Professional Documents

Culture Documents

Sibre Crane Wheel Systems

Sibre Crane Wheel Systems

Uploaded by

dotsy11Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sibre Crane Wheel Systems

Sibre Crane Wheel Systems

Uploaded by

dotsy11Copyright:

Available Formats

etc.

ing function. , a broad variety of options is available. s of diameter 315 to 1000 mm as well as complete wheel ing or as design proposal approved by our customer. Driven- high ders of material 42CrMo4V. For particularlyand Non-Driven educed tread-wear.

Sibre Crane Wheel Systems b Assemblies with roller

oller bearing similar to DIN 15090

pict. 1: Driven Wheel Assembly: T- BHKE 500x90 Z 100x152 222

Alterations re Siegerland Bremsen Emde GmbH & Co. KG Au Tel.: +49 2773 94000 Fax: +49 2773 9400-1

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Co

pict. 2: Non-Driven Wheel Assembly: M- BHKE 500x90 222

Sibre Crane Wheel Systems

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

General

B06 20 224 E-EN page 2 / 12 11.2008

Wheels are machine-components with load bearing function. When selecting wheels and their material quality, a broad variety of options is available. Our production portfolio includes separate wheels of diameter 315 to 1000 mm as well as complete wheel assemblies similar to DIN, as per customer drawing or as design proposal approved by our customer. SIBRE standard wheels are made of forged cylinders of material 42CrMo4V. For particularly high demands the wheels can be deep-hardened for reduced tread-wear.

Applications

Gantry Travel Drives Trolley Travel Drives Slewing Drives etc.

Driven- and Non-Driven Assemblies with roller bearing similar to DIN 15090

pict. 1: Driven Wheel Assembly: T- BHKE 500x90 Z 100x152 222

pict. 2: Non-Driven Wheel Assembly: M- BHKE 500x90 222

Sibre Crane Wheel Systems

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

B06 20 224 E-EN page 3 / 12 11.2008

pict. 3: Driven Wheel Assembly: T- SHKD 500x90 P 90x132

pict. 4: Non-Driven Wheel Assembly: M- SHKD 500x90 222

codification of Wheels

T BHKE 500x90 Z100x152 222 bearing series shaft end as adapter shaft 100x152, series 2 wheel , dimension b1 wheel shape codification

driven wheel assembly

Wheel shape codification

code

S B

H

G K D E

meaning narrow wheel wide wheel wheel with flanges wheel without flanges wheel without rim with oil-pressure interference fit assembly without oil-pressure interference fit assembly

Sibre Crane Wheel Systems

C1-30-EN C1-30-EN

SIBRE Crane Wheel Systems SIBRE Crane Wheel Systems SIBRE Crane Wheel Systems Laufradsysteme Laufradsysteme Laufradsysteme

Shaft Types of driven Wheel Assemblies Shaft Types of driven Wheel Assemblies Shaft Types of driven Wheel Assemblies

We supply driven wheel assemblies with shafts for any type of drive We supply driven wheel assemblies with shafts for any type of drive We supply driven wheel assemblies with shafts type any type of drive for

Ausf hr ung " P" Ausf hrtype " P" ung Ausf hrtype " P" ung

C1-30-EN B06 20 224 E-EN B06 20 224 12 page 4 / E-EN 20 224 E-E B06 page 4 / 12 11.2008 page 4 / 12 11.2008 11.2008

Ausf hrtype " Z" ung Ausf hrtype " Z" ung Ausf hrtype " Z" ung

Ausf hrtype " H" ung Ausf hrtype " H" ung Ausf hrtype " H" ung

Ausf hrtype " V" ung Ausf hrtype " V" ung Ausf hrtype " V" ung

DI N 5480 DI N 5480

DI N pict. 5480

pict. 5 5

with connecting shaft resp. coupling hub with connecting shaft resp. coupling hub with key-way acc. connecting shaft resp. coupling hub with DIN 6885 T1 with key-wayacc. DIN 5480 T1 DIN 6885 with gearing acc. key-way acc. DIN 6885 T1 with with gearing acc. DIN 5480 on gear box with extendedwith gearing acc. DIN 5480 shaft for slide with shrink disc shaft for slide on gear with extendedwith extended shaft for box on gear box slide with shrink disc with shrink disc

type Z type Z type P type P type V type H type V type H

pict. 5

type Z type P type V type H

Selection Parameter Selection Parameter Selection Parameter

For an optimum selection, the following parameter must be indicated by the customer For an optimum selection, the following parameter must be indicated by the customer For an optimum selection, the following parameter must be indicated by the customer wheel load wheel load rail profile and material wheel load rail profile and material travelling speed, rotation speed rail profile and material travelling speed, rotation speed life expectiation travelling speed, rotation speed life expectiation ambient conditions life expectiation ambient conditions dimensions availableassembly conditions ambient available assembly dimensions wheel shape B (wide), S (narrow) available assembly dimensions wheel shape end (wide), S (narrow) type of shaft B for shapewheel assemblies wheel drive B (wide), S (narrow) type of shaft end for drive wheel assemblies type of shaft end for drive wheel assemblies Wheel calculation is made acc. to DIN 15070 and the bearing calculation is made acc. to DIN 15071. Wheel calculation is profile and rail is 15070 and the DIN 15072. Correlation of Wheel made acc. to DINselected acc. to bearing calculation is made acc. to DIN 15071.to DIN 15071. wheel Correlation of wheel calculation rail is selected acc. to DIN 15072. bearing calculation is made acc. profile and is made acc. to DIN 15070 and the Correlation of wheel profile and rail is selected acc. to DIN 15072.

Sibre Crane Wheel Systems

C1-30-EN C1-30-EN

SIBRE Crane Wheel Systems SIBRE Crane Wheel Systems Laufradsysteme Laufradsysteme

Support of Wheel Assemblies Support of Wheel Assemblies

B06 20 224 E-EN B06 20 224 12 page 5 / E-EN page 5 / 12 11.2008 11.2008

In parallel to the wheel assemblies with 45 split support (pict. 6), we can also supply driven- and nonIn parallel to assemblies with rectangular split support (pict. 7) similar to also supply driven wheel the wheel assemblies with 45 split support (pict. 6), we canTGL 34968. driven- and nondriven wheel assemblies with rectangular split support (pict. 7) similar to TGL 34968.

pict. 6: pict. 6: 45 split support 45 split support

pict. 7: pict. 7: rectangular split support rectangular split support

B06 20 224 E-EN SIBRE Crane Wheel Systems 12 page 6 / SIBRE Crane Wheel Systems Laufradsysteme 11.2008 Laufradsysteme

Sibre Crane Wheel Systems

b2 b1 b2 b1 9 10 16 11 1 11 16 10 1 11 16 10 9 15 15 15 n n 7 12 d2 d1 d 3d 5 d4 11 l 5 n 11 9

C1-30-EN

Dimensions and Nomenclature of Wheel Assemblies Dimensions and Nomenclature of Wheel Assemblies

9 10 16 11

15

l 5

7 12 d2 d1 d5 d4

Area drawn 15 offset Ber ei ch um 15 ver set zt gez Area drawn 15 offset Ber ei ch um 15 ver set zt gezei chnet

d3

17 4 2

17 4

d7 2 8 6 14 6 3 13 l 2 l 12

13 13 3 5 14 l 6 l 1 l 2 3 14 5 6 14 3 l 1 13

8 6

l 6 l 12

pict. 8: pict. 8: driven wheel assembly type T-BHKE driven wheel assembly type T-BHKE

9 10 16 11 b2 b1 b2 b1 9 10 16 11 1 11 16 10 9 1 11 16 10 9 15 15 15 7 n l 57 n n l 5 n 15

12 12 d2 d1 d5 d3 d4 d2 d1 d5 d4 17 4 4

Area ch um 15 ver Ber ei drawn 15 offset set zt ge Area ch um 15 ver Ber ei drawn 15 offset set zt gezei chnet 12 12

17

17

d3

17

2 2 4 4

13 13 3 3 5 14 l 1 l 6 14 l 1 5 14 6 l 1 3 13 l 6 14 l 1 6 3

13

Alterations reserved Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke +49 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: 1-5 2773 9400-10 e-mail: info@sibre.de www.sib

pict. 9: pict. 9: non-driven wheel type M-BHKE non-driven wheel type M-BHKE

Sibre Crane Wheel Systems

C1-30-EN

C1-30-E

SIBRE Crane Wheel Systems SIBRE Crane Wheel Systems Laufradsysteme Laufradsysteme

B06 20 224 E B06 20 224 E-EN page 7 / 1 page 7 / 12 11.2008 11.2008

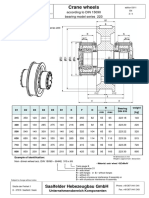

Driven- & Non-Driven Assemblies with spherical roller bearing series 222 Driven- & Non-Driven Assemblies with spherical roller bearing series 222

dimensions and shape for wheels dimensions1) and shape for wheels 2) 6) 3) 6) d1 2) Form 6) b1 b d2 d3 6) d4 d5 l5 l1 3) 2 1) Form b1 b2 d3 d5 l5 l1 l6 n d2 d4 +0,15 h9 h7 h7 +0,05 171 S 45-55 90 110 210 220 315 350 110 S 45-55 90 110 210 220 171 173 B 55-65 110 120 230 240 350 110 235 62 B 55-65 110 120 230 240 173 120 230 240 188 S 55-65 110 400 440 S 55-65 110 120 230 240 188 265140 62 B 70-90 140 130 250 260 202 440 140 B 70-90 140 130 250 260 202 280 72 S 55-65 110 130 250 260 202 500 540 S 55-65 110 130 250 260 202 280140 72 B 70-90 140 140 265 275 210 540 140 B 70-90 140 140 265 275 210 290 82 S 65-75 120 160 290 305 150 237 630 680 S 65-75 120 160 290 305 150 237 325 B 80-110 160 180 330 345 160 94 245 680 B 80-110 160 180 330 345 160 245 335 S 75-90 140 170 310 325 180 249 710 760 S 75-90 140 170 310 325 180 249 350 94 B 95-160 210 190 350 365 210 278 760 B 95-160 210 190 350 365 210 278 395 104 180 330 345 180 255 S 75-90 140 800 850 S 75-90 140 180 330 345 180 255 355 94 B 95-160 210 200 370 385 210 289 850 B 95-160 210 200 370 385 210 289 405 114 190 350 365 190 268 S 75-90 140 900 950 S 75-90 140 190 350 365 190 268 375 104 B 95-160 210 230 420 435 210 315 950 B 95-160 210 230 420 435 210 315 430 134 200 370 385 190 279 S 75-90 140 1050 S 1000 75-90 140 200 370 385 190 279 385 114 B 95-160 210 250 480 500 210 332 1050 B 95-160 210 250 480 500 210 332 450 146

d1 h9 315 400 500 630 710 800 900 1000

dims. only for driven whe Roller dims. only for driven wheel Roller assemblies bearings bearings acc.assemblies 4) 4) l6 l12 d7 7 acc. n DINd 4) 635-2 l l2 dd4) l12 7 12 7 DIN 635-2 l2 +0,15 +0,05 series1 series 5) series1 series 2 222 18 185 70 235 1862 185 222 70 105 105 80 222 20 190 70 222 20 190 70 105 80 120 265 62 222 20 205 70 105 80 222 20 205 70 105 80 120 280 72 222 22 215 80 120 90 222 22 215 80 120 90 132 280 72 222 22 215 90 80 132 120 222 22 215 90 100 290 82 222 24 120 225 80 222 24 225 100 152 325 222 26 250 100 222 2694 250 100 222 30 265 100 152 335 152 110 222 30 265 100 152 110 350 94 222 28 260 100 110 152 222 28 260 100 110 152 395 104 222 32 152 300 110 130 222 32 300 110 130 172 355 94 222 30 275 110 152 120 222 30 275 110 152 120 172 405 114 222 34 310 130 172 140 222 34 310 130 172 140 202 375 104 222 32 290 130 222 32 290 130 172 430 134 222 40 335 140 202 160 222 40 335 140 202 160 202 385 114 222 34 300 140 222 34 300 140 202 450 146 222 44 355 160 202 180 222 44 355 160 202 180 252

1) S = narrow wheel B = wide wheel 1) S = narrow2) dimension for track gauge b1 when ordering please advise wheel B = wide wheel 2) dimension 3) interference fit 1of wheel and shaft; H7 /advise for track gauge b when ordering please u6 3) interference fit of wheelfor d7shaft;to DIN 15091. 4) tolerance and acc. H7 / u6 4) tolerance for d7 acc.2 isDIN 15091. 5) series to in accordance with cardan shaft classification acc. to DIN 15450. 5) series 2 is 6) accordance with S dimensionsclassification not identical15450. in for wheel shape cardan shaft b2 and l5 are acc. to DIN 6) for wheel shape S dimensions b2 and l5 are not identical

approx. Weights of Driven- & Non-Driven Wheel Assemblies approx. Weights of Driven- & Non-Driven Wheel Assemblies

series 222 1) S = narrow wheel B = wide wheel. weight2) series 222 B = wide wheel. Wheel = in kgs1) S = narrow wheel weight2) 1) 3) Wheel d = in kgs 3) 2) weight calculation is based on series 2 of driven shape3) 1) 1 3) non-driven driven non-driven HK 2) weight calculation is based on series 2 of flange shape h9 d1 shaft ends, without connecting HK GK GK shaft ends, without coupling disc, referring to max. b1. h9 HK S GK 100 HK - GK 95 resp. connecting flange resp. coupling disc, referring to are approx. figures and 315 100 S Indicated weights max. b1. B - 150 95 - - 145 315 Indicated weightssupposed to provideandorientation. are are approx. figures an B 150 S - 155 145 - - 150 are supposedTheprovide weight depends on the to actual an orientation. 400 155 S B - 230 150 220 - 220 210 400 The actual weight depends on and the selected selected version the B 230 S 220 215 220 - 210 205 selected version and the selected manufacturing process. S 500 215 B - 315 205 300 - 305 manufacturing process. 290 500 B 315 S 300 360 305 - 290 345 3) see codification S 630 360 B - 560 345 530 - 540 3) see codification 515 630 B 560 S 530 475 540 - 515 460 S 710 475 B - 820 460 780 - 790 755 710 B 820 S 780 580 790 - 755 560 800 580 S 560 960 - 975 B - 1010 930 800 B 1010 S 960 700 975 - 930 675 S 900 700 B - 1310 675 1240 - 1260 1220 900 B 1310 S 1240 865 1260 - 1220 835 S 1000 865 B - 1680 835 1590 - 1610 1570 1000 B 1680 1590 1610 1570

Alterations reserved Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany

Sibre Crane Wheel Systems

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Parts List for Driven- & Non-Driven Wheel Assemblies

quantities for wheel- d1 Pos. No. Nomenclature 315 S 1 wheel B 400 S B 500 S B Driven Wheel assy 630 S B 1 710 S B 800 S B 900 S B 1000 S B 315 S B 400 S B 500 S B Non-driven wheel assy 630 S B 1 710 S B 800 S B 900 S B

B06 20 224 E-EN page 8 / 12 11.2008

material / DIN 1000 S B 42CrMo4V

wheel shaft

42CrMo4V

bearing frame

St 52-3

cover

St 52-3

cover

St 52-3

cover

St 52-3

shaft washer

St 52-3

wheel bushing

C 45

nipple adapter

9SMn28K

10

spherical roller bearing

222 SNR premier

11

shaft sealing

NBR

12

hexagon screw

DIN 933-8.8 VZ

13

hexagon screw

16

16

16

16

24

16

24

24

24

24

16

16

16

16

24

16

24

24

24

24

DIN 931-8.8 VZ

14

hexagon nut

16

16

16

16

24

16

24

24

24

24

16

16

16

16

24

16

24

24

24

24

DIN 934-8 VZ

15

grease nipple

DIN 3404 A2

16

grub screw

DIN 913-45H VZ

17

lock washer

B 53070 VZ

Sibre Crane Wheel Systems

C1-30-EN

C1

SIBRE Crane Wheel Systems Systems SIBRE Crane Wheel Laufradsysteme Laufradsysteme

Basics of Wheel Assembly Calculation (extract of DIN(extract of DIN 15070) Basics of Wheel Assembly Calculation 15070)

Calculation of wheels: Calculation of wheels: The wheel force isThe wheel force following formula: following formula: calculated acc. is calculated acc.

B06 20 224 E-EN B06 20 22 page 9 / 12 page 9 11.2008 11.20

R p zul c 2 c 3 R pk 2 r1 c 3 d1 (k 2(1)) d1 ( zul c 2 ) r1

The result is the wheelresult is the wheel diameter: The diameter:

(1)

d1 =

R R d1 = (2) p zul c 2 c 3 (k 2 r1)c 2 c 3 (k 2 r1 ) p zul

R k-2r pzul d1 c2 c3

(2)

= wheel force [N] = wheel force [N] R = ideal usable width ideal usable [mm] of rail head [mm] k-2r = of rail head width = allowed pzul compression between wheel and rail [N/mm] and rail [N/mm = allowed compression between wheel = diameter 1 wheel diameter of wheel [mm] = [mm] dof = rotation speed factor [chart mating of materials] = rotation speed factor [chart mating of materials] c2 = operating3time factor [chart mating of materials] = operating time factor [chart mating of materials] c

The characteristic The characteristicthe result of equation (1) if: of equation (1) if: wheel force R0 is wheel force R0 is the result pzul c2 c3 inserted to: inserted to: R 0 = 5,6 N/mm pzul =1 c2 =1 c3 = 5,6 N/mm =1 =1 (3) (3)

= 5,6 d1 (k 2 r1 )5,6 d1 (k 2 r1 ) R0 =

R0

= characteristic wheel force = characteristic wheel force R0

By usage of characteristic wheel force the allowed wheel the allowed wheel force can By usage of characteristic wheel force force can be calculated simplified by following formula following formula be calculated simplified by

R R 0 c 1 c 2 c 3 R 0 c 1 c 2 c 3 R

(4)

(4)

For crane wheels: For crane wheels: + 2 R max R + 2 R max R R = min R = min 3 3 Rmax Rmin For trolley wheels:For trolley wheels:

(5)

(5)

= max wheel force=[N] wheel force [N] max Rmax = min. wheel force=[N] wheel force [N] min. Rmin

R = R max

R = R max

(6)

(6)

Rmax and Rmin should be found by the frequent operatingfrequent operating position of charged trolley. Rmax and Rmin should be found by the position of charged trolley.

Sibre Crane Wheel Systems

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Mating of Materials Rail / Wheel

allowed compression pzul and material- factor c1 material pzul tensile strength at least c1 N/mm N/mm rail wheel 590 330 2.8 0.5 410 3.6 0.63 490 4.5 0.8 590 5.6 1.0 690 740 7.0 1.25 operating time- factor c3 Operating time c3 of travel drive (referred to 1 hour) up to 16% 1.25 over 16 25% 1.12 over 25 40% 1 over 40 63% 0.9 over 65% 0.8

B06 20 224 E-EN page 10 / 12 11.2008

wheel - rotation speed - factor n, c2 -1 n min 200 160 125 112 100 90 80 71 63 58 50 45 40 35.5 31.5 c2 0.66 0.7 0.77 0.79 0.82 0.84 0.87 0.89 0.91 0.92 0.94 0.96 0.97 0.99 1.0 wheel - rotation speed - factor n, c2 -1 n min 28 25 22.4 20 18 16 c2 1.02 1.03 1.04 1.06 1.07 1.09

14 1.1

12.5 11.2 10 8 6.3 5.6 5 1.11 1.12 1.13 1.14 1.15 1.16 1.17

Characteristic Wheel Force R0

Chart I wheeldiameter d1 [mm] 315 400 500 630 710 800 900 1000 R0 in N narrow wheel for crane rail: A 45 A 55 A 65 65000 83000 101000 104000 126000 159000 187000 211000 R0 in N wide wheel for crane rail: A 75 A 55 A 65 A 75 A 100 79000 119000 132000 148000 165000 208000 282000 235000 318000 264000 358000 297000 403000 330000 448000

A 120 398000 448000 504000 560000

Sibre Crane Wheel Systems

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Rectified nominal life time of bearings L10h in hours [h]

B06 20 224 E-EN page 11 / 12 11.2008

Nominal characteristic- life time of bearings LKenn in hours [h] (calculatet with characteristic wheel forces R0 and the factors c1 = c2 = c3 = 1,0) for spherical roller bearings, type 222, SNR premium. Chart II wheeldiameter d1 [mm] 315 400 500 630 710 800 900 1000 narrow wheel wide wheel

for crane rail: for crane rail: A 45 A 55 A 65 A 75 A 55 A 65 A 75 A 100 A 120 336000 355000 297000 154000 215000 152000 330000 174000 155000 108000 210000 122000 218000 79000 119000 83000 83000 39000 95000 91000 43000 100000 135000 64000 114000 183000 87000

The figures for bearing lifetime L Kenn as mentioned in chart II are based on characteristic wheel force R0 with factors c1 = c2 = c3 = 1,0 according DIN 15070. Differing wheel forces and factors can be calculated simplified as follows: Nominal life time of bearings:

L10 h

1 = LKenn c Ges

10 / 3

31,5 nvorh

[h]

(7)

L Kenn: according Chart II [h] -1 n vorh: existing rotation speed [min ] C ges: total factor Based on given wheel force R and by usage of characteristic wheel force acc. DIN 15070, the total factor can be calculated simplified with following formula:

R R 0 c 1 c 2 c 3 R 0 c Ges c Ges = R R0

(8)

(9)

Sibre Crane Wheel Systems

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Example of calculation

wheel diameter wheel type existing rail average rotation speed max. wheel force min. wheel force : d1 : B : A : n vorh : R max : R min = 75 = 77 min

-1

B06 20 224 E-EN page 12 / 12 11.2008

= 400 mm

= 145 kN = 45 kN

Wheel force:

R=

R min + 2 R max 3

(5) = 111,7 kW

R=

45 + 2 145 3

Total factor:

c Ges =

R R0

= 132 kN DIN 15070 = 400 mm = A 75

(6)

R0 wheel crane rail

c Ges =

111,7 132

= 0,85

Nominal life time:

L10h

1 = L Kenn c Ges

L Kenn

10 / 3

31,5 n vorh

[h]

(7) [from chart II]

= 152000 h

10 / 3

1 L 10h = 152000 h 0,85

L10h = 106800 h

31,5 = 77

You might also like

- Reach and ICAS Sample Questions Writing Persuasive Paper IDocument6 pagesReach and ICAS Sample Questions Writing Persuasive Paper IGreta Lo100% (1)

- 3774Document8 pages3774Valter AraujoNo ratings yet

- U 336380Document332 pagesU 336380Nguyễn Văn ĐiệpNo ratings yet

- Marketing Plan of Oberoi HotelsDocument7 pagesMarketing Plan of Oberoi HotelsPooja Vaid100% (7)

- C1 30 - 3 EN Crane Wheel SystemsDocument16 pagesC1 30 - 3 EN Crane Wheel SystemsKovács EndreNo ratings yet

- Sibre Crane Wheel SystemsDocument13 pagesSibre Crane Wheel SystemsLeonardo CanditoNo ratings yet

- DesignDocument4 pagesDesignJigneshkumar PatelNo ratings yet

- Flyer Rolling Bearing AnalysisDocument4 pagesFlyer Rolling Bearing AnalysisBikash Ranjan SahooNo ratings yet

- Bhatkar (2015) - Finite Element Analysis of Crane Hook and Optimization Using Taguchi ApproachDocument5 pagesBhatkar (2015) - Finite Element Analysis of Crane Hook and Optimization Using Taguchi ApproachGogyNo ratings yet

- IS Code For StackerDocument20 pagesIS Code For StackerManish VermaNo ratings yet

- WL 00200 5 T6-8 de enDocument39 pagesWL 00200 5 T6-8 de enrwva20No ratings yet

- Axle HoldersDocument1 pageAxle HoldersjoseocsilvaNo ratings yet

- Loading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesDocument12 pagesLoading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesNenad VulićNo ratings yet

- Din 471 Ext CirclipsDocument5 pagesDin 471 Ext Circlipschaitanya_kumar_13No ratings yet

- 04274108foto BigDocument6 pages04274108foto BigvalstavNo ratings yet

- CV 01 Shaft Report Drive P5Document2 pagesCV 01 Shaft Report Drive P5Waris La Joi WakatobiNo ratings yet

- Conveyor BeltDocument13 pagesConveyor BeltRajesh KumarNo ratings yet

- Vishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479Document4 pagesVishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479divjak70No ratings yet

- 2 RollersDocument128 pages2 RollersCésarRenatoCopacondoriCuaylaNo ratings yet

- Coal Conveyor Belt Fault DetectionDocument4 pagesCoal Conveyor Belt Fault Detectionc pawarNo ratings yet

- The Performance and Service Life of Wire Ropes Under Deep Koepe and Drum Winders Conditions - Laboratory SimulationDocument9 pagesThe Performance and Service Life of Wire Ropes Under Deep Koepe and Drum Winders Conditions - Laboratory SimulationRicardo Ignacio Moreno MendezNo ratings yet

- Chassis MechanicsDocument37 pagesChassis Mechanicsneerajsingh000007No ratings yet

- Pulley Design - TrackingDocument18 pagesPulley Design - TrackingRuben SalgadoNo ratings yet

- Non-Driven Wheel DIN15090 Series 223 EN PDFDocument1 pageNon-Driven Wheel DIN15090 Series 223 EN PDFayavuzbvsNo ratings yet

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatNo ratings yet

- 11-Winches.50 2002 200603Document16 pages11-Winches.50 2002 200603Mohamed SalemNo ratings yet

- ShackleDocument2 pagesShackleRizwan Ahmed100% (1)

- Full CatalogDocument92 pagesFull CatalogYip Ying MunNo ratings yet

- AUFT ProduktkatalogDocument104 pagesAUFT Produktkatalogengineer86No ratings yet

- Stuttgart Seiltagung IMWDocument14 pagesStuttgart Seiltagung IMWSelva Kumar0% (1)

- RCA en Fajas - 2 PDFDocument6 pagesRCA en Fajas - 2 PDFVíctor Fernández Narváez100% (1)

- Design of Hyd. CylindersDocument10 pagesDesign of Hyd. CylindersVinod YbNo ratings yet

- Emm 3506 - Group 3Document132 pagesEmm 3506 - Group 3Griffin ThomasNo ratings yet

- Impact LoadDocument16 pagesImpact Loaddeepak_dce_meNo ratings yet

- As 4100Document1 pageAs 4100shiruhanNo ratings yet

- Reducing Crane Wheel Assembly Failures at Burns Harbor - CTottenDocument10 pagesReducing Crane Wheel Assembly Failures at Burns Harbor - CTottenTximis KurdiNo ratings yet

- Belt ConveyorsDocument10 pagesBelt ConveyorsRaja PalasaNo ratings yet

- Grooved Drum ArticleDocument2 pagesGrooved Drum ArticleLizardladNo ratings yet

- Slewing Bearing Inspection PDFDocument4 pagesSlewing Bearing Inspection PDFMalek Anas MahmoudNo ratings yet

- Paper Gondola WagonDocument2 pagesPaper Gondola WagonrentizahariaNo ratings yet

- O SPC07 PDFDocument124 pagesO SPC07 PDFdenisonocNo ratings yet

- MDG 12 Guide For The Construction of Friction WindersDocument23 pagesMDG 12 Guide For The Construction of Friction WindersbenssjNo ratings yet

- Slewing Gantry Crane With Double-Link System: Spare Parts CatalogueDocument28 pagesSlewing Gantry Crane With Double-Link System: Spare Parts Catalogueduyhp231296No ratings yet

- Michael M. Calistrat: Safety, Application, and Service Factors As Applied To Shaft Couplings byDocument8 pagesMichael M. Calistrat: Safety, Application, and Service Factors As Applied To Shaft Couplings byronny_fernandes363No ratings yet

- Chapter 2-Gear SystemDocument26 pagesChapter 2-Gear SystemNui Yuhu KuwNo ratings yet

- Crane Rail Selection: Calculation of Required Rail Head WidthDocument1 pageCrane Rail Selection: Calculation of Required Rail Head WidthMAHMOUD YOUNISNo ratings yet

- Belt Conveyor Idler CatalogDocument160 pagesBelt Conveyor Idler CatalogFer LopezNo ratings yet

- Conveyor Chain Design GuideDocument64 pagesConveyor Chain Design GuideAtacomaNo ratings yet

- Selecting A Conveyor DriveDocument7 pagesSelecting A Conveyor Drivegopi_ggg20016099100% (1)

- How To Tackle Convergence Issues Without Compromising Accuracy in Any Static Structural Non Linear Analysis Using ANSYS Workbench 13Document5 pagesHow To Tackle Convergence Issues Without Compromising Accuracy in Any Static Structural Non Linear Analysis Using ANSYS Workbench 131105456No ratings yet

- 2.2 Peter DelphinDocument32 pages2.2 Peter DelphinANANo ratings yet

- 31 SeriesDocument4 pages31 SeriesJESUSCALVILLONo ratings yet

- Machine Element Moving Parts Linear Rotation Around A Fixed Axis Vectors Normal ForcesDocument8 pagesMachine Element Moving Parts Linear Rotation Around A Fixed Axis Vectors Normal Forceslavish100% (1)

- Calculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMADocument9 pagesCalculation of Artificial Friction Conveying Coefficient F, and A Comparison Between ISO and CEMAretrospect1000No ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Gantry Crane WheelDocument12 pagesGantry Crane Wheelspnatu100% (1)

- STAR - Linear Bushings and ShaftsDocument236 pagesSTAR - Linear Bushings and ShaftsGiuseppe CondòNo ratings yet

- Icp Sibre Non Driven Crane Wheel Assembly eDocument12 pagesIcp Sibre Non Driven Crane Wheel Assembly eLVBNo ratings yet

- Sibre Crane Wheel Systems PDFDocument13 pagesSibre Crane Wheel Systems PDFLuka BornaNo ratings yet

- Sibre Crane Wheel Systems PDFDocument13 pagesSibre Crane Wheel Systems PDFZehNo ratings yet

- ISR Price ListDocument6 pagesISR Price ListPhilip KamardinNo ratings yet

- Roller BrochureDocument16 pagesRoller BrochurePeterson MagroNo ratings yet

- 3002 - SCS - Pump StationsDocument2 pages3002 - SCS - Pump StationsBhavanishankar ShettyNo ratings yet

- Virtual CockpitDocument10 pagesVirtual CockpitNavaneeth Krishnan BNo ratings yet

- Intercity Express Ice T - Class 411 High Speed TrainDocument14 pagesIntercity Express Ice T - Class 411 High Speed TrainOmar TahaouiNo ratings yet

- Data Acquisition Catalog enDocument17 pagesData Acquisition Catalog enmsureNo ratings yet

- Cognitive Frameworks: Learning GoalsDocument8 pagesCognitive Frameworks: Learning GoalshhumasNo ratings yet

- English Practice 26: SECTION I. PPPPPPPPP: (10 Points)Document8 pagesEnglish Practice 26: SECTION I. PPPPPPPPP: (10 Points)Ken BiNo ratings yet

- E000000813.3262.Tata GroupDocument47 pagesE000000813.3262.Tata GroupKamlesh TripathiNo ratings yet

- Miniature Advanced Communication Engine (Mini-Ace) and Mini-Ace PlusDocument13 pagesMiniature Advanced Communication Engine (Mini-Ace) and Mini-Ace Plusgotcha75No ratings yet

- Cisco AP Debug Authentication ErrorDocument21 pagesCisco AP Debug Authentication ErrorveenaajainNo ratings yet

- 6 SIGMA Vs ACE Case Study-1Document13 pages6 SIGMA Vs ACE Case Study-1gopala krishnaNo ratings yet

- Siemens SAS61.03U User GuideDocument50 pagesSiemens SAS61.03U User GuideSaulo TrejoNo ratings yet

- Daihatsu Sirion Model m300 Series Service Manual No9890 Door Lock Theft DeterrentDocument42 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 Door Lock Theft DeterrentMarx RedzNo ratings yet

- Series CouplingsDocument8 pagesSeries CouplingsEagle1968No ratings yet

- Motor de Partida - IPU MANUAL Hy-Starter 12072401Document85 pagesMotor de Partida - IPU MANUAL Hy-Starter 12072401Luiz Alberto MagriNo ratings yet

- Fortisalberta Inc. D02-06 Design Policies: Double Circuit Distribution LinesDocument18 pagesFortisalberta Inc. D02-06 Design Policies: Double Circuit Distribution LineskiyottaNo ratings yet

- Ed 4Document2 pagesEd 4Vaibhav KumarNo ratings yet

- 1679 10099Document52 pages1679 10099Benjamín LarrozaNo ratings yet

- 4teen - Virtual Advertising Agency Business Plan - PDFDocument9 pages4teen - Virtual Advertising Agency Business Plan - PDFMustafa ZamanNo ratings yet

- Yotpo Generic Installation Manual - v.2.0.Document27 pagesYotpo Generic Installation Manual - v.2.0.Dino TomljanovićNo ratings yet

- SIMATIC-IOT2020 FlyerDocument2 pagesSIMATIC-IOT2020 FlyerJorge_Andril_5370No ratings yet

- B767 IPC SupplementDocument133 pagesB767 IPC Supplementadonis hernandezNo ratings yet

- Perf MonDocument4 pagesPerf MonsrihariNo ratings yet

- Load Schedule and Single Line Engr GorospeDocument1 pageLoad Schedule and Single Line Engr GorospeMichael Pepz DatuinNo ratings yet

- Chapter 8 Steam PipingDocument14 pagesChapter 8 Steam PipingDak Serik100% (2)

- Cooperheat 6kanalniDocument2 pagesCooperheat 6kanalnier111poNo ratings yet

- R.E.A.G.E.N.T. Final PDFDocument5 pagesR.E.A.G.E.N.T. Final PDFEsteban TamayoNo ratings yet

- Ielts Reading Test 1Document11 pagesIelts Reading Test 1Hoàng DungNo ratings yet

- Anand Automotive Limited EmailDocument9 pagesAnand Automotive Limited EmailGirish SharmaNo ratings yet