Professional Documents

Culture Documents

Escalator&Moving Walk Controller - ZXK1600 - User Manual

Escalator&Moving Walk Controller - ZXK1600 - User Manual

Uploaded by

Ken LeeCopyright:

Available Formats

You might also like

- Acute Coronary Syndrome NCP 01Document5 pagesAcute Coronary Syndrome NCP 01AgronaSlaughter0% (1)

- Nova Ev3200 ManualDocument25 pagesNova Ev3200 ManualCarolina Sansón100% (1)

- Operation and Service Manual: Status 26.05.1998Document58 pagesOperation and Service Manual: Status 26.05.1998raymon janszenNo ratings yet

- Fuji Starting Guide G11S-LE2 - Lift - 7Document54 pagesFuji Starting Guide G11S-LE2 - Lift - 7Nguyen Anh Tu100% (3)

- ME-LIFT-P Microprocessor Control User Manual 20071226 PDFDocument38 pagesME-LIFT-P Microprocessor Control User Manual 20071226 PDFKen LeeNo ratings yet

- COP User Manual 2.0 PDFDocument5 pagesCOP User Manual 2.0 PDFخالدعبدالله100% (1)

- nUPS-M Inverter User ManualDocument11 pagesnUPS-M Inverter User ManualخالدعبداللهNo ratings yet

- BL3-U Quick Commissioning Menu V1.2 PDFDocument32 pagesBL3-U Quick Commissioning Menu V1.2 PDFRandy VanegasNo ratings yet

- A NICE3000new 2018Document203 pagesA NICE3000new 2018Bahodur ToshevNo ratings yet

- Simply Handbook of Debugging (F5021-32 Bit Board)Document3 pagesSimply Handbook of Debugging (F5021-32 Bit Board)thanggimme.phanNo ratings yet

- Sjg18-046 (03) - Guangri New ControlDocument53 pagesSjg18-046 (03) - Guangri New Controlratan.m1010No ratings yet

- NICE7000 DebuggingDocument4 pagesNICE7000 DebuggingTroubleshootingNo ratings yet

- ARL700 UCM Test Instructions For Hydraulic Lifts V1.EnDocument5 pagesARL700 UCM Test Instructions For Hydraulic Lifts V1.EnkizonimeisterNo ratings yet

- Troubleshooting-Inverter User ManualDocument4 pagesTroubleshooting-Inverter User Manualqison.yanNo ratings yet

- ARES Escalator 6Document7 pagesARES Escalator 6GutmonarchNo ratings yet

- Integrated Door Motor Controller User Manual: Shenyang Bluelight Automatic Technology Co., LTDDocument56 pagesIntegrated Door Motor Controller User Manual: Shenyang Bluelight Automatic Technology Co., LTDJulio Cesar GonzalezNo ratings yet

- ARCUBE Change Log - enDocument4 pagesARCUBE Change Log - enВячеслав ЯкимовNo ratings yet

- Manual EC20 (English) PDFDocument79 pagesManual EC20 (English) PDFDalat TigonNo ratings yet

- Machine Brakes Self-Monitoring Test Instructions V10.EnDocument5 pagesMachine Brakes Self-Monitoring Test Instructions V10.EnKs BharathiyarNo ratings yet

- AS380 Series Elevator Intergrated Controller User Instruction V2.13 PDFDocument296 pagesAS380 Series Elevator Intergrated Controller User Instruction V2.13 PDFRogério da Silva de OliveiraNo ratings yet

- VVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelDocument13 pagesVVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelKen LeeNo ratings yet

- Yaskawa L1000A Quick Start Guide TOEPC71061638Document204 pagesYaskawa L1000A Quick Start Guide TOEPC71061638younesNo ratings yet

- LM 3 ParameterliftDocument1 pageLM 3 ParameterliftVinay SharmaNo ratings yet

- MicroZed v35 CatalogDocument32 pagesMicroZed v35 CataloghabibullaNo ratings yet

- Dri Ve Ci Rcui T AS360P01V01Document13 pagesDri Ve Ci Rcui T AS360P01V01Javier MartínezNo ratings yet

- C604 AttachmentpaperDocument32 pagesC604 AttachmentpaperWander GomesNo ratings yet

- MCTC-KZ-B0S To Customer Side Protocol Details V1.2Document14 pagesMCTC-KZ-B0S To Customer Side Protocol Details V1.2John ClarenceNo ratings yet

- CL - Omkar ElectronicsDocument16 pagesCL - Omkar ElectronicsSazzad Hossan RaselNo ratings yet

- ARL-300 UCM Test Instructions For Gearless Machines - enDocument2 pagesARL-300 UCM Test Instructions For Gearless Machines - enkizonimeisterNo ratings yet

- WB Installation Manual EL ENG 4.3Document121 pagesWB Installation Manual EL ENG 4.3dianelys Sivada100% (1)

- Startup VDL200 Geared EngDocument7 pagesStartup VDL200 Geared EngSamih AlraghbanNo ratings yet

- AE Hex Series User ManualDocument34 pagesAE Hex Series User Manualdidik sukocoNo ratings yet

- Motherboard Manual Bx2000 1101 eDocument44 pagesMotherboard Manual Bx2000 1101 eGoran MojsilovicNo ratings yet

- Alc Series Lift Control Systems: User ManualDocument105 pagesAlc Series Lift Control Systems: User Manualمحمد حسينNo ratings yet

- Jarless Con Door DriveDocument1 pageJarless Con Door Drivewakeel ahmedNo ratings yet

- 20190401Document232 pages20190401rendy kurniawanNo ratings yet

- Arkel AR500 Gray - Binary Converte - 1 PDFDocument1 pageArkel AR500 Gray - Binary Converte - 1 PDFHenri KleineNo ratings yet

- Appendix 2: System TroubleshootingDocument4 pagesAppendix 2: System Troubleshootingعلاء صقرNo ratings yet

- Starting Guide: Frenic LiftDocument14 pagesStarting Guide: Frenic LiftخالدعبداللهNo ratings yet

- Error TableDocument19 pagesError TableJesús David Diaz MontesNo ratings yet

- FILE 20221010 095658 X11joDocument22 pagesFILE 20221010 095658 X11joNguyễn ThànhNo ratings yet

- ARCODE PLC Module Manual V10.enDocument4 pagesARCODE PLC Module Manual V10.enBrahim CherguiNo ratings yet

- Monarch Mctcpece1Document48 pagesMonarch Mctcpece1Sazzad Hossan RaselNo ratings yet

- Instruction Manual For BLT Armeg Group Control System: SERIAL NO. GNCG0002Document33 pagesInstruction Manual For BLT Armeg Group Control System: SERIAL NO. GNCG0002Cristian de LeonNo ratings yet

- AS350 Series Elevator Intergrated Controller User Instruction V1.0Document109 pagesAS350 Series Elevator Intergrated Controller User Instruction V1.0Nguyen VuongNo ratings yet

- Elevator Programming CodeDocument178 pagesElevator Programming Code100mphNo ratings yet

- Vacon NX Lift Application Manual UD00758L ENDocument69 pagesVacon NX Lift Application Manual UD00758L ENDean LefebvreNo ratings yet

- Movilift Encoder Stand Alone Eng Ver. 2.0Document6 pagesMovilift Encoder Stand Alone Eng Ver. 2.0JoseNo ratings yet

- Faults ARCA IIDocument13 pagesFaults ARCA IIStefan PopovNo ratings yet

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDocument13 pagesMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010No ratings yet

- JSA07924E-AA - E-Com Local Wiring (V300)Document17 pagesJSA07924E-AA - E-Com Local Wiring (V300)Mahmoud Omar RobNo ratings yet

- HB As380 E20 PDFDocument70 pagesHB As380 E20 PDFjonathanNo ratings yet

- User'S Manual: GMBH, GermanyDocument167 pagesUser'S Manual: GMBH, GermanyAndres Felipe CaceresNo ratings yet

- ARES Escalator BDocument2 pagesARES Escalator BGutmonarchNo ratings yet

- Monarch MCTC-CTW-A3 Car Top Intergrated Control BoxDocument2 pagesMonarch MCTC-CTW-A3 Car Top Intergrated Control BoxNick OngNo ratings yet

- ARL-700 Firmware Update V1.2.EnDocument8 pagesARL-700 Firmware Update V1.2.EnkizonimeisterNo ratings yet

- Sod IvarDocument41 pagesSod IvarSacha's ChannelNo ratings yet

- Homex SVTDocument23 pagesHomex SVTAlan TacherNo ratings yet

- UCMPDocument2 pagesUCMPTushar ImranNo ratings yet

- 87 Catalog Invertere Ic5Document19 pages87 Catalog Invertere Ic5vga1234No ratings yet

- Tài Liệu Biến Tần LS IC5Document20 pagesTài Liệu Biến Tần LS IC5hieudaivuongNo ratings yet

- AS320 InverterDocument43 pagesAS320 Inverterthi tranNo ratings yet

- Car Door M-TypeDocument1 pageCar Door M-TypeKen LeeNo ratings yet

- Planning GuideDocument11 pagesPlanning GuideKen LeeNo ratings yet

- 9.15 Opposite Door Control SchemeDocument4 pages9.15 Opposite Door Control SchemeKen LeeNo ratings yet

- SCM Go Flex: Product Technical SheetDocument8 pagesSCM Go Flex: Product Technical SheetKen LeeNo ratings yet

- Emesa Tech SheetDocument3 pagesEmesa Tech SheetKen LeeNo ratings yet

- User Manual DVM 70Document28 pagesUser Manual DVM 70Ken LeeNo ratings yet

- Transformer-1 /75W Battery Group: 12V 12V 12V 12V 12VDocument1 pageTransformer-1 /75W Battery Group: 12V 12V 12V 12V 12VKen LeeNo ratings yet

- Gate Controller Manual: AAD03010 Frequency Control SystemDocument17 pagesGate Controller Manual: AAD03010 Frequency Control SystemKen LeeNo ratings yet

- Transformer-1 /75W Battery Group: Drw. Apprv. M. Aybey Date Series Proj. Rev. LRS LRS02 M. AkkuşDocument1 pageTransformer-1 /75W Battery Group: Drw. Apprv. M. Aybey Date Series Proj. Rev. LRS LRS02 M. AkkuşKen LeeNo ratings yet

- Emesa CAR FRAMES 1Document2 pagesEmesa CAR FRAMES 1Ken LeeNo ratings yet

- Windsor: Self-Contained Drive System! Optional Recessed Telephone Box Operating Controls No Pit!Document2 pagesWindsor: Self-Contained Drive System! Optional Recessed Telephone Box Operating Controls No Pit!Ken LeeNo ratings yet

- Lrs 3Document1 pageLrs 3Ken Lee100% (1)

- Service Manual: SchematicsDocument42 pagesService Manual: SchematicsKen LeeNo ratings yet

- Planning Guide: For Residential Elevator With Hydraulic Drive or Winding Drum Drive ASME A17.1-2000 Part 5.3Document8 pagesPlanning Guide: For Residential Elevator With Hydraulic Drive or Winding Drum Drive ASME A17.1-2000 Part 5.3Ken LeeNo ratings yet

- NICE3000 - Technical Manual-060710Document109 pagesNICE3000 - Technical Manual-060710Ken Lee100% (8)

- Series Incremental Encoders: Environmental SpecificationsDocument2 pagesSeries Incremental Encoders: Environmental SpecificationsKen LeeNo ratings yet

- Safety For Technicians: 2 EN 81-20 & EN 81-50Document2 pagesSafety For Technicians: 2 EN 81-20 & EN 81-50Ken LeeNo ratings yet

- Bl3-U AsyncDocument23 pagesBl3-U AsyncKen Lee100% (1)

- VVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelDocument13 pagesVVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelKen LeeNo ratings yet

- MicroZed v33Document18 pagesMicroZed v33Ken LeeNo ratings yet

- Galaxy Traction Elevator ControllerDocument327 pagesGalaxy Traction Elevator ControllerKen LeeNo ratings yet

- Operation Manual: Rcf-1 Door Operator ControllerDocument31 pagesOperation Manual: Rcf-1 Door Operator ControllerKen LeeNo ratings yet

- Kasvar: User ManualDocument31 pagesKasvar: User ManualKen LeeNo ratings yet

- A30t U Type C Type Photoemission Switch For Lift and Elevator User Manual 2009Document3 pagesA30t U Type C Type Photoemission Switch For Lift and Elevator User Manual 2009Ken LeeNo ratings yet

- Omega LiftDocument2 pagesOmega LiftKen LeeNo ratings yet

- GMP Checklist Sanitary Facilities and ControlsDocument1 pageGMP Checklist Sanitary Facilities and ControlsATSEDENo ratings yet

- Talent Acquisition 2008 - Survey and Analysis of The Changing Recruiting Landscape PDFDocument20 pagesTalent Acquisition 2008 - Survey and Analysis of The Changing Recruiting Landscape PDFVaishnavi SivaNo ratings yet

- Instant Download Ebook PDF Dorlands Illustrated Medical Dictionary 32nd Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Dorlands Illustrated Medical Dictionary 32nd Edition PDF Scribdemiko.johnson659100% (44)

- Agrirobot PDFDocument103 pagesAgrirobot PDFMuhamad Azlan ShahNo ratings yet

- Training Notebook December 2021Document619 pagesTraining Notebook December 2021martelldanielscilabsNo ratings yet

- TFG Miguel SanchezDocument77 pagesTFG Miguel SanchezMazin MursiNo ratings yet

- EC 03 - Archetypes - GM BinderDocument128 pagesEC 03 - Archetypes - GM BinderLeonxdNo ratings yet

- Free Bhel Transformer Book PDFDocument4 pagesFree Bhel Transformer Book PDFMilan ShahNo ratings yet

- PetretecDocument8 pagesPetretecVenkatesan KrishnachariNo ratings yet

- West Elm Digital CatalogueDocument131 pagesWest Elm Digital CatalogueogkanishkNo ratings yet

- 6 Feasibility Assessment ToolDocument5 pages6 Feasibility Assessment Toolalibaba1888No ratings yet

- Voslp /F 38: Overcenter ValvesDocument2 pagesVoslp /F 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Golden Gate PDFDocument42 pagesGolden Gate PDFJose David Vivas AbrilNo ratings yet

- Joel Nicholas Feimer - The Figure of Medea in Medieval Literature - A Thematic Metamorphosis-City University of New York (1983)Document342 pagesJoel Nicholas Feimer - The Figure of Medea in Medieval Literature - A Thematic Metamorphosis-City University of New York (1983)grzejnik1No ratings yet

- Braintree 15Document6 pagesBraintree 15paypaltrexNo ratings yet

- PPE Lab ManualDocument27 pagesPPE Lab ManualDinesh Chavhan100% (1)

- Math Chapter 3 Study GuideDocument3 pagesMath Chapter 3 Study Guideapi-311999132No ratings yet

- Presentation in BadmintonDocument68 pagesPresentation in BadmintonJohn Paul Espiña CandoNo ratings yet

- 100 Project Topic For PHP WebDocument4 pages100 Project Topic For PHP Weblalit amitNo ratings yet

- Sales and Purchases 2021-22Document15 pagesSales and Purchases 2021-22Vamsi ShettyNo ratings yet

- Schindler Escalator 9700AE - Brake MaintenanceDocument4 pagesSchindler Escalator 9700AE - Brake MaintenanceHùng VĩNo ratings yet

- Q3-TOS Science 7Document2 pagesQ3-TOS Science 7Carlo Rico ReyesNo ratings yet

- Block 3Document17 pagesBlock 3Dianne ChristineNo ratings yet

- PS2 VGA Diagram Rev by GillBert - Rev2 PDFDocument6 pagesPS2 VGA Diagram Rev by GillBert - Rev2 PDFwuemuraNo ratings yet

- Group 1 Dorb001 Bsce3aDocument16 pagesGroup 1 Dorb001 Bsce3aJan TheGamerNo ratings yet

- Talent Scout Test Body Mass ARM Span Basketball Throw Agility RUN 40 Metre SprintDocument6 pagesTalent Scout Test Body Mass ARM Span Basketball Throw Agility RUN 40 Metre SprintSoekemalNo ratings yet

- R (Ax) 30 KipsDocument9 pagesR (Ax) 30 KipsRey Kevin OrtuosteNo ratings yet

- Guide Raotm2014 JakartaDocument23 pagesGuide Raotm2014 JakartarajavinugmailcomNo ratings yet

- Bhopal Chapter of ISSS 1st NewsletterDocument8 pagesBhopal Chapter of ISSS 1st NewsletterBankesh ChatterjeeNo ratings yet

Escalator&Moving Walk Controller - ZXK1600 - User Manual

Escalator&Moving Walk Controller - ZXK1600 - User Manual

Uploaded by

Ken LeeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Escalator&Moving Walk Controller - ZXK1600 - User Manual

Escalator&Moving Walk Controller - ZXK1600 - User Manual

Uploaded by

Ken LeeCopyright:

Available Formats

WP1600

Microprocessor Based Escalator&Moving Walk Controller

User Manual

Ver1.04

ef

Subject to change without notice Wuxi WIPO Electronic Co.,Ltd

&

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

Preface

Microprocessor Based Escalator & Moving Walk Controller WP1600is the main controller specially designed for Escalator & Moving Walk, applied for normal motor drive control system, and VVVF drive control system. It is functionally featured as following: 1. With high capacity control code memorizer applied for PC controller acts together with ST Microelectronics CPU for upgrading programs conveniently according to the specific requirement. 2. Fault & operation module applied CanBus LAN Serial Communication with speed up to 125Kbit/S, High-spped data transmission, real-time control and quick response. 3.LED display with high brightness is applied for function setting. Such as port polarity setting, clock setting, speed setting, stop/start time setting, password setting. 4.Inside blackbox function following up the lift running & recording the time of running, code of faults leads to the poWPrful maintenance. 5.Supporting multi-remote display drive to show the running direction and code of faults. 6.SMT technology delivers reliable quality and small & delicate appearance to PCBs with low poWPr-consumption. It is a valuable green electronic product. 7.With unique anti-interference technology. All the components WPre selected strictly to guarantee the quality.

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

Contests

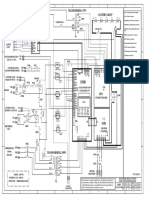

CHAPTER 1 MAIN CONTROLLERWP1600.. 3 1.1( WP1600) IN PICTURE 3 1.2( WP1600) EXTERNAL DIMENSIONS. 4 1.3( WP1600) DIMENSION DRAWING OF MOUNTING. 4 1.4 ELECTRIC SPECIFICATION. 4 1.4.1 supply input J12. 4 1.4.2 switching input5 1.4.3 switching output. 5 1.4.4 input principle. 6 1.4.5 output principle... 6 1.5 PORT DESCRIPTION: INPUTS J1J2J3J4J5J6J7 7

INPUT PORTS DESCRIPTION 7

1.6 PORT DESCRIPTION: OUTPUTS J8J9J10J11 8

OUTPUT PORTS DESCRIPTION

1.7 OUTPUT PORT: J14. 9 1.8 SUPPLY INPUT: J12.. 9

SUPPLY INPUT DESCRIPTION..

CHAPTER 2: OPERATION AND FAULT DISPLAY MODULEWP1600-01... 10 2.1WP1600-01IN PICTURE..10 2.2WP1600-01EXTERNAL DIMENSION.10 2.3WP1600-01DIMENSION DRAWING OF MOUNTING... 10 2.4WP1600-01PORT DESCRIPTION. 11 CHAPTER 3: CONFIGURATION OF MAIN CONTROLLER.. 12 3.1 GENERAL VIEW...12 3.2 PARAMETERS SETTING... 14 CHAPTER 4: MAIN CONTROLLER ADJUSTMENT..19 4.1 BEFORE THE ADJUSTMENT. 19 4.2 INSPECTION RUNNING 19 4.3 RUNNING NORMALLY.. 19 4.4 OPERATION OF OIL PUTTING19 4.5 APTITUDE RUNNING FUNCTION... 20 CHAPTER 5: FAMILIAR FAULT AND TROUBLESHOOTING. 21

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

Chapter 1 : Main Controller (WP1600)

1.1( WP1600) in picture and description of interface

Table 1.1 Description of the outside interface No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Code J1 J2 J3 J4 J5 J6 J7 J8 J9 J10 J11 J14 J15 J12 BT1 Item Input/output port 1 Input port 2 Input port 3 Input port 4 Input port 5 Input port 6 Input port 7 Output port 8 Output port 9 Output port 10 Output port 11 Output port 12 Short circuit port PoWPr supply input 3V lithium battery2032 Remarks Switching input / providing output supply Switching input Switching input Switching input Switching input Switching input Switching input Switching output Switching output Switching output Switching output (backup for expanding) Connect with another display board Match with resistance 5V and 24V separately

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

1.2 External Dimensions

Unit mm Width 181 Length 108 Thickness <24

1.3 Dimension drawing of mounting base plate

1.4 Electric specifications

1.4.1 PoWPr supply port J12

Rated voltage Rated current

DC 5V5 0.4 A

DC24V5 1A

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

1.4.2 Switching input

Input Level 0 Current Signal Level 1 Level 0 Voltage Signal Level 1

Open collector inputs photo-electricity Isolation 0~2mA 4.5~8mA 18~24V DC 0~5V DC 30mS 330Hz

Digital signal filtering delay Signal responding frequency

1.4.3 Switching output There are two types of switching output: transistor output and relay output. Their electric specifications show as follows. Electric specifications of transistor output: Output form Load voltage Load current DC Transistor outputJ11 24V DC

Resistance load Single output 100mA, whole output 400mA *note 1 Inductive load 20mA Note 1On the port J11, the summation of all the transistor output current cannot 400 mA

Electric specifications of relay output: Output form AC Load Voltage DC Inductive load Load Current Service life Resistance load Electric service life Mechanical service life Relay OutputJ8J9J10 250V AC 110V DC 3A 5A 3,000,000 times 10,000,000 times

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

1.4.4 Input principle:

1.4.5 Output principle:

Transistor output

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

Relay output

1.5 Port description: inputs J1J2J3J4J5J6J7

Port No. P1 P2 J1 P3 2424+ P4 P5 J2 P6 P7 P8 P9 P10 J3 P11 P12 P13 J4 P14 P15 P16 Relative component Testing motor speed Testing left armrest speed Testing right armrest speed Supply 24VSupply 24V+ Inspection signals Going up signals Going down signals Oil pump operation button Contactor conglutination inspection Brake traveling switch inspection Safety loop relay Drive chain break off Apron left-upside Apron right-upside Gear left-upside Gear right-upside Armrest entrance left-upside Provide supply 24V to photocouple for testing speed N/C signals (normal:N/C, inspection:N/O.) Going-up: press close input Going-down: press close input Put the oil by manual N/C signalsrunning:N/O, stop:N/C N/O/N/C can be selected through the menu Including P11~P29 relative switch, phase relay, hot relay, emergency switch all safty loop connect: close,fault anywhere: break off All the switch inputs in safety loop, when the switch activated, the relative input was lightened. Impulse input, working frequency under 50Hz Remarks

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

P17 P18 P19 P20 J5 P21 P22 P23 P24 P25 J6 P26 P27 P28 P29 P30 J7 P31 P32 CM6

Armrest entrance right-upside Step stop upside Apron left-underside Apron right-underside Gear left-underside Gear right-underside Armrest entrance left-underside Armrest entrance right-underside Left traction chain break off Right traction chain break off Step underside break off Left armrest break off Right armrest break off Upside entrance sensor input Underside entrance sensor input Backup input 1 Common input

Used for the inputs driving by mode of VVVF & energy -saving Backup for function expanding P1-P32 commonly use CM624V-

1.6 Port description: outputs J8J9J10J11

Port No. T1 T2 J8 CM1 T3 T4 CM2 T5 J9 T6 T7 CM3 T8 CM4 J10 NC NC NC J11 C1 Relative component Star contactor Triangle contactor Signals output: common port 1 Going-up contactor Going-down contactor Signals output: common port 2 Brake contractor 1 Brake contractor 2 Cooling oilpump valve contactor Signals output: common port 3 T5T7 commonly use CM3 Alarm bell When there is fault, it alarm. Signals output: common port 4 Empty Empty Empty Going-up contactor control (VVVF) output VVVF speed control (transistor output) T8 CM4 independent connection Remarks Using as supply input (VVVF) Running contactor T1T2 commonly use CM1 Going-up contactor Going-down contactor T3T4 commonly use CM2 contactor

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

C2 C3 C4 CM5

Going-down contactor output control (VVVF) High-speed output (VVVF) Low-speed output (VVVF) Signals output: common port 5 C1C4 commonly use CM524+

J8,J9,J10 are relay outputs, J11 is transistor output.

1.7 Port description: output J14

Port No. CANL CANH J14 24+ 24Relative component CAN interface CAN interface + 24V DC supply output + 24V DC supply output Remarks Note the interface polarity.

Supplying 200mA current.

This port used for besides display boardmax. 4pcs, and also can provide 24V voltage( from 24+ to 24-), 200mA. current to the other equipment (such as photocouple for testing speed).

1.8 port description: supply input J12

Port No. 5V+ 5VJ12 FG 24V+ 24V24V DC supply 5V DC supply Grounded port Note: the polarity of the connection , dont connect contrarily. Relative component Remarks

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

Chapter 2: Operation and fault display moduleWP1600-01

2.1WP1600-01in picture:

WP1600-01 display side

WP1600-01 component side

2.2WP1600-01External dimension:

Unit mm Width 576 Length 772 Thickness <22

2.3WP1600-01installation dimensions drawing:

10

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

2.4WP1600-01 port description:

Port JI J2 Description CAN used for short circuit port of resistance matching CAN interface and supply input

Operation & fault display moduleWP1600-01is used for Escalator & Moving Walk controller to display the running direction. Fault code module, it is used with Escalator & Moving Walk main controllerWP1600. The controller can work with 4 pcs operation & fault display module WP1600-01at most. Regarding to the port J1, when there is one piece of WP1600-01 in the controller, it will be short connected with port J1used for resistance matching to reduce CAN bus signals reflection.if there is more than one piece of WP1600-01, one of them should be short connected with J1, others are not. J2 is supply input and CAN-BUS input, please note the polarity of the supply and CAN-BUS avoiding to destroy it. LED display screen used super two-colours display module, fresh colour, high brightness, far optical distance. The display figure can be set in the main controller by users themselves. Default figure: big arrowhead, small arrowhead, rolling arrowhead etc. All of them can be set in the main controller. On the display board, port J4 is used to set the installation place of the display module, if J4 was short connected, this module will be installed on the top of the Escalator, if not, it will be in the bottom. This port deside the right display information.

11

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

Chapter 3: Configuration of the main controller

3.1 General view:

Microprocessor Based Escalator & Moving Walk Controller should configure with some parameters to work WPll. It will use LED display and keyboard to finish these configurations. Menu operation screen(located on the left-underside of the controller) show as below:

ESC

Including 4 LED display, 4 touch button. ESC---------Exit UP----------up

UP

DOWN OK

DOWN-------down

OK------------confirm

Note menu operation should be do under stop status, otherwise, it is not be alloWPd. Menu catalogue is as follows: Main menu FUN1 First menu Menu function setting description Default

F1-1 F1-2

Brake traveling switch inspect N/O,N/C selection setting: 0---N/C, 1---N/O. Under VVVF drive& energy-saving control, upside entrance inductive switch input setting: 0---N/C, 1---N/O.

0 0

F1-3

Under VVVF drive& energy-saving control, underside entrance inductive switch input setting: 0---N/C, 1---N/O.

FUN2

F2-1 F2-2 F2-3

Under automaticly putting the oil, time interval setting Under automaticly putting the oil, time setting

scope: 09999min scope:09999 sec

120 60 1000

Brake contactor run to the Up(Down) contactor, delaying time setting scope:09999 MSEL

F2-4 F2-5 F2-6 F2-7 F2-8

Star contactor running time setting System clock setting Lift stop automaticly time setting Lift start automaticly time setting Before lift start, the time setting of the bell

scope:09999 MSEL scope:00:0023:59 scope:00:0023:59 scope:00:0023:59 scope:099sec

1000 06:00 88:88 88:88 1S

12

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

F2-9

Under mode of VVVF, the delaying time of output in the leisure energy-saving running scope:1-99sec

30

F211

Under aptitude running, no one use the lift, delaying time to stop the lift scope:1-99sec

60

F2-0 Main menu FUN3 First menu F3-1

System default: all the parameters will be back to the default set by manufacture Menu function setting description Motor speed setting Unit: impulse interval time counting value Default 180

Value = 0, cancel this speed control. F3-2 Left armrest speed setting Unit: impulse interval time counting value 180

Value = 0, cancel this speed control. F3-3 Right armrest speed setting Unit: impulse interval time counting value 180

Value = 0, cancel this speed control.

FUN4

F4-1 F4-2 F4-3

The type of lift poWPr control setting: 0VVVF, 1Y/ Parameters setting of the controller running status monitor scope: 07

1 7 0

Display mode of the outside display figure setting: 0-big arrowhead, 1-small arrowhead, 2-step arrowhead, 3-rotated arrowhead

F4-4 F4-5 F4-6 F4-7 F4-8

Oil putting equipment selection: 0motor, 1electromagnetic valve. Running direction selection of poWPr on automatic: 0going up, 1going down Self-learning of the lift speed: 0----run normally, 1----self-learn. Under VVVF control, output speed ratio betWPen high-speed and low-speed. The ability of the lift aptitude running: 0---NO, 1---YES.

1 0 0 5 0

FUN5

F5-1 F5-2

Popedom password of the lift maintain time Maintain time of the lift

scope: 0-99999999 scope: 0-9999 hour

00000000 0

FUN6 FUN7

Fault inquiry, it can store 4 fault records. Show the edition of the software.

13

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

3.2 Parameters setting description:

When the controller is poWPr on, pressOK to enter the menu setting: 1 PressUP or DOWN to turn the pages to select the menu. 2 If there is submenu under ths menu, pressOK to enter the next menu. 3 If there is no submenu, pressOK to enter the function parameters setting. 4 Anytime you can pressESC to back to the last menu without saving. 5 Entering the parameters setting, the place you want to set will flash, indicate that it can be revised. UP can change the number, DOWN changes the digit. 6 After revised, press OK to save the settings, and finish with YES. ( If you set the wrong number, it will show ERR.) And then back to the last menu. 7 All the input datas should be algorism data. 3.2-1 FUN1 Menu description: FUN1 includes 3 submenus to finish the polarity setting of the hardware inputs. 1F1-1 Brake traveling switch inspection N/O, N/C selection: 0---N/C (stopclose; runbreak off), 1---N/O (stopbreak off; run--close) 2F1-2F1-3 Used for the polarity setting of the VVVF inductive inputs, please check the menu catalogue for some details. 3.2-2 FUN2 Menu description: FUN2 includes 9 submenus to finish the time setting : 1 F2-1F2-4 please check the parameters description of catalogue. 2 F2-5 system clock setting, the first two digits on the LED display are hours (scope:0-23), the next two are minutes(scope:0-59). 3 F2-6 escalator stop automaticly time setting: the format of the time is XX:XX such as 18:00, means that the escalator stop at 6:00 pm. If you want to cancel this function, yue can set the number beyond the scope 00:0023:59. (But because of the safety criterion, it will not be provided). 4 F2-7 escalator start automaticly time setting: the format of the time is XX:XX such as 06:00 means that the escalator start at 6:00 am. If you want to cancel this function, yue can set the number beyond the scope 00:0023:59. (But because of the safety criterion, it will not be provided).

14

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

5 F2-8 the bell setting before escalator start: please check the catalogue for some details. 6 F2-9 UP/DOWN inductive ertrance fault inspection delay time, means that when it goes up, the upside inductive ertrance inspect the inputs, after the delay time reach to max, the underside inductive ertrance still cannot inspect the inputs, it will show fault. When it goes down, in the contrary. 7 F2-0 system default setting: all the parameters set same with it set by manufacturer. The details show as follows: Entering to the menu F2-9, press OK, the display will show REAL, means that are you sure all of them back to the default?, then press OK to confirm and save it. Press ESC to quit without any changes. 3.2-3 FUN3 Menu description:

FUN3 includes 3 submenus: Motor speed setting, left armrest speed limit setting and right armrest speed limit setting, these three settings are used to test the escalator speed. Show the detailed setting as below: 1. 2. Set F4-6 is1(self-learning)under inspection mode to start the escalator. After inspection running, pressUP or DOWN to turn the pages, LED display will show the parameters monitored currently, the parameters including: RUN----------------------total running time parameter STP----------------------- total leisure time parameter NSP-----------------------motor speed impulse counting value parameter USP-----------------------left armrest speed impulse counting value parameter DSP-----------------------right armrest speed impulse counting value parameter CLOC--------------------system clock STU-----------------------running status parameter NSPC---------------------motor speed time counting value parameter USPC---------------------left armrest speed time counting value parameter DSPC-------------------- right armrest time counting value parameter Record the relative value of these three parameters by researching NSPCUSPC DSPC. 3. Stopenter the menuFUN3 then enter to the submenu

15

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

F3-1----------record the relative value of NSPC, and save it. F3-2--------record the relative value of USPC, and save it. F3-3--------- record the relative value of DSPC, and save it.

4. If using VVVF drive mode, you should set the speed ratio of output betWPen high-speed and low-speed to the menu F4-7.

3.2-4 FUN4 Menu description: FUN4 includes 6 submenus to set the system control parameters. 1 F4-1 is the setting reference menu catalogue which set the type of the escalator poWPr control, when set Y/, the drive mode is star/triangle drive; when select VVVF drive, ourput: the star contactor output change into VVVF contactor output 1; triangle contactor output change into VVVF contactor output 2; output C1 or T3 works as the VVVF control up contactor, C2H or T4 works as the VVVF control down contactor,C3 works as the VVVF control high-speed output, C4 works as the VVVF control low-speed outputP30 P31works as speed adjustment .Note: Please select the right drive type according to the different drive mode. 2 F4-2 Parameters setting of controller running status monitor, used after escalator start, LED display the current parameters, value: 0-----7: 0------ poWPr-saving mode, LED sleep, brightless 1------monitor the total running time, unit is hour, max. value is 9999 hours, beyond 9999 hours,it will recount the number from 0, running time data will not lost even poWPr off. 2------PoWPr on, escalator non-running using time, unit is hour, max. value is 9999 hours, beyond 9999 hours,it will recount the number from 0, running time data will lost if it is poWPr off. 3------Motor speed 4------Left armrest speed 5------ Right armrest speed 6------System clock 7------Running direction. Such asUPDNSTOP.

16

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

3F4-3 display mode of outside display figure, which match with the operation&fault display module. WP1600-01display mode setting, parameter from 0 to 3. 0------big arrowhead to display the running direction 1------small arrowhead to display the running direction 2------step arrowhead to display the running direction 3------rotated arrowhead to display the running direction 4F4-4 oil-putting equipment selection 0 or 1: 0------motor drive oil-putting mode, when manual oil-putting signal exits, or auto/half-auto signals exit, oil-putting control output T7 works all the time, if the signals disappear, outputs stop. 1------electromagnetic valve drive oil-putting mode, when manual oil-putting signal exits, or auto signals exit, oil-putting control output T7 works 1 second & stops 3 seconds, output circularly till the signals disappear. 5F4-5 running direction of starting the escalator automaticly: 0-------Up, 1-------Down. 6F4-6 self-learning: is the speed setting of the self-learning. 0----cancel self-learning, 1--start self-learning. If stop the escalator, this parameters will back to 0cancel self-learning. So everytime you want to set this speed, you should select 1. 3.2-5 FUN5 Menu description: FUN5 includes 2 submenus to set the system maintenance time limit. Password8digits to limit setting the maintenance time random. Only one know the passwordcan do it. Default: 00000000. Maintenance time4digits Default:0000. If it is set 0, there is no any limit, if not, such as set 0002, the system can run 2 hours at most, after that, system enter into maintenance status(all the escalator functions are invalid), finishing it, you should set 0 again to resume all the functions. The setting method show as follows: 1. F5-1 popedom password setting (1) Enter menu F5-1, press OK, LED display CD01 (input the ability operation password[Note1]higher 4 digits), then display 0000, start to input. (2) Input the ability operation password the higher 4 digits, press OK, LED display CD02

17

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

(input the ability operation password the loWPr 4 digits), then display 0000, start to input. (3) Input the ability operation password the loWPr 4 digits, press OK, if the input 8 digits ability operation password is unconformity with the former one, it will display ERR, and let you input again, if it is conformity, displayYES, then SET, set the next new popedom password. (4) LED displaySD01 input the higher 4 digits of the new password, then display 0000, start to input. (5) Input the higher 4 digits of the new password, press OK, LED display SD02input the loWPr 4 digits of the new password, then display 0000, start to input. (6) Input the loWPr 4 digits of the new password, press OK, LED display YES, means password set successfully. Note 1: Ability operation password is the former popedom password. 2. F5-2 Maintenance time setting: 1Enter menu F5-2, press OK, LED display CD01 (input the ability operation password[Note1]higher 4 digits), then display 0000, start to input. 2Input the ability operation password the higher 4 digits, press OK, LED display CD02 (input the ability operation password the loWPr 4 digits), then display 0000, start to input. 3Input the ability operation password the loWPr 4 digits, press OK, if the input 8 digits ability operation password is unconformity with the former one, it will display ERR, and let you input again, if it is conformity, displayYES, then SET, set the next maintenance time. 4Input the time, press OK to finish the set. NoteAfter setting the password, please keep it in your mind, never forget.

18

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

Chapter 4: Main controller adjustment

4.1 Before the adjustment:

1 Inspect all the output/input wires connecting right.

2 Inspect the lift parameters set right or not.

4.2 Inspection running:

The condition under inspection running: 1Safety loop normalP10 is lighten. 2Contactor conglutination testing input normal, stop(P8 is lighten), run(P8 isnt lighten) 3Brake traveling switch testing input normal. After start the escalator, observe the sequence is right or not, output is right or not (indication LED lighten). Using Y/ drive, the sequence is: Up Down signal inputDelayBrake contactor openDelayUpDowncontactor openStar contactor openInspection running. Using VVVF drive, the sequence is: Up Down signal inputDelayBrake contactor openDelayoutput contactor 1 & 2 open together UpDowncontactor open Fast car and slow car contactor open(under self-learning, only fast car open) Inspection running.

4.3 Running normally:

The condition under running normally: 1Safety loop normalP10 is lighten. 2Contactor conglutination testing input normal, stop(P8 is lighten), run(P8 isnt lighten) 3Brake traveling switch testing input normal. After start the escalator, observe the sequence is right or not, output is right or not (indication LED lighten). Using Y/ drive, the sequence is: Up Down signal inputDelay Alarm bell ring DelayBrake contactor openDelayUpDowncontactor openStar contactor openDelay Star contactor close Triangle contactor open running normally. Using VVVF drive, the sequence is: Up Down signal inputDelayBrake contactor openDelayoutput contactor 1 & 2 open together UpDowncontactor open Fast car contactor open running normally.

4.4Oil-putting operation:

Oil-putting button input port input signals, oil-putting control output port output signals, the sequenceof output show as below: 1 Under motor drive oil-putting mode, when manual oil-putting signal exits, oil-putting control output T7 works all the time(LED lighten), if the signals disappear, outputs stop.

19

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

2Under electromagnetic valve drive oil-putting mode, when manual oil-putting signal exits, oil-putting control output T7 works 1 second & stops 3 seconds, output circularly till the signals disappear. When time of automatic oil-putting interval is up, it is also do it as the above sequence. When the time of automatic oil-putting is up, stop putting the oil, T7 doesnt output(LED go out.) 3Half-auto oil-putting: After escalator running, keep the Up/Down key switch in the status of going up or input status of going down 8 seconds, system will come to oil-putting status automaticly. Using this mode, please note that keep the key input status conformity with the running direction, otherwise, escalator will stop.

4.5 Aptitude running function:

This function mainly used for Moving Walk system, not suitable for Escalator. Suitable for Y/ drive and VVVF drive. Working mode: after lift running, if no one use it, it will use time set in advance(F211). If it is Y/ drive mode, the lift will stop at once. But if it is under VVVF mode, no one use it, the delay stopping time(F211) is more than delay time of leisure energy-saving running output(F2-9). The lift firstly enter to the slow speed running, till the time of stop delay is up, it will stop. But if the delay stopping time(F211) is less than delay time of leisure energy-saving running output(F2-9), the lift will stop at once. After than, when there is passenger, it will start automaticly or change into high-speed running from low-speed, according the direction passenger entered(judging by the two inductive port on the entrance). Under running, if the key switch works 3 times continuously(in 3 seconds), and keep consistent with the running direction, lift will keep this running direction till stop it. This function should be carefully used by customer according the fact.

20

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

Chapter 5: Familiar faults & troubleshooting

Code P-01 P-02 P-03 C-05 P-05 P-06 P-08 P-09 P-10 P-11 P-12 P-13 P-14 P-15 P-16 P-17 P-18 P-19 P-20 P-21 P-22 P-23 P-24 P-25 P-26 P-27

Fault Motor speed unconformity Left armrest speed unconformity Right armrest speed unconformity Up&Dn signals appear together Up-button conglutination Down-button conglutination Contactor conglutination Brake traveling switch no action Safety loop fault Drive chain break off Apron left-upside Apron right-upside Gear left-upside Gear right-upside Armrest entrance left-upside Armrest entrance right-upside Step stop upside Apron left-underside Apron right-underside Gear left-underside Gear right-underside Armrest entrance left-underside Armrest entrance right-underside Left traction chain break off Right traction chain break off Step underside break off

Cause Motor fault Left armrest testing speed fault Right armrest testing speed fault Touchpoint/input wire fault After lift running, button wasnt be released. After lift running, button wasnt be released. Contactor/input wire fault Brake contactor/input wire fault Safety loop/relay/input wire fault Drive chain break off Apron left-upside Apron right-upside Gear left-upside Gear right-upside Armrest entrance left-upside Armrest entrance right-upside Step stop upside Apron left-underside Apron right-underside Gear left-underside Gear right-underside Armrest entrance left-underside Armrest entrance right-underside Left traction chain break off Right traction chain break off Step underside break off

Troubleshooting Inspect the motor, testing speed part, ¶meters setting, if hardware is bad, replace the bad parts. Inspect left armrest testing speed part, & parameters setting, if hardware is bad, replace the bad parts. Inspect right armrest testing speed part, & parameters setting, if hardware is bad, replace the bad parts. Inspect up/dn switch and input wire, if the switch is bad, replace it. Inspect UP button is bad or not, replace it. Inspect DOWN button is bad or not, replace it. Inspect input wire and contactor, if the contactor is bad, replace it. Inspect input wire and brake contactor, if the contactor is bad, replace it. Inspect input wire and safety relay, if the relay is bad, replace it. Inspect input wire and drive chain, if drive chain break off , replace it. Inspect input wire and apron left-upside, replace the bad one. Inspect input wire and apron right-upside, replace the bad one. Inspect input wire and gear left-upside, replace the bad one. Inspect input wire and gear right-upside, replace the bad one. Inspect input wire and armrest entrance left-upside, replace the bad one. Inspect input wire and armrest entrance right-upside, replace the bad one. Inspect input wire and step upside, replace the bad one. Inspect input wire and armrest entrance left-underside, replace the bad one. Inspect input wire and armrest entrance left-underside, replace the bad one. Inspect input wire and armrest entrance left-underside, replace the bad one. Inspect input wire and armrest entrance left-underside, replace the bad one. Inspect input wire and armrest entrance left-underside, replace the bad one. Inspect input wire and armrest entrance left-underside, replace the bad one. Inspect input wire and traction left chain, replace the bad one. Inspect input wire and traction right chain, replace the bad one. Inspect input wire and step underside, replace the bad one.

21

WIPO Electronic

Microprocessor Based Escalator&Moving Walk Controller WP1600 user manual

P-28 P-29 P-30 P-31

Left armrest break off Right armrest break off Upside entrance sensor input Underside entrance sensor input Function limit

NUSE

Inspect input wire and left armrest, replace the bad one. Inspect input wire and right armrest, replace the bad Right armrest break off one. Upside entrance sensor input Inspect input wire and up touchpoint, replace the bad one. Underside entrance sensor input Inspect input wire and down touchpoint, replace the bad one. If the maintenance time is up, or clock doesnt work, please check the clock chip, set the function using limit time 0. If the clock show the wrong number, take down the battery(poWPr off), put it again after few seconds. PoWPr on, enter into the menu F2-0, reset the default. Left armrest break off

If there is any fault when escalator is running, stop it at once.

22

You might also like

- Acute Coronary Syndrome NCP 01Document5 pagesAcute Coronary Syndrome NCP 01AgronaSlaughter0% (1)

- Nova Ev3200 ManualDocument25 pagesNova Ev3200 ManualCarolina Sansón100% (1)

- Operation and Service Manual: Status 26.05.1998Document58 pagesOperation and Service Manual: Status 26.05.1998raymon janszenNo ratings yet

- Fuji Starting Guide G11S-LE2 - Lift - 7Document54 pagesFuji Starting Guide G11S-LE2 - Lift - 7Nguyen Anh Tu100% (3)

- ME-LIFT-P Microprocessor Control User Manual 20071226 PDFDocument38 pagesME-LIFT-P Microprocessor Control User Manual 20071226 PDFKen LeeNo ratings yet

- COP User Manual 2.0 PDFDocument5 pagesCOP User Manual 2.0 PDFخالدعبدالله100% (1)

- nUPS-M Inverter User ManualDocument11 pagesnUPS-M Inverter User ManualخالدعبداللهNo ratings yet

- BL3-U Quick Commissioning Menu V1.2 PDFDocument32 pagesBL3-U Quick Commissioning Menu V1.2 PDFRandy VanegasNo ratings yet

- A NICE3000new 2018Document203 pagesA NICE3000new 2018Bahodur ToshevNo ratings yet

- Simply Handbook of Debugging (F5021-32 Bit Board)Document3 pagesSimply Handbook of Debugging (F5021-32 Bit Board)thanggimme.phanNo ratings yet

- Sjg18-046 (03) - Guangri New ControlDocument53 pagesSjg18-046 (03) - Guangri New Controlratan.m1010No ratings yet

- NICE7000 DebuggingDocument4 pagesNICE7000 DebuggingTroubleshootingNo ratings yet

- ARL700 UCM Test Instructions For Hydraulic Lifts V1.EnDocument5 pagesARL700 UCM Test Instructions For Hydraulic Lifts V1.EnkizonimeisterNo ratings yet

- Troubleshooting-Inverter User ManualDocument4 pagesTroubleshooting-Inverter User Manualqison.yanNo ratings yet

- ARES Escalator 6Document7 pagesARES Escalator 6GutmonarchNo ratings yet

- Integrated Door Motor Controller User Manual: Shenyang Bluelight Automatic Technology Co., LTDDocument56 pagesIntegrated Door Motor Controller User Manual: Shenyang Bluelight Automatic Technology Co., LTDJulio Cesar GonzalezNo ratings yet

- ARCUBE Change Log - enDocument4 pagesARCUBE Change Log - enВячеслав ЯкимовNo ratings yet

- Manual EC20 (English) PDFDocument79 pagesManual EC20 (English) PDFDalat TigonNo ratings yet

- Machine Brakes Self-Monitoring Test Instructions V10.EnDocument5 pagesMachine Brakes Self-Monitoring Test Instructions V10.EnKs BharathiyarNo ratings yet

- AS380 Series Elevator Intergrated Controller User Instruction V2.13 PDFDocument296 pagesAS380 Series Elevator Intergrated Controller User Instruction V2.13 PDFRogério da Silva de OliveiraNo ratings yet

- VVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelDocument13 pagesVVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelKen LeeNo ratings yet

- Yaskawa L1000A Quick Start Guide TOEPC71061638Document204 pagesYaskawa L1000A Quick Start Guide TOEPC71061638younesNo ratings yet

- LM 3 ParameterliftDocument1 pageLM 3 ParameterliftVinay SharmaNo ratings yet

- MicroZed v35 CatalogDocument32 pagesMicroZed v35 CataloghabibullaNo ratings yet

- Dri Ve Ci Rcui T AS360P01V01Document13 pagesDri Ve Ci Rcui T AS360P01V01Javier MartínezNo ratings yet

- C604 AttachmentpaperDocument32 pagesC604 AttachmentpaperWander GomesNo ratings yet

- MCTC-KZ-B0S To Customer Side Protocol Details V1.2Document14 pagesMCTC-KZ-B0S To Customer Side Protocol Details V1.2John ClarenceNo ratings yet

- CL - Omkar ElectronicsDocument16 pagesCL - Omkar ElectronicsSazzad Hossan RaselNo ratings yet

- ARL-300 UCM Test Instructions For Gearless Machines - enDocument2 pagesARL-300 UCM Test Instructions For Gearless Machines - enkizonimeisterNo ratings yet

- WB Installation Manual EL ENG 4.3Document121 pagesWB Installation Manual EL ENG 4.3dianelys Sivada100% (1)

- Startup VDL200 Geared EngDocument7 pagesStartup VDL200 Geared EngSamih AlraghbanNo ratings yet

- AE Hex Series User ManualDocument34 pagesAE Hex Series User Manualdidik sukocoNo ratings yet

- Motherboard Manual Bx2000 1101 eDocument44 pagesMotherboard Manual Bx2000 1101 eGoran MojsilovicNo ratings yet

- Alc Series Lift Control Systems: User ManualDocument105 pagesAlc Series Lift Control Systems: User Manualمحمد حسينNo ratings yet

- Jarless Con Door DriveDocument1 pageJarless Con Door Drivewakeel ahmedNo ratings yet

- 20190401Document232 pages20190401rendy kurniawanNo ratings yet

- Arkel AR500 Gray - Binary Converte - 1 PDFDocument1 pageArkel AR500 Gray - Binary Converte - 1 PDFHenri KleineNo ratings yet

- Appendix 2: System TroubleshootingDocument4 pagesAppendix 2: System Troubleshootingعلاء صقرNo ratings yet

- Starting Guide: Frenic LiftDocument14 pagesStarting Guide: Frenic LiftخالدعبداللهNo ratings yet

- Error TableDocument19 pagesError TableJesús David Diaz MontesNo ratings yet

- FILE 20221010 095658 X11joDocument22 pagesFILE 20221010 095658 X11joNguyễn ThànhNo ratings yet

- ARCODE PLC Module Manual V10.enDocument4 pagesARCODE PLC Module Manual V10.enBrahim CherguiNo ratings yet

- Monarch Mctcpece1Document48 pagesMonarch Mctcpece1Sazzad Hossan RaselNo ratings yet

- Instruction Manual For BLT Armeg Group Control System: SERIAL NO. GNCG0002Document33 pagesInstruction Manual For BLT Armeg Group Control System: SERIAL NO. GNCG0002Cristian de LeonNo ratings yet

- AS350 Series Elevator Intergrated Controller User Instruction V1.0Document109 pagesAS350 Series Elevator Intergrated Controller User Instruction V1.0Nguyen VuongNo ratings yet

- Elevator Programming CodeDocument178 pagesElevator Programming Code100mphNo ratings yet

- Vacon NX Lift Application Manual UD00758L ENDocument69 pagesVacon NX Lift Application Manual UD00758L ENDean LefebvreNo ratings yet

- Movilift Encoder Stand Alone Eng Ver. 2.0Document6 pagesMovilift Encoder Stand Alone Eng Ver. 2.0JoseNo ratings yet

- Faults ARCA IIDocument13 pagesFaults ARCA IIStefan PopovNo ratings yet

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDocument13 pagesMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010No ratings yet

- JSA07924E-AA - E-Com Local Wiring (V300)Document17 pagesJSA07924E-AA - E-Com Local Wiring (V300)Mahmoud Omar RobNo ratings yet

- HB As380 E20 PDFDocument70 pagesHB As380 E20 PDFjonathanNo ratings yet

- User'S Manual: GMBH, GermanyDocument167 pagesUser'S Manual: GMBH, GermanyAndres Felipe CaceresNo ratings yet

- ARES Escalator BDocument2 pagesARES Escalator BGutmonarchNo ratings yet

- Monarch MCTC-CTW-A3 Car Top Intergrated Control BoxDocument2 pagesMonarch MCTC-CTW-A3 Car Top Intergrated Control BoxNick OngNo ratings yet

- ARL-700 Firmware Update V1.2.EnDocument8 pagesARL-700 Firmware Update V1.2.EnkizonimeisterNo ratings yet

- Sod IvarDocument41 pagesSod IvarSacha's ChannelNo ratings yet

- Homex SVTDocument23 pagesHomex SVTAlan TacherNo ratings yet

- UCMPDocument2 pagesUCMPTushar ImranNo ratings yet

- 87 Catalog Invertere Ic5Document19 pages87 Catalog Invertere Ic5vga1234No ratings yet

- Tài Liệu Biến Tần LS IC5Document20 pagesTài Liệu Biến Tần LS IC5hieudaivuongNo ratings yet

- AS320 InverterDocument43 pagesAS320 Inverterthi tranNo ratings yet

- Car Door M-TypeDocument1 pageCar Door M-TypeKen LeeNo ratings yet

- Planning GuideDocument11 pagesPlanning GuideKen LeeNo ratings yet

- 9.15 Opposite Door Control SchemeDocument4 pages9.15 Opposite Door Control SchemeKen LeeNo ratings yet

- SCM Go Flex: Product Technical SheetDocument8 pagesSCM Go Flex: Product Technical SheetKen LeeNo ratings yet

- Emesa Tech SheetDocument3 pagesEmesa Tech SheetKen LeeNo ratings yet

- User Manual DVM 70Document28 pagesUser Manual DVM 70Ken LeeNo ratings yet

- Transformer-1 /75W Battery Group: 12V 12V 12V 12V 12VDocument1 pageTransformer-1 /75W Battery Group: 12V 12V 12V 12V 12VKen LeeNo ratings yet

- Gate Controller Manual: AAD03010 Frequency Control SystemDocument17 pagesGate Controller Manual: AAD03010 Frequency Control SystemKen LeeNo ratings yet

- Transformer-1 /75W Battery Group: Drw. Apprv. M. Aybey Date Series Proj. Rev. LRS LRS02 M. AkkuşDocument1 pageTransformer-1 /75W Battery Group: Drw. Apprv. M. Aybey Date Series Proj. Rev. LRS LRS02 M. AkkuşKen LeeNo ratings yet

- Emesa CAR FRAMES 1Document2 pagesEmesa CAR FRAMES 1Ken LeeNo ratings yet

- Windsor: Self-Contained Drive System! Optional Recessed Telephone Box Operating Controls No Pit!Document2 pagesWindsor: Self-Contained Drive System! Optional Recessed Telephone Box Operating Controls No Pit!Ken LeeNo ratings yet

- Lrs 3Document1 pageLrs 3Ken Lee100% (1)

- Service Manual: SchematicsDocument42 pagesService Manual: SchematicsKen LeeNo ratings yet

- Planning Guide: For Residential Elevator With Hydraulic Drive or Winding Drum Drive ASME A17.1-2000 Part 5.3Document8 pagesPlanning Guide: For Residential Elevator With Hydraulic Drive or Winding Drum Drive ASME A17.1-2000 Part 5.3Ken LeeNo ratings yet

- NICE3000 - Technical Manual-060710Document109 pagesNICE3000 - Technical Manual-060710Ken Lee100% (8)

- Series Incremental Encoders: Environmental SpecificationsDocument2 pagesSeries Incremental Encoders: Environmental SpecificationsKen LeeNo ratings yet

- Safety For Technicians: 2 EN 81-20 & EN 81-50Document2 pagesSafety For Technicians: 2 EN 81-20 & EN 81-50Ken LeeNo ratings yet

- Bl3-U AsyncDocument23 pagesBl3-U AsyncKen Lee100% (1)

- VVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelDocument13 pagesVVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelKen LeeNo ratings yet

- MicroZed v33Document18 pagesMicroZed v33Ken LeeNo ratings yet

- Galaxy Traction Elevator ControllerDocument327 pagesGalaxy Traction Elevator ControllerKen LeeNo ratings yet

- Operation Manual: Rcf-1 Door Operator ControllerDocument31 pagesOperation Manual: Rcf-1 Door Operator ControllerKen LeeNo ratings yet

- Kasvar: User ManualDocument31 pagesKasvar: User ManualKen LeeNo ratings yet

- A30t U Type C Type Photoemission Switch For Lift and Elevator User Manual 2009Document3 pagesA30t U Type C Type Photoemission Switch For Lift and Elevator User Manual 2009Ken LeeNo ratings yet

- Omega LiftDocument2 pagesOmega LiftKen LeeNo ratings yet

- GMP Checklist Sanitary Facilities and ControlsDocument1 pageGMP Checklist Sanitary Facilities and ControlsATSEDENo ratings yet

- Talent Acquisition 2008 - Survey and Analysis of The Changing Recruiting Landscape PDFDocument20 pagesTalent Acquisition 2008 - Survey and Analysis of The Changing Recruiting Landscape PDFVaishnavi SivaNo ratings yet

- Instant Download Ebook PDF Dorlands Illustrated Medical Dictionary 32nd Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Dorlands Illustrated Medical Dictionary 32nd Edition PDF Scribdemiko.johnson659100% (44)

- Agrirobot PDFDocument103 pagesAgrirobot PDFMuhamad Azlan ShahNo ratings yet

- Training Notebook December 2021Document619 pagesTraining Notebook December 2021martelldanielscilabsNo ratings yet

- TFG Miguel SanchezDocument77 pagesTFG Miguel SanchezMazin MursiNo ratings yet

- EC 03 - Archetypes - GM BinderDocument128 pagesEC 03 - Archetypes - GM BinderLeonxdNo ratings yet

- Free Bhel Transformer Book PDFDocument4 pagesFree Bhel Transformer Book PDFMilan ShahNo ratings yet

- PetretecDocument8 pagesPetretecVenkatesan KrishnachariNo ratings yet

- West Elm Digital CatalogueDocument131 pagesWest Elm Digital CatalogueogkanishkNo ratings yet

- 6 Feasibility Assessment ToolDocument5 pages6 Feasibility Assessment Toolalibaba1888No ratings yet

- Voslp /F 38: Overcenter ValvesDocument2 pagesVoslp /F 38: Overcenter ValvesSachin RamadasanNo ratings yet

- Golden Gate PDFDocument42 pagesGolden Gate PDFJose David Vivas AbrilNo ratings yet

- Joel Nicholas Feimer - The Figure of Medea in Medieval Literature - A Thematic Metamorphosis-City University of New York (1983)Document342 pagesJoel Nicholas Feimer - The Figure of Medea in Medieval Literature - A Thematic Metamorphosis-City University of New York (1983)grzejnik1No ratings yet

- Braintree 15Document6 pagesBraintree 15paypaltrexNo ratings yet

- PPE Lab ManualDocument27 pagesPPE Lab ManualDinesh Chavhan100% (1)

- Math Chapter 3 Study GuideDocument3 pagesMath Chapter 3 Study Guideapi-311999132No ratings yet

- Presentation in BadmintonDocument68 pagesPresentation in BadmintonJohn Paul Espiña CandoNo ratings yet

- 100 Project Topic For PHP WebDocument4 pages100 Project Topic For PHP Weblalit amitNo ratings yet

- Sales and Purchases 2021-22Document15 pagesSales and Purchases 2021-22Vamsi ShettyNo ratings yet

- Schindler Escalator 9700AE - Brake MaintenanceDocument4 pagesSchindler Escalator 9700AE - Brake MaintenanceHùng VĩNo ratings yet

- Q3-TOS Science 7Document2 pagesQ3-TOS Science 7Carlo Rico ReyesNo ratings yet

- Block 3Document17 pagesBlock 3Dianne ChristineNo ratings yet

- PS2 VGA Diagram Rev by GillBert - Rev2 PDFDocument6 pagesPS2 VGA Diagram Rev by GillBert - Rev2 PDFwuemuraNo ratings yet

- Group 1 Dorb001 Bsce3aDocument16 pagesGroup 1 Dorb001 Bsce3aJan TheGamerNo ratings yet

- Talent Scout Test Body Mass ARM Span Basketball Throw Agility RUN 40 Metre SprintDocument6 pagesTalent Scout Test Body Mass ARM Span Basketball Throw Agility RUN 40 Metre SprintSoekemalNo ratings yet

- R (Ax) 30 KipsDocument9 pagesR (Ax) 30 KipsRey Kevin OrtuosteNo ratings yet

- Guide Raotm2014 JakartaDocument23 pagesGuide Raotm2014 JakartarajavinugmailcomNo ratings yet

- Bhopal Chapter of ISSS 1st NewsletterDocument8 pagesBhopal Chapter of ISSS 1st NewsletterBankesh ChatterjeeNo ratings yet