Professional Documents

Culture Documents

JSA Word Construction of Workshop

JSA Word Construction of Workshop

Uploaded by

gerard_borbonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA Word Construction of Workshop

JSA Word Construction of Workshop

Uploaded by

gerard_borbonCopyright:

Available Formats

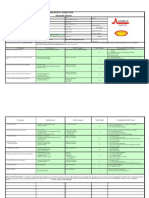

AIR LIQUIDE PHILIPPINES

SAFETY DEPARTMENT

LAJMAR MANAGEMENT AND TECHNOLOGY RESOURCES

11 Gamma Road, Villa Jose, Batangas City Author: RG BORBON ALPI Safety TI Project

TI CLARK BULK GAS PROJECT

AIR LIQUIDE PHILIPPINES

TI CLARK BULK GAS PROJECT

JHA NO:

JHA TITLE:

JOB HAZARD ANALYSIS CONSTRUCTION OF WORKSHOP

DATE: 3/25/08

Approved By:

Company: Prepared By: Reviewed By: AIR LIQUIDE PHILIPPINES RGG BORBON Scope (Definition of Work / Activities): Construction of Workshop for Phase 2 of the Bulk Gas Project

Basic Job Task / Steps

PREPARATION AND HAULING OF MATERIALS (MANUAL LIFTING)

Recommended Control Measures

Potential Hazards

Lifting of Heavy Objects

Potential Accidents

Back Injury

Administrative Control Measures

Engineering Control Measures

Responsible Persons (By Whom?)

Date

Lifting of Objects with: Sharp Edges Pointed Edges Irregularly Shaped Materials Tripping Hazards Slipping Hazards

Hand Injury Laceration, Cut, Splinters, Puncture Wounds, etc. Fall on the same level Injuries

Train workers on proper lifting techniques Workers to get help if load is too heavy Use carts if load is too heavy Wear proper PPE (Gloves) Use carts to transport load Tools to be kept properly when not in use Waste materials to be hauled regularly Regular housekeeping to eliminate tripping and slipping hazards Wear safety glasses all the times while working Always wear proper PPEs Always wear complete PPEs Use gloves Proper tool usage Do not use makeshift tools Use tools for their intended purpose only Keep tools in safe places / position when not in use Use gloves Use gloves with rubber palms Take rest if nailing for a long time Observe proper body posture while working Stretch out once in a while Take rest if awkward posture is unavoidable Wear Proper PPE (Safety Shoes / Gloves) Take out protruding nails from wood Haul used wood pieces out of area immediately with caution In case of puncture wounds, Antitetanus shots should be administered to victim Inspect tools before and after using Use Gloves Maintain safe distance of hands from saw edges Keep tools in safe places / position when not in use Dont leave tools unattended Take rest if nailing for a long time Wear Safety Glasses / Goggles while working Observe proper body posture while working Stretch out once in a while Take rest if awkward posture is unavoidable Inspection of ICE prior to use Check for oil / fuel leaks Tender / Fire Watcher present Fire Extinguisher ready Train workers on Proper use of equipment Keep away from moving parts if exposure is unavoidable Ensure Cover / Guards are in place Use gloves Wash Hands thoroughly when taking breaks and after finishing activity Ensure Machine Guards are present Training for workers on proper use of equipment Use proper PPE Training for workers on proper use of equipment Do not wear loose clothing Ensure Machine Guards are in place Install Machine Guards if not installed Do not remove guards Ensure Machine Guards are in place Install Machine Guards if not

Mgmt. Supervisor

Workers

Workers

WOOD NAILING

Dust / Minute / Foreign Objects that may enter Eyes Bump Into or Being Hit by Materials and Tools Hit by Tools (Hammer)

Eye Injury Head Injury Eye Injury Hand Injury Bruises, wound, etc.

Workers

Rough wood surface Slippery Handle / Hands Repetitive Stress / Motion of the hands Awkward Body Posture in Long time length

Hand Injury - Splinters Injury (Hit by hammer) Strain / Sprain Back Injury

Workers Workers Workers Workers

Sharp Pointed Objects (Protruding Nails on Wood)

Puncture Wounds (Biological Hazard) Tetanus

Mgmt. Workers

WOOD CUTTING (Handsaw)

Defective Tools Shear Points / Sharp Points (Saw Tooth)

Injury Injury Cut, Laceration, Splinters, etc.

Workers Workers

Repetitive Stress / Motion of the Hands Flying Objects Awkward Body Posture in Long time length

Strain / Sprain Eye Injury Back Injury

Workers Workers Workers

CEMENT MIXING (Using Cement Mixer)

Defective Internal Combustion Engine

Fire

Tender / Fire Watcher Ensure Machine Guards are in place Install Machine Guards if not installed Do not remove guards Mgmt. Supervisor Workers

Exposed Moving Parts Catch Points, Pinch Points, etc.

Injury Wounds (Laceration, Cut, etc.)

HOT WORKS (Cutting of Materials Cutter/Grinder)

Skin Contact with Chemical (Cement Corrosive) / Ingestion of Chemical through unwashed hands when eating Cutting Points (Cutter Edge)

Allergic Reactions

Workers

Injuries Lacerations, Cuts, etc.

Mgmt. Supervisor Workers

Rotating Points / Parts (Rotating Disc)

Being caught in the rotating point

Mgmt. Supervisor Workers

ALPI SAFETY FILES 2008 JHATEMPLATE / 03-25-08 RGGBorbon

AIR LIQUIDE PHILIPPINES

SAFETY DEPARTMENT

LAJMAR MANAGEMENT AND TECHNOLOGY RESOURCES

11 Gamma Road, Villa Jose, Batangas City Author: RG BORBON ALPI Safety TI Project

TI CLARK BULK GAS PROJECT

Sparks flying from contact between disc and material being cut

Fire

Burns

Fumes coming from hot works / cutting activities Shattering of Cutting Disc while performing cutting works Flying Objects (pieces of the disc)

Inhalation of fumes / Breathing Difficulty Injury Laceration, Cuts, etc.

Remove plug from power source to avoid injuries from accidental powering on of equipment when changing discs Do not leave grinder unattended and plugged into power source Inspection of equipment prior to use ensure all equipments are in good working condition Train workers on fire hazards and fire control measures Fire watchers should be trained Fire Extinguisher and Fire Watcher should be present at all times during hot works Do not wear clothing with tears and holes Always wear complete and proper PPE for tasks in hand Wear Proper respirator for the job Inspection of equipment prior to use Grinding discs should be inspected if it is in good condition and should be used according to manufacturers recommendations Training for workers on proper use of equipment Use proper PPE Workers should be trained in the proper use of equipment Workers should be trained in the proper positioning when using grinder Workers should wear Safety Glass and Face Shield Inspect equipment prior to use Do not use defective electrical equipment Inspect equipment wires for wear and exposed wires Use tagging system for equipment inspections Install Ground Fault Circuit Interrupter (GFCI) to the power source Inspect equipment prior to use Do not use defective electrical equipment Inspect equipment wires for wear and exposed wires Use tagging system for equipment inspections Take rest / breaks if cutting for a long time Observe proper body posture while working Stretch out once in a while Take rest if awkward posture is unavoidable Wear Welding mask with the correct lens gauge / shade Inspect equipment prior to use Check for leaks on connections and hoses Do not use defective equipment / equipment parts Ensure Flashback Arresters are installed Observe proper cylinder care Use proper tool to ignite gas outfit Wear Proper respirator for the job Wear Welding mask to prevent fumes from entering eyes Inspection of equipment prior to use ensure all equipments are in good working condition Train workers on fire hazards and fire control measures Fire watchers should be trained Fire Extinguisher and Fire Watcher should be present at all times during hot works Remove combustible materials Remove unused cylinders from area Leaking cylinders should be immediately removed from the site Do not leave equipment unattended Inspect equipment prior to use Check for leaks on connections and hoses Do not use defective equipment / equipment parts Ensure Flashback Arresters are installed

installed Do not remove guards

Separation by Barricades use fire blankets to isolate sparks coming from cutting activities

Mgmt. Supervisor Workers

Mgmt. Supervisor Workers Mgmt. Supervisor Workers Mgmt. Supervisor Workers

Ensure Machine Guards are in place Install Machine Guards if not installed Do not remove guards Separation / Isolation by Barricades Use Fire Blankets and/or plywood to isolate cutting works

Eye Injury Unsafe Wiring / Exposed Electrical Wiring Electrocution

Workers Mgmt. Supervisor Workers

Fire

Mgmt. Supervisor Workers

Repetitive Stress / Motion of the Hands Awkward Body Posture in Long time length

Strain / Sprain Back Injury

Workers Workers

HOT WORKS (Welding Works)

Intense Light from Welding Works Flashbacks

Eye Injury Blindness Fire / Explosion Injury / Burns

Workers

Fumes coming from hot works / cutting activities

Inhalation of fumes / Breathing Difficulty Sore Eyes Fire

Ensure proper ventilation for the welders Separation / Isolation by Barricades Use Fire Blankets and/or plywood to isolate welding works

Workers Workers Mgmt. Supervisor Workers

Sparks

Leaks on connections / gauges

Fire Accumulation of gas in area

Workers

ALPI SAFETY FILES 2008 JHATEMPLATE / 03-25-08 RGGBorbon

AIR LIQUIDE PHILIPPINES

SAFETY DEPARTMENT

LAJMAR MANAGEMENT AND TECHNOLOGY RESOURCES

11 Gamma Road, Villa Jose, Batangas City Author: RG BORBON ALPI Safety TI Project

TI CLARK BULK GAS PROJECT

Tripping hazard presented by the hoses used in the hot works

Injury

Working in areas with high temperatures / Working under the sun OTHER PRECAUTIONS

Heat stroke Health problems Dehydration

Observe proper cylinder care Use proper tool to ignite gas outfit / nozzle Arrange the hoses in a manner that they do not present tripping hazards Put signs or caution tapes on the hoses for added visibility Provision of Drinking Water in area Provision for proper ventilation More frequent breaks Brief workers on activities prior to start Workers should be trained in proper cylinder care Welders doing hot works should be certified Presence of Mind for the workers Worker should not work if he is not 100% fit Housekeeping Before, After, and During Activities

Mgmt. Supervisor Workers Mgmt. Supervisor Workers Mgmt. Supervisor Workers

Barricade work area to deny entry to other workers not connected to the activities being done

HAZARD CLASSIFICATION:

PHYSICAL HAZARDS / UNSAFE CONDITIONS: 1. 2. 3. 4. 5. 6. 7. 8. 9. Catch Points Pinch Points Run-in Points Shear Points Squeeze Points Rotating Parts Flying Objects Falling Objects Sharp / Pointed Objects 10. Tripping Hazard 11. Heavy Objects 12. Temperature Extremes 13. Spills 14. Slippery Surfaces 15. Flammable Materials 16. Electricity 17. Radiation 18. Noise Exposure (TLV) 19. Pressure Extremes 20. Work at Heights 21. Oxygen Deficient/Rich Atmosphere Poor Lighting / Illumination Intense Lighting / Illumination Cave-Ins / Landslide Flooding Infrastructure Collapse CHEMICAL HAZARDS: Points of Entry: 1. Ingestion 2. Inhalation 3. Injection 4. Skin Contact / Absorption 5. Eye Contact / Absorption 6. Nail Absorption Accumulation of Gas Classification of Chemical Hazards: 1. Mist 2. Fumes 3. Dust 4. Vapors 5. Flammable / Highly Flammable 6. Explosive 7. Pyrophoric Chem. 8. Oxidizers 9. Corrosives 10. Reactives 11. 12. 13. 14. 15. 16. 17. 18. Asphyxiants Irritants Sensitizers Hepatotoxins Nephrotoxins Hemotoxins Neurotoxins Toxic / Acutely Toxic Chem. 19. Radioactive Chem. 20. Teratogens 21. Reproductive Toxin 22. Cryogenic 23. Anesthetics BIOLOGICAL: Bacteria Virus Fungi GENERAL ADMINISTRATIVE CONTROL MEASURES: 1. Regular Housekeeping 2. Rotation / Scheduling 3. Planning of Work Activities 4. Proper Training 4.1 Work Safety Orientation 4.2 Additional Training for Special Tasks 5. Health Provisions 5.1 Health & Sanitation e.g. Portalet, First Aid Kit, etc 5.2 Provision of Drinking Water at Work Area 5.3 Provisions of Proper PPE and Usage Training 6. Regular Inspection (Area, Equipment, Tools, etc.) 7. Assigning of Complete and Competent Personnel for Activity GENERAL ENGINEERING CONTROL MEASURES: 1. Ventilation 2. Proper Illumination 3. Isolation of Work Area 4. Substitution (on Process or Materials) 5. Prevention of Energy Release (LOTO-TO) 6. Separation (by Time or Location) 7. Separation (by Barriers or Barricades) 8. Strengthening/Modification (Structure or Design) 9. Strengthening/Modification (Excavationwalls Shoring, Timbering) 10. Provision / Installation of Equipment to Minimize Hazard

22. 23. 24. 25. 26.

ERGONOMICS 1. Sprain / Strain 2. Repetitive Stress / Motion 3. Awkward Body Posture 4. Musculoskeletal Risks 5. Un-calibrated Equipment

ALPI SAFETY FILES 2008 JHATEMPLATE / 03-25-08 RGGBorbon

You might also like

- Jha Tree Cutting, Felling, Balling v. 2Document10 pagesJha Tree Cutting, Felling, Balling v. 2arsenio100% (1)

- Jha For Earth WorkDocument6 pagesJha For Earth Worknik100% (14)

- JHA 15-Work at Height Using ScaffoldingDocument3 pagesJHA 15-Work at Height Using ScaffoldingWte SB100% (7)

- 006 HIRARC Hacking of Pile CapDocument5 pages006 HIRARC Hacking of Pile Capbdiey71% (7)

- JHA For Tiling WorkDocument1 pageJHA For Tiling WorkMuhammad Suffyanazwan80% (5)

- Jsa ExcavationDocument33 pagesJsa Excavationlal5012002390782% (17)

- JSA Erection of Gathering TentDocument12 pagesJSA Erection of Gathering TentMuhammad Tariq100% (2)

- Hazard Analysis Structural SteelDocument3 pagesHazard Analysis Structural SteelRobbie Grose100% (3)

- JSA - Cable Trench ExcavationDocument9 pagesJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- Job Safety AnalysisDocument1 pageJob Safety AnalysisChowKC03100% (5)

- Job Safety Analysis - : Installing Wall Frames and Roof Trusses On-SiteDocument6 pagesJob Safety Analysis - : Installing Wall Frames and Roof Trusses On-SiteNaz ッ Wany100% (2)

- JSA For Demobilization WorksDocument2 pagesJSA For Demobilization WorksIanne Dee85% (13)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- Concrete Work JSADocument1 pageConcrete Work JSAAnonymous goXrLOI50% (4)

- Job Hazard Analysis of Site SURVEYINGDocument1 pageJob Hazard Analysis of Site SURVEYINGYogesh Gowda100% (1)

- Jha For RoadworksDocument15 pagesJha For RoadworksHenry RajahNo ratings yet

- 03 Hirarc Construction o Contiguous Bore Pile BiaxisDocument6 pages03 Hirarc Construction o Contiguous Bore Pile BiaxisRosli Bin Abdul Shukor100% (1)

- JSA Steel Erection ManliftsDocument1 pageJSA Steel Erection Manliftsrudygoot100% (1)

- BYDP-JHA-05 Erection of ScaffoldingDocument4 pagesBYDP-JHA-05 Erection of ScaffoldingAhmad Shauqi100% (6)

- Actions To Protect and Safeguard All Persons On Board in EmergenciesDocument29 pagesActions To Protect and Safeguard All Persons On Board in EmergenciesnikoskarandinosNo ratings yet

- 2.4 JHA Slope Triming & Laying Alpha MatDocument10 pages2.4 JHA Slope Triming & Laying Alpha MatSamsiah Tola100% (1)

- Health, Safety, & Environment Manual: Piling WorksDocument12 pagesHealth, Safety, & Environment Manual: Piling Worksrizal azizanNo ratings yet

- Painting Job Hazard AnalysisDocument2 pagesPainting Job Hazard Analysisisaacjoe77100% (1)

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- JHA For Concreting WorkDocument2 pagesJHA For Concreting WorkTigor GurningNo ratings yet

- Excavation Job Safety AnalysisDocument1 pageExcavation Job Safety AnalysisVishal Upadhyay100% (3)

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- JSA WeldingDocument2 pagesJSA WeldingSigint Sides0% (3)

- 33 - Demolition Works & DebrisDocument2 pages33 - Demolition Works & DebrisRafee PieNo ratings yet

- Jha New Format-Painting Revision)Document8 pagesJha New Format-Painting Revision)Kenny Hassan100% (1)

- 013 JSA For Earthwork at Receiving BasinDocument4 pages013 JSA For Earthwork at Receiving BasinHilbrecht De Pedro100% (1)

- Job Hazard Analysis For Desalination of First Effect RetubingDocument7 pagesJob Hazard Analysis For Desalination of First Effect Retubingmc chesterNo ratings yet

- Apollo Fire Detectors UL 268 7th Edition HandoutDocument2 pagesApollo Fire Detectors UL 268 7th Edition HandoutnaveedfndNo ratings yet

- FM-GUIDE Rubber StorageDocument20 pagesFM-GUIDE Rubber StorageTeodorescu Andrei0% (1)

- JSA MasnoryDocument4 pagesJSA Masnorysubhanmusadiq100% (1)

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisChristine YasaNo ratings yet

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- JHA ConcretePlacingOperationDocument3 pagesJHA ConcretePlacingOperationAnonymous XJ9663C6N4No ratings yet

- JHA Example - CHC ScenarioDocument2 pagesJHA Example - CHC ScenarioBNCHNo ratings yet

- PTW JHA Installation of New Control Panel at WWTPDocument2 pagesPTW JHA Installation of New Control Panel at WWTPPHH9834100% (1)

- Pile Cutting / Hacking (Sub-Structure Work)Document2 pagesPile Cutting / Hacking (Sub-Structure Work)Rahmat HariNo ratings yet

- SWMS - Hot WorkDocument14 pagesSWMS - Hot WorkParasNo ratings yet

- JHA For Painting WorkDocument2 pagesJHA For Painting WorkTigor Gurning100% (1)

- Concrete Formwork Suspended SlabDocument5 pagesConcrete Formwork Suspended SlabKate HopleyNo ratings yet

- Rohan Abuilders (India) PVT - LTD: Job Hazard AnalysisDocument2 pagesRohan Abuilders (India) PVT - LTD: Job Hazard AnalysisMc Evans Magallanes100% (1)

- R.K Construction: Job Hazard AnalysisDocument8 pagesR.K Construction: Job Hazard AnalysisDwitikrushna Rout100% (1)

- 1installation of Steel Structures JHA 1 (06!06!2015)Document33 pages1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Hirarc CRDocument76 pagesHirarc CRNazri100% (1)

- ScaffoldingDocument7 pagesScaffoldingFreshop SurabayaNo ratings yet

- Job Hazard Analysis Site InspectionDocument12 pagesJob Hazard Analysis Site InspectionNonsoufo eze100% (1)

- 1 Scaffolding Work PDFDocument16 pages1 Scaffolding Work PDFfadliNo ratings yet

- Job Safety Analysis For Rebar FixingDocument4 pagesJob Safety Analysis For Rebar FixingJayvee Baradas Valdez67% (3)

- Job Hazard Analysis Form (Shutdown Activites)Document4 pagesJob Hazard Analysis Form (Shutdown Activites)MARK ARQUE LACANARIA100% (2)

- Job Hazard Analysis: Task/Procedure Hazard Safe ProcedureDocument2 pagesJob Hazard Analysis: Task/Procedure Hazard Safe ProcedureKhairul MuzamilNo ratings yet

- Jha of PaintingDocument3 pagesJha of PaintingAllan Camacho Regalado100% (1)

- Tool Box Talk: House KeepingDocument1 pageTool Box Talk: House KeepingAli Alqaisy100% (1)

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- Hazard Identification, Risk Assessment and Determining Control (Hiradc)Document8 pagesHazard Identification, Risk Assessment and Determining Control (Hiradc)mohd addin100% (1)

- Health Safety & Environment Procter & Gamble, Ibadan PlantDocument6 pagesHealth Safety & Environment Procter & Gamble, Ibadan PlantsacbaloNo ratings yet

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Job Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Document20 pagesJob Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Barkat Ullah50% (2)

- OME553 Industrial Safety Engineering: (Open Elective)Document47 pagesOME553 Industrial Safety Engineering: (Open Elective)Jana garan.s100% (1)

- Fire Safety For Commercial Building in Malaysia Business EssayDocument6 pagesFire Safety For Commercial Building in Malaysia Business EssaySuriati100% (2)

- Code of Practice Hardware For Fire and Escape DoorsDocument122 pagesCode of Practice Hardware For Fire and Escape DoorsShannon HopkinsNo ratings yet

- Nfpa 45Document19 pagesNfpa 45moha19841100% (1)

- Computer Center Security and ControlsDocument10 pagesComputer Center Security and ControlsSyra Soriano100% (1)

- Regular and Irregular Verbs ListDocument13 pagesRegular and Irregular Verbs ListRobert Boris Vaca ReyesNo ratings yet

- Government of The People's Republic of Bangladesh Sample Question Bank For Certificate of Proficiency (COP) MCQ ExamDocument13 pagesGovernment of The People's Republic of Bangladesh Sample Question Bank For Certificate of Proficiency (COP) MCQ ExamGazi Amir hamzaNo ratings yet

- Disaster MGT BooksDocument38 pagesDisaster MGT BooksBeenu BhallaNo ratings yet

- New York State and Municipal Facilities Program Project NominationDocument627 pagesNew York State and Municipal Facilities Program Project NominationNew York SenateNo ratings yet

- Spred Enamel Latex Semi-GlossDocument2 pagesSpred Enamel Latex Semi-GlossJodyNo ratings yet

- PSCRB+ Exit Exam Q & A - 5Document4 pagesPSCRB+ Exit Exam Q & A - 5Nima Kamal100% (1)

- Propilena DatasheetDocument10 pagesPropilena DatasheetDiana BanuNo ratings yet

- UntitledDocument22 pagesUntitledcollins ogudoNo ratings yet

- Fire Fighting SystemsDocument4 pagesFire Fighting SystemsUsmanNo ratings yet

- 910-14 (Military MedJHHGical) SBGDocument15 pages910-14 (Military MedJHHGical) SBGSamsam Dequito AlthalathiniNo ratings yet

- Smoke Alarms PamphletDocument2 pagesSmoke Alarms PamphletBeacon HoseNo ratings yet

- DS310 (New Electric Box) - GDocument122 pagesDS310 (New Electric Box) - GIrvinDiazOscategui100% (2)

- Swami Vivekanand University, SAGAR (M.P.) : SyllabusDocument29 pagesSwami Vivekanand University, SAGAR (M.P.) : SyllabusKiran ReddyNo ratings yet

- DC-8 Tires Fatal Crash Accident Prevention AviationDocument6 pagesDC-8 Tires Fatal Crash Accident Prevention AviationRebecca RiversNo ratings yet

- ALISTODocument20 pagesALISTOJO ANN DURADONo ratings yet

- Disaster Prevention and MitigationDocument65 pagesDisaster Prevention and MitigationKeyvin dela CruzNo ratings yet

- Emergency Prepareness PlanDocument3 pagesEmergency Prepareness PlanRomelyn LaguraNo ratings yet

- 5 Safety UscgDocument146 pages5 Safety Uscgavinash90No ratings yet

- TFP1346 10 2014Document10 pagesTFP1346 10 2014Nguyễn Thống NhấtNo ratings yet

- Ficha Tecnica Junta Flexible RciDocument1 pageFicha Tecnica Junta Flexible Rcikind23No ratings yet

- The Black PyramidDocument4 pagesThe Black PyramidGeorge FuryNo ratings yet

- Hyperion: Written By: Emily ReichDocument8 pagesHyperion: Written By: Emily Reichemily_reichNo ratings yet

- Ethanol Tank FireDocument20 pagesEthanol Tank FireAhmedAmer1No ratings yet