Professional Documents

Culture Documents

Parts of A Hydraulic Cylinder

Parts of A Hydraulic Cylinder

Uploaded by

Samma Noor GujjarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parts of A Hydraulic Cylinder

Parts of A Hydraulic Cylinder

Uploaded by

Samma Noor GujjarCopyright:

Available Formats

Parts of a hydraulic cylinder

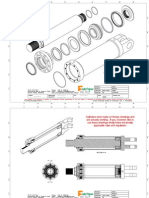

A hydraulic cylinder consists of the following parts:[1] [edit]Cylinder

barrel

The cylinder barrel is mostly a seamless thick walled forged pipe that must be machined internally. The cylinder barrel is ground and/or honed internally [edit]Cylinder

base or cap

In most hydraulic cylinders, the barrel and the bottom portion are welded together. This can damage the inside of the barrel if done poorly. Therefore, some cylinder designs have a screwed or flanged connection from the cylinder end cap to the barrel. (See "Tie rod cylinder", below) In this type the barrel can be disassembled and repaired. [edit]Cylinder

head

The cylinder head is sometimes connected to the barrel with a sort of a simple lock (for simple cylinders). In general, however, the connection is screwed or flanged. Flange connections are the best, but also the most expensive. A flange has to be welded to the pipe before machining. The advantage is that the connection is bolted and always simple to remove. For larger cylinder sizes, the disconnection of a screw with a diameter of 300 to 600 mm is a huge problem as well as the alignment during mounting. [edit]Piston The piston is a short, cylindrical metal component that separates the two parts of the cylinder barrel internally. The piston is usually machined with grooves to fit elastomeric or metal seals. These seals are often O-rings, U-cups or cast iron rings. They prevent the pressurized hydraulic oil from passing by the piston to the chamber on the opposite side. This difference in pressure between the two sides of the piston causes the cylinder to extend and retract. Piston seals vary in design and material according to the pressure and temperature requirements that the cylinder will see in service. Generally speaking, elastomeric seals made from nitrile rubber or other materials are best in lower temperature environments, while seals made of Viton are better for higher temperatures. The best seals for high temperature are cast iron piston rings. [edit]Piston

rod

The piston rod is typically a hard chrome-plated piece of cold-rolled steel which attaches to the piston and extends from the cylinder through the rod-end head. In double rod-end cylinders, the actuator has a rod extending from both sides of the piston and out both ends of the barrel. The piston rod connects the hydraulic actuator to the machine component doing the work. This connection can be in the form of a machine thread or a mounting attachment, such as a rod-clevis or rod-eye. These mounting attachments can be threaded or welded to the piston rod or, in some cases, they are a machined part of the rod-end. [edit]Rod

gland

The cylinder head is fitted with seals to prevent the pressurized oil from leaking past the interface between the rod and the head. This area is called the rod gland. It often has another seal called a rod wiper which prevents contaminants from entering the cylinder when the extended rod retracts back into the cylinder. The rod gland also has a rod wear ring. This wear ring acts as alinear bearing to support the weight of the piston rod and guides it as it passes back and forth through the rod gland. In some cases,

especially in small hydraulic cylinders, the rod gland and the rod wear ring are made from a single integral machined part. [edit]Other

parts

Cylinder base connection Seals Cushions

[edit]Single

acting vs. double acting

You might also like

- English Translation of A Birth Certificate From Honduras PDFDocument1 pageEnglish Translation of A Birth Certificate From Honduras PDFDulce m vazquez67% (6)

- Aluminium Foil & Sheet Project ReportDocument90 pagesAluminium Foil & Sheet Project Reportsugaimpax60% (10)

- Reciprocating Compressor IIDocument59 pagesReciprocating Compressor IIAbdussalamElhanashi75% (4)

- Camden County College MTH-111 Final Exam Sample QuestionsDocument13 pagesCamden County College MTH-111 Final Exam Sample QuestionsAkirajane De GuzmanNo ratings yet

- Volume-2. Design and Manufacturing of Hydraulic CylindersDocument53 pagesVolume-2. Design and Manufacturing of Hydraulic CylindersQ.S. Khan96% (49)

- Submission DrawingDocument9 pagesSubmission DrawingSamma Noor Gujjar0% (1)

- 25X501 ModelDocument1 page25X501 ModelSamma Noor GujjarNo ratings yet

- Hydraulic CylinderDocument6 pagesHydraulic Cylindermichol2014No ratings yet

- Hydraulic CylindersDocument7 pagesHydraulic Cylinderspacopil34No ratings yet

- Hydraulic Cylinders: Faculty of Engineering Cairo University Mechanical Design & Prod. DepartmentDocument21 pagesHydraulic Cylinders: Faculty of Engineering Cairo University Mechanical Design & Prod. DepartmentengmomoNo ratings yet

- Hydraulic Cylinder: The Hydraulic Cylinders On This Control The Machine'sDocument9 pagesHydraulic Cylinder: The Hydraulic Cylinders On This Control The Machine'smanojpro21_9131911970% (1)

- ME080 Section 8 - Other Hydraulic ComponentsDocument101 pagesME080 Section 8 - Other Hydraulic ComponentsAhmed Farag100% (1)

- Materi 3 B.ingDocument27 pagesMateri 3 B.ingAina RamizaNo ratings yet

- Identification of The Diesel Engine ComponentsDocument13 pagesIdentification of The Diesel Engine Componentsguswerino240% (1)

- Parts and Functional Description of Diesel EngineDocument12 pagesParts and Functional Description of Diesel EngineVinay GirdharNo ratings yet

- 1 4dieselenginemovingcomponents 110211123407 Phpapp02Document20 pages1 4dieselenginemovingcomponents 110211123407 Phpapp02Srimaden SuharningsihNo ratings yet

- Compressor PartsDocument7 pagesCompressor PartsinamNo ratings yet

- CH 1 Cylinder Block Cylinder Head, GasketsDocument49 pagesCH 1 Cylinder Block Cylinder Head, GasketsBogdan Constantin CristeaNo ratings yet

- Basic Components of Internal Combustion EnginesDocument62 pagesBasic Components of Internal Combustion EnginesEnergy KojoNo ratings yet

- Engine Construction 1Document11 pagesEngine Construction 1collins arogoNo ratings yet

- Construction of Automotive EngineDocument55 pagesConstruction of Automotive EngineArindom NagNo ratings yet

- What Is Cylinder BlockDocument6 pagesWhat Is Cylinder BlockJa Phe TiNo ratings yet

- Hydraulic Cylinder by Syed Jaffer PDFDocument39 pagesHydraulic Cylinder by Syed Jaffer PDFSiraj Busse100% (7)

- Chapter 3Document29 pagesChapter 3Abdullah OmerNo ratings yet

- Fundamentals of Engine Construction and OperationDocument10 pagesFundamentals of Engine Construction and OperationAnonymous R4WpNx100% (4)

- English Invention ProjectDocument18 pagesEnglish Invention Projectapi-301281543No ratings yet

- Reciprocating Compressor IIDocument59 pagesReciprocating Compressor IISagar Naduvinamani100% (1)

- Piston RingDocument8 pagesPiston RingashokkumarNo ratings yet

- Engine Design and Components: Crank ShaftDocument17 pagesEngine Design and Components: Crank Shaftanjali sharmaNo ratings yet

- Engine TechnologyDocument236 pagesEngine TechnologyjeffkwentrickksivorNo ratings yet

- The Diesel LocomotiveDocument24 pagesThe Diesel LocomotivePool KingNo ratings yet

- Laporan Praktikum Sealing-BearingDocument26 pagesLaporan Praktikum Sealing-Bearinga2sn_elizNo ratings yet

- Reciprocating Compressor IIDocument66 pagesReciprocating Compressor IIAli O Dalki100% (1)

- 03 Engine Bottom EndDocument31 pages03 Engine Bottom EndRohit Raj100% (1)

- IC Presentation TwoDocument50 pagesIC Presentation Twofirst lastNo ratings yet

- Pneumatic Auto Feed Drilling Machine With Indexing Machine: SynopsisDocument30 pagesPneumatic Auto Feed Drilling Machine With Indexing Machine: SynopsisMaruthi JacsNo ratings yet

- 05 BPPistons 000Document59 pages05 BPPistons 000rabbajNo ratings yet

- Construction of Ic EngineDocument11 pagesConstruction of Ic EngineAfifah ZaynabNo ratings yet

- Construction of Automotive EngineDocument83 pagesConstruction of Automotive EngineSaqlain Mushtaque FahimNo ratings yet

- What When How - Com Cylinder Block AutomobileDocument19 pagesWhat When How - Com Cylinder Block AutomobilerameshgmorayNo ratings yet

- Hydraulic Cylinder AppDocument5 pagesHydraulic Cylinder AppwanradhiahNo ratings yet

- Components of Ic Engine T613010Document9 pagesComponents of Ic Engine T613010Kolte RushikeshNo ratings yet

- Chapter - 3 Study of The Components of The EngineDocument14 pagesChapter - 3 Study of The Components of The EngineKenmoe T DonasNo ratings yet

- ChatGPT AutotronicsDocument28 pagesChatGPT AutotronicsGokul Thalapthy Harish KumarNo ratings yet

- Gas Turbine Engine Bearings and Seals PDFDocument2 pagesGas Turbine Engine Bearings and Seals PDFInsan PratamaNo ratings yet

- Differences Between Crosshead and Trunk EnginesDocument12 pagesDifferences Between Crosshead and Trunk Engineshpss77No ratings yet

- Positive Displacement Compressors: Rotary Compressors or BlowersDocument11 pagesPositive Displacement Compressors: Rotary Compressors or BlowersMuhammad AsadNo ratings yet

- Components of EngineDocument3 pagesComponents of EngineajayNo ratings yet

- Part OneDocument9 pagesPart OneJesson Jade PahitNo ratings yet

- IC Engines: - Dhruv ShahDocument21 pagesIC Engines: - Dhruv ShahAshitaNo ratings yet

- Basic Engine: Systems OperationDocument3 pagesBasic Engine: Systems OperationTri WahyuningsihNo ratings yet

- Components of Ic Engine: Bed PlateDocument7 pagesComponents of Ic Engine: Bed PlatePrathamesh ThubeNo ratings yet

- Block - ConrodDocument22 pagesBlock - ConrodArnold ChafewaNo ratings yet

- Main Parts of An Internal Combustion EngineDocument9 pagesMain Parts of An Internal Combustion EngineVenkatNo ratings yet

- Chapter-3 Cylinder Heads, Cylinders & LinersDocument18 pagesChapter-3 Cylinder Heads, Cylinders & LinersRam KumarNo ratings yet

- CylinderDocument2 pagesCylinderSrikanthreddy AnnadiNo ratings yet

- Give Examples of Internal Combustion Engine That Is Commonly Used in Engineering FieldDocument11 pagesGive Examples of Internal Combustion Engine That Is Commonly Used in Engineering Fieldaruna MoonNo ratings yet

- 03 Frames & Tie RodsDocument24 pages03 Frames & Tie RodsnareshNo ratings yet

- IntroductionDocument9 pagesIntroductionBekalu DanielNo ratings yet

- Marine Diesel EngineDocument5 pagesMarine Diesel Enginemy generalNo ratings yet

- Components or Parts of IC Engine With Its Function PDFDocument9 pagesComponents or Parts of IC Engine With Its Function PDFMilbert Vaz AlfonsoNo ratings yet

- Short Notes of Fundamental of AutomativeDocument83 pagesShort Notes of Fundamental of AutomativeOMKAR ZITENo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- 25X50 2-ModelDocument1 page25X50 2-ModelSamma Noor GujjarNo ratings yet

- Unity Free SourceDocument35 pagesUnity Free SourceSamma Noor GujjarNo ratings yet

- 25X50 ModelDocument1 page25X50 ModelSamma Noor GujjarNo ratings yet

- Curriculam Vitae: Muhammad AdeebDocument2 pagesCurriculam Vitae: Muhammad AdeebSamma Noor GujjarNo ratings yet

- 25X50 2modelDocument1 page25X50 2modelSamma Noor GujjarNo ratings yet

- CivilDocument1 pageCivilSamma Noor GujjarNo ratings yet

- Architectural - Notes Ilir NurediniDocument11 pagesArchitectural - Notes Ilir NurediniSamma Noor GujjarNo ratings yet

- Study Guide CEG UpdatedDocument15 pagesStudy Guide CEG UpdatedSamma Noor GujjarNo ratings yet

- Introduction To Autocad Basic Drawing SkillsDocument6 pagesIntroduction To Autocad Basic Drawing SkillsSamma Noor GujjarNo ratings yet

- Vocational Training Institute Gujranwala: Govt. of The PunjabDocument2 pagesVocational Training Institute Gujranwala: Govt. of The PunjabSamma Noor GujjarNo ratings yet

- Basic Lines and ViewsDocument15 pagesBasic Lines and ViewsSamma Noor GujjarNo ratings yet

- P Types of Computer PPT 111228100651 Phpapp01Document17 pagesP Types of Computer PPT 111228100651 Phpapp01Samma Noor GujjarNo ratings yet

- IEDD - 4 - Alphabet of Lines QuizDocument1 pageIEDD - 4 - Alphabet of Lines QuizSamma Noor GujjarNo ratings yet

- Autocad 2008 3D TutorialDocument29 pagesAutocad 2008 3D TutorialMarisete de Azevedo92% (13)

- Autocad 2008, 1. Level, 2dDocument29 pagesAutocad 2008, 1. Level, 2dSamra DukićNo ratings yet

- Research Proposal: Designing and Manufacturing of GearsDocument1 pageResearch Proposal: Designing and Manufacturing of GearsSamma Noor GujjarNo ratings yet

- Activity 3 - Trim and ExtendDocument7 pagesActivity 3 - Trim and ExtendSamma Noor GujjarNo ratings yet

- Project TimeLineDocument1 pageProject TimeLineSamma Noor GujjarNo ratings yet

- Computer Systems: Standard Grade RevisionDocument25 pagesComputer Systems: Standard Grade RevisionSamma Noor GujjarNo ratings yet

- Introduction To ComputersDocument144 pagesIntroduction To ComputersSamma Noor GujjarNo ratings yet

- The Impact of National Culture PDFDocument30 pagesThe Impact of National Culture PDFJovanaNo ratings yet

- Accounting Cycle Journal Entries With Chart of AccountsDocument3 pagesAccounting Cycle Journal Entries With Chart of AccountsLala BoraNo ratings yet

- RCDC SWOT Analysis - Tech Manufacturing FirmsDocument6 pagesRCDC SWOT Analysis - Tech Manufacturing FirmsPaul Michael AngeloNo ratings yet

- The Rise of Judicial Governance in The Supreme Court of IndiaDocument56 pagesThe Rise of Judicial Governance in The Supreme Court of IndiaMAHANTESH GNo ratings yet

- 02 Security Market Indices and Market Efficiency PDFDocument27 pages02 Security Market Indices and Market Efficiency PDFNgân Hà NguyễnNo ratings yet

- Products For Leisure TourismDocument32 pagesProducts For Leisure TourismMayet BautistaNo ratings yet

- User Manual: HMC4000 Marine Genset ControllerDocument50 pagesUser Manual: HMC4000 Marine Genset ControllerVinhNo ratings yet

- MSA CalculationDocument1 pageMSA Calculationshivshankar kushwahaNo ratings yet

- Sample Cover Letter and Resume - Director Public Sector Appeals Grievance ReviewsDocument6 pagesSample Cover Letter and Resume - Director Public Sector Appeals Grievance ReviewsManojNo ratings yet

- Industrial Marketing 5-6Document2 pagesIndustrial Marketing 5-6Mary Grace Ygot ParachaNo ratings yet

- Set Up A Branch in The UK of Your Business in 90 DAYSDocument3 pagesSet Up A Branch in The UK of Your Business in 90 DAYSThe SmartMove2UkNo ratings yet

- Product Life Cycle of Lux SoapDocument66 pagesProduct Life Cycle of Lux SoapAbhimita GaineNo ratings yet

- Syllabus DJT 50110Document3 pagesSyllabus DJT 50110Sharizal SanikNo ratings yet

- Create Your Family Emergency Communication Plan PDFDocument8 pagesCreate Your Family Emergency Communication Plan PDFMary GarrisNo ratings yet

- Time Series AnalysisDocument24 pagesTime Series AnalysisEzra AhumuzaNo ratings yet

- NTSE Odisha Merit ListDocument8 pagesNTSE Odisha Merit ListShrutija SwainNo ratings yet

- Using A ComputerDocument30 pagesUsing A ComputerJEEHANDSOME RANDOMNo ratings yet

- Jawaban Suzette WashingtonDocument1 pageJawaban Suzette Washingtonakmal muzamarNo ratings yet

- Experiment No.4 Generatiton of Sequence With MATLABDocument12 pagesExperiment No.4 Generatiton of Sequence With MATLABDaniel BobisNo ratings yet

- Smoke Calculation Based On ACPHDocument8 pagesSmoke Calculation Based On ACPHabuwaquaseNo ratings yet

- Recommended Books For RBI Grade B Exam With Bonus Online MaterialDocument15 pagesRecommended Books For RBI Grade B Exam With Bonus Online MaterialrahulNo ratings yet

- Summer Internship File Very ImportantDocument32 pagesSummer Internship File Very ImportantYash SharmaNo ratings yet

- Pumps Request LetterDocument1 pagePumps Request LetterJazz SicatNo ratings yet

- Service Standard 05 Prevention and Control of InfectionDocument25 pagesService Standard 05 Prevention and Control of InfectionSuhaimeNo ratings yet

- Mary Oneill Resume - LatestDocument2 pagesMary Oneill Resume - Latestapi-237173493No ratings yet

- Astm E94 2004Document14 pagesAstm E94 2004Adam GrajewskiNo ratings yet

- 3 BOARD OF COMMISSIONER V DELA ROSADocument3 pages3 BOARD OF COMMISSIONER V DELA ROSAAnne VallaritNo ratings yet