Professional Documents

Culture Documents

629 Iom

629 Iom

Uploaded by

234534Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

629 Iom

629 Iom

Uploaded by

234534Copyright:

Available Formats

Bulletin E-112

Series 629 Differential Pressure Transmitter

Specifications - Installation and Operating Instructions

43/64 [17.07] 1-11/32

[34.13] 3-9/32 [83.34] LIQUID TIGHT FITTING CORD DIAMETER RANGE: .200 TO .350 [5.06 TO 8.89] 1/4 NPT TYP

1-5/8 [41.28] 5-25/32 [146.84] 1/4 NPT FEMALE FITTING 6-59/64 [175.82] OPTIONAL 1/4 NPT MALE FITTING

629 shown with optional cable gland.

The Series 629 Differential Pressure Transmitter monitors differential pressure of air and compatible gases and liquids with 0.5% accuracy. The design employs dual pressure sensors converting pressure changes into a standard 4-20 mA output signal for two wire circuits. Small internal volume and minimum moving parts result in exceptional response and reliability. Terminal block, zero and span adjustments are easily accessed under the top cover. The Series 629 Differential Pressure Transmitter is designed to meet NEMA-4X (IP66) construction.

Range (psid) 10 25 50 100

Pressure Limits Working* Pressure (psid) 20 50 100 200

Over Pressure (psi) 100 250 250 500

* Pressures exceeding the working pressure limit may cause a calibration shift of up to 3% of full scale.

INSTALLATION 1. Location: Select a location where the temperature of the unit will be between 0F and 175F. Distance from the receiver is limited only by total loop resistance (see electrical connections).The tubing feeding pressure to the instrument can be practically any length required, but long lengths will increase the response time slightly. Mount the instrument in a location that will not be subject to excessive temperature, shock or vibration. 2. Position: A vertical position is recommended (pressure connections pointing horizontally) since that is how all standard models were originally spanned and zeroed at the factory. They can be used at other angles, but may require final spanning and zeroing. 3. Pressure Connection: Dual 1/4 female NPT pressure connections are provided. Use pipe thread sealant tape or other suitable pipe joint compound when making connection to the pressure source. Avoid excess sealant which could block the pressure passage. When monitoring liquid pressures, air trapped in the lines can cause incorrect readings. Bleed fittings or similar mechanisms should be used to bleed off any trapped air. Optional 3-Way Valve For applications where higher line pressures may be encountered at installation or when it is necessary to remove the transmitter for maintenance without interrupting the process, the optional three way valve is recommended (See Fig. A). Begin with valve V1 open and valves V2 and V3 closed (See Fig. B). Slowly open valves V2 and V3. Once the pressure has stabilized and is equal on the high and low side of the transmitter, valve V1 can be closed and normal operation can proceed. To ensure proper pressures will be detected by the 629 use the bleed fitting provided with this package to free media of bubbles. Before applying pressure to the process connections, turn V1 to the open position and back off the bleed screw. Next apply pressure. After the flowing liquid is free of bubbles, retighten the bleed screw. Before removing the transmitter from operation, open valve V1 then close valves V2 and V3.

SPECIFICATIONS Service: Compatible gases & liquids. Wetted Materials: Types 316, 316L SS. Accuracy: +/- 0.5% F.S. (includes linearity, hysteresis & repeatability). Temperature Limits: 0 to 200F (-18 to 93C). Compensated Temperature Limits: 0 to 175F (-18 to 79C). Pressure Limits: See chart. Thermal Effect: 0.02%/F (0.036%/C) includes zero & span. Power Requirements: 13-30 VDC. Output Signal: 4 to 20 mA. Optional 0-5, 1-5, 0-10, 1-6 or 2-10 VDC. Zero & Span: Potentiometers inside conduit enclosure Response Time: 50 msec. Loop Resistance: 0-1300 ohms maximum for current output. For voltage outputs, minimum load resistance: 2000 ohms.

6-29/32 [175.42] 2.400 [60.69]

Current Consumption: Transmitter: 40 mA max; Transmitter with optional display: 140 mA max. Electrical Connections: Terminal block. Process Connections: 1/4 female NPT. Display: Optional 4-1/2 digit 1/2 (12.7 mm) height LED. Enclosure Rating: Designed to meet NEMA 4X (IP66). Mounting Orientation: Not position sensitive. Weight: 10.1 oz (286 g). Agency Approvals: CE: EN 61000-4-2 EN 61000-4-3 EN 61000-4-4 EN 61000-4-5 EN 61000-4-6

9/32 [7.14]

13/64 [5.64] DIA MOUNTING HOLES TYP 4 PLACES

5-7/16 [138.11] 6-1/64 [152.81]

2.400 [60.69] 3 [76.20]

2-1/16 [52.39]

Fig. A

BLEED SCREW

Fig. B

DWYER INSTRUMENTS, INC.

P.O. BOX 373 MICHIGAN CITY, INDIANA 46361, U.S.A.

Phone: 219/879-8000 Fax: 219/872-9057

www.dwyer-inst.com e-mail: info@dwyer-inst.com

ELECTRICAL CONNECTIONS Shielded cable is recommended for control loop wiring. Current Output

Wire Length - The maximum length of wire connecting transmitter and receiver is a function of wire size and receiver resistance. Wiring should not contribute to more than 10% of receiver resistance to total loop resistance. For extremely long runs (over 1000 ft.), choose receivers with higher resistance to minimize size and cost of connecting leads. When the wiring length is under 100 feet, lead wire as small as 22 AWG can be used. Current (4-20 mA) Output Operation - An external power supply delivering 13-30 VDC with minimum current capability of 40 mA DC (per transmitter)is required to power the control loop. See Fig. C for connection of the power supply, transmitter, and receiver. The range of the appropriate receiver load resistance (RL) for the DC power supply voltage available is expressed by the formula:

Fig. C: Current output connection Electrical connections to the Series 629 pressure transmitters are made to the terminal block located inside the housing. Remove the screws and lift off the cover. Wire as shown in Fig. C, D or E. Use Fig. C for current output connection. Use Fig. D for current output with optional LED display. Use Fig. E for current output with optional LED display using two power supplies. If ordering pre-wired cable, black wire is negative (-) and red wire is positive (+). RL Max = Vps 13 20 mA DC VOLTAGE (0-5, 1-5, 0-10, 1-6 or 2-10 Volt) OUTPUT OPERATION For voltage outputs, wire as shown in Fig. F or Fig. G. Use Fig. F for voltage output connection. Use Fig. G for voltage output with optional LED display. Terminal 1 is positive (+), terminal 2 is negative (-), terminal 3 is +Vout, terminal 4 is LED positive supply. If ordering optional pre-wired cable, black wire is negative (-), red wire is positive (+) and white wire is +Vout. Voltage Output

1 RED 2 BLACK (COMMON) PRESSURE TRANSMITTER 3 WHITE (+V OUT) POWER SUPPLY 13-30 VDC

ZERO POWER SUPPLY 13-30 VDC + (140 ma) RECEIVER mA LED DISPLAY POSITIVE SUPPLY SPAN TERM 1 (+) TERM 2 (-) TERM 4 (+) YELLOW

PRESS AND HOLD TO ZERO THE DISPLAY PRESS TO DISPLAY THE GAGES PRESSURE RANGE LED DISPLAY CONNECTOR

4 (NC)

+V in RECEIVER

Fig. F: Voltage output connection

TRANSMITTER CONNECTION: - TURN OFF POWER - CONNECT THE POWER SUPPLY AND RECEIVER TO TERM 1 AND TERM 2 OF THE GAGE AS SHOWN - CONNECT POWER SUPPLY (+) TO TERMINAL 4 (REQUIRED FOR THE OPTIONAL DISPLAY ONLY) - INSTALL THE DISPLAYS CONNECTOR - TURN ON POWER

OPTIONAL LED DISPLAY POWER SUPPLY

BE SURE TO TURN OFF POWER WHEN CONNECTING OR REMOVING THE DISPLAYS CONNECTOR. FAILURE TO DO SO CAN RESULT IN THE GAGE DAMAGE.

+ 13-30 VDC (140 ma) -

ZERO LED DISPLAY SPAN POSITIVE SUPPLY TERM 4 (+) TERM 1 (+) TERM 2 (-)

PRESS AND HOLD TO ZERO THE DISPLAY PRESS TO DISPLAY THE GAGES PRESSURE RANGE YELLOW LED DISPLAY CONNECTOR

Fig. D: Current output with optional LED display

RECEIVER + V OUT TRANSMITTER CONNECTION: - TURN OFF POWER - CONNECT POWER SUPPLY (+) TO TERMINAL 1 - CONNECT POWER SUPPLY (-) TO TERMINAL 2 AND THE RECEIVER (-) - CONNECT THE RECEIVER (+) TO TERMINAL 3 - CONNECT LED POWER SUPPLY (+) TO TERMINAL 4 - INSTALL THE DISPLAYS CONNECTOR - TURN ON POWER

TERM 3 (-)

VOLTAGE OUTPUT OPTIONAL LED DISPLAY BE SURE TO TURN OFF POWER WHEN CONNECTING OR REMOVING THE DISPLAYS CONNECTOR. FAILURE TO DO SO CAN RESULT IN THE GAGE DAMAGE.

+ 13-30 VDC (40 ma) -

POWER SUPPLY

ZERO SPAN RECEIVER TERM 1 (+) mA TERM 2 (-) TERM 3 (-) TERM 4 (+) YELLOW

PRESS AND HOLD TO ZERO THE DISPLAY PRESS TO DISPLAY THE GAGES PRESSURE RANGE LED DISPLAY CONNECTOR

Fig. G: Voltage output with optional LED display

LED DISPLAY 13-30 VDC NEGATIVE SUPPLY (100 ma) + LED DISPLAY POSITIVE SUPPLY LED SUPPLY POWER SUPPLY TRANSMITTER CONNECTION: - TURN OFF POWER - CONNECT THE POWER SUPPLY AND RECEIVER TO TERM 1 AND TERM 2 OF THE GAGE AS SHOWN OPTIONAL DISPLAY CONNECTION: - CONNECT LED POWER SUPPLY (-) TO TERMINAL 3 - CONNECT LED POWER SUPPLY (+) TO TERMINAL 4 - INSTALL THE DISPLAYS CONNECTOR - TURN ON POWER

MULTIPLE RECEIVER INSTALLATION An advantage of the standard 4-20 mA DC output signal provided by the Series 629 Differential Transmitter is that any number or receivers can be connected in series in the current loop. Thus, an A-701 digital readout, an analog panel meter, a chart recorder, process controlling equipment, or any combination of these devices can be operated simultaneously. It is necessary only that each be equipped with a standard 4-20 mA input and proper polarity of the input connections be observed when inserting the device into the current loop. If any of the receiving devices displays a negative or downscale reading this indicates that the signal input leads are reversed. MAINTENANCE Upon final installation of the Series 629 Differential Pressure Transmitter and the companion receiver, no routine maintenance is required. A periodic check of the system calibration is recommended. The Series 629 Differential Pressure Transmitter is not field serviceable and should be returned if repair is needed (field repair should not be attempted and may void warranty). Be sure to include a brief description of the problem plus any relevant application notes. Contact customer service to receive a return goods authorization number before shipping.

OPTIONAL LED DISPLAY

BE SURE TO TURN OFF POWER WHEN CONNECTING OR REMOVING THE DISPLAYS CONNECTOR. FAILURE TO DO SO CAN RESULT IN THE GAGE DAMAGE.

Fig. E: Current output with optional LED display using two power supplies

Copyright 2009 Dwyer Instruments, Inc.

Printed in U.S.A. 7/09 Phone: 219/879-8000 Fax: 219/872-9057

FR# 01-443277-00 Rev. 8 www.dwyer-inst.com e-mail: info@dwyer-inst.com

DWYER INSTRUMENTS, INC.

P.O. BOX 373 MICHIGAN CITY, INDIANA 46361, U.S.A.

You might also like

- Instruction Manual: Models 7EF and 7HF ControllersDocument48 pagesInstruction Manual: Models 7EF and 7HF ControllerskmpoulosNo ratings yet

- CIAT Space Gas Control ManualDocument136 pagesCIAT Space Gas Control ManualDorinNo ratings yet

- 32.2.3.4 Wireless - PD - 4 ZXSDR B8200 Product DescriptionDocument32 pages32.2.3.4 Wireless - PD - 4 ZXSDR B8200 Product DescriptionRajesh PorwalNo ratings yet

- Parameters of Choke CoilDocument5 pagesParameters of Choke Coilkrishnareddy_chintalaNo ratings yet

- Group IV June 4,2013 EE 3303 Engr - Kenneth F. FajilanDocument170 pagesGroup IV June 4,2013 EE 3303 Engr - Kenneth F. Fajilanjenixson tamondong100% (2)

- DP Sensor Tech Sheet (Dwyer Series 629)Document2 pagesDP Sensor Tech Sheet (Dwyer Series 629)jed_poliNo ratings yet

- Series 626 & 628 Pressure Transmitters: Specifications - Installation and Operating InstructionsDocument4 pagesSeries 626 & 628 Pressure Transmitters: Specifications - Installation and Operating InstructionslacoalicionpetroleraNo ratings yet

- MTB Oi 4-12Document19 pagesMTB Oi 4-12JerNo ratings yet

- Advanced Motion Controls Sr30a40acDocument11 pagesAdvanced Motion Controls Sr30a40acElectromateNo ratings yet

- Druck PT Data SheetDocument7 pagesDruck PT Data Sheethits289No ratings yet

- Altronic DSG1611DUPS Gauge Install. - Oper. Instructions (FORM DSG1611DUPS II)Document47 pagesAltronic DSG1611DUPS Gauge Install. - Oper. Instructions (FORM DSG1611DUPS II)francis_mouille_iiNo ratings yet

- Sensor de Presion AndersonDocument6 pagesSensor de Presion AndersonHector VelazquezNo ratings yet

- Powersupply 4A12-P4Document4 pagesPowersupply 4A12-P4FightingEntropyNo ratings yet

- Setra Systems: DPT 264 Series Low Pressure Transducers and Transmitters Installation GuideDocument4 pagesSetra Systems: DPT 264 Series Low Pressure Transducers and Transmitters Installation Guidesuperpuma86No ratings yet

- RMC-131D Data Sheet 4921240104 UK - 2014.06.25Document8 pagesRMC-131D Data Sheet 4921240104 UK - 2014.06.25Muhammad AhmadNo ratings yet

- Digital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Document15 pagesDigital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Clever Negrete NovaNo ratings yet

- Digital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Document15 pagesDigital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Clever Negrete NovaNo ratings yet

- Dvpes2 ManualDocument10 pagesDvpes2 Manualmarie1320No ratings yet

- 250T Frequency TransmitterDocument13 pages250T Frequency Transmitterreality88No ratings yet

- Dwyer Ms2 w101 102 LCD ManualDocument8 pagesDwyer Ms2 w101 102 LCD Manualg3qwsfNo ratings yet

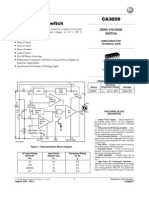

- CA3059Document13 pagesCA3059Luis Miguel BarrenoNo ratings yet

- DWYER - RHP-3D-11.instruções PDFDocument4 pagesDWYER - RHP-3D-11.instruções PDFMarcio Issao WatanabeNo ratings yet

- Setra Model 264 Operating InstructionsDocument4 pagesSetra Model 264 Operating Instructionssuperpuma860% (1)

- m264 PDFDocument4 pagesm264 PDFVidya MuthukrishnanNo ratings yet

- B 15 A 20Document5 pagesB 15 A 20ElectromateNo ratings yet

- 7225 AcDocument12 pages7225 AcEdson AyalaNo ratings yet

- M/V™ Series Servo Drive: Description Power RangeDocument11 pagesM/V™ Series Servo Drive: Description Power RangeElectromateNo ratings yet

- Manual Gp4303d A Gp4185d ADocument11 pagesManual Gp4303d A Gp4185d ADiego AsiconaNo ratings yet

- CA3059Document9 pagesCA3059chinametalNo ratings yet

- Fuente Goldstar PDFDocument11 pagesFuente Goldstar PDFdirectNo ratings yet

- TP2L-3W - 3KVDCDocument3 pagesTP2L-3W - 3KVDCtoppowerNo ratings yet

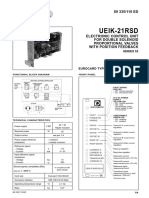

- Amplifier Card For Valve With Feedback UEIK 11RSDocument4 pagesAmplifier Card For Valve With Feedback UEIK 11RSLibin100% (1)

- 004 Pwm-OcxiDocument7 pages004 Pwm-OcxiNeodymeNo ratings yet

- ZI-CT-100 Rev 1Document6 pagesZI-CT-100 Rev 1Harish NarasiahNo ratings yet

- 100 VOLT 30 AMP H-Bridge PWM Motor Driver/Amplifier: M.S.Kennedy CorpDocument7 pages100 VOLT 30 AMP H-Bridge PWM Motor Driver/Amplifier: M.S.Kennedy CorpDaniel SanchezNo ratings yet

- Amplifier Card Euro Card Format UEIK 21 RSDDocument4 pagesAmplifier Card Euro Card Format UEIK 21 RSDLibinNo ratings yet

- DVP-Slim Digitai IO Module Instruction SheetDocument2 pagesDVP-Slim Digitai IO Module Instruction SheetAgnimuthuNo ratings yet

- M/V™ Series Servo Drive: Description Power RangeDocument11 pagesM/V™ Series Servo Drive: Description Power RangeElectromateNo ratings yet

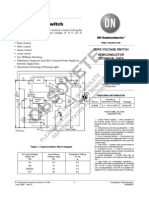

- Semiconductor Technical Data Zero Voltage SwitchDocument6 pagesSemiconductor Technical Data Zero Voltage SwitchMuresan SanduNo ratings yet

- Advanced Monolithic Systems: Features ApplicationsDocument8 pagesAdvanced Monolithic Systems: Features ApplicationsAndres AlegriaNo ratings yet

- DVP06SN11R DatasheetDocument2 pagesDVP06SN11R DatasheetBustamante PerroneNo ratings yet

- Milti TesterDocument5 pagesMilti Testerkdm004xxNo ratings yet

- 25 A 20Document9 pages25 A 20s_barriosNo ratings yet

- H1000e I Ema-Emc PDFDocument4 pagesH1000e I Ema-Emc PDFNguyen Van ChungNo ratings yet

- Advantech Adam 3016Document15 pagesAdvantech Adam 3016maxi_1987No ratings yet

- API DC Input SplittersDocument6 pagesAPI DC Input SplittersAnonymous zdCUbW8HfNo ratings yet

- Multifunctional Digital Multimeter: User Manual Gebruikershandleiding Manuel D'UtilisationDocument9 pagesMultifunctional Digital Multimeter: User Manual Gebruikershandleiding Manuel D'UtilisationtonielhageNo ratings yet

- Dixell: XV105D Fan Speed ControllerDocument2 pagesDixell: XV105D Fan Speed ControllerdbricchiNo ratings yet

- 207 - USER ManualDocument28 pages207 - USER ManualQsanac KumbaraNo ratings yet

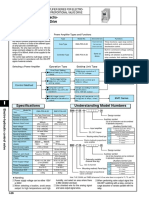

- Series 120A10 Servo Amplifiers MODEL: 120A10: FeaturesDocument5 pagesSeries 120A10 Servo Amplifiers MODEL: 120A10: FeaturesElectromateNo ratings yet

- Series 120A10 Servo Amplifiers MODEL: 120A10: FeaturesDocument5 pagesSeries 120A10 Servo Amplifiers MODEL: 120A10: FeaturesElectromateNo ratings yet

- Series 120A10 Servo Amplifiers MODEL: 120A10: FeaturesDocument5 pagesSeries 120A10 Servo Amplifiers MODEL: 120A10: FeaturesElectromate100% (1)

- PWBXXXXMD-3W Aislado PDFDocument2 pagesPWBXXXXMD-3W Aislado PDFePotyNo ratings yet

- TermostatDocument1 pageTermostatDIANTORONo ratings yet

- Ca3130, Ca3130aDocument17 pagesCa3130, Ca3130aproctepNo ratings yet

- RMP-111D - Installation Instructions 4189340123 UKDocument4 pagesRMP-111D - Installation Instructions 4189340123 UKDuy KhaNo ratings yet

- Panasonic TX-14b4tp B Tc-14b4rp B CH z185Document17 pagesPanasonic TX-14b4tp B Tc-14b4rp B CH z185Marius IonescuNo ratings yet

- High Voltage: SpellmanhighvoltageelectronicscorporationDocument2 pagesHigh Voltage: Spellmanhighvoltageelectronicscorporation박만진No ratings yet

- TAS-331DG Data Sheet 4921220036 UKDocument4 pagesTAS-331DG Data Sheet 4921220036 UKRicardo NunesNo ratings yet

- DdcaDocument2 pagesDdcaVilas BorleNo ratings yet

- Conzerv 6438Document10 pagesConzerv 6438Pur WantoNo ratings yet

- Transductor FLOWSERVE NT3000Document20 pagesTransductor FLOWSERVE NT3000Xavier EspinozaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Sizing of Reactive Power Compensators For Onshore and Offshore Grid Connected Wind FarmsDocument7 pagesSizing of Reactive Power Compensators For Onshore and Offshore Grid Connected Wind FarmsshimymbNo ratings yet

- Product Catalogue Product CatalogueDocument36 pagesProduct Catalogue Product CatalogueDILEEPNo ratings yet

- Acer Travelmate 5310 5710 5710g Extensa 5210 5610 Wistron Dellen Rev Sa SCHDocument43 pagesAcer Travelmate 5310 5710 5710g Extensa 5210 5610 Wistron Dellen Rev Sa SCHЕвгений АвазачемNo ratings yet

- Lab 11 (Linearity & Scaling)Document6 pagesLab 11 (Linearity & Scaling)muhammad hassanNo ratings yet

- AlternatorDocument84 pagesAlternatorVignesh Kumar100% (1)

- 505 Enhanced Service Manual V2Document144 pages505 Enhanced Service Manual V2metalshock75% (4)

- LH 265 BrochureDocument12 pagesLH 265 BrochureHarsha Vardhan BNo ratings yet

- Brushless Alternator SeminarDocument15 pagesBrushless Alternator SeminarGorishsharma67% (3)

- PIC16F73Document174 pagesPIC16F73dan_tiganucNo ratings yet

- Job Sheet: Name: Date: Use of A VoltmeterDocument5 pagesJob Sheet: Name: Date: Use of A VoltmeterJonephine Gonzales PortonNo ratings yet

- Manual Equinox 600 800Document68 pagesManual Equinox 600 800Alexandru VladNo ratings yet

- COMPARISON BETWEEN Satellite-Fiber Optics and Microwave CommunicationsDocument2 pagesCOMPARISON BETWEEN Satellite-Fiber Optics and Microwave CommunicationsKishori Sharan Mathur86% (7)

- Located In: Arcgis/Bin/Styles/Utilities - Style Version: Arcgis 9.0 1Document21 pagesLocated In: Arcgis/Bin/Styles/Utilities - Style Version: Arcgis 9.0 1Ephrem GizachewNo ratings yet

- Jumper: Source Connector Signal Pin - Pin Signal Connector DestinationDocument142 pagesJumper: Source Connector Signal Pin - Pin Signal Connector DestinationFrank OforiNo ratings yet

- CAT - C-10 (Prefix MBJ or 3CS) .Prefix 3CSDocument10 pagesCAT - C-10 (Prefix MBJ or 3CS) .Prefix 3CSPhil B.0% (1)

- Irfp 2907Document9 pagesIrfp 2907Anonymous u8GkNaNo ratings yet

- PowerXL DG1 Application ManualDocument312 pagesPowerXL DG1 Application ManualAlejo RamirezNo ratings yet

- Liebert ITON 600/1000: KEEPS IT ON: A Reliable Power Protection and Backup Solution For Your PCDocument2 pagesLiebert ITON 600/1000: KEEPS IT ON: A Reliable Power Protection and Backup Solution For Your PCVivek BhardwajNo ratings yet

- PW 1980 03 PDFDocument92 pagesPW 1980 03 PDFjolupeco44100% (1)

- DG - Dali - Lighting - DeSIGN GUIDEDocument26 pagesDG - Dali - Lighting - DeSIGN GUIDEAnonymous L3WIDg03No ratings yet

- EG8145V5 Quick Start 01 (R20C00)Document16 pagesEG8145V5 Quick Start 01 (R20C00)cj cjNo ratings yet

- Optimized Design of Substation Grounding System UsDocument7 pagesOptimized Design of Substation Grounding System Usmehrnoosh fakhariNo ratings yet

- Specifications of 3c20ks-lcd En-Sp011222-3c20ks-LcdDocument4 pagesSpecifications of 3c20ks-lcd En-Sp011222-3c20ks-LcdBbb AaaNo ratings yet

- EEE 124 Exp5Document4 pagesEEE 124 Exp5Rakibul Hassan SajonNo ratings yet

- TSK II Series: In-Line Centrifugal Duct FanDocument4 pagesTSK II Series: In-Line Centrifugal Duct FanLuciano EbangNo ratings yet

- Powermax 65 Error CodesDocument4 pagesPowermax 65 Error CodesLuis TorresNo ratings yet