Professional Documents

Culture Documents

R07 Set No. 2

R07 Set No. 2

Uploaded by

Muhammad Asif AliCopyright:

Available Formats

You might also like

- 7 ElevenDocument2 pages7 ElevenyoosahuNo ratings yet

- Hand Over ReportDocument1 pageHand Over ReportRami Allouh Abu OmarNo ratings yet

- Arduino VDI ExperimentsDocument7 pagesArduino VDI ExperimentsJuanCarlosCaballeroNo ratings yet

- Code No: 35033Document5 pagesCode No: 35033SRINIVASA RAO GANTANo ratings yet

- Machine ToolsDocument5 pagesMachine ToolsSavantNo ratings yet

- 3-1 MT (Nov 2009 Regular)Document5 pages3-1 MT (Nov 2009 Regular)micmechNo ratings yet

- MCMT Mid-1 P-QusDocument5 pagesMCMT Mid-1 P-QusN Dhanunjaya Rao BorraNo ratings yet

- rr320303 Machine ToolsDocument4 pagesrr320303 Machine ToolsSRINIVASA RAO GANTA100% (1)

- MCMT QBDocument3 pagesMCMT QBKrishna MurthyNo ratings yet

- Estelar: Faculty of EngineeringDocument1 pageEstelar: Faculty of EngineeringPrasad Apv100% (1)

- 3.manufacturing Technology IIDocument6 pages3.manufacturing Technology IIprasanthprpNo ratings yet

- Manufacturing Technology - IIDocument2 pagesManufacturing Technology - IIMANOJ MNo ratings yet

- Up QPDocument2 pagesUp QPkannanviknesh086319No ratings yet

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNo ratings yet

- Machine Tools - 1st MID - 3rd B.tech (2009)Document2 pagesMachine Tools - 1st MID - 3rd B.tech (2009)micmechNo ratings yet

- Vsa School of Engineering, Salem Department of Mechanical Engineering Manufacturing Technology Ii Internal Test-IiDocument1 pageVsa School of Engineering, Salem Department of Mechanical Engineering Manufacturing Technology Ii Internal Test-IiDmj Anbu RajNo ratings yet

- Jntuworld: R09 Set No. 2Document6 pagesJntuworld: R09 Set No. 2Dr-Asit Kumar ParidaNo ratings yet

- B-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Document6 pagesB-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Michael ButlerNo ratings yet

- Code No: 25056Document8 pagesCode No: 25056SRINIVASA RAO GANTANo ratings yet

- Mt-Ii QBDocument10 pagesMt-Ii QBRavi ChandranNo ratings yet

- 9A03503 Machine ToolsDocument1 page9A03503 Machine ToolssivabharathamurthyNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- Machine Tools 3Document4 pagesMachine Tools 3Aaron HarriganNo ratings yet

- Sathyabama Question PaperDocument3 pagesSathyabama Question PaperamiestudentNo ratings yet

- Me1252 MT 2 Question BankDocument10 pagesMe1252 MT 2 Question BankJ R Vinod KumaarNo ratings yet

- MT Question Bank PDFDocument9 pagesMT Question Bank PDFHarish RajaNo ratings yet

- 9A03503 Machine ToolsDocument4 pages9A03503 Machine ToolssivabharathamurthyNo ratings yet

- G.Hraisoni College of Engineering, NagpurDocument7 pagesG.Hraisoni College of Engineering, Nagpurphase_shekhar21No ratings yet

- Answer Any Five Questions From Section-BDocument1 pageAnswer Any Five Questions From Section-BCharyNo ratings yet

- ME6402-Manufacturing Technology-IIDocument10 pagesME6402-Manufacturing Technology-IINIVAS S. SNo ratings yet

- 1-Casting Jntuh QSDocument4 pages1-Casting Jntuh QSMr. T. Anjaneyulu Mr. T. AnjaneyuluNo ratings yet

- (Question Paper C: 0 Ma KsDocument2 pages(Question Paper C: 0 Ma KsvsanthanamNo ratings yet

- Periyar Centenary Polytechnic Collage Manufacturing Technology - II Subcode: Meb520Document5 pagesPeriyar Centenary Polytechnic Collage Manufacturing Technology - II Subcode: Meb520Muthu KumarNo ratings yet

- B E1135 Pages: 2: Answer Any Three Full Questions, Each Carries 10marksDocument2 pagesB E1135 Pages: 2: Answer Any Three Full Questions, Each Carries 10marksRahul KorothNo ratings yet

- ME3201Document1 pageME3201Md. Tariqul Islam MunnaNo ratings yet

- Assigenment QuestionsDocument4 pagesAssigenment Questionsphase_shekhar21No ratings yet

- r05322001 Tool DesignDocument8 pagesr05322001 Tool DesignSRINIVASA RAO GANTA100% (1)

- Mid 2Document6 pagesMid 2N Dhanunjaya Rao BorraNo ratings yet

- 29-05 Manufacturing Technology (MT)Document1 page29-05 Manufacturing Technology (MT)a11972003No ratings yet

- WWW - Manaresults.Co - In: III B. Tech I Semester Regular/Supplementary Examinations, October/November-2016 MetrologyDocument4 pagesWWW - Manaresults.Co - In: III B. Tech I Semester Regular/Supplementary Examinations, October/November-2016 MetrologyKKNo ratings yet

- Some Questions From JNTU B TechDocument15 pagesSome Questions From JNTU B Techjithinaravind007No ratings yet

- Production TechnologyDocument4 pagesProduction TechnologysandchinniNo ratings yet

- AssignmentDocument3 pagesAssignmentAviral Sansi0% (1)

- Jig and Fix Model QPDocument4 pagesJig and Fix Model QPDharmaraj ParamasivamNo ratings yet

- Machining Processes and Metrology Question PaperDocument2 pagesMachining Processes and Metrology Question PaperHarshan ArumugamNo ratings yet

- Pt-I-Important QuestionsDocument3 pagesPt-I-Important QuestionsSRAVANNo ratings yet

- Assignment ADocument2 pagesAssignment AMemer PointNo ratings yet

- Me2252 Manufacturing Technology II r8 April - May 2010Document2 pagesMe2252 Manufacturing Technology II r8 April - May 2010nkchandruNo ratings yet

- 23 Batch PaperDocument1 page23 Batch Papervijaykandwal123No ratings yet

- r05320302 Metrology and Surface EngineeringDocument4 pagesr05320302 Metrology and Surface EngineeringSRINIVASA RAO GANTANo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityravi upadhyayNo ratings yet

- Me 2252Document3 pagesMe 2252cbeprabhugmailNo ratings yet

- DJFDocument2 pagesDJFRamesh VeerNo ratings yet

- 2013Document4 pages2013AmyRapaNo ratings yet

- Department of Mechanical Engineering Question Bank M E6402 M A N U F A CTU R ING Technolo G Y - IiDocument10 pagesDepartment of Mechanical Engineering Question Bank M E6402 M A N U F A CTU R ING Technolo G Y - Iiநான் என் மக்கள் எனதுNo ratings yet

- W 2019 A - Merged - WatermarkDocument18 pagesW 2019 A - Merged - WatermarkDivya ChandewarNo ratings yet

- ME6402 Manufacturing Technology IIDocument10 pagesME6402 Manufacturing Technology IIprasanthprpNo ratings yet

- Design of Jigs QP Upto 2010Document20 pagesDesign of Jigs QP Upto 2010Naresh Dharma100% (1)

- Question Bank - All UnitsDocument11 pagesQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- Tutorial MP.1 NewDocument4 pagesTutorial MP.1 Newtajap70949No ratings yet

- Research Paper On FmeaDocument8 pagesResearch Paper On Fmeahyz0tiwezif3100% (3)

- Indian Standard: Specification For Floor Door Stoppers (Document12 pagesIndian Standard: Specification For Floor Door Stoppers (ssaurav89No ratings yet

- Reading Comprehension Sheet-IiDocument4 pagesReading Comprehension Sheet-IiStella GomesNo ratings yet

- Claim Procedure and Terms & Conditions For Personal Accident InsuranceDocument11 pagesClaim Procedure and Terms & Conditions For Personal Accident InsuranceMayur AbhinavNo ratings yet

- Engine Block R22: Vasa 22 Spare Parts List 100-08Document4 pagesEngine Block R22: Vasa 22 Spare Parts List 100-08Jenni TecsumagaNo ratings yet

- In Vitro Dissolution Testing Models: DR Rajesh MujariyaDocument35 pagesIn Vitro Dissolution Testing Models: DR Rajesh MujariyaRajesh MujariyaNo ratings yet

- Resumen Conceptos Hidrológicos Básicos 1. Distribución de Agua en El PlanetaDocument2 pagesResumen Conceptos Hidrológicos Básicos 1. Distribución de Agua en El PlanetaAnderson Bruce Sosa RaymundoNo ratings yet

- Educating Green Building Stakeholders About The Benefits of BIM - The Philippines ExperienceDocument19 pagesEducating Green Building Stakeholders About The Benefits of BIM - The Philippines ExperiencePeter Adrian NgoNo ratings yet

- PC-12 NG PowerPoint Presentation - 220523 - 081602Document1,163 pagesPC-12 NG PowerPoint Presentation - 220523 - 081602Manuel CarteNo ratings yet

- MORRIS, CRAIG (1974) - Reconstructing Patterns of Non-Agricultural Production in The Inca Economy. Archaeology and Documents in Institutional Analysis PDFDocument21 pagesMORRIS, CRAIG (1974) - Reconstructing Patterns of Non-Agricultural Production in The Inca Economy. Archaeology and Documents in Institutional Analysis PDFTrejaucasNo ratings yet

- Basic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseDocument121 pagesBasic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseMarian VasileNo ratings yet

- Brochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTDocument8 pagesBrochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTArturo lopez abucharNo ratings yet

- Saes A 109Document4 pagesSaes A 109malika_00No ratings yet

- Article: ZootaxaDocument14 pagesArticle: ZootaxaSabrina Nur Fitri 2004125073No ratings yet

- ECONOMIZERDocument17 pagesECONOMIZERTrần Văn Trọng 7350No ratings yet

- Finals TheoriesDocument25 pagesFinals TheoriesQui Lea ChinNo ratings yet

- Bayloc Style Dry Disconnect - 2016Document8 pagesBayloc Style Dry Disconnect - 2016Eduardo Luna MaggiNo ratings yet

- Cat IQ TestDocument3 pagesCat IQ TestEm-Em 'Emstein' Lamento-VillegasNo ratings yet

- SQL Essentials PDFDocument36 pagesSQL Essentials PDFMadalina GrigoroiuNo ratings yet

- Tolerance and FitsDocument36 pagesTolerance and Fitsdevin wibowoNo ratings yet

- Marine-Unit Description - Game - StarCraft IIDocument8 pagesMarine-Unit Description - Game - StarCraft IIcalmansoorNo ratings yet

- A Study On Marketing Practices in Select PDFDocument137 pagesA Study On Marketing Practices in Select PDFSadik SadikaramaniNo ratings yet

- Rơ Le ToshibaDocument44 pagesRơ Le ToshibaTung Nguyen100% (1)

- Experiment No. 12: Implementation & Verification of Line Multiplexer & Demultiplexer ODocument30 pagesExperiment No. 12: Implementation & Verification of Line Multiplexer & Demultiplexer O5611 M.Mubeen M.yaseenNo ratings yet

- Aws Training Cloud Practitioner Essentials - Security - Certicate of CompletionDocument1 pageAws Training Cloud Practitioner Essentials - Security - Certicate of Completionapi-122816661No ratings yet

- Ya 8800 10-14reDocument44 pagesYa 8800 10-14remartin_jaitmanNo ratings yet

- Jurisprudence - Its Meaning, Nature and ScopeDocument10 pagesJurisprudence - Its Meaning, Nature and ScopeAnjali DixitNo ratings yet

R07 Set No. 2

R07 Set No. 2

Uploaded by

Muhammad Asif AliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R07 Set No. 2

R07 Set No. 2

Uploaded by

Muhammad Asif AliCopyright:

Available Formats

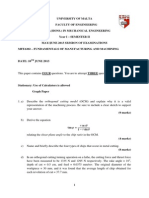

Code No: 07A50303

R07

Set No. 2

III B.Tech I Semester Supplementary Examinations,June 2010 MACHINE TOOLS Common to Mechanical Engineering, Mechatronics Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks

1. What is a planer? Explain the principal parts of planer with neat sketches.

[16]

2. Explain constructional features of various parts of lathe in detail with neat sketches. [16] 3. (a) Derive an expression for nding chip thickness ratio. (b) Briey discuss about chip breakers.

4. (a) Describe in detail about lapping with suitable sketches.

(b) Explain the tool life aspects of broaching, honing and lapping. 5. (a) Name and explain various work holding devices used on a lathe. (b) Describe the various grinding xtures .

6. (a) Classify the milling cutters according to the method of mounting the cutter. (b) Write a note on the carbide-tipped milling cutters.

7. (a) Calculate the time taken in seconds for a high-speed steel drill 10mm diameter to penetrate a 18mm thick steel plate. Assume a feed of 0.2mm/rev for the 12mm size drill and cutting speed for steel as 20m/min. (b) Explain the double column jig-boring machine with a neat sketch. 8. Sketch and explain the following grinding processes. (a) Form Grinding. (b) Gear tooth grinding. (c) Thread grinding. (d) Cam grinding. [4+4+4+4]

w w

jn .

w tu

r o

.c ld

m o

[12+4]

[8+8]

[8+8]

[8+8]

[8+8]

Code No: 07A50303

R07

Set No. 4

III B.Tech I Semester Supplementary Examinations,June 2010 MACHINE TOOLS Common to Mechanical Engineering, Mechatronics Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks

1. Explain about parting operation, nish turning, grooving, under cutting and shoulder turning on lathe machines with proper sketches. [16] 2. (a) What are the various factors to be considered in selection of grinding wheel? Discuss each in detail. (b) Dene grinding. Explain the cutting action in grinding.

3. Give classication of planer machine and explain about Double column planning machine and edge-planning machine. [16] 4. Explain the following: (a) Simple or plain indexing. (b) Dierential indexing.

5. (a) Write short notes on the following:

i. Purpose of honing and principle of operation of honing. ii. Explain about honing machines. 6. Write a short note on the following: (a) Horizontal boring machine. (b) Deep hole boring machine. (c) Fine boring machine.

w w

jn .

w tu

r o

.c ld

m o

[8+8]

[6+10]

[8+8]

[6+5+5]

7. (a) Compare compressed air and hydraulic power as means for operating clamping devices. (b) What do you understand by principle of least points and principle of extreme points. [8+8] 8. Design a nine-speed gearbox for the headstock of a lathe, the spindle ranges from 28 RPM to1000RPM. Draw the structural diagram and show the layout of the gears and connection to motors. [16]

Code No: 07A50303

R07

Set No. 1

III B.Tech I Semester Supplementary Examinations,June 2010 MACHINE TOOLS Common to Mechanical Engineering, Mechatronics Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks

1. Write short notes on the following: (a) Chip breakers. (b) Advantage of negative rake angle. (c) Curling of chip. (d) Cutting speed.

2. Explain constructional features and applications of chuck, lathe centers, collets, carriers and catch plates, and faceplate of lathe machine. [16] 3. Explain the theory of grinding.

4. What is a milling machine? How do you classify the milling machine? Give the working principle of milling machine with a neat sketch. Mention the size and specication of milling machine. [16] 5. (a) What heat treatments are given to manufactured broaches. (b) How push broaches dier from pull broach? 6. Write short notes on the following: (a) Elements of drilling machine. (b) Elements of vertical boring machine. [8+8]

7. (a) Explain in detail the Quick return mechanism of ram in shaper with neat sketch. (b) Explain about the quick-return mechanism for a planer table. [10+6]

w w

jn .

w tu

r o

.c ld

m o

[4+4+4+4]

[16]

[8+8]

8. (a) What is meant by Clearance and fool proong as applied to jigs and xtures. (b) Enumerate the design principles of milling xtures. [8+8]

Code No: 07A50303

R07

Set No. 3

III B.Tech I Semester Supplementary Examinations,June 2010 MACHINE TOOLS Common to Mechanical Engineering, Mechatronics Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks

1. (a) Briey discuss about tool signature with an example. (b) What are the requirements of cutting tool? (c) What are the variables that inuence the type of chip produced? And explain about continuous chip with built-up edge? [5+4+7] 2. What is the purpose of clamping? What factors govern the choice of a clamping device to achieve the purpose of clamping? Discuss in detail. [16] 3. (a) How do you specify the lathe machine?

(b) Discuss briey about the chucks used in lathe machine.

(c) Specify the type of lathe center with their gures and applications. [4+6+6] 4. (a) Calculate the dierential indexing to give 73 divisions. (b) A gear is to have 14 teeth. What is the indexing movement required? (c) Explain Dierential indexing.

5. (a) What are the advantages and limitations of using centre less grinding? (b) Describe the dressing and balancing requirements in grinding. [8+8]

6. (a) Write about work holding devices of drilling machine with suitable sketches. (b) Explain about deep hole drilling machine and portable drilling machine with neat sketches. [6+10] 7. How shapers are classied? Explain in detail the Quick return mechanism of ram in shaper with neat sketch. [16] 8. (a) Sketch a broaching tool and explain various elements. (b) Why robust xtures are required to support jobs to be broached? [8+8]

w w

jn .

w tu

r o

.c ld

m o

[5+5+6]

You might also like

- 7 ElevenDocument2 pages7 ElevenyoosahuNo ratings yet

- Hand Over ReportDocument1 pageHand Over ReportRami Allouh Abu OmarNo ratings yet

- Arduino VDI ExperimentsDocument7 pagesArduino VDI ExperimentsJuanCarlosCaballeroNo ratings yet

- Code No: 35033Document5 pagesCode No: 35033SRINIVASA RAO GANTANo ratings yet

- Machine ToolsDocument5 pagesMachine ToolsSavantNo ratings yet

- 3-1 MT (Nov 2009 Regular)Document5 pages3-1 MT (Nov 2009 Regular)micmechNo ratings yet

- MCMT Mid-1 P-QusDocument5 pagesMCMT Mid-1 P-QusN Dhanunjaya Rao BorraNo ratings yet

- rr320303 Machine ToolsDocument4 pagesrr320303 Machine ToolsSRINIVASA RAO GANTA100% (1)

- MCMT QBDocument3 pagesMCMT QBKrishna MurthyNo ratings yet

- Estelar: Faculty of EngineeringDocument1 pageEstelar: Faculty of EngineeringPrasad Apv100% (1)

- 3.manufacturing Technology IIDocument6 pages3.manufacturing Technology IIprasanthprpNo ratings yet

- Manufacturing Technology - IIDocument2 pagesManufacturing Technology - IIMANOJ MNo ratings yet

- Up QPDocument2 pagesUp QPkannanviknesh086319No ratings yet

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNo ratings yet

- Machine Tools - 1st MID - 3rd B.tech (2009)Document2 pagesMachine Tools - 1st MID - 3rd B.tech (2009)micmechNo ratings yet

- Vsa School of Engineering, Salem Department of Mechanical Engineering Manufacturing Technology Ii Internal Test-IiDocument1 pageVsa School of Engineering, Salem Department of Mechanical Engineering Manufacturing Technology Ii Internal Test-IiDmj Anbu RajNo ratings yet

- Jntuworld: R09 Set No. 2Document6 pagesJntuworld: R09 Set No. 2Dr-Asit Kumar ParidaNo ratings yet

- B-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Document6 pagesB-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Michael ButlerNo ratings yet

- Code No: 25056Document8 pagesCode No: 25056SRINIVASA RAO GANTANo ratings yet

- Mt-Ii QBDocument10 pagesMt-Ii QBRavi ChandranNo ratings yet

- 9A03503 Machine ToolsDocument1 page9A03503 Machine ToolssivabharathamurthyNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- Machine Tools 3Document4 pagesMachine Tools 3Aaron HarriganNo ratings yet

- Sathyabama Question PaperDocument3 pagesSathyabama Question PaperamiestudentNo ratings yet

- Me1252 MT 2 Question BankDocument10 pagesMe1252 MT 2 Question BankJ R Vinod KumaarNo ratings yet

- MT Question Bank PDFDocument9 pagesMT Question Bank PDFHarish RajaNo ratings yet

- 9A03503 Machine ToolsDocument4 pages9A03503 Machine ToolssivabharathamurthyNo ratings yet

- G.Hraisoni College of Engineering, NagpurDocument7 pagesG.Hraisoni College of Engineering, Nagpurphase_shekhar21No ratings yet

- Answer Any Five Questions From Section-BDocument1 pageAnswer Any Five Questions From Section-BCharyNo ratings yet

- ME6402-Manufacturing Technology-IIDocument10 pagesME6402-Manufacturing Technology-IINIVAS S. SNo ratings yet

- 1-Casting Jntuh QSDocument4 pages1-Casting Jntuh QSMr. T. Anjaneyulu Mr. T. AnjaneyuluNo ratings yet

- (Question Paper C: 0 Ma KsDocument2 pages(Question Paper C: 0 Ma KsvsanthanamNo ratings yet

- Periyar Centenary Polytechnic Collage Manufacturing Technology - II Subcode: Meb520Document5 pagesPeriyar Centenary Polytechnic Collage Manufacturing Technology - II Subcode: Meb520Muthu KumarNo ratings yet

- B E1135 Pages: 2: Answer Any Three Full Questions, Each Carries 10marksDocument2 pagesB E1135 Pages: 2: Answer Any Three Full Questions, Each Carries 10marksRahul KorothNo ratings yet

- ME3201Document1 pageME3201Md. Tariqul Islam MunnaNo ratings yet

- Assigenment QuestionsDocument4 pagesAssigenment Questionsphase_shekhar21No ratings yet

- r05322001 Tool DesignDocument8 pagesr05322001 Tool DesignSRINIVASA RAO GANTA100% (1)

- Mid 2Document6 pagesMid 2N Dhanunjaya Rao BorraNo ratings yet

- 29-05 Manufacturing Technology (MT)Document1 page29-05 Manufacturing Technology (MT)a11972003No ratings yet

- WWW - Manaresults.Co - In: III B. Tech I Semester Regular/Supplementary Examinations, October/November-2016 MetrologyDocument4 pagesWWW - Manaresults.Co - In: III B. Tech I Semester Regular/Supplementary Examinations, October/November-2016 MetrologyKKNo ratings yet

- Some Questions From JNTU B TechDocument15 pagesSome Questions From JNTU B Techjithinaravind007No ratings yet

- Production TechnologyDocument4 pagesProduction TechnologysandchinniNo ratings yet

- AssignmentDocument3 pagesAssignmentAviral Sansi0% (1)

- Jig and Fix Model QPDocument4 pagesJig and Fix Model QPDharmaraj ParamasivamNo ratings yet

- Machining Processes and Metrology Question PaperDocument2 pagesMachining Processes and Metrology Question PaperHarshan ArumugamNo ratings yet

- Pt-I-Important QuestionsDocument3 pagesPt-I-Important QuestionsSRAVANNo ratings yet

- Assignment ADocument2 pagesAssignment AMemer PointNo ratings yet

- Me2252 Manufacturing Technology II r8 April - May 2010Document2 pagesMe2252 Manufacturing Technology II r8 April - May 2010nkchandruNo ratings yet

- 23 Batch PaperDocument1 page23 Batch Papervijaykandwal123No ratings yet

- r05320302 Metrology and Surface EngineeringDocument4 pagesr05320302 Metrology and Surface EngineeringSRINIVASA RAO GANTANo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityravi upadhyayNo ratings yet

- Me 2252Document3 pagesMe 2252cbeprabhugmailNo ratings yet

- DJFDocument2 pagesDJFRamesh VeerNo ratings yet

- 2013Document4 pages2013AmyRapaNo ratings yet

- Department of Mechanical Engineering Question Bank M E6402 M A N U F A CTU R ING Technolo G Y - IiDocument10 pagesDepartment of Mechanical Engineering Question Bank M E6402 M A N U F A CTU R ING Technolo G Y - Iiநான் என் மக்கள் எனதுNo ratings yet

- W 2019 A - Merged - WatermarkDocument18 pagesW 2019 A - Merged - WatermarkDivya ChandewarNo ratings yet

- ME6402 Manufacturing Technology IIDocument10 pagesME6402 Manufacturing Technology IIprasanthprpNo ratings yet

- Design of Jigs QP Upto 2010Document20 pagesDesign of Jigs QP Upto 2010Naresh Dharma100% (1)

- Question Bank - All UnitsDocument11 pagesQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- Tutorial MP.1 NewDocument4 pagesTutorial MP.1 Newtajap70949No ratings yet

- Research Paper On FmeaDocument8 pagesResearch Paper On Fmeahyz0tiwezif3100% (3)

- Indian Standard: Specification For Floor Door Stoppers (Document12 pagesIndian Standard: Specification For Floor Door Stoppers (ssaurav89No ratings yet

- Reading Comprehension Sheet-IiDocument4 pagesReading Comprehension Sheet-IiStella GomesNo ratings yet

- Claim Procedure and Terms & Conditions For Personal Accident InsuranceDocument11 pagesClaim Procedure and Terms & Conditions For Personal Accident InsuranceMayur AbhinavNo ratings yet

- Engine Block R22: Vasa 22 Spare Parts List 100-08Document4 pagesEngine Block R22: Vasa 22 Spare Parts List 100-08Jenni TecsumagaNo ratings yet

- In Vitro Dissolution Testing Models: DR Rajesh MujariyaDocument35 pagesIn Vitro Dissolution Testing Models: DR Rajesh MujariyaRajesh MujariyaNo ratings yet

- Resumen Conceptos Hidrológicos Básicos 1. Distribución de Agua en El PlanetaDocument2 pagesResumen Conceptos Hidrológicos Básicos 1. Distribución de Agua en El PlanetaAnderson Bruce Sosa RaymundoNo ratings yet

- Educating Green Building Stakeholders About The Benefits of BIM - The Philippines ExperienceDocument19 pagesEducating Green Building Stakeholders About The Benefits of BIM - The Philippines ExperiencePeter Adrian NgoNo ratings yet

- PC-12 NG PowerPoint Presentation - 220523 - 081602Document1,163 pagesPC-12 NG PowerPoint Presentation - 220523 - 081602Manuel CarteNo ratings yet

- MORRIS, CRAIG (1974) - Reconstructing Patterns of Non-Agricultural Production in The Inca Economy. Archaeology and Documents in Institutional Analysis PDFDocument21 pagesMORRIS, CRAIG (1974) - Reconstructing Patterns of Non-Agricultural Production in The Inca Economy. Archaeology and Documents in Institutional Analysis PDFTrejaucasNo ratings yet

- Basic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseDocument121 pagesBasic Manual: M.R. 307: 77 11 199 931 Edition AnglaiseMarian VasileNo ratings yet

- Brochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTDocument8 pagesBrochure - Sika FerroGard Galvanic and Hybrid Anode Technologies - PRINTArturo lopez abucharNo ratings yet

- Saes A 109Document4 pagesSaes A 109malika_00No ratings yet

- Article: ZootaxaDocument14 pagesArticle: ZootaxaSabrina Nur Fitri 2004125073No ratings yet

- ECONOMIZERDocument17 pagesECONOMIZERTrần Văn Trọng 7350No ratings yet

- Finals TheoriesDocument25 pagesFinals TheoriesQui Lea ChinNo ratings yet

- Bayloc Style Dry Disconnect - 2016Document8 pagesBayloc Style Dry Disconnect - 2016Eduardo Luna MaggiNo ratings yet

- Cat IQ TestDocument3 pagesCat IQ TestEm-Em 'Emstein' Lamento-VillegasNo ratings yet

- SQL Essentials PDFDocument36 pagesSQL Essentials PDFMadalina GrigoroiuNo ratings yet

- Tolerance and FitsDocument36 pagesTolerance and Fitsdevin wibowoNo ratings yet

- Marine-Unit Description - Game - StarCraft IIDocument8 pagesMarine-Unit Description - Game - StarCraft IIcalmansoorNo ratings yet

- A Study On Marketing Practices in Select PDFDocument137 pagesA Study On Marketing Practices in Select PDFSadik SadikaramaniNo ratings yet

- Rơ Le ToshibaDocument44 pagesRơ Le ToshibaTung Nguyen100% (1)

- Experiment No. 12: Implementation & Verification of Line Multiplexer & Demultiplexer ODocument30 pagesExperiment No. 12: Implementation & Verification of Line Multiplexer & Demultiplexer O5611 M.Mubeen M.yaseenNo ratings yet

- Aws Training Cloud Practitioner Essentials - Security - Certicate of CompletionDocument1 pageAws Training Cloud Practitioner Essentials - Security - Certicate of Completionapi-122816661No ratings yet

- Ya 8800 10-14reDocument44 pagesYa 8800 10-14remartin_jaitmanNo ratings yet

- Jurisprudence - Its Meaning, Nature and ScopeDocument10 pagesJurisprudence - Its Meaning, Nature and ScopeAnjali DixitNo ratings yet