Professional Documents

Culture Documents

Calculation Drain Pump A

Calculation Drain Pump A

Uploaded by

Sisira ChandrasomaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation Drain Pump A

Calculation Drain Pump A

Uploaded by

Sisira ChandrasomaCopyright:

Available Formats

CALCULATION

HFO / DO DRAIN PUMP SIZING

A 15/06/07 PRELIMINARY ISSUE PMK TAI KN

INL SIGN INL SIGN INL SIGN

REV DATE DESCRIPTION OF REVISION

PRED CHKD PM

OWNER

WEST COAST POWER PRIVATE LIMITED

PROJECT

300 MW CCPP, KERAWALAPITIYA

SRILANKA

EPC CONTRACTOR

LAKDHANAVI LIMITED

CIVIL CONTRACTOR

LTL PROJECTS (PVT) LTD

ENGINEERS FOR

EPC CONTRACTOR

FICHTNER

CONSULTING ENGINEERS (INDIA) PVT LIMITED

CHENNAI, INDIA

PROJECT NUMBER DOCUMENT NUMBER DOCUMENT TYPE REVISION

7856 7856-ME-DSN-131-004 - A

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 2 of 11

Calculation_drain pump_A

TABLE OF CONTENTS

1.0 GENERAL ...................................................................................................... 3

2.0 REFERENCE DOCUMENTS.......................................................................... 3

3.0 DESIGN INPUTS............................................................................................ 3

4.0 ASSUMPTIONS.............................................................................................. 3

5.0 DESIGN CODES............................................................................................ 4

6.0 DESIGN CALCULATIONS ............................................................................. 4

7.0 RESULTS....................................................................................................... 6

ANNEX - I : PIPE SIZING CALCULATIONS.......................................................................... 7

ANNEX II : PIPE THICKNESS CALCULATIONS................................................................. 8

ANNEX III : PRESSURE DROP SUMMARY........................................................................ 9

ANNEX IV : UNLOADING AREA HFO/DO DRAIN PUMP SIZING CALCULATIONS........ 10

ANNEX V : FORWARDING AREA HFO/DO DRAIN PUMP SIZING CALCULATIONS ..... 11

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 3 of 11

Calculation_drain pump_A

1.0 GENERAL

This document provides the HFO/DO Drain Pump sizing calculations.

2.0 REFERENCE DOCUMENTS

The following documents have been referred in carrying out this calculation.

i) Plot Plan : 00-7856-G-001

ii) DBR - Fuel Oil System : 7856-ME-DBR-131-001

iii) Flow diagram - Fuel oil system : 10-7856-M-026

iv) GA of Untreated HFO storage tank : 10-7856-M-108

3.0 DESIGN INPUTS

3.1 General

Maximum allowable stress (S) for Carbon steel (A 106 Gr. B) is considered as 17.1 ksi

(1202.26 kg/cm) for seamless pipes. (Refer Table A1 - Appendix A of ASME B31.1a)

Weld joint efficiency (E) for Carbon steel (A 106 Gr. B) is considered as 1.0 for seamless

pipes. (Refer Table A1 - Appendix A of ASME B31.1a)

Material coefficient (y) is considered as 0.4. (Refer Table 104.1.2(A) of ASME B31.1a)

Corrosion allowance (A) is considered as 1.5 mm.

Manufacturing tolerance (tol) is considered as 12.5%.

The design pressure (P) is the maximum sustained pressure, which is the shut-off

pressure of the system. Design pressure of 15 bar (a) [15.30kg/cm

2

(a)] is considered

adequate.

The design temperature for the piping is considered as 60C.

3.2 Drain Pump Sizing Criteria

The design velocity is limited to 0.9 m/s at suction side and 1.5 m/s at the discharge side

of the Drain oil pump.

Specific gravity of Drain oil at operating temperature is considered as 0.97.

Kinematic viscosity of Drain oil at operating temperature is considered as 1000cSt.

Vapour pressure of Drain oil at operating temperature is considered as 0.2mlc

(Preliminary data).

4.0 ASSUMPTIONS

Pressure drop across suction strainer is considered as 0.45mlc.

The pipe routing considered for pressure drop calculations is preliminary and is subject to

changes based on finalised piping layout

Roughness of the pipe is considered as 0.05mm.

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 4 of 11

Calculation_drain pump_A

5.0 DESIGN CODES

The following codes, standards and publications have been referred

ASME B31.1 Addenda-2005 : Power Piping

ASME B36.10 : Welded & Seamless wrought steel pipe

Flow of fluids Crane hand book.

6.0 DESIGN CALCULATIONS

6.1 Line Sizing Calculation

The pipe inner diameter is calculated based on design flow rate and allowable velocity

Where,

ID = Inside diameter of pipe (m)

Q = Design Flow rate (m

3

/ h)

V = Velocity of flow (m / s)

Based on the calculated inner diameter of the steel pipe, a standard pipe is selected.

6.2 Pipe Wall Thickness Calculation

Using the internal fluid pressure, outer diameter and allowable stress of the material, the

minimum pipe wall thickness is calculated as per ASME B 31.1a, clause 104.1.2 by,

t

m+ t

= t

m

(

tol 100

100

Where,

t

m

= Minimum required wall thickness (mm)

t

m+ t

= Minimum required wall thickness with manufacturing tolerance (mm)

P = Internal design pressure (kg/cm

2

)

OD = Outside diameter of pipe (mm)

S = Maximum allowable stress in material due to internal pressure (kg/cm

2

)

E = Weld joint efficiency

y = Material coefficient

A = Corrosion allowance (mm)

tol = Manufacturing tolerance (%)

( )

(

+

+

= A

Py SE

OD P

t

m

2

V

Q

ID

3600) / ( 4

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 5 of 11

Calculation_drain pump_A

Based on calculated minimum wall thickness a standard pipe thickness is selected. For the

selected pipe thickness, the maximum pressure that can be withstood by the pipe is

calculated as follows:

t

s

= Selected pipe thickness (mm)

For detailed calculations refer ANNEX I & II

6.3 Pressure Drop Calculation

6.3.1 Criteria for Pressure Drop Calculation

A) Pressure drop in the fuel oil piping is calculated using Darcy's equation

Where,

H

f

= Pressure drop in the piping (mlc)

f = Darcy's friction factor for pipe (which is 4 times the Chen's friction

factor)

f ' = Chen's friction factor

L = length of pipe (m)

V = Velocity of the fluid (m/s)

d = Internal diameter of the pipe (m)

g = Acceleration due to gravity (9.81 m/s

2

)

Reynolds number (Re) is calculated by following equation

Where,

= Density (kg/m

3

)

= Viscosity (kg/m sec)

Chen's Friction factor (f ') for piping is calculated by following equation

( )

(

=

) ( 2

2

max

A t y OD

A t E S

P

s

s

2gd

LV f

H

2

f

=

(

(

(

(

|

.

|

\

|

= A4 log

Re

5.0452

-

3.7065

d

k

log 4 -

'

1

f

Vd

Re =

2gd

LV 4f

H

2 '

f

=

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 6 of 11

Calculation_drain pump_A

Where,

k = Roughness of the pipe (mm)

B) For valves and fittings the pressure drop is calculated as follows:

Where,

H

f t

= Pressure drop in valves and fitting in mlc.

K = Resistance co-efficient of fitting as per Flow of Fluids by

Crane.

For pressure drop summary refer ANNEX - III

6.4 HFO/DO Drain Pump Sizing Calculations

The detailed Drain pump sizing calculations are carried out for the HFO/DO Unloading area

and HFO/DO Forwarding area to determine the Total Developed Head (TDH), Available

NPSH and Estimated Shaft power. The detailed calculations are furnished in

ANNEX IV & V.

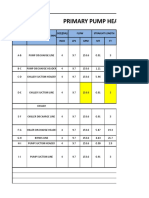

7.0 RESULTS

The results of calculation and final selected parameters for the Unloading and Forwarding

area HFO/DO Drain pump are tabulated below

7.1 Unloading area HFO/DO Drain Pump

Number of working pumps : 1

Pump type : Positive displacement, Single screw,

Vertical tank mounted type.

Rated capacity of the pump : 5 m

3

/hr

Pump design TDH : 50 mlc

Available NPSH : 10.20 mlc

Estimated shaft power : 1.65 kW

7.2 Forwarding area HFO/DO Drain Pump

Number of working pumps : 1

Pump type : Positive displacement, Single screw,

Vertical tank mounted type.

Rated capacity of the pump : 5 m

3

/hr

Pump design TDH : 50 mlc

Available NPSH : 10.20 mlc

Estimated shaft power : 1.65 kW

Re

7.149

2.8257

d

k

A4

0.8981

1098 . 1

|

.

|

\

|

+

|

.

|

\

|

=

g

V

K H

ft

2

2

=

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 7 of 11

Calculation_drain pump_A

ANNEX - I : PIPE SIZING CALCULATIONS

NB

OD of the

pipe

Available ID

of the pipe

m

3

/ h m / s mm - mm SCH mm mm m / s

HFO/DO Unloading area

1

Pipe line from Drain oil pump outlet to

Untreated HFO tank recirculation nozzle

inlet

5 1.5 34.34 50 60.3 80 5.54 49.22 0.73

HFO/DO Forwarding area

2

Pipe line from Drain oil pump outlet to

Untreated HFO tank recirculation nozzle

inlet

5 1.5 34.34 50 60.3 80 5.54 49.22 0.73

Selected pipe details

Calculated

velocity

Location Sl. No.

Flow rate

Limiting

Velocity

Required

ID of the

pipe

Thickness

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 8 of 11

Calculation_drain pump_A

ANNEX II : PIPE THICKNESS CALCULATIONS

UNIT

-

HFO/DO Unloading area

Pipe line from Drain oil pump 1 outlet

to Untreated HFO tank recirculation

nozzle inlet

HFO/DO Forwarding area

Pipe line from Drain oil pump 2 outlet

to Untreated HFO tank recirulation

nozzle inlet

SELECTED PIPE SIZE NB 50 50

mm 60.30 60.30

- SA 106 Gr B SA 106 Gr B

kg / cm(a) 15.30 15.30

C 60 60

kg / cm 1202.26 1202.26

mm 1.50 1.50

- 1 1

- 0.4 0.4

MANUFACTURING TOLERANCE % 12.5 12.5

MINIMUM REQUIRED THICKNESS mm 1.88 1.88

mm 2.15 2.15

SCH 80 80

mm 5.54 5.54

kg / cm 170.22 170.22 MAXIMUM WITH STANDING PRESSURE

PROVIDED THICKNESS

VARIABLE COEFFICIENT

SELECTED PIPE SCHEDULE

MINIMUM REQUIRED THICKNESS

WITH MANUFACTURING

TOLERANCE

MATERIAL

OUTER DIAMETER OF THE PIPE

DESIGN PRESSURE

EFFICIENCY FACTOR

CORROSION ALLOWANCE

DESIGN TEMPERATURE

ALLOWABLE STRESS

PARTICULARS DATA

DESCRIPTION

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 9 of 11

Calculation_drain pump_A

ANNEX III : PRESSURE DROP SUMMARY

bar mlc

1 1.9626 20.625

HFO / DO Forwarding area

2 3.5274 37.069

Pressure drop

Pressure Drop Calculation

HFO / DO Unloading area

Pressure drop in piping from Drain oil pump outlet to

Untreated HFO tank recirculation nozzle inlet

Location S. No

Pressure drop in piping from Drain oil pump outlet to

Untreated HFO tank recirculation nozzle inlet

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 10 of 11

Calculation_drain pump_A

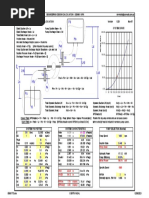

ANNEX IV : UNLOADING AREA HFO/DO DRAIN PUMP SIZING CALCULATIONS

1 Total Number of pumps 1

2 Number of operating pumps 1

3 Total flow per pump (m / h) 5

4 (kg / m

3

) 970

5 Capacity of the drain oil tank m

3

2

I

I. SUCTION SIDE :

1 (mlc) 10.65 (Atmospheric Pressure : 1.01325 bar a )

2 Static Head (mlc) 0.20 (Assumed min.submergence in

the tank)

3 (mlc) 0.00 (Not applicable)

4 Pressure drop in suction strainer (mlc) 0.45 (Preliminary data)

5 Available Suction Head [ Atmospheric pressure + Static head in the tank - (mlc) 10.40

Pressure drop in suction strainer ]

II. DISCHARGE SIDE :

1 Pressure required at destination (mlc) 10.65 (Atmospheric Pressure : 1.01325 bar a )

2 Static head required (mlc) 11.635 (From GA of untreated Heavy fuel

oil storage tank)

3 Friction loss in the piping (mlc) 20.62 (Refer ANNEX - III)

4 Required Discharge Head [ Pressure required at destination + Static head (mlc) 42.91

required + Friction loss in piping ]

III. TOTAL DEVELOPED HEAD :

1 Total Developed Head (mlc) 32.51

[ Required Discharge head - Available Suction head ]

2 Selected Total Develoed Head (mlc) 50.00

II

1 Available pressure (mlc) 10.65 (Atmospheric Pressure : 1.01325 bar a )

2 Static Head (mlc) 0.20 (Assumed min. submergence in the

tank)

3 Piping friction loss in suction line (mlc) 0.00 (Not applicable)

4 Vapour pressure of fuel oil at operating temperature (mlc) 0.20 (Preliminary data)

5 Pressure drop in suction strainer (mlc) 0.45 (Preliminary data)

6 Available NPSH [ Atmospheric pressure + Static head in the tank - (mlc) 10.20

Vapour pressure of fuel oil at operating temperature - Pressure drop in

Suction Strainer)

III

1 Pump type

2 Rated Capacity per pump (m / h) 5

3 Selected Total Developed Head for pump (mlc) 50.00

4 Available NPSH (mlc) 10.20

5 Pump efficiency % 40 (Vendor to confirm)

6 Estimated Shaft power kW 1.65

Vertical tank mounted type

Positive displacement, Singl Screw,

Density of drain oil

PUMP DESIGN PARAMETERS

HEAD CALCULATION

AVAILABLE NPSH CALCULATION

Available pressure

Friction loss in the piping

WCPPL

300 MW Combined Cycle Power Plant

Calculation

HFO / DO Drain Pump Sizing

Doc. No. 7856-ME-DSN-131-004, Rev. A FICHTNER India Page : 11 of 11

Calculation_drain pump_A

ANNEX V : FORWARDING AREA HFO/DO DRAIN PUMP SIZING CALCULATIONS

1 Total Number of pumps 1

2 Number of operating pumps 1

3 Total flow per pump (m / h) 5

4 (kg / m

3

) 970

5 Capacity of the drain oil tank m

3

2

I

I. SUCTION SIDE :

1 (mlc) 10.65 (Atmospheric Pressure : 1.01325 bar a )

2 Static Head (mlc) 0.20 (Assumed min.submergence in

the tank)

3 (mlc) 0.00 (Not applicable)

4 Pressure drop in suction strainer (mlc) 0.45 (Preliminary data)

5 Available Suction Head [ Atmospheric pressure + Static head in the tank - (mlc) 10.40

Pressure drop in suction strainer ]

II. DISCHARGE SIDE :

1 Pressure required at destination (mlc) 10.65 (Atmospheric Pressure : 1.01325 bar a )

2 Static head required (mlc) 11.635 (From GA of untreated Heavy fuel

oil storage tank)

3 Friction loss in the piping (mlc) 37.07 (Refer ANNEX - III)

4 Required Discharge Head [ Pressure required at destination + Static head (mlc) 59.35

required + Friction loss in piping ]

III. TOTAL DEVELOPED HEAD :

1 Total Developed Head (mlc) 48.95

[ Required Discharge head - Available Suction head ]

2 Selected Total Developed Head (mlc) 50.00

II

1 Available pressure (mlc) 10.65 (Atmospheric Pressure : 1.01325 bar a )

2 Static Head (mlc) 0.20 (Assumed min. submergence in the

tank)

3 Piping friction loss in suction line (mlc) 0.00 (Not applicable)

4 Vapour pressure of fuel oil at operating temperature (mlc) 0.20 (Preliminary data)

5 Pressure drop in suction strainer (mlc) 0.45 (Preliminary data)

6 Available NPSH [ Atmospheric pressure + Static head in the tank - (mlc) 10.20

Vapour pressure of fuel oil at operating temperature - Pressure drop in ]

Suction Strainer)

III

1 Pump type

2 Rated Capacity per pump (m / h) 5

3 Selected Total Developed Head for pump (mlc) 50.00

4 Available NPSH (mlc) 10.20

5 Pump efficiency % 40 (Vendor to confirm)

6 Estimated Shaft power kW 1.65

Vertical tank mounted type

Positive displacement, Singl Screw,

Density of drain oil

PUMP DESIGN PARAMETERS

HEAD CALCULATION

AVAILABLE NPSH CALCULATION

Available pressure

Friction loss in the piping

You might also like

- Pump SizingDocument2 pagesPump Sizingfzida8942100% (4)

- Cswip 3.2 Notes 1Document42 pagesCswip 3.2 Notes 1Sisira Chandrasoma100% (7)

- Design Computation Penstock 3Document26 pagesDesign Computation Penstock 3Roland TagufaNo ratings yet

- PUmp Hydraulic Calc SheetDocument2 pagesPUmp Hydraulic Calc Sheetbhavesh dabhi100% (1)

- Pipe Sizing Calculation DumaiDocument39 pagesPipe Sizing Calculation DumaiKemas Muhandis M.100% (3)

- Instrument Air Dryer Sizing CalculationDocument1 pageInstrument Air Dryer Sizing CalculationAravind Kannan100% (3)

- Pump Sizing CalculationDocument12 pagesPump Sizing CalculationLee Min Hyuk100% (5)

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- CW Pump CalculationDocument22 pagesCW Pump Calculationzamijaka100% (2)

- ASME IX PresentationDocument68 pagesASME IX PresentationLalit MohanNo ratings yet

- ASME IX PresentationDocument68 pagesASME IX PresentationLalit MohanNo ratings yet

- Astm C 171 2007Document2 pagesAstm C 171 2007sabruno100% (3)

- HSC 4 1823df c750gpm @190psi - Speed 3350rpmDocument2 pagesHSC 4 1823df c750gpm @190psi - Speed 3350rpmJwardNo ratings yet

- Pump CalculationDocument20 pagesPump Calculationcoolsummer1112143100% (3)

- Hydraulic CalculationDocument7 pagesHydraulic CalculationRais Rijal100% (1)

- Pump SelectionDocument2 pagesPump Selectiongroup2sd1314100% (1)

- Flow Rate CalculationDocument7 pagesFlow Rate CalculationManish PatilNo ratings yet

- Pump Sizing ParametersDocument1 pagePump Sizing ParametersBramJanssen76No ratings yet

- Hydraulic CalculationsDocument20 pagesHydraulic CalculationsJayesh ChandranNo ratings yet

- Pump Head ExampleDocument3 pagesPump Head Examplesulaiman_dme50% (6)

- Sizing Calculation of General Service PumpsDocument193 pagesSizing Calculation of General Service Pumpsmkha87100% (1)

- Pump Sizing Calculation SheetDocument20 pagesPump Sizing Calculation Sheetvazzoleralex6884100% (1)

- PPL CS 10 003 A4 Rev.0 Calculation Hydraulic Pump (A)Document11 pagesPPL CS 10 003 A4 Rev.0 Calculation Hydraulic Pump (A)kemas biruNo ratings yet

- Pipe Thermal ExpansionDocument6 pagesPipe Thermal ExpansionyemoxyNo ratings yet

- Tank SizingDocument1 pageTank SizingSaeid Rahimi Mofrad100% (2)

- Head Loss Calculation - Fire Hydrant Sys..Temporary ReiserDocument15 pagesHead Loss Calculation - Fire Hydrant Sys..Temporary ReiserEngFaisal AlraiNo ratings yet

- Cylinder Hydraulic CalculationDocument4 pagesCylinder Hydraulic Calculationjcpolicarpi0% (1)

- Calculation of Height of The Siphon SystemDocument2 pagesCalculation of Height of The Siphon SystemPhyu Mar Thein Kyaw100% (1)

- Pump Calculation SpreadsheetDocument28 pagesPump Calculation SpreadsheetSHAILENDRANo ratings yet

- Pressure Drop CalculationDocument30 pagesPressure Drop CalculationEbby Onyekwe100% (2)

- Pump and Line Sizing CalcDocument5 pagesPump and Line Sizing CalcMuthuKumar ArunachalamNo ratings yet

- Line Sizing PresentationDocument26 pagesLine Sizing Presentationtagne simo rodrigueNo ratings yet

- Pumps PresentationDocument44 pagesPumps Presentationoida_adNo ratings yet

- Water Booster Pump Calculations - Plumbing Engineering - Eng-TipsDocument3 pagesWater Booster Pump Calculations - Plumbing Engineering - Eng-TipsNeal JohnsonNo ratings yet

- Pump Head CalculationDocument1 pagePump Head CalculationMFaiz RHamiraNo ratings yet

- PRV-1 StepxStep PDFDocument8 pagesPRV-1 StepxStep PDFmiltonNo ratings yet

- 2013lect4 Pumping System of FluidDocument30 pages2013lect4 Pumping System of Fluidmustikaaryanti100% (1)

- Pressure DropDocument23 pagesPressure DropAmr TarekNo ratings yet

- 12.primary Pump Head CalculationDocument4 pages12.primary Pump Head CalculationZain ShariffNo ratings yet

- Pump Hydraulic Check Calculation SheetDocument2 pagesPump Hydraulic Check Calculation Sheetpiziyu100% (1)

- Ventilation SystemDocument42 pagesVentilation SystemJuda Imanuel OsvaldoNo ratings yet

- Pump Head CalculationDocument22 pagesPump Head CalculationShesadri ChakrabartyNo ratings yet

- Pump Calculation ToolDocument8 pagesPump Calculation ToolNikos KolligrisNo ratings yet

- Line SizingDocument2 pagesLine SizingHarryBouterNo ratings yet

- Valve Sizing CalculationDocument1 pageValve Sizing CalculationGrupoMecatrónicaNo ratings yet

- Pump Sizing Calculation SheetDocument7 pagesPump Sizing Calculation SheetManik Kandan100% (1)

- Air Receiver SizingDocument3 pagesAir Receiver Sizingmazumdar_satyajit100% (3)

- PumpSizing SelectionDocument18 pagesPumpSizing SelectionJessicalba LouNo ratings yet

- Hydraulic Calculation For Pipeline PumpsDocument12 pagesHydraulic Calculation For Pipeline PumpsDEEPAK PAL100% (1)

- Pump and Hydraulic CalculationDocument9 pagesPump and Hydraulic CalculationHasen Bebba100% (1)

- Head CalculationDocument24 pagesHead CalculationdheerajNo ratings yet

- Pipe Flow Problems-III: Example 1Document10 pagesPipe Flow Problems-III: Example 1Chaithanya Kumar Dandu100% (1)

- Control Valve SizingDocument3 pagesControl Valve SizingN. S. PanditNo ratings yet

- Fuel Oil Pump Calculation 25-04-2017r4Document29 pagesFuel Oil Pump Calculation 25-04-2017r4Ardian20No ratings yet

- WS CalculationDocument36 pagesWS CalculationDesigner ForeverNo ratings yet

- All System Pump Head LoosDocument33 pagesAll System Pump Head LoosEngFaisal Alrai100% (2)

- Closed Return Loop SystemsDocument31 pagesClosed Return Loop Systemsrecep1No ratings yet

- Engineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System CurveDocument1 pageEngineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System Curvebuntimehta007No ratings yet

- Hydraulic Pump Power Calculation PDFDocument1 pageHydraulic Pump Power Calculation PDFSenthil Kumar75% (4)

- EngineerDocument11 pagesEngineerphaindikaNo ratings yet

- Attachment Doc 2 BGDocument13 pagesAttachment Doc 2 BGLucas JerichoNo ratings yet

- Ship Lube Oil CalculationDocument33 pagesShip Lube Oil Calculation123habib123fikri67% (6)

- RNZ Integrated (M) SDN BHD: Calculation SheetDocument14 pagesRNZ Integrated (M) SDN BHD: Calculation SheetNhantran VanNo ratings yet

- Guidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousesDocument17 pagesGuidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousessubasratnaNo ratings yet

- Fo System Revisi 1Document28 pagesFo System Revisi 1Panji Kresno WijanarkoNo ratings yet

- Waste To Energy Power Plant - Indinisia by JFEDocument167 pagesWaste To Energy Power Plant - Indinisia by JFESisira ChandrasomaNo ratings yet

- Application of Dry Flue Gas Scrubbing To Hazardous Waste IncinerationDocument7 pagesApplication of Dry Flue Gas Scrubbing To Hazardous Waste IncinerationSisira ChandrasomaNo ratings yet

- Basic Principles of Ultrasonic Testing PDFDocument73 pagesBasic Principles of Ultrasonic Testing PDFSisira Chandrasoma100% (1)

- Titanium - Welding and Heat Treating: Topics CoveredDocument13 pagesTitanium - Welding and Heat Treating: Topics CoveredSisira Chandrasoma100% (1)

- WeldingDocument21 pagesWeldingprabhatkumar_6657012No ratings yet

- Welding MetallurgyDocument37 pagesWelding Metallurgyhemant1886100% (4)

- Steel Bridge Design Handbook - Bridge Steels - Mech - Properties - Vol - 01Document59 pagesSteel Bridge Design Handbook - Bridge Steels - Mech - Properties - Vol - 01Cyril VomáčkaNo ratings yet

- Offshore SteelDocument42 pagesOffshore SteelPuvas NandakwangNo ratings yet

- Tank DesignDocument5 pagesTank Designlcabreraduque67% (3)

- AWS A5.01 Filler Metal Procurement GuidelinesDocument19 pagesAWS A5.01 Filler Metal Procurement Guidelinesharpreetresearch100% (4)

- Basic Principles of Ultrasonic TestingDocument73 pagesBasic Principles of Ultrasonic TestingDeepulal LalanNo ratings yet

- Fibre To Fabric Notes 1Document3 pagesFibre To Fabric Notes 1Mohan Reddy KothapetaNo ratings yet

- Purification of Transformer Oil in Pt. PJB Up Paiton: January 2016Document5 pagesPurification of Transformer Oil in Pt. PJB Up Paiton: January 2016Venkataramanan SNo ratings yet

- Relay Ladder LogicDocument3 pagesRelay Ladder LogicChucho KeopsNo ratings yet

- Sika Cemflex 1Document3 pagesSika Cemflex 1rasasiNo ratings yet

- Luk Fail Diag Zms de enDocument48 pagesLuk Fail Diag Zms de enIndranil BhattacharyyaNo ratings yet

- Test Report: Newage CablesDocument4 pagesTest Report: Newage CablesMuhammad Shabbir AwanNo ratings yet

- Forcasting Time HorizonDocument2 pagesForcasting Time HorizonMuhammad MoizNo ratings yet

- WSM Vs ULM Vs LSMDocument3 pagesWSM Vs ULM Vs LSMSameer BelimNo ratings yet

- Simply Supported BeamsDocument5 pagesSimply Supported Beamscataice100% (1)

- Pwps Asme Gtaw & SmawDocument2 pagesPwps Asme Gtaw & SmawMuhammad Fitransyah Syamsuar Putra100% (1)

- Principal I&C Engineer or Principal Instrumentation and ControlDocument3 pagesPrincipal I&C Engineer or Principal Instrumentation and Controlapi-78419400100% (1)

- Dokumen - Tips - Yorkshire Man Steam BoilerDocument8 pagesDokumen - Tips - Yorkshire Man Steam BoilerMAI 1No ratings yet

- Quote For SCR Load Box: Price Schedule & Bill of MaterialDocument2 pagesQuote For SCR Load Box: Price Schedule & Bill of Materialmydearbhava1No ratings yet

- Engineering Drawing Notes ADocument35 pagesEngineering Drawing Notes AShahebaz WandrickNo ratings yet

- Taborex-Ta 2124 HD Catalyst Masterbatch: Product DescriptionDocument1 pageTaborex-Ta 2124 HD Catalyst Masterbatch: Product DescriptionJaime222No ratings yet

- Graco Agitators and MixersDocument14 pagesGraco Agitators and Mixerscumpio425428No ratings yet

- Clay Brick LCADocument1 pageClay Brick LCAsustainbeloit100% (2)

- Equipment and Systems - HVAC and Refrigeration PE Exam Tools - Mechanical PE Sample Exams, Technical Study Guides and ToolsDocument35 pagesEquipment and Systems - HVAC and Refrigeration PE Exam Tools - Mechanical PE Sample Exams, Technical Study Guides and ToolsFaquruddin AliNo ratings yet

- Milling Machine OperationsDocument7 pagesMilling Machine OperationsSachinNo ratings yet

- Why Si Better Over Ge SemiconductorDocument3 pagesWhy Si Better Over Ge Semiconductornishant205kumarNo ratings yet

- Astm-D3914 2002R-2008 933696652097Document6 pagesAstm-D3914 2002R-2008 933696652097Malik AzeemNo ratings yet

- Nitrate and NitriteDocument8 pagesNitrate and Nitritesyafiqabang75% (4)

- 14 Design of Sheet-Pile Walls & BulkheadsDocument10 pages14 Design of Sheet-Pile Walls & BulkheadsbarouniamineNo ratings yet

- Openair Rotary Actuators With Spring Return Gca 1: Technical BasicsDocument36 pagesOpenair Rotary Actuators With Spring Return Gca 1: Technical Basicse-genieclimatique.comNo ratings yet

- Steam - Boilers and TurbinesDocument45 pagesSteam - Boilers and TurbinesVineet KumarNo ratings yet

- Fan Coil Asia York FICHADocument4 pagesFan Coil Asia York FICHAAnderson Márquez PaniaguaNo ratings yet

- LIXI Profiler-ANSIaDocument2 pagesLIXI Profiler-ANSIachen kongNo ratings yet

- B. Prestart Checks of Boiler LightupDocument14 pagesB. Prestart Checks of Boiler LightupPrudhvi RajNo ratings yet