Professional Documents

Culture Documents

123

123

Uploaded by

frndstovijay6617Copyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Baking Tools and EquipmentDocument45 pagesBaking Tools and EquipmentPega Suze68% (25)

- Delta's 2013 Flight PlanDocument1 pageDelta's 2013 Flight PlanSheryl100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6 Sigma in HotelsDocument8 pages6 Sigma in HotelsSanju Dev100% (1)

- MDRT Author IndexDocument4 pagesMDRT Author IndexErwin Dela CruzNo ratings yet

- JW Development BrochureDocument18 pagesJW Development Brochuredaedric13No ratings yet

- Case Study On Saku BreweryDocument10 pagesCase Study On Saku BreweryGreeshma Babu Shylaja100% (1)

- Welding QA Quidelines For FabricationDocument12 pagesWelding QA Quidelines For FabricationRyan Vizcarra FerrerNo ratings yet

- SWAT HyundaiDocument3 pagesSWAT HyundaiKhan IzharNo ratings yet

- Basilan Estates Vs Cir (1967)Document7 pagesBasilan Estates Vs Cir (1967)RavenFoxNo ratings yet

- CERC Project Cost For Solar PVDocument17 pagesCERC Project Cost For Solar PVNidhi GolaNo ratings yet

- Print Control PageDocument1 pagePrint Control PageAkhil DayalNo ratings yet

- "Illicit Trade" in South SumatraDocument40 pages"Illicit Trade" in South SumatraMuhammad Nabil BerriNo ratings yet

- Assignment Business CommunicationDocument3 pagesAssignment Business CommunicationShailesh BhargavaNo ratings yet

- GV-RETAILDocument39 pagesGV-RETAILVenkat GVNo ratings yet

- MSRTC - Online Reservation SystemDocument1 pageMSRTC - Online Reservation Systemgetgaurav100% (1)

- Chapter Two: Choice, Opportunity Costs and SpecializationDocument39 pagesChapter Two: Choice, Opportunity Costs and SpecializationMyra SinhaNo ratings yet

- Balance Sheet of Shakti PumpsDocument2 pagesBalance Sheet of Shakti PumpsAnonymous 3OudFL5xNo ratings yet

- Ed Kargbo-Ann Kitchen EmailsDocument14 pagesEd Kargbo-Ann Kitchen EmailsJeff KirkNo ratings yet

- Chapter 7 - Tendering ProceduresDocument28 pagesChapter 7 - Tendering ProceduresHannan Ruslim100% (1)

- English Medication and Medical Equipment GlossaryDocument7 pagesEnglish Medication and Medical Equipment GlossaryVeronicaGelfgrenNo ratings yet

- Chapter 3-The Adjusting Process: Multiple ChoiceDocument2 pagesChapter 3-The Adjusting Process: Multiple ChoiceChloe Gabriel Evangeline ChaseNo ratings yet

- SSAE16 and ISA3402 PDFDocument8 pagesSSAE16 and ISA3402 PDFSarah DchiecheNo ratings yet

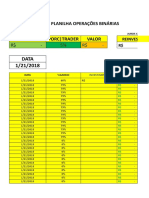

- Querino Dicas Banca Opções BináriasDocument60 pagesQuerino Dicas Banca Opções BináriasLeonardo PinheiroNo ratings yet

- Classroom Exerisises On Presentation of Financial Statements PDFDocument2 pagesClassroom Exerisises On Presentation of Financial Statements PDFalyssaNo ratings yet

- Key Employee DefinitionDocument1 pageKey Employee DefinitionDanielle MartinNo ratings yet

- CAE R (Rep) Unit 10 Exam PracticeDocument2 pagesCAE R (Rep) Unit 10 Exam PracticeLillian LöweNo ratings yet

- ABC Oh CostsDocument27 pagesABC Oh CostsArmstrong Arlo MaiNo ratings yet

- Clean Edge RazorDocument11 pagesClean Edge RazorPramod Rao100% (1)

- Tauber Family Railroad1Document3 pagesTauber Family Railroad1api-236123725No ratings yet

- Incentive ProgramDocument5 pagesIncentive ProgramMandy ZimmermanNo ratings yet

123

123

Uploaded by

frndstovijay6617Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

123

123

Uploaded by

frndstovijay6617Copyright:

Available Formats

Derrick Naukam, P.E. The material of origin requirements are common in project s pecifications.

There are many reasons for this. The primary one is quality contr ol. The quality control employed by "emerging markets" is not on par with other countries established standards and industry practices. This is similar to the l ead paint found in children toys and toxins found in food products which has bee n found in products coming out of China a few years back. In one instance that I personally experienced, pipe elbow material was from Chin a for a quick turnaround fabrication. Material was supposed to be SA-234-WP11 (1 .25 Cr - 1/2 Mo). The MTR matched the heat number of the part and reported prope r chemistry and physical testing. PMI indicated chrome at less than 0.3 % and in significant molly. Wet chemical tests also reported that the material was basica lly carbon steel. Carbon steel components operating at the elevated temperatures would have failed. The WPS used to weld the parts would have been wrong. The above example has been repeated enough times in different fashion by multipl e suppliers that many companies experience has indicated that the higher priced material from reliable suppliers has much less risk than gambling with suppliers from certain regions. 1 month ago Like 12 david newton Follow david david newton I have personally experienced issues with certain pipe fittings fro m India and also China. I have found in the past when welding certain dairy fitt ings the weld cracks near the fitting collar and in certain situations the mater ial either side of the weld (in the heat affected area) peels away. There does s eem to be quality control issues from both markets - I have also been made aware that mill certs from either country of origin will not be accepted or recognise d by certain insurance companies and inspectors due to known quality issues. It boils down to the age old "true value" versus "cheapest market solution" and in my experience true value is the way to go. 1 month ago Like 4 Michael Cronin; P.E. Follow Michael Michael Cronin; P.E. There is also a legal dimension to this arguement.....

If you purchase US made piping components from a US supplier who is supplying so mething in accordance with and ASME or ASTM standard, you have LEGAL RECOURSE in a US court if the product fails to meet the contract document and if there are consquential damages (i.e. someone gets hurt). If you make a quick purchase of a component from an international supplier, you may not have any legal recourse. The additional cost of the "extra" quality control from the international suppli er frequently out weighs the initial savings in the price of the imported compon ent 1 month ago Like 5 Paul Lemke

Follow Paul Paul Lemke The reality is your clients are buying into bad press regarding Chine se and Indian parts and are not willing to actually source control their vendors . Everyone needs to have as part of their Quality Assurance Plan a means of audi ting vendors and sample test all materials purchased no matter if they come from US sources or foreign sources. Even though an item might be advertised as being "Made in the USA" there is no assurance that, for example, the steel blanks use d in fabricating the part are from a reputable source. As the global marketplace becomes more ubiquitous buyers need to recognize that they simply can't rely on the "old company name" attitude any more as "proof" an item is of good quality. Buyers must be willing to travel to the vendor's manufacturing facilities and a ctually read the vendor's QA plan to make sure the vendor is doing the same for his suppliers. If a buyer is not willing to travel to a foreign country to do th is then they should include in their specification the proviso "no foreign sourc es" but to proscribe two countries' products while allowing items in from others without due diligence is just prejudiced. 1 month ago Like 6 david newton Follow david david newton Paul - we have recently had a documentary here in the UK regarding surgical instrumentation imported from China and India. The fact of the matter i s these "vendors" were caught on film saying they could mark any instrument to a ny desired standard without the costs and management of undergoing rigorous test ing procedures. The hospitals within my area now employ a diamond expert to prov ide analysis on each and every item they receive - he uses his microscopic equip ment with hospital staff present -they currently have over 90% rejection on thes e items. Never before have the hospital curators required this intervention or l evel of inspection when materials were sourced from reliable sources. I watched as they were sharpening scalpels outside in sandy conditions on an old fashioned "stone wheel" as children as young as 8 sharpened these tools ready to flood th e market - bearing in mind these "tools" are used to operate on people it's real ly not a risk worth taking. It was horrible watching these "surgical tools" gath ered from the sand and packed ready for export - not a tool I'd like used on me for sure......... 1 month ago Like 2 Follow Michael Michael Morgan There is a credibility issue with some items received from those sources. I have a customer in China that comes to us to build small reactors bec ause even though they have the ability to build them in China. The customer cann ot be sure that the materials are according to specification and that the paperw ork matches the material. As we all know any Quality Plan depends sole on the et hics, morality, and credibility of the persons involved in the implementation of the plan. It is another reason why Positive Material identification is becoming a requirement in many facilities. 1 month ago Like 2 Ingrid Blain Follow Ingrid

Ingrid Blain For instance for a project in Germany, bolts and nuts produced in C hina was prohibited. There are also some projects in China, where materials from China are not allowed... There are examples of very impressive pressure tests failures, due to defects in the shell material. So currently, there are rational reasons for this. 1 month ago Like 2 Follow Keith Keith Nelson I work on US contracts overseas and have often been offered product s from China, India and other 3rd world markets. I have not found ANY item yet t hat even comes close to the quality of items manufactured in the US and to US qu ality control specifications. This is true for raw metal materials, bolts, fitti ngs, wiring, lubricants.....even welding rods and wire. As a certified welder my self, I have personally experienced the welding issues and structural strength a nd dynamics issues. As noted above, these issues are REAL and the safety of huma n beings and machinery, the integrity of your project and your company's reputat ion are all seriously at risk from using uncertifiable products...... my recomme ndation: JUST DONT! The possible expected $$ savings are really not there and th e risk is not worth it! 1 month ago Like 4 Follow Randy Randy Clover, P.E. Another reason for this may be the country of destination. It ems sold into Mexico, as an example, must pay higher taxes if components are man ufactured in China. 1 month ago Like Follow David David Reynolds Short answer, China can't be trusted. There are 1,000,000 s of Chin a stories on qualities issues and so on. Plus, China does not respect other's IP and steal what they want. They are also known to renege on commercial contacts if it goes bad for them. How can they continue to do this you may ask? Because, people are always looking to shave a few corners and cheat to just to make a few bucks themselves. 1 month ago Like 3 Paul Lemke Follow Paul Paul Lemke The point I was trying to get across before is that one should audit and inspect _all_ of your vendors and you should only accept parts from those ve ndors you have done due diligence with regarding thier QA processes (i.e. prepar e an approved vendors list). Simply proscribing parts from vendors based on what the country of origin is inappropriate. By proscribing, for example, Chinese pa rts in your specifications you are by implication permitting your suppliers to p rovide you with parts made in other countries such as the "Republic of Elbonia" which may have also have bad QA processes (watch out for the mud weasels during your plant tour). You must be explicit in your specifications what vendors you w ill accept parts from and what the process is to get alternate submissions appro ved. 1 month ago Like

2 Tom Winter Follow Tom Tom Winter You cannot condemn a whole country of manufacturers because of some b ad apples. We buy stainless steel tubing and fittings from all over the world, e xcept India, and have found problems with just about all suppliers from time to time. We also have received great products from these countries. Everyone has pr oblems as we producing products with humans involved. Mistakes are made, greed i s also a factor. It is our responsibility to make sure the products we buy and s ell are made and tested properly for whichever specification or standard they ar e bought and used. We audit all of our suppliers and make sure they have quality systems in place to produce at the highest level. We "trust, but verify". We do additional testing ourselves using third party labs and other inspections to ma ke sure we are getting safe products, even those produced in Europe or USA. Also you can buy a product in the US or Europe and the product may have an old relia ble brand name but it is now produced in one of these third world countries. It is still our responsibility to know the product meets our customer's needs. 1 month ago Like 5 Follow Anno Anno Alex It is just a prejudice and i have experienced same situation where mat erials are being sent with changed labels from a third country (eg. USA) in orde r to avoid these restrictions. This age all major organisations are establishing their hubs in these countries and it is meaningless to place such restrictions. 1 month ago Like 1 Michael Cronin; P.E. Follow Michael Michael Cronin; P.E. Here are some other fun discussions from other engineering fora on the same subject: http://www.eng-tips.com/viewthread.cfm?qid=304464http://www.eng-tips.com/viewthr ead.cfm?qid=195299 Judge these for yourself...... Yes, OF COURSE ! !if you have the money and the trained staff available to perfo rm a competent Quality Control effort in China....you can get quality products. ! ! ! AGAIN, I stand by my point.....IF YOU HAVE A US MADE PRODUCT, AND YOU PURCHASE D EFECTIVE US PRODUCTS THAT CAUSE CONSEQUENTIAL DAMAGES, YOU CAN SUE AND YOU WILL WIN>>> ! ! PURCHASE DEFECTIVE PRODUCTS FROM CHINA (or anyone else) YOU WILL HAVE NO LEGAL R ECOURSE. !! Following on the comments by Ms. Blain; there are, of course, components whose f ailure will cost lives, and much more importantly, vast amounts of money to the corporation.....

Read this 2006 account of "quality" Chinese piping materials and the people who make money by mis-lableing ASTM materials..... http://www.eng-tips.com/viewthread.cfm?qid=176859 1 month ago Like 1 david newton Follow david david newton Anno alex - is it really prejudiced to select the best materials fo r the job? Is it really so wrong to feel secure when purchasing materials where lives are at risk?? These restrictions are not meaningless when substandard materials are effectivel y kept from the common market. It's profit related, the companies producing and supplying substandard materials are making far greater profits than those who play the game fairly and stick to mandates set out depicting grades and integrity of these materials. We should be grateful these restrictions are in place and not in condemnation of those who seek to protect us........... If you were jumping from a plane I bet the parachute you chose would be from a r eputable manufacturer and who could be trusted.............. 1 month ago Like 1 Follow Anno Anno Alex I agree with you David, but please note that all popular brands have s et up their offices in these countries and definitely you will be receiving mate rials from these locations and how can we justify this, It is just about selecti ng the right supplier/ manufacturer rather than a country or region in particula r. 1 month ago Like 2 david newton Follow david david newton It's nothing to do with the country of origin as such, they're give n every chance to produce the quality and introduce their products into the mark et place. The issues arise when greed takes over, quality drops and quality assu rance is non existent-the fact they are Chinese or Indian is irrelevant-the asso ciation of sub-standard products is rightly tagged to the countries guilty of th is production/quality deficiency and the market within these countries gets a ba d name. Undoubtedly some of their products reach common market through unscrupulous supp ly chain and persons trying to make the quick+sneaky buck.......it always comes back to haunt you. There is no substitute for honesty, quality and integrity what ever the product or market you operate within, should you fall outside of this ethical working pr actice it is only fair that others should know this and have opportunity to vote with their purse strings and buy from more reliable and trustworthy sources whi ch again country of origin should not be the deciding factor but quality, honest y and integrity. 1 month ago Like 2

Ziru Wang Follow Ziru Ziru Wang I agree with Anno, supplier selecting is more important than country o r region where the material come from. Bayer purchased many equipment from China for US and German, and we specified all material suppliers, we hired third part y company to provide strict process quality control, and up to now, there is no big quality problems found. 1 month ago Like 1 david newton Follow david david newton Had you not hired third party company would you expect the same/sim ilar quality batches??? Ziru Wang - perhaps not an unbiased viewpoint given your name as an indication?? My point is that third party inspection has become more prevalent and necessary. Previously quality control was assured by manufacturer and those producing good s, now it seems without the "magnifying glass" over them and left to their own d evices unscrupulous production and marketing of substandard products/materials w ould be far more commonplace. It is the job of the manufacturer to produce to the quality and designated spec, requiring specific analysis and constant "nannying" to ensure quality and integ rity is far more prevalent now than it's ever been as substandard materials get produced and supplied at vast profits,geographically it's more likely to occur i n some corners of the globe than others and consumers should have the option to opt out as desired. It's not where you're from that matters it's what you produce.....the end result is all that matters and quality is everything. 1 month ago Like Avedhesh Gupta Follow Avedhesh Avedhesh Gupta I just need to know one thing from Nasrul that who is the client who is restricting to source the material from India and China. Check the client country of origin and their political relation with India and China. I am not c laiming but at some instances it is also governing for International business. If you are concerned about the quality, I give you one name from India "Ratnaman i Pipes and Tubes" who is very well know for the quality products and has been i ncluded as approved vendors by reputed client like Shell and others. Quality is not an asset of any particular country. It is result of continuous im provements. So if my products are not best today, it doesn't mean it will not be improved ever. Like some one said, one or two name can not put whole country's reputation at st ake, at the end fittest and best will survive.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Baking Tools and EquipmentDocument45 pagesBaking Tools and EquipmentPega Suze68% (25)

- Delta's 2013 Flight PlanDocument1 pageDelta's 2013 Flight PlanSheryl100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6 Sigma in HotelsDocument8 pages6 Sigma in HotelsSanju Dev100% (1)

- MDRT Author IndexDocument4 pagesMDRT Author IndexErwin Dela CruzNo ratings yet

- JW Development BrochureDocument18 pagesJW Development Brochuredaedric13No ratings yet

- Case Study On Saku BreweryDocument10 pagesCase Study On Saku BreweryGreeshma Babu Shylaja100% (1)

- Welding QA Quidelines For FabricationDocument12 pagesWelding QA Quidelines For FabricationRyan Vizcarra FerrerNo ratings yet

- SWAT HyundaiDocument3 pagesSWAT HyundaiKhan IzharNo ratings yet

- Basilan Estates Vs Cir (1967)Document7 pagesBasilan Estates Vs Cir (1967)RavenFoxNo ratings yet

- CERC Project Cost For Solar PVDocument17 pagesCERC Project Cost For Solar PVNidhi GolaNo ratings yet

- Print Control PageDocument1 pagePrint Control PageAkhil DayalNo ratings yet

- "Illicit Trade" in South SumatraDocument40 pages"Illicit Trade" in South SumatraMuhammad Nabil BerriNo ratings yet

- Assignment Business CommunicationDocument3 pagesAssignment Business CommunicationShailesh BhargavaNo ratings yet

- GV-RETAILDocument39 pagesGV-RETAILVenkat GVNo ratings yet

- MSRTC - Online Reservation SystemDocument1 pageMSRTC - Online Reservation Systemgetgaurav100% (1)

- Chapter Two: Choice, Opportunity Costs and SpecializationDocument39 pagesChapter Two: Choice, Opportunity Costs and SpecializationMyra SinhaNo ratings yet

- Balance Sheet of Shakti PumpsDocument2 pagesBalance Sheet of Shakti PumpsAnonymous 3OudFL5xNo ratings yet

- Ed Kargbo-Ann Kitchen EmailsDocument14 pagesEd Kargbo-Ann Kitchen EmailsJeff KirkNo ratings yet

- Chapter 7 - Tendering ProceduresDocument28 pagesChapter 7 - Tendering ProceduresHannan Ruslim100% (1)

- English Medication and Medical Equipment GlossaryDocument7 pagesEnglish Medication and Medical Equipment GlossaryVeronicaGelfgrenNo ratings yet

- Chapter 3-The Adjusting Process: Multiple ChoiceDocument2 pagesChapter 3-The Adjusting Process: Multiple ChoiceChloe Gabriel Evangeline ChaseNo ratings yet

- SSAE16 and ISA3402 PDFDocument8 pagesSSAE16 and ISA3402 PDFSarah DchiecheNo ratings yet

- Querino Dicas Banca Opções BináriasDocument60 pagesQuerino Dicas Banca Opções BináriasLeonardo PinheiroNo ratings yet

- Classroom Exerisises On Presentation of Financial Statements PDFDocument2 pagesClassroom Exerisises On Presentation of Financial Statements PDFalyssaNo ratings yet

- Key Employee DefinitionDocument1 pageKey Employee DefinitionDanielle MartinNo ratings yet

- CAE R (Rep) Unit 10 Exam PracticeDocument2 pagesCAE R (Rep) Unit 10 Exam PracticeLillian LöweNo ratings yet

- ABC Oh CostsDocument27 pagesABC Oh CostsArmstrong Arlo MaiNo ratings yet

- Clean Edge RazorDocument11 pagesClean Edge RazorPramod Rao100% (1)

- Tauber Family Railroad1Document3 pagesTauber Family Railroad1api-236123725No ratings yet

- Incentive ProgramDocument5 pagesIncentive ProgramMandy ZimmermanNo ratings yet