Professional Documents

Culture Documents

A 090

A 090

Uploaded by

birimpompaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A 090

A 090

Uploaded by

birimpompaCopyright:

Available Formats

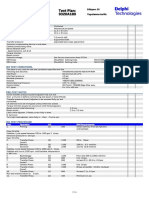

Test Plan: 3042090

Applic: Issue No: Date: Pumps covered: Cummins 4B 3.9 1 00/00/00 3042F090 U3042F090 Mechanical all-speed. Uprated with supported shaft. Clockwise. 53.5 0.5 mm. See nameplate code. 9.0 mm. 49.8 mm. Automatic speed.

PUMP SPECIFICATION.

Governor Type: Drive Type: Rotation: Gov.Link Length: Governor Spring Position: Plunger Diameter: Roller to Roller: Advance Type: Transfer pressure adjuster in end plate. Solenoid shut-off device, 12 volts. OEM Code:

ISO Code:

A53L800/2/2500

ISO TEST CONDITIONS.

This data is only valid for the test conditions specified and the following test benches: HA700/HA400/AVM/PGM Test Fluid: Nozzles: Nozzle Opening Pressure: H.P. Pipes: HA3000/HA2500/HA1150/HA1100MkII/HA875 ISO 4113 at 40 2 C ISO 4010. 172 + 3 - 0 bar. 6 x 2 x 845 mm (ISO 4093.2).

PRE-TEST NOTES.

Minimum piston spring cap shim thickness 1.0 mm . No additional shimming is required. Screw transfer pressure adjuster fully out, then 3 turns in.

ISO TEST PROCEDURE.

Test 1. Operation Priming. S/C RPM Requirement Obtain delivery from (C) 100 all injectors. No air in pump back leak. Minimum 0.7 bar,( 10 (C) 100 psi). (S) 800 5. Adjust T.P. Screw. (S) 1100 7.75 to 8.25 5.2 to 6.2 bar(75 to 90 (C) 1100 psi) 1100 10 to 100 cm3 per 100

2. 3. 4. 5. 6.

Transfer Press. Advance. Advance. Transfer Press. Back leakage.

7.

Max. Delivery (Coded Pumps)

8. 9. 10. 11. 12. 13. 14.

Delivery. Cambox Press. Shut-off lever Delivery - Low load Delivery. Governor Delivery.

15.

Governor (Coded Pumps)

strokes . (Flow rate 110to 1100cm3/min.) Coded value 0.6 (S)* See mm3/st. code Max. spread 6 mm3/st. Minimum as test(7 ) (C)* 100 18.0 mm3/st. 0.2 to 0.4 bar( 3to 6 (C) 800 psi) Max. 0.8cm3. Shut-off (C) 200 lever closed S/C 200 Maximum 1.0cm3. Throttle lever closed. (C) 1150 Record delivery cm3. 2.0 cm3. Max.Line 3.0 (S) 1280 cm3. (C) 1150 Throttle as test(13), Minimum as test(12) 0.4 cm3. (S) See 2.0cm3. (Pump speed is half Code engine speed)

Stop machine, remove T.P. gauge and replace head locking fitting. Prime as at test (1 ). 16. 17. Stop solenoid Timing. (C) 325 S/C Max. 0.5cm3. Deenergise solenoid. Outlet 'U ' ( Pressure 55 bar) Indexing tool at 114, Scribe line. Depressurise. Rotate drive 8 to pos'n 106 . Slide washer and torque shaft locking screw to 6.8 Nm Circlip at drive plate letter 'G '

Note: housing & drive shaft respectively - see SIN DPA A153.

Tie-on labels 6409-17A and 6409-17B should be tied to pump

REFER TO STATEMENT AT END OF EXPLANATORY NOTES REGARDING MAXIMUM FUEL AND SPEED SETTING AND VARIATIONS IN ENGINE PERFORMANCE.

You might also like

- Caterpillar C7 - C9 - Sample EngDocument11 pagesCaterpillar C7 - C9 - Sample Engpp100% (4)

- 4Ja1-Tc & 4Jh1-Tc Engine: Engine Management System Operation & DiagnosisDocument91 pages4Ja1-Tc & 4Jh1-Tc Engine: Engine Management System Operation & DiagnosisNguyễn ĐángNo ratings yet

- Manual de Partes 6110D Tractor AgricolaDocument868 pagesManual de Partes 6110D Tractor AgricolaJUAN CARLOS PAZ100% (2)

- 205 Rotary RigDocument4 pages205 Rotary RigBungleBugarlisNo ratings yet

- GX120 160 200 UT2 English PDFDocument61 pagesGX120 160 200 UT2 English PDFRazielboy Kain100% (1)

- 3042F331 DATA CatalogDocument2 pages3042F331 DATA CatalogMilanNo ratings yet

- 3042f843 Plano de TesteDocument1 page3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- 9322A010Document5 pages9322A010BaytolgaNo ratings yet

- 9320A020GDocument6 pages9320A020GBaytolgaNo ratings yet

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- 3249F532 TabelaDocument1 page3249F532 TabelaLIONN SOFTWARESNo ratings yet

- Test Plan: 8921A000: Pump SpecificationDocument3 pagesTest Plan: 8921A000: Pump SpecificationBaytolgaNo ratings yet

- Bomba Dpa 3340f371g - TesteDocument2 pagesBomba Dpa 3340f371g - TesteOseasJuniorNo ratings yet

- Delphi 9322a000Document5 pagesDelphi 9322a000BaytolgaNo ratings yet

- 9320A070GDocument7 pages9320A070GBaytolgaNo ratings yet

- 8921A091WDocument2 pages8921A091WLTurboNo ratings yet

- 9520A192G - PlanDocument3 pages9520A192G - PlanMihai-Eugen Popa100% (1)

- 3233F390 TabelaDocument1 page3233F390 TabelaOFFICE DANACNo ratings yet

- Testplan 3238360Document1 pageTestplan 3238360Fx_205No ratings yet

- Testplan 3343010Document1 pageTestplan 3343010Fx_205No ratings yet

- 3662F871 TablaDocument1 page3662F871 TablaLIONN SOFTWARESNo ratings yet

- 8443A260EDocument2 pages8443A260EMiguel ChaconNo ratings yet

- 823A593T DATA CatalogDocument2 pages823A593T DATA CatalogMilanNo ratings yet

- Test Plan: Pump SpecificationDocument3 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- 821A661X DATA CatalogDocument2 pages821A661X DATA CatalogMilanNo ratings yet

- 8522a090 Delphi PDFDocument7 pages8522a090 Delphi PDFBaytolgaNo ratings yet

- 8961A020WDocument2 pages8961A020WLTurboNo ratings yet

- 3239F592TDocument2 pages3239F592TAnderson London67% (3)

- Testplan 3242920Document1 pageTestplan 3242920Fx_205No ratings yet

- Test Plan: 3443890: Pump SpecificationDocument2 pagesTest Plan: 3443890: Pump SpecificationLTurboNo ratings yet

- 8520A060A TestplanDocument2 pages8520A060A TestplanBaytolga can100% (1)

- Test Plan: 8923A050: Pump SpecificationDocument2 pagesTest Plan: 8923A050: Pump Specificationveshat100% (1)

- 3349F330Document2 pages3349F330marco rod100% (1)

- Test PlanDocument1 pageTest PlanOFFICE DANACNo ratings yet

- Test Plan: 8522A130: Pump SpecificationDocument2 pagesTest Plan: 8522A130: Pump SpecificationJose Alexandre SunhegaNo ratings yet

- 9320a225g Plano LHDocument3 pages9320a225g Plano LHForteLubNo ratings yet

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump Specificationmecanik.veracruzNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- Test Plan: 3349330: Pump SpecificationDocument2 pagesTest Plan: 3349330: Pump SpecificationLIONN SOFTWARESNo ratings yet

- 8550A223ADocument2 pages8550A223ALTurboNo ratings yet

- 3340F322 Lionn Auto SoftwaresDocument2 pages3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- 8444B360ADocument2 pages8444B360ABaytolgaNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- Testplan 3239590Document2 pagesTestplan 3239590Fx_2050% (1)

- 3230f582T PTDocument2 pages3230f582T PTHeitor Gael Alves de FreitasNo ratings yet

- 01EJ3051Document3 pages01EJ3051ForteLubNo ratings yet

- Test Plan: Pump SpecificationDocument4 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- 3340F401G Plano de Teste DelphiDocument2 pages3340F401G Plano de Teste DelphiJunior Iung100% (1)

- 9320A185H TestplanDocument4 pages9320A185H TestplanBaytolga canNo ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- (Oto-Hui - Com) Edc Hino s05Document2 pages(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500No ratings yet

- Test Plan Delphi TechnologiesDocument2 pagesTest Plan Delphi TechnologiesFRANCISCONo ratings yet

- 9323A271G Catalog DATADocument4 pages9323A271G Catalog DATALIONN SOFTWARESNo ratings yet

- SDM 143 eDocument20 pagesSDM 143 eseaqu3st100% (1)

- Testplan 9521A330TDocument3 pagesTestplan 9521A330TMilanNo ratings yet

- 9320a217 TabelaDocument4 pages9320a217 TabelaLIONN SOFTWARESNo ratings yet

- 9320A380 TestDocument4 pages9320A380 TestVyacheslav ShatalovNo ratings yet

- JCB DELPHI PUMP-9520A500-509S03 - Iss 03Document7 pagesJCB DELPHI PUMP-9520A500-509S03 - Iss 03Ravikant Saini100% (2)

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- Ss01014 SmithDocument6 pagesSs01014 SmithAchmad TabaNo ratings yet

- Inj - Pump C Alibratio N Data: 1.test ConditionsDocument2 pagesInj - Pump C Alibratio N Data: 1.test ConditionsDavid Carlos Dady0% (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Je01 Haynes Jet Engine Uk Manual Lo ResDocument11 pagesJe01 Haynes Jet Engine Uk Manual Lo ResMauricio SantanaNo ratings yet

- Overhaul EngineDocument4 pagesOverhaul EngineAngga RezzaNo ratings yet

- Lobe and Gear PumpsDocument17 pagesLobe and Gear PumpsCarl Angelo A. LiwanagNo ratings yet

- Turbocharger Programme 2011 PDFDocument36 pagesTurbocharger Programme 2011 PDFAlexander Akimov100% (1)

- 2012 A7 Vehicle IntroductionDocument56 pages2012 A7 Vehicle IntroductionAfranio Batista100% (1)

- Technical Specification of IVECO-AIFO Powered Gensets, From 150 To 450kVA - Page 16Document1 pageTechnical Specification of IVECO-AIFO Powered Gensets, From 150 To 450kVA - Page 16Elt IngNo ratings yet

- md2030 md2030Document2 pagesmd2030 md2030Carlos RiveroNo ratings yet

- Classification of Combustion ChambersDocument3 pagesClassification of Combustion ChambersNoufal NSNo ratings yet

- Catalogo ATEXDocument153 pagesCatalogo ATEXWilber P ZuritaNo ratings yet

- Training of G-3520 H PresentationDocument87 pagesTraining of G-3520 H PresentationLio Messi100% (1)

- Ausa Forklift c250h Parts ManualDocument20 pagesAusa Forklift c250h Parts ManualMarcelle100% (60)

- Catalogue of Ghana Standards 2012Document467 pagesCatalogue of Ghana Standards 2012saisridhar99100% (1)

- Wartsila o e W 46f PG M.Document168 pagesWartsila o e W 46f PG M.Uhrin ImreNo ratings yet

- U GAT4825 GatesDocument9 pagesU GAT4825 GatesJD libNo ratings yet

- Wheel Loader: Boost Your SuccessDocument17 pagesWheel Loader: Boost Your SuccessLaxman AhirNo ratings yet

- Workshop Manual For Perkins 4.108M, 4.107M and 4.99M Diesel Engines - Compressed PDFDocument134 pagesWorkshop Manual For Perkins 4.108M, 4.107M and 4.99M Diesel Engines - Compressed PDFAlfredo GuzmánNo ratings yet

- ReFlex Wiring Diagram - 02-10-2021Document5 pagesReFlex Wiring Diagram - 02-10-2021sachtdeNo ratings yet

- Me Lab 3Document71 pagesMe Lab 3JV Lopez0% (2)

- GM Ecotec Engine: Generation IDocument20 pagesGM Ecotec Engine: Generation Iroberto100% (1)

- Otto CycleDocument16 pagesOtto CycleSwati MadanNo ratings yet

- Electromagnetic EngineDocument2 pagesElectromagnetic EngineGiri Wip NxNo ratings yet

- Warranty Manual: Failure CodesDocument60 pagesWarranty Manual: Failure CodesibrahemNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 098902-0380-01Document23 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 098902-0380-01Solofoniaina Ginô ChristianNo ratings yet

- Cat It28g 5Document5 pagesCat It28g 5Oecox Cah DjadoelNo ratings yet

- English HAZET 3488 - 8 FordDocument13 pagesEnglish HAZET 3488 - 8 FordkallatisNo ratings yet