Professional Documents

Culture Documents

Kennedy - Modelo 2945A - Poste Indicador

Kennedy - Modelo 2945A - Poste Indicador

Uploaded by

cchristt2584Copyright:

Available Formats

You might also like

- Same SDF Engines WORKSHOP MANUALDocument170 pagesSame SDF Engines WORKSHOP MANUAL1ansu100% (11)

- 1987 Chevrolet Caprice-Monte Carlo-El Camino Service ManualDocument1,654 pages1987 Chevrolet Caprice-Monte Carlo-El Camino Service ManualPinko Pallino75% (4)

- S2000 SOS Supercharger Install ManualDocument43 pagesS2000 SOS Supercharger Install ManualMatthew Chtchavlinski100% (4)

- Delphi DP210 Fuel Injection Pump CatDocument3 pagesDelphi DP210 Fuel Injection Pump CatSilas F Pimenta90% (20)

- Manual de Instalacion Angelus 60LDocument15 pagesManual de Instalacion Angelus 60LAnonymous WaC9PaQmr100% (1)

- Aw60 40le Zip inDocument10 pagesAw60 40le Zip inMarko PavlovicNo ratings yet

- XTV Trip ValvesDocument4 pagesXTV Trip ValvesBharath Nadimpalli50% (4)

- SOP Terminal Tractor01Document11 pagesSOP Terminal Tractor01vozefjadavNo ratings yet

- Maytag Neptune MAH3000AWW Washing Machine Service ManualDocument157 pagesMaytag Neptune MAH3000AWW Washing Machine Service Manualrhondafos100% (2)

- 5r55e Valve Body SonnaxDocument8 pages5r55e Valve Body SonnaxjoshetoNo ratings yet

- ICC-ES Report: Simpson Strong-Tie Company IncDocument20 pagesICC-ES Report: Simpson Strong-Tie Company Incmmendez113No ratings yet

- Manual Bomba SihiDocument32 pagesManual Bomba SihiAlex Serna RestrepoNo ratings yet

- Viking Post Indicator PDFDocument12 pagesViking Post Indicator PDFpequenita34No ratings yet

- Pressure Reducing Valve GP-2000Document8 pagesPressure Reducing Valve GP-2000Anonymous jEXSJ0ebNo ratings yet

- 810586Document11 pages810586John MaldonadoNo ratings yet

- Mechanical RepairsDocument22 pagesMechanical RepairsGranoindustriaNo ratings yet

- 4r44e 5r55e Zip BookletDocument8 pages4r44e 5r55e Zip BookletDaniel BernardNo ratings yet

- Liquid-Pump-75-HP-Series-Model-4B-S User ManualDocument26 pagesLiquid-Pump-75-HP-Series-Model-4B-S User ManualLuis Felipe Córdova RodríguezNo ratings yet

- DACRON HighlanderManualChapter4Document18 pagesDACRON HighlanderManualChapter4wordpower777No ratings yet

- Tci-378805 378905 PDFDocument6 pagesTci-378805 378905 PDFAntonio PerezNo ratings yet

- Excess Pressure Valve (EPV) Type 44-6: 1. Design and Principle of OperationDocument4 pagesExcess Pressure Valve (EPV) Type 44-6: 1. Design and Principle of OperationcartarNo ratings yet

- Features/Description: 054-0240-001 CSU-1 Tubing Tester, 2-3/8" 054-0240-001Document3 pagesFeatures/Description: 054-0240-001 CSU-1 Tubing Tester, 2-3/8" 054-0240-001scignoniNo ratings yet

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranNo ratings yet

- Cam-Tite Ball Valve Operating Instructions: WarningDocument3 pagesCam-Tite Ball Valve Operating Instructions: WarningSubbarayan SaravanakumarNo ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- 9902 VwballjointandlinkpinfrontadjustersDocument4 pages9902 VwballjointandlinkpinfrontadjustersJuan SorleyNo ratings yet

- Jamesbury Butterfly Valves 8000 and 8200Document8 pagesJamesbury Butterfly Valves 8000 and 8200Uday GokhaleNo ratings yet

- Worcester Cryogenic Manual WceimstemDocument15 pagesWorcester Cryogenic Manual Wceimstem윤병택No ratings yet

- Es Acv 1116FMDocument4 pagesEs Acv 1116FMWattsNo ratings yet

- Maintenance Instruction Manual: Severe Service Control ValvesDocument9 pagesMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقNo ratings yet

- CHEETAH E-SHIFT Pro Series Valve BodyDocument8 pagesCHEETAH E-SHIFT Pro Series Valve BodyhidraulicNo ratings yet

- Governor AssemblyDocument2 pagesGovernor AssemblyMohammed MochrifNo ratings yet

- P15025-Lower Well Control Valve ManualDocument5 pagesP15025-Lower Well Control Valve ManualAlex Ramirez100% (1)

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezNo ratings yet

- Ball Injector O&m InstructionDocument12 pagesBall Injector O&m InstructionArgonauta_navegadorNo ratings yet

- Acura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6Document200 pagesAcura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6CandieApple100% (2)

- Manual Elevated Monitor Style 3530 Installation, Operating and Maintenance InstructionsDocument6 pagesManual Elevated Monitor Style 3530 Installation, Operating and Maintenance Instructionshendra saputraNo ratings yet

- IOM Actuator AutomaxSupernovaDocument4 pagesIOM Actuator AutomaxSupernovaNaser JahangiriNo ratings yet

- 2 Piece Threaded Steel Ball Valves Installation, Operation, & Maintenance GuideDocument2 pages2 Piece Threaded Steel Ball Valves Installation, Operation, & Maintenance GuideLucianNo ratings yet

- Wa-4 Alivio Ul-Fm 1116fmDocument4 pagesWa-4 Alivio Ul-Fm 1116fmeselcosac100% (1)

- Section 32 - Hi-Lo Press PilotDocument46 pagesSection 32 - Hi-Lo Press PilothammamiNo ratings yet

- MT 170Document4 pagesMT 170mafambaNo ratings yet

- Bushing ABB Con Diseño en PapelDocument5 pagesBushing ABB Con Diseño en Papelhugopacoluis1No ratings yet

- 8in Wafer Ball Vale IMODocument2 pages8in Wafer Ball Vale IMOw4uengineerNo ratings yet

- 1 Thru 6in E Series Globe Valves ED ET PDFDocument16 pages1 Thru 6in E Series Globe Valves ED ET PDFakhileshkuniyilNo ratings yet

- Sno 450 XRDocument20 pagesSno 450 XRMelvin HrsNo ratings yet

- Rolling InstallnstructionsDocument8 pagesRolling InstallnstructionsANDINo ratings yet

- Abd 350 - 360 - 375Document64 pagesAbd 350 - 360 - 375Jose Rodriguez CorporanNo ratings yet

- CVS Controls Series 470 Piston Actuators Sept 2014 PDFDocument12 pagesCVS Controls Series 470 Piston Actuators Sept 2014 PDFVIVIANA ESQUIVELNo ratings yet

- g512 ManualDocument20 pagesg512 ManualValmac ServicesNo ratings yet

- GT7638Document8 pagesGT7638LorenzoNo ratings yet

- CVS Controls Series 470 Piston Actuators: Instruction ManualDocument12 pagesCVS Controls Series 470 Piston Actuators: Instruction ManualisctomaslopezNo ratings yet

- 09-2916 Regulador Series Four WaukeshaDocument14 pages09-2916 Regulador Series Four WaukeshaMaria Fernanda Bonilla SalasNo ratings yet

- Installation Instructions For Electric Choke KIT P/Ns 45-224, 45-224S, & 745-224Document6 pagesInstallation Instructions For Electric Choke KIT P/Ns 45-224, 45-224S, & 745-224dave pNo ratings yet

- Instruction Manual: Bharat Heavy Electricals Limited TiruchirapalliDocument7 pagesInstruction Manual: Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYNo ratings yet

- LS Furmanite OyMDocument26 pagesLS Furmanite OyMDanny Carrasco Vicharra0% (2)

- Butterfly Valve Installation Guide Series ADocument10 pagesButterfly Valve Installation Guide Series Asaxenamech_ariesNo ratings yet

- Model GP-1000 Pressure Reducing Valve For Steam Service: Installation and Maintenance InstructionsDocument2 pagesModel GP-1000 Pressure Reducing Valve For Steam Service: Installation and Maintenance InstructionsMykweall_Kenz_3204No ratings yet

- Mini Countryman Atmospheric/Recirculation Dump Valve InstallationDocument23 pagesMini Countryman Atmospheric/Recirculation Dump Valve InstallationEduardo MendozaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Documents - MX Grinnellfirepanel PDFDocument8 pagesDocuments - MX Grinnellfirepanel PDFcchristt2584No ratings yet

- FMM-7045 Series Multiplex Addressable Manual StationsDocument2 pagesFMM-7045 Series Multiplex Addressable Manual Stationscchristt2584No ratings yet

- AG Piping Specification SPEL en M SG 12 002 Rev0Document31 pagesAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584No ratings yet

- 83V 1ceng0000Document2 pages83V 1ceng0000cchristt2584No ratings yet

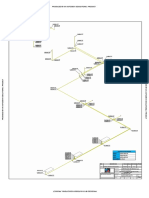

- WM01 Weldingmap GNCDocument1 pageWM01 Weldingmap GNCcchristt2584No ratings yet

- MA3000 Installation ManualDocument48 pagesMA3000 Installation Manualcchristt2584No ratings yet

- HOJA TECNICA Modulo D7039 PDFDocument8 pagesHOJA TECNICA Modulo D7039 PDFcchristt2584No ratings yet

- FMM-100 Series Die-Cast Metal Fire Alarm Manual StationsDocument2 pagesFMM-100 Series Die-Cast Metal Fire Alarm Manual Stationscchristt2584No ratings yet

- 03aiv. DFP4 2012 C10 Technical Data PDFDocument2 pages03aiv. DFP4 2012 C10 Technical Data PDFcchristt2584No ratings yet

- "DS" Series 70% "T" Series 85% "KO" Series 95% "H3" Series 90% "SL" Series 85% "HS" Series 90%Document1 page"DS" Series 70% "T" Series 85% "KO" Series 95% "H3" Series 90% "SL" Series 85% "HS" Series 90%cchristt2584No ratings yet

- Battery Calc v1 - 04 111810Document18 pagesBattery Calc v1 - 04 111810cchristt2584No ratings yet

- d2300cps - SiemensDocument2 pagesd2300cps - Siemenscchristt2584No ratings yet

- Station Manual An-SgxseriesDocument2 pagesStation Manual An-Sgxseriescchristt2584No ratings yet

- D7030X Series LED AnnunciatorsDocument1 pageD7030X Series LED Annunciatorscchristt2584No ratings yet

- Flujometro Digital Ttfm100 Handleiding f1 NG Uk Rev231Document124 pagesFlujometro Digital Ttfm100 Handleiding f1 NG Uk Rev231cchristt2584No ratings yet

- Model A240 Indicator PostDocument5 pagesModel A240 Indicator Postcchristt2584No ratings yet

- OMRON MK-I-S RelayDocument13 pagesOMRON MK-I-S Relaycchristt2584No ratings yet

- 4090 9001+Supervised+IAM+Installation+Manual+Rev+EDocument2 pages4090 9001+Supervised+IAM+Installation+Manual+Rev+Ecchristt2584No ratings yet

- Call Today: 800-264-8958: Diversified Air Systems, Inc. Firetrace TechnologyDocument9 pagesCall Today: 800-264-8958: Diversified Air Systems, Inc. Firetrace Technologycchristt2584No ratings yet

- Bonpet Zlozenka EngDocument2 pagesBonpet Zlozenka Engcchristt2584No ratings yet

- ReD AlertDocument1 pageReD Alertcchristt2584No ratings yet

- Maximize Your M-Lok Experience With These Tips: As PackagedDocument5 pagesMaximize Your M-Lok Experience With These Tips: As PackagedlowjackNo ratings yet

- Saic M 1065Document2 pagesSaic M 1065Hussain Nasser Al- NowiesserNo ratings yet

- XL2+Field+Cultivator+5 Section+Assembly+Manual+Document41 pagesXL2+Field+Cultivator+5 Section+Assembly+Manual+Максим КрикунNo ratings yet

- Ime35670f6 DRS2D 4D 4a-25aDocument52 pagesIme35670f6 DRS2D 4D 4a-25aAnonymous xj489fNo ratings yet

- EASA Chapter 05Document20 pagesEASA Chapter 05Abdul Qadeer KhanNo ratings yet

- HoffmanDocument12 pagesHoffmanAnonymous 7xHNgoKE6eNo ratings yet

- TorqueDocument1 pageTorqueAnonymous oWDHhPNo ratings yet

- Libro Motores VW Volkswagen Datos HaynesDocument127 pagesLibro Motores VW Volkswagen Datos HaynesCésar Santos100% (1)

- Bisagras ParkerDocument10 pagesBisagras ParkerHUGO ARMANDO ROJAS GONZALEZNo ratings yet

- Multi Mill SOPDocument14 pagesMulti Mill SOPDilraj KohliNo ratings yet

- SyncrometerDocument192 pagesSyncrometerlbassam100% (5)

- Roger Gibson Auto Restoration CatalogDocument67 pagesRoger Gibson Auto Restoration CatalogmacvsogchingaNo ratings yet

- Piston Engine Cylinder Removal and InstallationDocument4 pagesPiston Engine Cylinder Removal and InstallationZyrick Laurence Eslao TimmangoNo ratings yet

- Catalog Tiranti DT08 eDocument16 pagesCatalog Tiranti DT08 ebogdan tanasoiuNo ratings yet

- DODGE® GRIP TIGHT Adapter Mount Ball BearingsDocument4 pagesDODGE® GRIP TIGHT Adapter Mount Ball BearingsDaNnIe09No ratings yet

- Model K: Installation, Operation, Maintenance, and Storage ManualDocument26 pagesModel K: Installation, Operation, Maintenance, and Storage Manualjhon jairo arangoNo ratings yet

- Inspection Side Door ElevatorDocument22 pagesInspection Side Door ElevatorAnthony WaaliaNo ratings yet

- Hammer A3-31 Planer Head Removal Notes JGTDocument39 pagesHammer A3-31 Planer Head Removal Notes JGTprays123No ratings yet

- tm2307 - 844J Loader - Axle Planetary Gear Case Disassemble and AssembleDocument25 pagestm2307 - 844J Loader - Axle Planetary Gear Case Disassemble and AssemblegerardoespadasNo ratings yet

- HGU84 ManualDocument62 pagesHGU84 Manualwindblast100% (1)

- OGLAEND-Product Catalogue - 03.2021Document50 pagesOGLAEND-Product Catalogue - 03.2021Ángel Durán LópezNo ratings yet

- 10 Hydraulic Meachnical Drivers Pullers PDFDocument50 pages10 Hydraulic Meachnical Drivers Pullers PDFJuancho MogollonNo ratings yet

- Full-Leno Selvage Device PDFDocument12 pagesFull-Leno Selvage Device PDFMonirul SkNo ratings yet

- Loctite 277Document3 pagesLoctite 277Sreenivas TalariNo ratings yet

- Constructing A DOMEDocument28 pagesConstructing A DOMEvigyanashram50% (2)

Kennedy - Modelo 2945A - Poste Indicador

Kennedy - Modelo 2945A - Poste Indicador

Uploaded by

cchristt2584Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kennedy - Modelo 2945A - Poste Indicador

Kennedy - Modelo 2945A - Poste Indicador

Uploaded by

cchristt2584Copyright:

Available Formats

Kennedy Valve Indicator Posts

Section Style 2945A Adjustable Barrel Assembly Drawing Dimensions & Instructions Style 2945 Fixed Length Assembly Drawing Dimensions & Instructions Style 2945 & 2945A Parts List Style 2945 & 2945A Trench Depths for Gate Valves Style 2945 & 2945A Installation & Maintenance Style 2945 & 2945A Lower Standpipe Change Instructions Style 2945A Post Extension Instructions Style 641 Wall Type Indicator Post Style 641-14 Flanged Base Post Indicator 2-3 2 3 4-5 4 5 6 7 8-10 11 12 13 14

***Please check our website www.kennedyvalve.com for any product updates and/or changes***

Installation The valve should be opened to the fully open position before proceeding with the Indicator Post installation. 1. Disassembly of the Indicator Post Unit Telescoping Barrel Units Remove the Top Section from the end of the barrel. Loosen the two screws on the barrel and slide off the top of the standpipe. Fixed Length Units Remove the Top Section from the end of the standpipe. 2. Base Flange Installation: Attach the base flange along with the standpipe to the valve plate using the four 5/8 bolts and nuts provided. 3. Grade Line Adjustments: Telescoping Barrel Units Lower the barrel over the standpipe until the grade line mark on the barrel is at ground line height and then tighten the two screws securely. Fixed Length Units Cut the required length off the bottom of the standpipe so that the indicated grade line of the standpipe is at the ground line height and then secure to the base flange by tightening the two screws. 4. Extension Rod Adjustments: Lower the stem into the barrel/standpipe, placing the crane coupling over the valve operating nut. It is necessary that the stem engage the operating nut a minimum of 2 inches, but not more than 5 inches. To check for correct engagement, the end of the stem should be from 7 inches to 10 inches above the top of the standpipe (Fixed Length Units) or the top of the telescoping barrel. 5. Target (Open and Shut) Adjustments

Remove the target assembly from inside the body by rotating the operating nut counterclockwise. Loosen the target retainer screws, but do not remove them. Open Left Valves Move the OPEN target to the top of the plate. Note: Position of the SHUT target can be determined by the following chart: Valve Size Gate Valve A RW Valve A

4 1 7/8

6 1 3/8 1 5/16

8 1 3/16 1 11/16

10 2 3/16 2 1/8

12 2 5/8 2

14 3 NA

Position the SHUT target as indicated below and tighten the retainer screws until snug. Avoid over tightening. Repeat the procedure for the other side.

Open Right Valves The procedure is similar as for open left, but with two differences: A: The open target is placed below the shut target. B: The open target is placed at the very bottom of the plate. The position of the shut target above the open target is then determined and set as described above. Maintenance 1. Lubrication

Oil upper bearing at least once per year, adding several drops of oil in the hole located on the top of the main stem flange. Access to lubrication hole is gained by raising the locking wrench off the main stem nut. 2. Operation

The target mechanism will travel off the threads of the operating nut in both directions should the targets or target mechanism be positioned incorrectly. Should this happen, readjust targets. If the target mechanism falls from the operating nut, it will be stopped a short distance below the window.

2945 (A) Vertical Indicator Post Changing the Lower Standpipe

1. 2. 3. 4. 5. 6. 7. 8. Loosen (2) UNC Bolts (Items P-15) that retain the Telescoping Barrel (Item P-16) to the lower Standpipe (Item P-17) Working in a safe manner lift off the entire top assembly (Items P-1 through P-16) from the Telescoping Barrel and Base Flange. Remove the Stem (Item P-12) and Crane Coupling (Item P-13) subassembly. Loosen the UNC Bolts that retain the Lower Standpipe to the Base Flange. Remove the existing Lower Standpipe and set the new one into the socket in the Base Flange. Securely tighten the bolts that were loosened in Step 4 (50-100 ft. lbs) Working safely, slide the entire top assembly over the new Lower Standpipe. Tighten the (2) UNC Bolts that retain the Telescoping Barrel to the Lower Standpipe (Item P-15) Tighten them securely enough to safely maneuver the Post in the field. Remove the Wrench (Item P-1), the 3/8 UNC Bolt (Item 11A) and the eyebolt (Item P-10). Lift the assembly of the Top Section (Item P-4), Operating Nut (Item P-2), Target Carrier Assembly (Items P-6 through P-8), etc. from the Telescoping Barrel. If a longer Lower Standpipe has been installed it will be necessary to procure a longer Stem. Slip the Crane Coupling (Item P-13) over one end of the new Stem and cross drill a new, cotter pin hole through the new stem. If the Lower Standpipe just installed is shorter than the one it replaced, the Stem will have to be cut. Bolt the Base Flange of the sub-assembly that includes the Base Flange, Lower Standpipe and Telescoping Barrel to the flange of the valve, using the UNC Bolts & Nuts provided by Kennedy Valve. Place the square socket in the Crane Coupling on the Stem & Coupling subassembly over the 2 Square Nut at the top of the stem of the valve. See page F-4 of the Kennedy Valve Product Catalog and follow the directions.

9. 10.

11.

12. 13.

14. 15.

NOTE: Kennedy Valve does offer for sale Couplings to extend Stems.

Instructions for Extending a 2945A Post

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Loosen the two screws on top pipe section (near grade line at bottom of pipe) Pull apart the upper section from the lower pipe section. Place new extension coupling with new extension pipe over the existing lower pipe section. Tighten screws provided on the extension pipe and lower pipe (3/4 X 1 square head screw). Take existing stem and place the new extension stem with coupling on top of original stem. Drill through stem and coupling (pilot holes provided on one side), then pin together with pins provided (1/4 X 3 br. cotter keys.) Place stem down the inside of new extension and lower pipe assembly aligning it on the 2 square nut on valve. At this time, remove top section (with operating nut assembly) from off the top of indicator post standpipe (two bolts). Place complete upper section over top of stem and align with the new extension pipe. Push together, adjust to desired height, and retighten the two screws in top pipe section. Stem should be cut 7-10 above the pipe. Adjust open/shut plates per instructions and replace top section wit hstem nut (can also be extended at bottom end).

You might also like

- Same SDF Engines WORKSHOP MANUALDocument170 pagesSame SDF Engines WORKSHOP MANUAL1ansu100% (11)

- 1987 Chevrolet Caprice-Monte Carlo-El Camino Service ManualDocument1,654 pages1987 Chevrolet Caprice-Monte Carlo-El Camino Service ManualPinko Pallino75% (4)

- S2000 SOS Supercharger Install ManualDocument43 pagesS2000 SOS Supercharger Install ManualMatthew Chtchavlinski100% (4)

- Delphi DP210 Fuel Injection Pump CatDocument3 pagesDelphi DP210 Fuel Injection Pump CatSilas F Pimenta90% (20)

- Manual de Instalacion Angelus 60LDocument15 pagesManual de Instalacion Angelus 60LAnonymous WaC9PaQmr100% (1)

- Aw60 40le Zip inDocument10 pagesAw60 40le Zip inMarko PavlovicNo ratings yet

- XTV Trip ValvesDocument4 pagesXTV Trip ValvesBharath Nadimpalli50% (4)

- SOP Terminal Tractor01Document11 pagesSOP Terminal Tractor01vozefjadavNo ratings yet

- Maytag Neptune MAH3000AWW Washing Machine Service ManualDocument157 pagesMaytag Neptune MAH3000AWW Washing Machine Service Manualrhondafos100% (2)

- 5r55e Valve Body SonnaxDocument8 pages5r55e Valve Body SonnaxjoshetoNo ratings yet

- ICC-ES Report: Simpson Strong-Tie Company IncDocument20 pagesICC-ES Report: Simpson Strong-Tie Company Incmmendez113No ratings yet

- Manual Bomba SihiDocument32 pagesManual Bomba SihiAlex Serna RestrepoNo ratings yet

- Viking Post Indicator PDFDocument12 pagesViking Post Indicator PDFpequenita34No ratings yet

- Pressure Reducing Valve GP-2000Document8 pagesPressure Reducing Valve GP-2000Anonymous jEXSJ0ebNo ratings yet

- 810586Document11 pages810586John MaldonadoNo ratings yet

- Mechanical RepairsDocument22 pagesMechanical RepairsGranoindustriaNo ratings yet

- 4r44e 5r55e Zip BookletDocument8 pages4r44e 5r55e Zip BookletDaniel BernardNo ratings yet

- Liquid-Pump-75-HP-Series-Model-4B-S User ManualDocument26 pagesLiquid-Pump-75-HP-Series-Model-4B-S User ManualLuis Felipe Córdova RodríguezNo ratings yet

- DACRON HighlanderManualChapter4Document18 pagesDACRON HighlanderManualChapter4wordpower777No ratings yet

- Tci-378805 378905 PDFDocument6 pagesTci-378805 378905 PDFAntonio PerezNo ratings yet

- Excess Pressure Valve (EPV) Type 44-6: 1. Design and Principle of OperationDocument4 pagesExcess Pressure Valve (EPV) Type 44-6: 1. Design and Principle of OperationcartarNo ratings yet

- Features/Description: 054-0240-001 CSU-1 Tubing Tester, 2-3/8" 054-0240-001Document3 pagesFeatures/Description: 054-0240-001 CSU-1 Tubing Tester, 2-3/8" 054-0240-001scignoniNo ratings yet

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranNo ratings yet

- Cam-Tite Ball Valve Operating Instructions: WarningDocument3 pagesCam-Tite Ball Valve Operating Instructions: WarningSubbarayan SaravanakumarNo ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- 9902 VwballjointandlinkpinfrontadjustersDocument4 pages9902 VwballjointandlinkpinfrontadjustersJuan SorleyNo ratings yet

- Jamesbury Butterfly Valves 8000 and 8200Document8 pagesJamesbury Butterfly Valves 8000 and 8200Uday GokhaleNo ratings yet

- Worcester Cryogenic Manual WceimstemDocument15 pagesWorcester Cryogenic Manual Wceimstem윤병택No ratings yet

- Es Acv 1116FMDocument4 pagesEs Acv 1116FMWattsNo ratings yet

- Maintenance Instruction Manual: Severe Service Control ValvesDocument9 pagesMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقNo ratings yet

- CHEETAH E-SHIFT Pro Series Valve BodyDocument8 pagesCHEETAH E-SHIFT Pro Series Valve BodyhidraulicNo ratings yet

- Governor AssemblyDocument2 pagesGovernor AssemblyMohammed MochrifNo ratings yet

- P15025-Lower Well Control Valve ManualDocument5 pagesP15025-Lower Well Control Valve ManualAlex Ramirez100% (1)

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezNo ratings yet

- Ball Injector O&m InstructionDocument12 pagesBall Injector O&m InstructionArgonauta_navegadorNo ratings yet

- Acura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6Document200 pagesAcura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6CandieApple100% (2)

- Manual Elevated Monitor Style 3530 Installation, Operating and Maintenance InstructionsDocument6 pagesManual Elevated Monitor Style 3530 Installation, Operating and Maintenance Instructionshendra saputraNo ratings yet

- IOM Actuator AutomaxSupernovaDocument4 pagesIOM Actuator AutomaxSupernovaNaser JahangiriNo ratings yet

- 2 Piece Threaded Steel Ball Valves Installation, Operation, & Maintenance GuideDocument2 pages2 Piece Threaded Steel Ball Valves Installation, Operation, & Maintenance GuideLucianNo ratings yet

- Wa-4 Alivio Ul-Fm 1116fmDocument4 pagesWa-4 Alivio Ul-Fm 1116fmeselcosac100% (1)

- Section 32 - Hi-Lo Press PilotDocument46 pagesSection 32 - Hi-Lo Press PilothammamiNo ratings yet

- MT 170Document4 pagesMT 170mafambaNo ratings yet

- Bushing ABB Con Diseño en PapelDocument5 pagesBushing ABB Con Diseño en Papelhugopacoluis1No ratings yet

- 8in Wafer Ball Vale IMODocument2 pages8in Wafer Ball Vale IMOw4uengineerNo ratings yet

- 1 Thru 6in E Series Globe Valves ED ET PDFDocument16 pages1 Thru 6in E Series Globe Valves ED ET PDFakhileshkuniyilNo ratings yet

- Sno 450 XRDocument20 pagesSno 450 XRMelvin HrsNo ratings yet

- Rolling InstallnstructionsDocument8 pagesRolling InstallnstructionsANDINo ratings yet

- Abd 350 - 360 - 375Document64 pagesAbd 350 - 360 - 375Jose Rodriguez CorporanNo ratings yet

- CVS Controls Series 470 Piston Actuators Sept 2014 PDFDocument12 pagesCVS Controls Series 470 Piston Actuators Sept 2014 PDFVIVIANA ESQUIVELNo ratings yet

- g512 ManualDocument20 pagesg512 ManualValmac ServicesNo ratings yet

- GT7638Document8 pagesGT7638LorenzoNo ratings yet

- CVS Controls Series 470 Piston Actuators: Instruction ManualDocument12 pagesCVS Controls Series 470 Piston Actuators: Instruction ManualisctomaslopezNo ratings yet

- 09-2916 Regulador Series Four WaukeshaDocument14 pages09-2916 Regulador Series Four WaukeshaMaria Fernanda Bonilla SalasNo ratings yet

- Installation Instructions For Electric Choke KIT P/Ns 45-224, 45-224S, & 745-224Document6 pagesInstallation Instructions For Electric Choke KIT P/Ns 45-224, 45-224S, & 745-224dave pNo ratings yet

- Instruction Manual: Bharat Heavy Electricals Limited TiruchirapalliDocument7 pagesInstruction Manual: Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYNo ratings yet

- LS Furmanite OyMDocument26 pagesLS Furmanite OyMDanny Carrasco Vicharra0% (2)

- Butterfly Valve Installation Guide Series ADocument10 pagesButterfly Valve Installation Guide Series Asaxenamech_ariesNo ratings yet

- Model GP-1000 Pressure Reducing Valve For Steam Service: Installation and Maintenance InstructionsDocument2 pagesModel GP-1000 Pressure Reducing Valve For Steam Service: Installation and Maintenance InstructionsMykweall_Kenz_3204No ratings yet

- Mini Countryman Atmospheric/Recirculation Dump Valve InstallationDocument23 pagesMini Countryman Atmospheric/Recirculation Dump Valve InstallationEduardo MendozaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Documents - MX Grinnellfirepanel PDFDocument8 pagesDocuments - MX Grinnellfirepanel PDFcchristt2584No ratings yet

- FMM-7045 Series Multiplex Addressable Manual StationsDocument2 pagesFMM-7045 Series Multiplex Addressable Manual Stationscchristt2584No ratings yet

- AG Piping Specification SPEL en M SG 12 002 Rev0Document31 pagesAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584No ratings yet

- 83V 1ceng0000Document2 pages83V 1ceng0000cchristt2584No ratings yet

- WM01 Weldingmap GNCDocument1 pageWM01 Weldingmap GNCcchristt2584No ratings yet

- MA3000 Installation ManualDocument48 pagesMA3000 Installation Manualcchristt2584No ratings yet

- HOJA TECNICA Modulo D7039 PDFDocument8 pagesHOJA TECNICA Modulo D7039 PDFcchristt2584No ratings yet

- FMM-100 Series Die-Cast Metal Fire Alarm Manual StationsDocument2 pagesFMM-100 Series Die-Cast Metal Fire Alarm Manual Stationscchristt2584No ratings yet

- 03aiv. DFP4 2012 C10 Technical Data PDFDocument2 pages03aiv. DFP4 2012 C10 Technical Data PDFcchristt2584No ratings yet

- "DS" Series 70% "T" Series 85% "KO" Series 95% "H3" Series 90% "SL" Series 85% "HS" Series 90%Document1 page"DS" Series 70% "T" Series 85% "KO" Series 95% "H3" Series 90% "SL" Series 85% "HS" Series 90%cchristt2584No ratings yet

- Battery Calc v1 - 04 111810Document18 pagesBattery Calc v1 - 04 111810cchristt2584No ratings yet

- d2300cps - SiemensDocument2 pagesd2300cps - Siemenscchristt2584No ratings yet

- Station Manual An-SgxseriesDocument2 pagesStation Manual An-Sgxseriescchristt2584No ratings yet

- D7030X Series LED AnnunciatorsDocument1 pageD7030X Series LED Annunciatorscchristt2584No ratings yet

- Flujometro Digital Ttfm100 Handleiding f1 NG Uk Rev231Document124 pagesFlujometro Digital Ttfm100 Handleiding f1 NG Uk Rev231cchristt2584No ratings yet

- Model A240 Indicator PostDocument5 pagesModel A240 Indicator Postcchristt2584No ratings yet

- OMRON MK-I-S RelayDocument13 pagesOMRON MK-I-S Relaycchristt2584No ratings yet

- 4090 9001+Supervised+IAM+Installation+Manual+Rev+EDocument2 pages4090 9001+Supervised+IAM+Installation+Manual+Rev+Ecchristt2584No ratings yet

- Call Today: 800-264-8958: Diversified Air Systems, Inc. Firetrace TechnologyDocument9 pagesCall Today: 800-264-8958: Diversified Air Systems, Inc. Firetrace Technologycchristt2584No ratings yet

- Bonpet Zlozenka EngDocument2 pagesBonpet Zlozenka Engcchristt2584No ratings yet

- ReD AlertDocument1 pageReD Alertcchristt2584No ratings yet

- Maximize Your M-Lok Experience With These Tips: As PackagedDocument5 pagesMaximize Your M-Lok Experience With These Tips: As PackagedlowjackNo ratings yet

- Saic M 1065Document2 pagesSaic M 1065Hussain Nasser Al- NowiesserNo ratings yet

- XL2+Field+Cultivator+5 Section+Assembly+Manual+Document41 pagesXL2+Field+Cultivator+5 Section+Assembly+Manual+Максим КрикунNo ratings yet

- Ime35670f6 DRS2D 4D 4a-25aDocument52 pagesIme35670f6 DRS2D 4D 4a-25aAnonymous xj489fNo ratings yet

- EASA Chapter 05Document20 pagesEASA Chapter 05Abdul Qadeer KhanNo ratings yet

- HoffmanDocument12 pagesHoffmanAnonymous 7xHNgoKE6eNo ratings yet

- TorqueDocument1 pageTorqueAnonymous oWDHhPNo ratings yet

- Libro Motores VW Volkswagen Datos HaynesDocument127 pagesLibro Motores VW Volkswagen Datos HaynesCésar Santos100% (1)

- Bisagras ParkerDocument10 pagesBisagras ParkerHUGO ARMANDO ROJAS GONZALEZNo ratings yet

- Multi Mill SOPDocument14 pagesMulti Mill SOPDilraj KohliNo ratings yet

- SyncrometerDocument192 pagesSyncrometerlbassam100% (5)

- Roger Gibson Auto Restoration CatalogDocument67 pagesRoger Gibson Auto Restoration CatalogmacvsogchingaNo ratings yet

- Piston Engine Cylinder Removal and InstallationDocument4 pagesPiston Engine Cylinder Removal and InstallationZyrick Laurence Eslao TimmangoNo ratings yet

- Catalog Tiranti DT08 eDocument16 pagesCatalog Tiranti DT08 ebogdan tanasoiuNo ratings yet

- DODGE® GRIP TIGHT Adapter Mount Ball BearingsDocument4 pagesDODGE® GRIP TIGHT Adapter Mount Ball BearingsDaNnIe09No ratings yet

- Model K: Installation, Operation, Maintenance, and Storage ManualDocument26 pagesModel K: Installation, Operation, Maintenance, and Storage Manualjhon jairo arangoNo ratings yet

- Inspection Side Door ElevatorDocument22 pagesInspection Side Door ElevatorAnthony WaaliaNo ratings yet

- Hammer A3-31 Planer Head Removal Notes JGTDocument39 pagesHammer A3-31 Planer Head Removal Notes JGTprays123No ratings yet

- tm2307 - 844J Loader - Axle Planetary Gear Case Disassemble and AssembleDocument25 pagestm2307 - 844J Loader - Axle Planetary Gear Case Disassemble and AssemblegerardoespadasNo ratings yet

- HGU84 ManualDocument62 pagesHGU84 Manualwindblast100% (1)

- OGLAEND-Product Catalogue - 03.2021Document50 pagesOGLAEND-Product Catalogue - 03.2021Ángel Durán LópezNo ratings yet

- 10 Hydraulic Meachnical Drivers Pullers PDFDocument50 pages10 Hydraulic Meachnical Drivers Pullers PDFJuancho MogollonNo ratings yet

- Full-Leno Selvage Device PDFDocument12 pagesFull-Leno Selvage Device PDFMonirul SkNo ratings yet

- Loctite 277Document3 pagesLoctite 277Sreenivas TalariNo ratings yet

- Constructing A DOMEDocument28 pagesConstructing A DOMEvigyanashram50% (2)