students With Learning Problems Powerful Teaching Strategies That WorkDocument79 pages18 Making Math Meaningful For Students With Learning Problems Powerful Teaching Strategies That WorkFroilan TinduganNo ratings yet

- Procedures of Experiments and Reading Materials For The Experiments Offer by NN Ghosh in CE II PDFDocument41 pagesProcedures of Experiments and Reading Materials For The Experiments Offer by NN Ghosh in CE II PDFshreyas patelNo ratings yet

- Annual Implementation PlanDocument4 pagesAnnual Implementation PlanNeil Atanacio50% (2)

- GREY BOOK August 2017 66thDocument146 pagesGREY BOOK August 2017 66thxedoyis969No ratings yet

- Acceleration & DecelerationDocument23 pagesAcceleration & Decelerationmrs azizi100% (1)

- The Architects of Islamic CivilizationDocument372 pagesThe Architects of Islamic Civilizationlazut273No ratings yet

- Task 1 (Primera Tarea) : ActualizaciónDocument3 pagesTask 1 (Primera Tarea) : ActualizaciónDiegoMartelVazquezNo ratings yet

- Health Teaching Plan SampleDocument4 pagesHealth Teaching Plan SampleLicha Javier100% (1)

- Filipino DissertationDocument7 pagesFilipino DissertationHelpWritingCollegePapersSavannah100% (1)

- Exclusive Seller Representation Agreement Feb 4Document5 pagesExclusive Seller Representation Agreement Feb 4Md IslamNo ratings yet

- Notes On Religious Knowledge Systems (Part 2)Document4 pagesNotes On Religious Knowledge Systems (Part 2)xNo ratings yet

- AdxDocument7 pagesAdxRishi BansalNo ratings yet

- Using Flexible Clinical Processes in The Unified Protocol For The Treatment of Emotional Disorders in AdolescenceDocument6 pagesUsing Flexible Clinical Processes in The Unified Protocol For The Treatment of Emotional Disorders in AdolescenceLaura SanabriaNo ratings yet

- A Study On Employee's Satisfaction With Special Reference To KKR Group of Companies (Nirapara), Okkal, ErnakulamDocument74 pagesA Study On Employee's Satisfaction With Special Reference To KKR Group of Companies (Nirapara), Okkal, ErnakulamClick Pick100% (1)

- Flamenco FormsDocument3 pagesFlamenco FormsNayvi KirkendallNo ratings yet