Professional Documents

Culture Documents

Customer Complaints Report

Customer Complaints Report

Uploaded by

Susan MalagobOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Customer Complaints Report

Customer Complaints Report

Uploaded by

Susan MalagobCopyright:

Available Formats

REPORT OF COMPLAINT BY CUSTOMERS, FINDINGS AND RECOMMENDATION FOR ACTION TO BE TAKEN Introduction We prepared this report because recently

we received several complaint about the stale frozen lambs that our customers had purchased from our hypermarket. At first we thought there was a problem with our refrigeration system but after further investigation, we found out that the affected frozen lamb came from one of our suppliers. We did a preliminary investigation at the suppliers premises especially into their quality control procedure and we found several weaknesses that can be easily corrected and improved. On our side there were also a couple of weaknesses especially the procedure when receiving frozen products from suppliers. Therefore we would like to recommend to the management the need to upgrade our quality control as to avoid further embarrassment that could tarnish the image of our company. We would like to propose several added measures to our quality control such as inspection of suppliers storage facilities from time to time, food handling, packaging, quality control procedure and workers health certificate and level of competence. On our side, all our workers must undergo competence training to handle food items from the moment they arrived to our hypermarket until there are sold to our customers. Our workers should also undergo regular medical check-up for fear of food contamination by unhealthy workers. Complaint By Our Customers As I have mentioned, we received several complaints from our regular customers after having purchased the frozen lamb from our hypermarket. At first, we thought our refrigeration system or the container where the frozen lambs were stored might have been faulty but upon investigation by our technical unit, we found that almost all the lamb supplied by Eatlamb Limited were staled. The other lambs supplied by two other suppliers were found to be in good condition. Action Taken We have wrote a letter to the supplier and at the same time sent back the affected lambs for them to take action. We have also reimbursed back the money to all the customers that had purchased the affected lambs. Our supplier has informed us that they will immediately look into the matter and will inform us once they have receive the report of their findings. We also conducted a surprise visit to the supplier storage and packing facilities which they kindly brought us around. We notice that the staff who are directly

involve in this two sections were not wearing suitable and standardize dressing. Some of the workers were not wearing caps to prevent hair from falling unto the food items. Some workers we noted were not wearing proper footwear at places where they are not suppose to. During the visit we conveyed our dissatisfaction and they have promise to come with a standard procedure for their workers to follow. We have also informed the supplier that affected customers may take legal action against them for having contravene the food safety regulation which falls under the Malaysian Food Act 1983 and Food Regulation 1985. At the moment we are glad that our customers have not taken any legal action as this incident was the first ever happened in our hypermarket. We are at the moment preparing Food Handling Procedure Manual for all staff to observe and comply strictly as to avoid further similar incident. The food handling procedure consist of : 1. 2. 3. 4. Inspection all food products received from suppliers. Our personnel must always be in proper attire when handling food items. To ensure storage, packaging and equipment facilities are clean and fit to be used. All packaging done must have expiry date and batch numbers printed on it which includes suppliers code name, batch numbers and date received from suppliers for easy reference. This is also to avoid accidently mix-up with other food products received on different dates. Before products are sold to customers they have to go through Quality Control for final checking, testing and approval. Technical unit must ensure that all freezing facilities are in good condition. Any significant fluctuation in the freezing temperature should report to quality control section immediately for further action. All personnel in the food section must undergo regular medical checkup to avoid food contamination.

5. 6. 7.

Prior to the complaint, most of our personnel have already gone for training in handling all types of frozen food items. They know the standard freezing temperature for meat is less than minus 18C which must be maintain at all time. We also have a very good technical team that ensure our refrigeration system are constantly running with backup power standing-by in case of electrical power failure. Apart from that, the areas that need to be improved are : 1. Knowing the condition of frozen food items upon received.

2. 3. 4.

Packing procedure. Dressing (Dress code) The need for Quality Control Officer, currently we do not have one. The officers job is to ensure the smooth flow of the frozen items, upon receiving them at our premises right until they goes out to our customers.

Knowing the condition of the frozen food items upon receiving at our premises is very important as it set the rest of the workflow. We believe the product was already contaminated before reaching our premises. Visual inspection did not suggest that the frozen lambs arrived were not fit for human consumption because the packages were not damaged or torn. Therefore we like to suggest to the management to test at least thirty percent of any frozen meat consignment upon received from suppliers and to be certified that they are fit for human consumption before being sold to customers. Secondly, our packaging procedure should be reviewed. I have observed that upon wrapping the frozen item, there was no identification to state which supplier this item came from, which batch and date. The only thing that is printed on the packaging is our company name, our own batch number, production date and expiry date. We may not need to use the suppliers actual names but we can use different codes to identify each supplier. With this method we can immediately identify which supplier the affected frozen products came from if there are any complaints in the future from our customers. Thirdly, our dress code need to be identifiable between the packaging section, meat processing section, management staff, technical section and quality control section. This to ensure management from other branch or head office can immediately identify each staff and which section he or she comes from. Presently, we do not have standardize dressing except that all staff especially those handling frozen meat are instructed to use gloves, head cap, mask and white overall to avoid contamination from hair, dry skin residue, saliva and so on. Fourthly, at the moment we do not have a qualified quality control officer. For now, we are using one of our experience senior officer to look into the quality control on all section of the production workflow. He is the one that will inspect, advice each section on the quality control procedure and; do analysis especially if there are any weaknesses in the workflow, report and provide suggestion to the management for further improvement. At the presence he is working alone and has done a good job. The only problem is we do not have testing facilities to test for example the frozen lamb received from supplier whether it is in good condition or not. I would also like to inform you in regards to the fourth item, after having discuss with my senior officers, we came to the conclusion that the extra cost will not be a burden to employ a qualified Quality Control Officer as well as getting testing

equipment for frozen meat and other food products. This is because it would be more expensive to pay for legal cost if we get sued by our customers for selling contaminated food products and not to mention the lost of jobs if the court decide to shutdown the hypermarket operation. Anyway, last year our hypermarket made about RM1,000,000,000.00 after tax and our annual operating expenses is only about RM 400,000.00. Our annual income has never gone down below the RM1,000,000,000.00 mark that we have set ourselves annually. My senior supervisor who is handling quality control has informed me that the cost of buying new outfit for the staff and the food product testing equipment would be about RM 20,000.00. He further informed me that a qualified quality control officer specialize in food products would cost the company an additional RM3000.00 to RM5000.00 a month in staff salary expenses. I hope the management will seriously consider as the benefit out weigh the cost and it will create a good image for the company in terms of our seriousness in ensuring our products sold to our customers are of the highest standard. Monitoring Suppliers Quality Standards We have informed all our suppliers of our intention to visit them from time to time to check their quality standard and workflow. In a way, it helps to protect our company reputation if there is any complain in the future. At least we can inform our customers that we do regular inspection at our suppliers premises on food handling which they must comply in accordance to the Food Act 1983 and Food Regulation 1985. In the meeting we had with them, we forwarded our suggestion to them how they can improve their product quality to meet up with customers, demand. The suggestion are as follows: 1. Hire a quality control officer to oversee all meat received, if they do not have one. He will ensure all meat received are fresh and in good condition, properly handle, packed and refrigerated according to specification. 2. To ensure all staff handling fresh meat are healthy. They must also undergo medical check-up by the companys panel of doctors at least once a year. 3. To ensure all staff handling fresh meat are properly trained. 4. To ensure premises are clean, tidy and organize especially packing and storage area. 5. All staff especially those handling fresh meat must have proper attire. 6. During handling of fresh meat and packing process, staff involve must wear mask, proper head covering, gloves, proper footwear and are healthy.

7. Their technician must ensure the refrigeration system are working properly and the management must ensure they have back-up power standing-by in case of power failure. 8. Proper log book should be prepared and any unexpected event occurred during the handling of fresh meat must be recorded such as power failure, meat contamination, staff did not follow procedure and so on. 9. Standardize packing and internationally approve material can only be used, this is to avoid chemical reaction to the meat. 10. Markings and labels on the packing must be clear and easy to read. 11. To ensure all equipment used in the handling of fresh meat are clean and free from contaminants. 12. To inform us immediately if problem occurs from any of the following mentioned above and to make available the log book to us upon request.

You might also like

- Lesson Plan Tle12-CookeryDocument7 pagesLesson Plan Tle12-Cookerygladys quiros91% (11)

- Complaint Letter SampleDocument4 pagesComplaint Letter Samplethivvv0% (1)

- Stuart McRobert - Big ArmsDocument8 pagesStuart McRobert - Big ArmsKaos Calmo100% (1)

- Retail Operations Standards ManualDocument17 pagesRetail Operations Standards ManualalmoezNo ratings yet

- New Purchase All SOPDocument82 pagesNew Purchase All SOPJowin RodriguesNo ratings yet

- Pari Bakery BBSRDocument10 pagesPari Bakery BBSRAditi100% (1)

- Purchasing Process in Prep For ISODocument4 pagesPurchasing Process in Prep For ISObrecht1980No ratings yet

- Goat Production Manual: Ministry of Agriculture, Animal Industry and FisheriesDocument84 pagesGoat Production Manual: Ministry of Agriculture, Animal Industry and FisheriesNGANJANI WALTERNo ratings yet

- A Report On Customers' Complaint of Frozen LambDocument12 pagesA Report On Customers' Complaint of Frozen LambMonica AdelineNo ratings yet

- Ayen - Scope of Management SystemDocument1 pageAyen - Scope of Management Systemaffiqaiman010503No ratings yet

- Food FlowDocument93 pagesFood FlowDilan PreciousNo ratings yet

- Purchase DepartmentDocument10 pagesPurchase Departmentscsreelakshmi3_67032No ratings yet

- Hwa Tai Code of Ethics and Business Conduct (Web)Document3 pagesHwa Tai Code of Ethics and Business Conduct (Web)Sweelin Tan0% (1)

- Peculiar Taste of Frozen Lamb: To: Anuar Bin Edon, Store ManagerDocument13 pagesPeculiar Taste of Frozen Lamb: To: Anuar Bin Edon, Store ManagerBello SyanilNo ratings yet

- Report of Complaint of Some Frozen Lambs Had A Peculiar Taste byDocument10 pagesReport of Complaint of Some Frozen Lambs Had A Peculiar Taste byazzi77No ratings yet

- Pob SbaDocument32 pagesPob SbaNOVA FFNo ratings yet

- Supply Chain Management in Mother Dairy: Prepared byDocument5 pagesSupply Chain Management in Mother Dairy: Prepared byArijitHawladerNo ratings yet

- Food and BeverageDocument35 pagesFood and BeverageLyn Escano50% (2)

- Cost Control PDFDocument30 pagesCost Control PDFmarierose matugasNo ratings yet

- KFC Is The Largest FastDocument3 pagesKFC Is The Largest FastTamilselvam PerassamiNo ratings yet

- Week 5 Risk MGTDocument10 pagesWeek 5 Risk MGTjudezaNo ratings yet

- Grace Medicare Private LimitedDocument4 pagesGrace Medicare Private Limitednew businessNo ratings yet

- Product Withdrawal and Recall: Safe MethodDocument2 pagesProduct Withdrawal and Recall: Safe MethodAlghubariNo ratings yet

- Supply Chain Management 1880575Document11 pagesSupply Chain Management 1880575Ravi KumawatNo ratings yet

- Warehouse Store Person Job AppointmentDocument3 pagesWarehouse Store Person Job Appointmentrifa.international.accNo ratings yet

- As The Store Manager For The Gemilang Hyper MarketDocument9 pagesAs The Store Manager For The Gemilang Hyper MarketZekiel KushanNo ratings yet

- Research On Different EstablishmentDocument2 pagesResearch On Different EstablishmentAlyssa Ashley Corpuz SevilleNo ratings yet

- Proprietor Responsibility: Control of Food Safety HazardsDocument3 pagesProprietor Responsibility: Control of Food Safety HazardsKenneth Alsola100% (1)

- Total Quality ManagementDocument10 pagesTotal Quality ManagementDikshita Jain100% (1)

- Internal Control Sample PapersDocument21 pagesInternal Control Sample PapersKamper DanNo ratings yet

- Crown Textile ProfileDocument18 pagesCrown Textile ProfileBilalNo ratings yet

- Assignment SurenDocument7 pagesAssignment SurenSisir MohantyNo ratings yet

- Group2 reportingRMDocument14 pagesGroup2 reportingRMMarlo CondeNo ratings yet

- Zulhairi Bin MD - Dawam 721121016501002Document11 pagesZulhairi Bin MD - Dawam 721121016501002Zulhairi Md DawamNo ratings yet

- A Seamark SummaryDocument5 pagesA Seamark SummaryMd Nazmus SakibNo ratings yet

- Purchasing AssignmentDocument28 pagesPurchasing AssignmentKubenKrishNo ratings yet

- GMP SopDocument5 pagesGMP SopHaider Ali100% (1)

- ProfilingDocument22 pagesProfilingAsif HabibNo ratings yet

- Contrato de FranquiciaDocument642 pagesContrato de FranquiciaEdisson Morales100% (1)

- FB COst Contro Textbook 25 (1) .11.11Document77 pagesFB COst Contro Textbook 25 (1) .11.11Rakesh SharmaNo ratings yet

- Serial Griller: ObjectivesDocument4 pagesSerial Griller: ObjectivesBinsu DanielNo ratings yet

- Kartik Nikam KRW MBA9Document2 pagesKartik Nikam KRW MBA9Kartik NikamNo ratings yet

- VII. Operation PlanDocument6 pagesVII. Operation PlanBianca Victoria Uy CorralNo ratings yet

- Food Safety ManualDocument47 pagesFood Safety ManualsalazarayieNo ratings yet

- Corporate Financial Reporting: ProjectDocument4 pagesCorporate Financial Reporting: Projecttayyab malikNo ratings yet

- Total Quality Management: Shaigan PharmaceuticalDocument18 pagesTotal Quality Management: Shaigan PharmaceuticalRabia RabiNo ratings yet

- Food Quality Management 650Document7 pagesFood Quality Management 650Waqar Ibrahim100% (1)

- Taaza Gosht Profile - 2Document7 pagesTaaza Gosht Profile - 2Imagiacian UKNo ratings yet

- OPERATIONS1234Document4 pagesOPERATIONS1234Nenith P. EsicNo ratings yet

- Quality Assurance O Cer: Posted 5 Days Ago Salary: - Closes: July 11, 2021Document5 pagesQuality Assurance O Cer: Posted 5 Days Ago Salary: - Closes: July 11, 2021joanmubzNo ratings yet

- V. Instructions: Operational Plan: 1. ProductionDocument4 pagesV. Instructions: Operational Plan: 1. ProductionGieann BustamanteNo ratings yet

- Ntroduction and PurposeDocument2 pagesNtroduction and PurposeSreelakshmiNo ratings yet

- Storing DHMControlDocument11 pagesStoring DHMControlOm SinghNo ratings yet

- Quality Process ProcurementDocument5 pagesQuality Process Procurementsid3286No ratings yet

- Org Poli Internal ContDocument9 pagesOrg Poli Internal ContVanessa Joanie G. GlorianiNo ratings yet

- Quality Control in The Food IndustryDocument33 pagesQuality Control in The Food Industrybiswassumit24680No ratings yet

- The Control ProcessDocument45 pagesThe Control Processmareng susanNo ratings yet

- SITXFSA002 A01 Participate in Safe Food Handling PracticesDocument19 pagesSITXFSA002 A01 Participate in Safe Food Handling PracticesPardeep Kumar100% (1)

- LERMA - Rules and Regulations of Esumart's Convenience StoreDocument5 pagesLERMA - Rules and Regulations of Esumart's Convenience StoreDanjave DumpaNo ratings yet

- Good Manufacturing PracticesDocument27 pagesGood Manufacturing PracticesNg Kai EnNo ratings yet

- Assignment 1 - Contents ARDocument20 pagesAssignment 1 - Contents ARJenny AnneNo ratings yet

- The Non-Commercial Food Service Manager's Handbook: A Complete Guide for Hospitals, Nursing Homes, Military, Prisons, Schools, and ChurchesFrom EverandThe Non-Commercial Food Service Manager's Handbook: A Complete Guide for Hospitals, Nursing Homes, Military, Prisons, Schools, and ChurchesNo ratings yet

- Conference Ankara Turkey Book PDFDocument696 pagesConference Ankara Turkey Book PDFOleksandra KovalevskaNo ratings yet

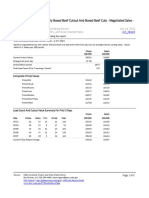

- National Daily Boxed Beef Cutout and Boxed Beef Cuts - Negotiated Sales - AfternoonDocument5 pagesNational Daily Boxed Beef Cutout and Boxed Beef Cuts - Negotiated Sales - AfternoonJuanCarlosMarrufoNo ratings yet

- Giovanni Carrick On Shannon 6pp A3 100112Document2 pagesGiovanni Carrick On Shannon 6pp A3 100112Darren McGreevyNo ratings yet

- Homemade Doner Kebab: A Turkish Classic: IngredientsDocument2 pagesHomemade Doner Kebab: A Turkish Classic: IngredientsTextiles CañamasNo ratings yet

- Case Study1 L1S20BBAM0288Document3 pagesCase Study1 L1S20BBAM0288MOHAMMAD ASHAR L1F17BSCS04060% (1)

- Diet. The Oxford Encyclopedia of ADocument13 pagesDiet. The Oxford Encyclopedia of ABlackStr3amNo ratings yet

- Poultry Meat DashboardDocument16 pagesPoultry Meat DashboardSylviaNo ratings yet

- Detailed Lesson Plan CookingDocument8 pagesDetailed Lesson Plan CookingRia Lopez100% (5)

- Meat and Environmental DestructionDocument2 pagesMeat and Environmental DestructionVegan FutureNo ratings yet

- Rabbit Meat - Production Consumption and Consumers - Attitudes andDocument15 pagesRabbit Meat - Production Consumption and Consumers - Attitudes andJasha Alexi FuentesNo ratings yet

- Intalacion Cria CerdoDocument268 pagesIntalacion Cria CerdoAsdrubal BoadaNo ratings yet

- Forschen: Microbiological Analysis of Commercial Raw Meat-Based Diets For DogsDocument6 pagesForschen: Microbiological Analysis of Commercial Raw Meat-Based Diets For DogsAndrea Guzman BotiaNo ratings yet

- Meadow Creek Buyers Guide GrillsDocument52 pagesMeadow Creek Buyers Guide GrillsMark Mihalko100% (1)

- XXXXXXXXXXXXXXXXXXXXXXXXXXXXDocument750 pagesXXXXXXXXXXXXXXXXXXXXXXXXXXXXjdgregorioNo ratings yet

- FREE NutritiontestDocument9 pagesFREE NutritiontestAdrian DabuNo ratings yet

- Survey of Downtown Calgary DonairsDocument21 pagesSurvey of Downtown Calgary DonairsRobson FletcherNo ratings yet

- Simulation of Cooking of Chicken PattiesDocument10 pagesSimulation of Cooking of Chicken PattiesazharijahinNo ratings yet

- Tilapia Cage Fish FarmDocument89 pagesTilapia Cage Fish FarmShudufhadzo KhorombiNo ratings yet

- Lamb and MuttonDocument12 pagesLamb and MuttonsakuraleeshaoranNo ratings yet

- Meat Inspection in The PhilippinesDocument59 pagesMeat Inspection in The PhilippinesNovaNonesLicayNo ratings yet

- I. Cultural AnalysisDocument6 pagesI. Cultural AnalysisDunggNo ratings yet

- Food Safety AssignmentDocument13 pagesFood Safety AssignmentNguyễn ThuNo ratings yet

- Diet of Disaster (Meat / Dairy)Document56 pagesDiet of Disaster (Meat / Dairy)Vegan Future100% (4)

- Sheikh Technical Veterinary SchoolDocument20 pagesSheikh Technical Veterinary SchoolCismaanAbdulahiFarahNo ratings yet

- The New Atkins Diet Low Carb Revolution Super Delicious Cookbook Collection Box Set #2 - NodrmDocument90 pagesThe New Atkins Diet Low Carb Revolution Super Delicious Cookbook Collection Box Set #2 - NodrmAndreeaNo ratings yet

- How To Structure An EssayDocument97 pagesHow To Structure An Essaypedro perezNo ratings yet

- Ibm Kampung Tempe Tenggilis Kauman SurabayaDocument6 pagesIbm Kampung Tempe Tenggilis Kauman SurabayaAgatha HannabelNo ratings yet