Professional Documents

Culture Documents

Transeng Eps13605

Transeng Eps13605

Uploaded by

Hallisa TamiciCopyright:

Available Formats

You might also like

- Concrete Batch Plant Operator Study GuideDocument49 pagesConcrete Batch Plant Operator Study Guiderajam199771% (7)

- Shotcrete RequirementsDocument16 pagesShotcrete Requirementstinz_3100% (2)

- Method Statement For Pile Head BreakingDocument18 pagesMethod Statement For Pile Head BreakingLijo Joseph100% (6)

- Inspection Checklist For Concrete Placement Pre & Post PlacementDocument4 pagesInspection Checklist For Concrete Placement Pre & Post PlacementUsman ShahidNo ratings yet

- Precast Post Tentioned TanksDocument20 pagesPrecast Post Tentioned TanksMarcel SteoleaNo ratings yet

- FHWA Shotcrete Guide SpecificationDocument7 pagesFHWA Shotcrete Guide SpecificationHector GalvezNo ratings yet

- BBS Book (PT 14) NeglyDocument7 pagesBBS Book (PT 14) Neglyapi-3871208No ratings yet

- Airport Literature StudyDocument15 pagesAirport Literature StudySoundar Rajan100% (2)

- Leg Support Calculation PDFDocument2 pagesLeg Support Calculation PDFSanjay MoreNo ratings yet

- Cellular Concrete Specifications Latest On 4-13Document3 pagesCellular Concrete Specifications Latest On 4-13diracmoutinhoNo ratings yet

- SP 401Document9 pagesSP 401azamislam726537No ratings yet

- Revision of Section 601 Latex Modified ConcreteDocument4 pagesRevision of Section 601 Latex Modified ConcreteSolomon AhimbisibweNo ratings yet

- Memo 097.7 - 121619 - Item 456 Tunnel Concrete LiningDocument5 pagesMemo 097.7 - 121619 - Item 456 Tunnel Concrete LiningBai Alleha MusaNo ratings yet

- Circular For Paver Blocks IRC SP 63-2004Document21 pagesCircular For Paver Blocks IRC SP 63-2004Ashwin SrikantaiahNo ratings yet

- Part417 Continuous Flight Auger PilesDocument5 pagesPart417 Continuous Flight Auger PilesNaga RjkNo ratings yet

- 2014 NYC Building Code BC1905 Concrete Quality, Mixing and PlacingDocument12 pages2014 NYC Building Code BC1905 Concrete Quality, Mixing and PlacingJohn DoeNo ratings yet

- Section V-2 Concrete Classes and Mixes: 502.01 DescriptionDocument5 pagesSection V-2 Concrete Classes and Mixes: 502.01 DescriptionAbdullah Aboodi67% (3)

- Specifications For Interlocking Concrete Blockpavement PDFDocument21 pagesSpecifications For Interlocking Concrete Blockpavement PDFVijaya KumarNo ratings yet

- ASTM C494 Admixtures Types A, F or G & Self Compacting Concrete (SCC) AdmixturesDocument3 pagesASTM C494 Admixtures Types A, F or G & Self Compacting Concrete (SCC) AdmixturesaminiskandarNo ratings yet

- Technical Specifications For Piling WorksDocument10 pagesTechnical Specifications For Piling WorksArzath SajeerNo ratings yet

- BIW Ref: 00-SP-03-3000 Rev 03Document46 pagesBIW Ref: 00-SP-03-3000 Rev 03niuxiaoliangNo ratings yet

- University of Northern PhilippinesDocument8 pagesUniversity of Northern PhilippinesMichael Mark Deompoc TimoteoNo ratings yet

- Rubble ConcreteDocument537 pagesRubble ConcreteRoshan Nanjundaiah100% (3)

- Dhofar Power Company Saog: Mott Macdona IdDocument1 pageDhofar Power Company Saog: Mott Macdona Id54045114No ratings yet

- DCA2007SS 07 PageDocument12 pagesDCA2007SS 07 PageAJITSINGHNo ratings yet

- Technical Specification For Micropile ConstructionDocument9 pagesTechnical Specification For Micropile ConstructionFFerideKochanNo ratings yet

- CPN SppsdsDocument10 pagesCPN SppsdsaliNo ratings yet

- Structural ConcreteDocument11 pagesStructural ConcreteNoel TerreNo ratings yet

- Spec 451 Reinforced Portland Cement Concrete PavementDocument6 pagesSpec 451 Reinforced Portland Cement Concrete PavementCharan ReddyNo ratings yet

- PillingDocument21 pagesPillingHadiyan RosyidiNo ratings yet

- Part 8 Kerbs, FootwaysDocument11 pagesPart 8 Kerbs, FootwaysElvis GrayNo ratings yet

- Technical Specification - Concrete WorksDocument5 pagesTechnical Specification - Concrete Workshendra djangNo ratings yet

- Section 503 Prestressed Concrete Members: 503.1 DescriptionDocument7 pagesSection 503 Prestressed Concrete Members: 503.1 DescriptionSyed Ali Raza ShahNo ratings yet

- Annex A - Technical SpecificationsDocument50 pagesAnnex A - Technical SpecificationsGAhr CeredonNo ratings yet

- SECTION 03 30 00 Cast-In-Place ConcreteDocument36 pagesSECTION 03 30 00 Cast-In-Place ConcreteJuanPaoloYbañezNo ratings yet

- Specifications For Concrete SleepersDocument28 pagesSpecifications For Concrete Sleepersgerfreecalls50% (2)

- Specification Jila Seva Sadan - 3Document176 pagesSpecification Jila Seva Sadan - 3Jignesh P KoratNo ratings yet

- Interlocking Bricks ProcedureDocument14 pagesInterlocking Bricks ProcedureSpchethan Chethansp100% (2)

- Sub Head 5.0: Reinforced Cement Concrete WorkDocument16 pagesSub Head 5.0: Reinforced Cement Concrete WorkPritam DharNo ratings yet

- Concrete PropertiesDocument14 pagesConcrete PropertiesIm ChinithNo ratings yet

- Item P-610 Structural Portland Cement Concrete 105Document11 pagesItem P-610 Structural Portland Cement Concrete 105Anthony McguireNo ratings yet

- Section 16 Plain and Reinforced Concrete: Code.16Document28 pagesSection 16 Plain and Reinforced Concrete: Code.16maeNo ratings yet

- Pervious+Concrete+SPEC Jan+2019Document12 pagesPervious+Concrete+SPEC Jan+2019Arvin BhurtunNo ratings yet

- Production MergedDocument89 pagesProduction Mergedpavelmagin78No ratings yet

- Appendix 6.1 Structural Repairs To RCC Columns, Beams and SlabsDocument4 pagesAppendix 6.1 Structural Repairs To RCC Columns, Beams and SlabsNirmal KishorNo ratings yet

- Public Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inDocument10 pagesPublic Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inSanthosh BabuNo ratings yet

- Precast Reinforced Concrete Vaults - MSTDocument9 pagesPrecast Reinforced Concrete Vaults - MSTwafikmh4No ratings yet

- Construction Specification Guideline For Concrete Streets and Local Roads IS119P 4Document24 pagesConstruction Specification Guideline For Concrete Streets and Local Roads IS119P 4wickremasingheNo ratings yet

- MF (1) 1Document24 pagesMF (1) 1Suranga ManuNo ratings yet

- Example Specifications For CEMATRIX Cellular ConcreteDocument9 pagesExample Specifications For CEMATRIX Cellular ConcreteRaffy Shaun CentenoNo ratings yet

- 03300Document13 pages03300Jeffrey Carlo Viduya AgliamNo ratings yet

- UG-IV-1-Concrete WorkDocument8 pagesUG-IV-1-Concrete WorkshreejeshNo ratings yet

- Irc DLCDocument56 pagesIrc DLCAniket Salvi100% (5)

- Trans 3 70 Portland Cement Concrete PavementDocument28 pagesTrans 3 70 Portland Cement Concrete Pavementjuandlc3368No ratings yet

- IRS T39 PSC SleepersDocument28 pagesIRS T39 PSC Sleepersradhakrishnang100% (2)

- Technical Detils of SiteDocument3 pagesTechnical Detils of SitePtpgStucNo ratings yet

- Concrete DocumentDocument8 pagesConcrete DocumentramNo ratings yet

- QCS 2010 Part 6.08 Kerbs, Footways and Paved AreasDocument8 pagesQCS 2010 Part 6.08 Kerbs, Footways and Paved AreasRotsapNayrbNo ratings yet

- Specs For Precast Sub ElementsDocument11 pagesSpecs For Precast Sub ElementsTimothy CruseNo ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Concrete-Block Manufacture - Processes and MachinesFrom EverandConcrete-Block Manufacture - Processes and MachinesRating: 5 out of 5 stars5/5 (1)

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- Petroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityDocument13 pagesPetroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityAli AbubakarNo ratings yet

- Describe Physical and Chemical Change OperationallyDocument2 pagesDescribe Physical and Chemical Change OperationallyMaria Anna GraciaNo ratings yet

- NEW Sales Tax Invoice - 2023-07-27T164634.549Document1 pageNEW Sales Tax Invoice - 2023-07-27T164634.549Saadat IrfanNo ratings yet

- HDR10+ System Whitepaper: September 4, 2019 HDR10+ Technologies, LLCDocument14 pagesHDR10+ System Whitepaper: September 4, 2019 HDR10+ Technologies, LLCDragomir ConstantinNo ratings yet

- Valve Body 55Document3 pagesValve Body 55Davidoff RedNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- ManvantaraDocument3 pagesManvantaraafterragnarokNo ratings yet

- 6 Landforms - SCIENCEDocument9 pages6 Landforms - SCIENCEArianne RealNo ratings yet

- Water Content in SoilDocument4 pagesWater Content in SoilJohn Paul CristobalNo ratings yet

- The Harrod-Domar Growth ModelDocument6 pagesThe Harrod-Domar Growth ModelSimeonNo ratings yet

- Bored Piles - Bilfinger Spezialtiefbau GMBHDocument4 pagesBored Piles - Bilfinger Spezialtiefbau GMBHOga MeoNo ratings yet

- ToR For Fiberglass Biogas Plants Installation - EOI PDFDocument4 pagesToR For Fiberglass Biogas Plants Installation - EOI PDFmy09No ratings yet

- HwyconstDocument23 pagesHwyconstAmulie JarjuseyNo ratings yet

- Gear Trains: 8.1. Angular Velocity RatioDocument16 pagesGear Trains: 8.1. Angular Velocity RatioaddisudagneNo ratings yet

- X PPT CH 12 ElectricityDocument12 pagesX PPT CH 12 ElectricityAakriti100% (1)

- Drawing Details: Cie 332 Quantity Surveying and Estimation Lecture Two Lecturer: Eng. Goodson MashekaDocument23 pagesDrawing Details: Cie 332 Quantity Surveying and Estimation Lecture Two Lecturer: Eng. Goodson MashekaPerpetual hubbyNo ratings yet

- Electronics Cooling: Mechanical Power Engineering DeptDocument22 pagesElectronics Cooling: Mechanical Power Engineering DeptneilNo ratings yet

- Straumann Product Catalogue 2018 2019Document260 pagesStraumann Product Catalogue 2018 2019kllasikalleNo ratings yet

- CR Unit 1 &11 (Part A &B)Document12 pagesCR Unit 1 &11 (Part A &B)durai muruganNo ratings yet

- Abb Reg615 Ansi Appl 859072 EndDocument124 pagesAbb Reg615 Ansi Appl 859072 EndjppreciadomNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet

- WiringDocument147 pagesWiringYovani Cortes50% (2)

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- Ignatian SpiritualityDocument16 pagesIgnatian SpiritualityMihai Frentz100% (2)

Transeng Eps13605

Transeng Eps13605

Uploaded by

Hallisa TamiciOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transeng Eps13605

Transeng Eps13605

Uploaded by

Hallisa TamiciCopyright:

Available Formats

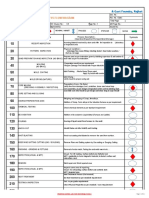

450 RIGID PAVEMENT Item 451 Reinforced Portland Cement Concrete Pavement

451.06 Placing Concrete. Delete last paragraph and add the following paragraphs: The City prepares four test cylinders from each 100 cubic yards (90m3) of concrete, or fraction thereof, each day. Test cylinders are made and tested in accordance with ASTM C 31 AND C 39. Testing includes breaking one cylinder after 7 days and two cylinders after 28 days (one cylinder is a hold cylinder). Use concrete, which develops an average seven-day compressive strength of 2,900 psi (20,000 kPa) and a minimum strength of 2,400 psi (16,550 kPa) and develops an average 28 day compressive strength of 4,000 psi (27,575 kPa) and a minimum strength of 3,400 psi (23,450 kPa). Increase the cement content of the mix without additional cost to the City when cylinders fall below the average compressive strengths of 2,900 psi (20,000 kPa) (seven-day) and 4,000 psi (27, 575 kPa) (28-day). Pavement will be rejected when cylinders fall below the minimum compressive strengths of 2,400 psi (16,550 kPa) (seven-day) and 3,400 psi (23,450 kPa) (28-day). Plan work so that the placing of concrete proceeds from the lower to the higher points along the profile of the street. Concrete placement may not proceed from higher to lower points when the grade is more than three percent without the approval of the Engineer. 451.08 Joints. Add after the sixth paragraph: Plan and execute paving and sawing operations so that any paving and/or sawing work is not in violation of the Citys Noise Ordinance unless otherwise directed or authorized in writing by the Engineer. D. Contraction Joint. Add after the final paragraph:

Construct contraction joints approximately 15 feet (4.6 m) apart unless otherwise directed by the Engineer. 451.09 Finishing. Delete the last paragraph of this section. 451.11 Removing Forms. Add: Cure concrete for at least 12 hours before removing forms. Leave the forms in place for at least 48 hours when the temperature is below 50o F. (100 C).

34

Item 499 Concrete General

499.06 Equipment. Add: C. Mobile Volumetric Batching and Continuous Mixing Plant. Provide mobile mixers capable of producing thoroughly mixed and uniform concrete within the specified mixing period and to discharge and distribute the mixture without segregation on the prepared grade as approved by the Engineer. The mixing mechanisms, calibrated proportioning devices, and equipment dial scales for each mobile mixer to be inspected and sealed by the City approved laboratory for conformance with ASTM C685-71T at no cost to the City. The Supplier's central loading plants or loading pads utilized for the loading cycle of the mobile mixers to meet the requirements of ASTM C94-71. Make available to a City approved laboratory the specified recommendations of the equipment manufacturer in the operation of the equipment and the calibration and use of the various equipment control devices necessary to produce City of Cincinnati specification concrete during the sealing of the mixer equipment and at such other times as recalibration of controls of the equipment are necessary. Comply with the strength requirements for acceptance under ASTM C685-71T for concrete mixed with mobile volumetric mixing plant under this item. Proportion mix to meet the design strength requirements of an over design factor of 1.34, consistent with obtaining a coefficient of variation of the tested concrete of 20 percent. Use this coefficient of variation until a history of use of the individual plant within a six-month period proves otherwise to the satisfaction of the City Engineer. 499.09 Mixing Concrete. Delete second last paragraph.

35

You might also like

- Concrete Batch Plant Operator Study GuideDocument49 pagesConcrete Batch Plant Operator Study Guiderajam199771% (7)

- Shotcrete RequirementsDocument16 pagesShotcrete Requirementstinz_3100% (2)

- Method Statement For Pile Head BreakingDocument18 pagesMethod Statement For Pile Head BreakingLijo Joseph100% (6)

- Inspection Checklist For Concrete Placement Pre & Post PlacementDocument4 pagesInspection Checklist For Concrete Placement Pre & Post PlacementUsman ShahidNo ratings yet

- Precast Post Tentioned TanksDocument20 pagesPrecast Post Tentioned TanksMarcel SteoleaNo ratings yet

- FHWA Shotcrete Guide SpecificationDocument7 pagesFHWA Shotcrete Guide SpecificationHector GalvezNo ratings yet

- BBS Book (PT 14) NeglyDocument7 pagesBBS Book (PT 14) Neglyapi-3871208No ratings yet

- Airport Literature StudyDocument15 pagesAirport Literature StudySoundar Rajan100% (2)

- Leg Support Calculation PDFDocument2 pagesLeg Support Calculation PDFSanjay MoreNo ratings yet

- Cellular Concrete Specifications Latest On 4-13Document3 pagesCellular Concrete Specifications Latest On 4-13diracmoutinhoNo ratings yet

- SP 401Document9 pagesSP 401azamislam726537No ratings yet

- Revision of Section 601 Latex Modified ConcreteDocument4 pagesRevision of Section 601 Latex Modified ConcreteSolomon AhimbisibweNo ratings yet

- Memo 097.7 - 121619 - Item 456 Tunnel Concrete LiningDocument5 pagesMemo 097.7 - 121619 - Item 456 Tunnel Concrete LiningBai Alleha MusaNo ratings yet

- Circular For Paver Blocks IRC SP 63-2004Document21 pagesCircular For Paver Blocks IRC SP 63-2004Ashwin SrikantaiahNo ratings yet

- Part417 Continuous Flight Auger PilesDocument5 pagesPart417 Continuous Flight Auger PilesNaga RjkNo ratings yet

- 2014 NYC Building Code BC1905 Concrete Quality, Mixing and PlacingDocument12 pages2014 NYC Building Code BC1905 Concrete Quality, Mixing and PlacingJohn DoeNo ratings yet

- Section V-2 Concrete Classes and Mixes: 502.01 DescriptionDocument5 pagesSection V-2 Concrete Classes and Mixes: 502.01 DescriptionAbdullah Aboodi67% (3)

- Specifications For Interlocking Concrete Blockpavement PDFDocument21 pagesSpecifications For Interlocking Concrete Blockpavement PDFVijaya KumarNo ratings yet

- ASTM C494 Admixtures Types A, F or G & Self Compacting Concrete (SCC) AdmixturesDocument3 pagesASTM C494 Admixtures Types A, F or G & Self Compacting Concrete (SCC) AdmixturesaminiskandarNo ratings yet

- Technical Specifications For Piling WorksDocument10 pagesTechnical Specifications For Piling WorksArzath SajeerNo ratings yet

- BIW Ref: 00-SP-03-3000 Rev 03Document46 pagesBIW Ref: 00-SP-03-3000 Rev 03niuxiaoliangNo ratings yet

- University of Northern PhilippinesDocument8 pagesUniversity of Northern PhilippinesMichael Mark Deompoc TimoteoNo ratings yet

- Rubble ConcreteDocument537 pagesRubble ConcreteRoshan Nanjundaiah100% (3)

- Dhofar Power Company Saog: Mott Macdona IdDocument1 pageDhofar Power Company Saog: Mott Macdona Id54045114No ratings yet

- DCA2007SS 07 PageDocument12 pagesDCA2007SS 07 PageAJITSINGHNo ratings yet

- Technical Specification For Micropile ConstructionDocument9 pagesTechnical Specification For Micropile ConstructionFFerideKochanNo ratings yet

- CPN SppsdsDocument10 pagesCPN SppsdsaliNo ratings yet

- Structural ConcreteDocument11 pagesStructural ConcreteNoel TerreNo ratings yet

- Spec 451 Reinforced Portland Cement Concrete PavementDocument6 pagesSpec 451 Reinforced Portland Cement Concrete PavementCharan ReddyNo ratings yet

- PillingDocument21 pagesPillingHadiyan RosyidiNo ratings yet

- Part 8 Kerbs, FootwaysDocument11 pagesPart 8 Kerbs, FootwaysElvis GrayNo ratings yet

- Technical Specification - Concrete WorksDocument5 pagesTechnical Specification - Concrete Workshendra djangNo ratings yet

- Section 503 Prestressed Concrete Members: 503.1 DescriptionDocument7 pagesSection 503 Prestressed Concrete Members: 503.1 DescriptionSyed Ali Raza ShahNo ratings yet

- Annex A - Technical SpecificationsDocument50 pagesAnnex A - Technical SpecificationsGAhr CeredonNo ratings yet

- SECTION 03 30 00 Cast-In-Place ConcreteDocument36 pagesSECTION 03 30 00 Cast-In-Place ConcreteJuanPaoloYbañezNo ratings yet

- Specifications For Concrete SleepersDocument28 pagesSpecifications For Concrete Sleepersgerfreecalls50% (2)

- Specification Jila Seva Sadan - 3Document176 pagesSpecification Jila Seva Sadan - 3Jignesh P KoratNo ratings yet

- Interlocking Bricks ProcedureDocument14 pagesInterlocking Bricks ProcedureSpchethan Chethansp100% (2)

- Sub Head 5.0: Reinforced Cement Concrete WorkDocument16 pagesSub Head 5.0: Reinforced Cement Concrete WorkPritam DharNo ratings yet

- Concrete PropertiesDocument14 pagesConcrete PropertiesIm ChinithNo ratings yet

- Item P-610 Structural Portland Cement Concrete 105Document11 pagesItem P-610 Structural Portland Cement Concrete 105Anthony McguireNo ratings yet

- Section 16 Plain and Reinforced Concrete: Code.16Document28 pagesSection 16 Plain and Reinforced Concrete: Code.16maeNo ratings yet

- Pervious+Concrete+SPEC Jan+2019Document12 pagesPervious+Concrete+SPEC Jan+2019Arvin BhurtunNo ratings yet

- Production MergedDocument89 pagesProduction Mergedpavelmagin78No ratings yet

- Appendix 6.1 Structural Repairs To RCC Columns, Beams and SlabsDocument4 pagesAppendix 6.1 Structural Repairs To RCC Columns, Beams and SlabsNirmal KishorNo ratings yet

- Public Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inDocument10 pagesPublic Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inSanthosh BabuNo ratings yet

- Precast Reinforced Concrete Vaults - MSTDocument9 pagesPrecast Reinforced Concrete Vaults - MSTwafikmh4No ratings yet

- Construction Specification Guideline For Concrete Streets and Local Roads IS119P 4Document24 pagesConstruction Specification Guideline For Concrete Streets and Local Roads IS119P 4wickremasingheNo ratings yet

- MF (1) 1Document24 pagesMF (1) 1Suranga ManuNo ratings yet

- Example Specifications For CEMATRIX Cellular ConcreteDocument9 pagesExample Specifications For CEMATRIX Cellular ConcreteRaffy Shaun CentenoNo ratings yet

- 03300Document13 pages03300Jeffrey Carlo Viduya AgliamNo ratings yet

- UG-IV-1-Concrete WorkDocument8 pagesUG-IV-1-Concrete WorkshreejeshNo ratings yet

- Irc DLCDocument56 pagesIrc DLCAniket Salvi100% (5)

- Trans 3 70 Portland Cement Concrete PavementDocument28 pagesTrans 3 70 Portland Cement Concrete Pavementjuandlc3368No ratings yet

- IRS T39 PSC SleepersDocument28 pagesIRS T39 PSC Sleepersradhakrishnang100% (2)

- Technical Detils of SiteDocument3 pagesTechnical Detils of SitePtpgStucNo ratings yet

- Concrete DocumentDocument8 pagesConcrete DocumentramNo ratings yet

- QCS 2010 Part 6.08 Kerbs, Footways and Paved AreasDocument8 pagesQCS 2010 Part 6.08 Kerbs, Footways and Paved AreasRotsapNayrbNo ratings yet

- Specs For Precast Sub ElementsDocument11 pagesSpecs For Precast Sub ElementsTimothy CruseNo ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Concrete-Block Manufacture - Processes and MachinesFrom EverandConcrete-Block Manufacture - Processes and MachinesRating: 5 out of 5 stars5/5 (1)

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- Petroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityDocument13 pagesPetroleum Engineering Lab 1 (PGE313) Experiment 2 Determination of PorosityAli AbubakarNo ratings yet

- Describe Physical and Chemical Change OperationallyDocument2 pagesDescribe Physical and Chemical Change OperationallyMaria Anna GraciaNo ratings yet

- NEW Sales Tax Invoice - 2023-07-27T164634.549Document1 pageNEW Sales Tax Invoice - 2023-07-27T164634.549Saadat IrfanNo ratings yet

- HDR10+ System Whitepaper: September 4, 2019 HDR10+ Technologies, LLCDocument14 pagesHDR10+ System Whitepaper: September 4, 2019 HDR10+ Technologies, LLCDragomir ConstantinNo ratings yet

- Valve Body 55Document3 pagesValve Body 55Davidoff RedNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- ManvantaraDocument3 pagesManvantaraafterragnarokNo ratings yet

- 6 Landforms - SCIENCEDocument9 pages6 Landforms - SCIENCEArianne RealNo ratings yet

- Water Content in SoilDocument4 pagesWater Content in SoilJohn Paul CristobalNo ratings yet

- The Harrod-Domar Growth ModelDocument6 pagesThe Harrod-Domar Growth ModelSimeonNo ratings yet

- Bored Piles - Bilfinger Spezialtiefbau GMBHDocument4 pagesBored Piles - Bilfinger Spezialtiefbau GMBHOga MeoNo ratings yet

- ToR For Fiberglass Biogas Plants Installation - EOI PDFDocument4 pagesToR For Fiberglass Biogas Plants Installation - EOI PDFmy09No ratings yet

- HwyconstDocument23 pagesHwyconstAmulie JarjuseyNo ratings yet

- Gear Trains: 8.1. Angular Velocity RatioDocument16 pagesGear Trains: 8.1. Angular Velocity RatioaddisudagneNo ratings yet

- X PPT CH 12 ElectricityDocument12 pagesX PPT CH 12 ElectricityAakriti100% (1)

- Drawing Details: Cie 332 Quantity Surveying and Estimation Lecture Two Lecturer: Eng. Goodson MashekaDocument23 pagesDrawing Details: Cie 332 Quantity Surveying and Estimation Lecture Two Lecturer: Eng. Goodson MashekaPerpetual hubbyNo ratings yet

- Electronics Cooling: Mechanical Power Engineering DeptDocument22 pagesElectronics Cooling: Mechanical Power Engineering DeptneilNo ratings yet

- Straumann Product Catalogue 2018 2019Document260 pagesStraumann Product Catalogue 2018 2019kllasikalleNo ratings yet

- CR Unit 1 &11 (Part A &B)Document12 pagesCR Unit 1 &11 (Part A &B)durai muruganNo ratings yet

- Abb Reg615 Ansi Appl 859072 EndDocument124 pagesAbb Reg615 Ansi Appl 859072 EndjppreciadomNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet

- WiringDocument147 pagesWiringYovani Cortes50% (2)

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- Ignatian SpiritualityDocument16 pagesIgnatian SpiritualityMihai Frentz100% (2)