Professional Documents

Culture Documents

Shell & Tube Condenser Design: O O O O O O

Shell & Tube Condenser Design: O O O O O O

Uploaded by

tpchoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell & Tube Condenser Design: O O O O O O

Shell & Tube Condenser Design: O O O O O O

Uploaded by

tpchoCopyright:

Available Formats

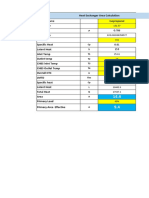

SHELL & TUBE CONDENSER DESIGN

NOTE:

DO NOT CHANGE THE FIGURES WHICH ARE COLOURED

STEP - 1

TO CALCULATE HEAT LOAD

1) SHELL SIDE FLUID (vapourizing fluid)

2) TUBE SIDE FLUID (utility)

INPUT DATA :

1) Cp OF SHELL SIDE FLUID HOT FLUID( Kcal/Kg OC)

2) Cp OF TUBE SIDE FLUID COLD FLUID( Kcal/Kg OC)

5) TEMP. OF HOT FLUID INLET ( OC )

6) TEMP. OF HOT FLUID OUTLET ( OC )

7) TEMP. OF COLD FLUID INLET ( OC )

8) TEMP. OF COLD FLUID OUTLET ( OC )

9)SP.GR. OF SHELL SIDE FLUID

10) LATENT HEAT OF VAPORISATION (Kcal/KG C)

11) FLOWRATE OF SHELL SIDE FLUID (Kg/Hr)

12) FLOWRATE OF TUBE SIDE UTILITY FLUID (Kg/Hr)

13) FLOWRATE OF TUBE SIDE UTILITY FLUID (m3/Hr)

STEP - 2

TO CALCULATE LMTD FOR COUNTER CURRENT FLOW :

HOT FLUID IN

41

COLD FLUID OUT

35

DIFFERENCE

6

HOT FLUID OUT

COLD FLUID IN

DIFFERENCE

STEP - 3

OVERALL HEAT TRANFER COEFFICIENT CONSIDERATION.

BTU/HrM2OK

CONSIDERED=

50

244

Kcal/M2.hr.C

STEP - 4

HEAT TRANSFER AREA CALCULATION

INPUT DATA

1) HEAT LOAD

2) LMTD

3) OVERALL HEAT TRANSFER COEFFICIENT

Heat Transfer Area ( M2 )

STEP - 5

AREA OF THE CONDENSER REQUIRED

(CONSIDERING 20 % DIVERSITY)

NSER DESIGN

water

water

1

0.35

41

35

30

35

1.32

87

792

42089

42

105.8 F

95 F

86 F

95 F

COLD FLUID

Total Boile up

Kg/Hr

m3/Hr

35

30

5

73656 Kcal/Hr

5.4848149

2 O

244 Kcal/Hr-M - C

55.037199

M2

66.04

M2

Acetonitrile

81.75

-47

Benzene

80.1

Carbon Bisulfide

46.3

Chloroform

Cyclohexane

DMF

152.8

EDC

600 torr

-59.4

500 torr

1.7

56.5

400 torr

139.6

Acetone

200 torr

Acetic Anhydride

100 torr

-17.2

63

80

99

105

110

82.2

100

119.8

126

133

7.7

22.7

39.5

46

51

15.9

27

43.7

62.5

68

74

7.6

15.4

26.1

42.2

60.6

67

73

-43.94

-21.16

-13.6

-5.1

10.4

28

34.57

39.5

-39.1

-29.7

-7.1

0.5

10.4

25.9

42.7

48

54

-25.4

-15.9

6.7

14.7

25.5

42

60.8

68

73

19.3

32.47

62.85

72.91

86.48

106.7

129.3

137.2

143.83

60 torr

118.1

40 torr

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

Solvent

10 torr

Acetic Acid

Sr.N

o.

5 torr

1 torr

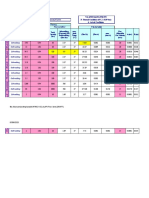

Common Solvent Data Sheet

B.P. in

o

C at

Atm Pr.

6.3

17.5

43

51.7

24.8

36

62.1

70.8

-40.5

-31.1

-9.4

-2

-26.6

-16.3

7.7

-36.7

-19.6

-11.5

-73.87

-53.8

61.3

-58

80.7

-45.3

84

-44.5

-24

-13.6

10

18.1

29.4

45.7

64

70

76

Ethanol

78.4

-31.3

-12

-2.3

19

26

34.9

48.4

63.5

68

72

EPH

117.9

-16.5

5.6

16.6

42

50.6

62

79.3

98

Ethyl Acetate

77

-43.4

-23.5

-13.5

9.1

16.6

27

42

59.3

64

70

FFA

146

14.5

27.59

57.48

67.38

80.74

100.62

124.88

130.62

137.17

Formaldehyde

-19.5

-88

-70.6

-65

-57.3

-46

-33

-32

-27

IPA

82.5

-26.1

-7

2.4

23.8

30.5

39.5

53

67.8

70

77

MDC

39.75

-70

-52.1

-43.3

-22.3

-15.7

-6.3

24.1

30

34

Methanol

64.7

-44

-25.3

-16.2

12.1

21.2

34.8

49.9

55

59

33

-82.17

-62.99

-53.49

-31.65

-24.42

-14.66

-0.14

16.11

21.76

26.55

MIPA

Mono Chloro Benzene

132

-13

10.6

22.2

49.7

58.3

70.7

89.4

110

117

123

MTBE

55.2

-68.32

-47.75

-37.56

-14.14

-6.38

4.07

19.65

37

43.15

48.28

n-Butanol

117.5

-1.2

n-Hexane

68.7

Petroleum Ether

60-80

20

30.2

41.5

60.3

70.1

84.3

100.8

106

111

-34.5

-25

-2.3

5.4

15.8

31.6

49.6

56

61

172

Phenol

182

40.1

62.5

73.8

100.1

108.4

121.4

139

160

168

Pyridine

115.4

-18.9

2.5

13.2

38

46.8

57.8

75

95.6

108

108

66

-61.58

-40.34

-29.81

-5.62

2.39

13.19

29.28

47.29

53.55

58.85

110.6

-26.7

-4.4

6.4

31.8

40.3

51.9

69.5

89.5

97

102

1.2

11.2

34

41.5

51.6

66.5

79.41

86.3

92.13

THF

Toluene

Water

100

o-Xylene

139.3

-15.86

9.97

22.78

52.2

61.94

75.08

94.65

116.55

124.16

130.61

m- Xylene

144

-12.93

13.2

26.15

55.9

65.76

79

98.84

120.99

128.69

135.21

p- Xyleme

137-138

Aniline

184

35

58

69.4

97

106

119

140

162

Carbon t Chloride

76.7

-50

-30

-20

4.3

12.3

23

38.3

57.8

Di Ethyl Ether

34.6

-74

-57

-48

-28

-22

-12

2.2

17.9

Dimethyl Sulfoxide

189

33

60

73

103

114

125

146

178

Dioxane

101

-36

-13

-1.2

25

33.8

45.1

62.3

81.8

Ethelene Glycol

197

53

78

92

120

130

142

159

179

Formamide

211

71

96

110

138

147

158

176

194

Methyl Acetate

57.8

-57

-39

-29

-8

-0.5

9.4

24

40

NitroBenzene

211

44

72

84.9

115

129

140

161

186

Propanol -1

82

97.8

-15

14.7

36

43.5

52.8

66.8

Heptane

98

-34

-13

-2

22

31

42

59

78

Glycerine

290

126

154

167

198

208

220

240

263

700 torr

Latent

Heat (Cal

Sp.Gr.

/gm)

115

1.053

96.75

138

1.082

55

0.78

79

78

43.9

Sp. Heat

Cp

(Kcal/Kgo

C)

Flash Point Viscosity

Vap.

Melting

(Close Cup) in CP (25 Density point

o

(oC)

C)

(Kg/m3)

(oC)

0.522

39

1.15

2.07

96.44

0.236

48.8

0.91

124.3

0.538

-18

0.33

0.783

173.68

0.541

0.38

0.8787

103

0.419

-11

0.65

1.263

59.35

-30

NA

59

1.484

59.01

0.231

none

0.57

78.5

0.7781

93.81

0.44

-18

0.98

149.6

0.945

137.81

0.486

58

0.82

82

1.2569

77.33

0.3015

13

0.9

3.35

76

0.789

204.26

0.68

13

1.2

1.62

1.183

97.95

94.26

0.457

-4.4

0.46

Mol.

Wt.

Solubility

in water at

20 oC (%

w/w)

16.7

60.05

3.52

-73

102.09

12

-94.6

58.08

infinite

1.5

0.41

41.05

infinite

5.5

78.11

0.18

-108.6

76.13

4.12

-63.5

119.4

0.82

2.9

6.6

54.16

0.0052

-61

73.1

infinite

-40

98

NIL

-112

46.07

infinite

-25.6

92.53

-82.4

88.1

3.05

infinite

74

0.901

142.87

1.03

7.7

-24

0.815

-92

30.03

Very soluble

80

0.785

159.35

0.67

-11.7

0.34

2.07

-101

60.1

infinite

37.5

1.3255

77.077

0.2888

None

0.44

2.93

-96.7

84.94

63

0.7915

269.79

0.605

12

..65

1.1

-97.8

32.04

infinite

30.72

0.692

119.09

0.65

129

1.107

78.3

0.311

29

0.8

52.75

0.747

78.196

0.508

-28

0.35

114

0.81

141.26

0.687

35

294

66

0.6591

80.48

0.527

-18

0.31

infinite

60

0.635

0.498

-40

59.111

3.04

2.97

-45.2

112.56

-109

88.15

0.049

4.8

-79.9

74.12

7.45

-94

86.17

0.001

2.5

178

1.071

0.561

79

2.8

113

0.982

107.36

40.6

94.11

8.2

0.431

20

0.88

-42

79.1

infinite

63.47

0.889

92.414

107

0.866

88.17

0.325

4.4

0.59

97.22

0.99

540

0.99

NA

0.89

136.22

0.88

81.86

0.4

27

0.85

140.89

0.87

81.86

0.4

32

0.86

81.86

0.4

1.032

103

0.512

46

0.2

0.713

123

0.473

-40

0.24

74.12

6.9

1.101

178

0.7

85

1.99

78

Fully Miscible

1.034

102

0.4

12

1.3

88

Fully Miscible

1.113

191

0.573

>110

20.9

62

Fully Miscible

1.134

112

0.595

154

3.8

45.04

Fully Miscible

0.932

98

0.4

-9

0.37

-98.7

74.08

24.5

1.196

79

0.339

87

1.86

5.7

123.11

0.19

0.804

164

0.582

15

1.72

60.1

Fully Miscible

0.684

87.18

0.518

-1

0.41

1.261

124.17

0.4

160

945

-17.22

2.5

-108

72.1

Fully Miscible

3.14

-95

92.13

0.06

18

100

3.6

-47.4

106.1

NIL

0.6

3.6

-25

106.4

0.02

27

0.65

3.6

13-14

106.1

NIL

70

3.8

-6.2

93.13

3.8

-22.6

153.84

9.5-10.5

9.6

100.21

0.005

92.09

Fully Miscible

Acetone Condenser

Tray Oven

Acetone Liquid

Coolant Fluid Out

Heat Input

Basis of Drying Oven Operation:

1.

2.

3.

4.

Wet solid product is put into Tray Oven; oven is sealed closed.

Heat input is applied to oven;

Cooling fluid is circulated through acetone condenser;

vacuum pump is started;

As the wet solid is heated in the oven, the vapor pressure of the acetone increases and the acetone starts to vaporiz

produced by the vacuum pump;

The vacuum pump works to maintain the set partial vacuum that is controlled by allowing atmospheric air to "bleed" i

vacuum pump - under ideal conditions - would not not normally have to continue to operate after extracting all non-co

in the real world situation, there will be air infiltration into the partial vacuum system through the oven door seals, the

These air infiltrations try to defeat the vacuum created and, as a consequence, the vacuum pump is left to continue t

by allowing the atmospheric air to bleed in and keep the pump working at capacity.

The partial vacuum is really set by the temperature of the cooling fluid in the acetone condenser. The acetone has t

that corresponds to the acetone vapor pressure equal to the partial vacuum setting. This allows the acetone to cond

as a liquid and not be "sucked" (extracted) out of the system by the vacuum pump.

If the temperature of the condensed acetone is sufficiently cold, there will little or undetected losses of acetone exitin

The addition of heat into the oven accelerates the rate of acetone evaporation and speeds up the drying process; the

the cold energy that has to be inputted into the condenser as the coolant fluid.

Vacuum Pump

ant Fluid Out

acetone starts to vaporize at the lower, partial vacuum pressure

mospheric air to "bleed" into the vacuum pump suction. The

after extracting all non-condensables from the system. However,

the oven door seals, the gaskets, equipment and piping joints, etc., etc.

pump is left to continue to operate - although at a reduced capacity

nser. The acetone has to be cooled and condensed at a temperature

llows the acetone to condense and drop out of the condenser

d losses of acetone exiting in the vacuum pump exhaust to atmosphere.

up the drying process; the price to pay for this capacity increase is

You might also like

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- Chemical Compatibility GuideDocument41 pagesChemical Compatibility Guidetpcho100% (1)

- Chemical Compatibility GuideDocument41 pagesChemical Compatibility Guidetpcho100% (1)

- Ammonia Wet Scrubber System (17-7-2018)Document12 pagesAmmonia Wet Scrubber System (17-7-2018)addin wokatuba100% (1)

- Aspen Case 4 RDocument137 pagesAspen Case 4 RItxaso Villanueva OraaNo ratings yet

- Major Project PPT GGBSDocument20 pagesMajor Project PPT GGBSNaReN KumarNo ratings yet

- En - 13384 2 EnglishDocument61 pagesEn - 13384 2 Englishbadmike71No ratings yet

- Distillation Column: Major Equipment DesignDocument45 pagesDistillation Column: Major Equipment Designrubesh_rajaNo ratings yet

- Blowdown Vessel CalculationDocument1 pageBlowdown Vessel CalculationOmkarNo ratings yet

- Centrif Pumps1 SpreadsheetDocument2 pagesCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Tank Venting Capacity-Fire CaseDocument1 pageTank Venting Capacity-Fire CaseAjay TiwariNo ratings yet

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Air Cooler Design (Ujian)Document36 pagesAir Cooler Design (Ujian)Wahyu JatiNo ratings yet

- Flash CalculationsDocument10 pagesFlash CalculationsHamza AliNo ratings yet

- Pipe DimensionDocument7 pagesPipe DimensionLily NurdianaNo ratings yet

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocument11 pagesProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemNo ratings yet

- Timah - Open Spray - Tower - For - Flue - Gas - Scrubbing - Design 56870 NCMHDocument1 pageTimah - Open Spray - Tower - For - Flue - Gas - Scrubbing - Design 56870 NCMHAyahKenzie100% (1)

- Flammability WorksheetDocument6 pagesFlammability WorksheetshailendraNo ratings yet

- Flue Gas 360 PDFDocument2 pagesFlue Gas 360 PDFwatson123No ratings yet

- Heatcalc: A Natural Gas Heat of Combustion CalculatorDocument7 pagesHeatcalc: A Natural Gas Heat of Combustion CalculatorMuzzamilNo ratings yet

- IncineratorDocument6 pagesIncineratorKamal DeshapriyaNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudylguardiaNo ratings yet

- Hitungan PPDocument30 pagesHitungan PPHamdan ShdNo ratings yet

- Pump CalcDocument121 pagesPump Calcravirawat15No ratings yet

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocument2 pagesBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1100% (1)

- N2 RequirementDocument2 pagesN2 RequirementsandeshNo ratings yet

- Ammonia Plant Simulation 25.08.2016Document81 pagesAmmonia Plant Simulation 25.08.2016Manish Gautam100% (1)

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 pagesSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNo ratings yet

- Design of Distillation Columns - ImpDocument13 pagesDesign of Distillation Columns - ImpAlla VijayNo ratings yet

- REBOILER (RB-101) : Operating ConditionsDocument27 pagesREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiNo ratings yet

- Ogpe OGPE Oil Fields: Calculation SheetDocument4 pagesOgpe OGPE Oil Fields: Calculation SheetFaber TrujilloNo ratings yet

- Separator Sizing SpreadsheetDocument10 pagesSeparator Sizing SpreadsheetEmmanuel ByensitaNo ratings yet

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- Heat Conduction Pipe InsulationDocument1 pageHeat Conduction Pipe InsulationJogender DhayalNo ratings yet

- Orifice Sizing TemplateDocument2 pagesOrifice Sizing TemplaterajeevjayanathNo ratings yet

- Horizontal KO PotDocument4 pagesHorizontal KO Pothk168No ratings yet

- Heat Transfer. Exchangers Design. Effectivness and Number of Transfer Units NTUDocument70 pagesHeat Transfer. Exchangers Design. Effectivness and Number of Transfer Units NTUHenry WicaksanaNo ratings yet

- Packed Column Calculation Results: Packing Details System DetailsDocument1 pagePacked Column Calculation Results: Packing Details System Detailsdinakaranpatel100% (1)

- Relief Load CalculationDocument8 pagesRelief Load CalculationMuthuKumar ArunachalamNo ratings yet

- Vent Line Pressure Drop CalculationDocument4 pagesVent Line Pressure Drop CalculationRubensBoerngenNo ratings yet

- Operating Data : Two Pahse Horizental Separator Sizing From Total CoDocument3 pagesOperating Data : Two Pahse Horizental Separator Sizing From Total CoadammzjinNo ratings yet

- Vapor Line Sizing-Mpp6Document10 pagesVapor Line Sizing-Mpp6Nitin KurupNo ratings yet

- Pump Affinity (K0 SNW)Document6 pagesPump Affinity (K0 SNW)Myat Kyaw HeinNo ratings yet

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- See Sheet API-2000: Normal Venting Liquid Movement Thermal EffectDocument33 pagesSee Sheet API-2000: Normal Venting Liquid Movement Thermal EffecthhvgNo ratings yet

- Steam Ejector CalculationsDocument7 pagesSteam Ejector Calculationshoangvubui4632No ratings yet

- Matreail BalanceDocument1 pageMatreail BalanceATUL SONAWANENo ratings yet

- Chimney Draught Calculations: //vboxsrv/conversion - Tmp/scratch - 4/195995390.xls - Ms - OfficeDocument1 pageChimney Draught Calculations: //vboxsrv/conversion - Tmp/scratch - 4/195995390.xls - Ms - OfficemohdnazirNo ratings yet

- Mass Balance (Final)Document26 pagesMass Balance (Final)Adeel AhmedNo ratings yet

- Condensate Line SizingDocument4 pagesCondensate Line SizingMubin Ashraf SheikhNo ratings yet

- 20120507091359 (1)Document6 pages20120507091359 (1)Noman Abu-FarhaNo ratings yet

- XSteam Excel v2.6Document3 pagesXSteam Excel v2.6pchanycNo ratings yet

- Cooling Tower. Merkel Theory - TreybalDocument39 pagesCooling Tower. Merkel Theory - TreybalMarx CesarNo ratings yet

- Bell Method Example 7 5Document9 pagesBell Method Example 7 5jnmanivannanNo ratings yet

- Upl HBDSDocument32 pagesUpl HBDSSuparna BhoseNo ratings yet

- Tutorial Steam GenerationDocument2 pagesTutorial Steam GenerationAmanda KodippiliNo ratings yet

- Bkf4143-Process Engineering Economics 11213 PDFDocument11 pagesBkf4143-Process Engineering Economics 11213 PDFJeevanNairNo ratings yet

- Water Chillers R407C - R22: Air Cooled Water Chillers With Scroll Compressors and Axial FansDocument4 pagesWater Chillers R407C - R22: Air Cooled Water Chillers With Scroll Compressors and Axial FansgoodtiNo ratings yet

- Prediction of Reaction Enthalpy and Adiabatic Temperature RiseDocument20 pagesPrediction of Reaction Enthalpy and Adiabatic Temperature RisetpchoNo ratings yet

- Itrform12bb PDFDocument3 pagesItrform12bb PDFtpchoNo ratings yet

- Petrofac WebinarDocument6 pagesPetrofac WebinarrrusNo ratings yet

- Dry HCL Gas HandlingDocument5 pagesDry HCL Gas HandlingtpchoNo ratings yet

- HydrogenationDocument3 pagesHydrogenationtpchoNo ratings yet

- Pfaudler Mixing SystemsDocument6 pagesPfaudler Mixing SystemstpchoNo ratings yet

- JS Pressure Safety Valve FinalDocument28 pagesJS Pressure Safety Valve FinaltpchoNo ratings yet

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To InformationtpchoNo ratings yet

- Evaporators PDFDocument31 pagesEvaporators PDFtpcho100% (5)

- Reboilers PDFDocument0 pagesReboilers PDFtpchoNo ratings yet

- Distillation Column Design: Syed Zaheer AbbasDocument21 pagesDistillation Column Design: Syed Zaheer AbbastpchoNo ratings yet

- Honeywell-Sensing-Kgz10 Series Oxygen SensorsDocument4 pagesHoneywell-Sensing-Kgz10 Series Oxygen SensorstpchoNo ratings yet

- CH 5 Ion PracticeDocument2 pagesCH 5 Ion PracticeMahmoud AladdasiNo ratings yet

- Instrukcja EasyMIG210 210s 215 225 EN-1Document28 pagesInstrukcja EasyMIG210 210s 215 225 EN-1Nick INo ratings yet

- Summer Training ReportDocument24 pagesSummer Training ReportJayant MathurNo ratings yet

- General Chemistry 1: Quarter 1 - Module 3 Determining Molar Mass Chemical Reactions and EquationsDocument26 pagesGeneral Chemistry 1: Quarter 1 - Module 3 Determining Molar Mass Chemical Reactions and EquationsVima SanchezNo ratings yet

- Variable Head Type FlowmetersDocument32 pagesVariable Head Type FlowmetersAnuNarayan R100% (2)

- A11.18 - Mobilux EP 2Document1 pageA11.18 - Mobilux EP 2Dony LieNo ratings yet

- SMS - Thin Film Evaporator PDFDocument20 pagesSMS - Thin Film Evaporator PDFdj22500100% (1)

- AnswersDocument5 pagesAnswers22 shantanu kapadnisNo ratings yet

- Me688 UsmDocument39 pagesMe688 UsmKETU PRINCE LEKUNo ratings yet

- Introduction To Environmental EngineeringDocument12 pagesIntroduction To Environmental EngineeringTemesgen SemagnNo ratings yet

- XI Science PDFDocument26 pagesXI Science PDFCreative GamingNo ratings yet

- Gas Turbine CoolingDocument13 pagesGas Turbine CoolingHimanshu DahireNo ratings yet

- Bengkel Biologi SmartGDocument6 pagesBengkel Biologi SmartGK XuanNo ratings yet

- Corrosion and Its PreventionDocument28 pagesCorrosion and Its PreventionMehul Neha Bisht100% (2)

- Gold Ore Processing PlantDocument4 pagesGold Ore Processing Plantjafer2000No ratings yet

- Petroleum Chemicals OverviewDocument1 pagePetroleum Chemicals OverviewhamburgermcgintyNo ratings yet

- Chapter 1 Solutions DetailedDocument30 pagesChapter 1 Solutions DetailedYeonjae JeongNo ratings yet

- 2017mar11 PHY1001 Assignment 4Document2 pages2017mar11 PHY1001 Assignment 4AbhimanyuNo ratings yet

- Acoustic Insulation Under FloorDocument11 pagesAcoustic Insulation Under FloorMiteshaNo ratings yet

- Mining: Supercritical Flow Critical Flow Subcritical FlowDocument3 pagesMining: Supercritical Flow Critical Flow Subcritical FlowBoonsita NammanaNo ratings yet

- Piu RajakDocument18 pagesPiu Rajakpiu_rajakNo ratings yet

- The Real Trick To Drying Ceramic Ware Is To Use A Method That Removes The Water From The Inside of The Ceramic As Fast As The Surface Water Is EvaporatedDocument55 pagesThe Real Trick To Drying Ceramic Ware Is To Use A Method That Removes The Water From The Inside of The Ceramic As Fast As The Surface Water Is EvaporatedMiguel OcampoNo ratings yet

- Edxrf VS WDXRF PDFDocument5 pagesEdxrf VS WDXRF PDFkulihat_hijauNo ratings yet

- Innovations in The Food Packaging Market - Intelligent Packaging - A ReviewDocument6 pagesInnovations in The Food Packaging Market - Intelligent Packaging - A ReviewISABELLA CUENÚNo ratings yet

- Impreglon 222M DataSheetDocument3 pagesImpreglon 222M DataSheetKyle S JonesNo ratings yet

- PH537/PI515: Astrostructure and Evolution: Answer With Examples and ReferencesDocument4 pagesPH537/PI515: Astrostructure and Evolution: Answer With Examples and ReferencesSDasNo ratings yet

- MSDS New BERKOCLEAN 508Document5 pagesMSDS New BERKOCLEAN 508haiderparrai00No ratings yet