Professional Documents

Culture Documents

10 11 10 Aeb31

10 11 10 Aeb31

Uploaded by

Vincent MalayaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 11 10 Aeb31

10 11 10 Aeb31

Uploaded by

Vincent MalayaoCopyright:

Available Formats

206 Chiang Mai J. Sci. 2008; 35(1) : 206-211 www.science.cmu.ac.th/journal-science/josci.

html Contributed Paper

NP-021 Chiang Mai J. Sci. 2008; 35(1)

Preparation of Nanosilica Powder from Rice Husk Ash by Precipitation Method

Nittaya Thuadaij* and Apinon Nuntiya

Department of Industrial Chemistry, Faculty of Science, Chiang Mai University, Chiang Mai 50200, Thailand. *Author for correspondence, e-mail: anuntiya@chiangmai.ac.th Received : 24 September 2007 Accepted : 15 October 2007

ABSTRACT This work presented a laboratory studies on the preparation of rice husk ash by burning at 700 oC for 3 and 6 h, respectively. Consequently, silica content obtained after heat treatment at 700 oC for 6 h was 98.14%. Rice husk ash (RHA) was purified by alkaline extraction method used 2.0, 2.5 and 3.0 N sodium hydroxide. Percent yield of silica extracted by 2.5 N. NaOH, was 90.3% and the infrared spectral data supported the presence of hydrogen bonded silinol group and the siloxane groups in silica. Subsequently, the RHA was subjected to precipitation method in order to produce nanosilica. The precipitation was done by refluxing silica from RHA in boiling 2.0, 2.5 and 3.0 N NaOH, respectively. TEM results showed that 2.5 N NaOH for 10 h provided agglomerate particles with dimension of 5-10. The specific surface area was found to be 656 m2/g. From X-ray diffractograms and diffraction pattern showed that the obtained products were amorphous nanosilica. Keywords: Nanosilica, Precipitation Method, Rice Husk Ash (RHA), TEM.

1. INTRODUCTION

The beneficiation of rice husk has been used in many applications. Burning rice hull as fuel to generate energy resulted in the waste product, rice husk ash (RHA). RHA is rich in silica (about 60 %) and can be an economically variable raw material for production of silica gels and powders. The amorphous nature of RHA silica makes it extractable at lower temperature, and hence provides a low energy method[1,2]. Recently, nanotechnology has attracted considerable scientific interest due to the new potential uses of particles in nanometer scale. Thus industries may be able to re-engineer many existing products that function at unprecedented levels. There are few reports

on mixing nanosilica in cement-based building materials. Chimera Research Institute (2002) addressed functional applications of SiO2 in nano scale. However, up to now, research performed over the years has been largely aimed at achieving high mechanical performance with cement replacement materials in micro size. The development of an ultra high strength concrete was made possible by the application of densified system containing homogeneously arranged ultra fine particles[3, 5-6]. The objectives of this work are to prepare stable nanosilica using precipitation method from rice husk ash and to characterize of as-precipitated nanosilica.

Chiang Mai J. Sci. 2008; 35(1)

207

2. MATERIALS AND METHODS

2.1 Material Rice husk ash from brick factory was washed by distilled water and burnt at 700 o C for 3 and 6 h. Chemical composition of RHA was accomplished by X-ray fluorescence (Horiba Mesa-500w). 2.2 Synthesis pure silica from rice husk ash Ten grams of RHA samples were stirred in 80 ml distilled 2.0, 2.5 and 3.0 N sodium hydroxide solution, respectively. RHA was boiled in a covered 250 ml Erlenmeyer flask for 3 h. The solution was filtered and the residue was washed with 20 ml boiling water. The filtrate was allowed to cool down to room temperature and added 5 N H2SO4 until pH 2 and then added NH4OH until pH 8.5 allowed to room temperature for 3.5 h. The filtrate was then dried at 120 oC for 12 h. Asreceived product was finally investigated by Fourier transform infrared (FTIR- model tenser 27). 2.3 Preparation of nanosilica Pure silica was extracted by refluxing with 6 N HCI for 4 h and then washed repeatedly using deionised water to make it acid free. It was then dissolved in 2, 2.5 and 3.0 N NaOH by continuous stirring for 10 h on a magnetic stirrer and then concentrated H2SO4 was added to adjust pH in the range of 7.5-8.5. The precipitated silica was washed repeatedly with warm deionised water until the filtrate became completely alkali free. The washing process continued by deionised water repeatedly and dried at 50 oC for 48 h in the oven. 2.4 Characterization of Nanosilica 2.4.1. Morphology of nanosilica Particle size and morpholog y of synthesized silica were examined by TEM (Jeol, JSM2010) using a 200 keV electron beam on the sample mounted on a carbon coated copper grid. With the assumption of

spherical shape, the size of the particle is determined from the number averaged particle radius. Silica sample (10 mg) was sonicated for 3 h in isopropyl alcohol (5 ml). About 50 ml of the silica suspension was taken using a dropper and spread on the carbon coated copper grid and allowed to dry in room temperature. The copper grid was introduced into the instrument and the sample chamber was evacuated. The sample was scanned along the path of the electron beam and photograph of the sample was taken at 200,000 magnification. 2.4.2. Surface area measurement Specific surface area of nanosilica was measured by nitrogen adsorption using BET equation. Samples were degassed in an oven at 383 K for 6 h and a five points BET analysis was conducted by using Quantachrome Autosorb-1 to obtain the specific area of the nanosilica powder. 2.4.3. Phase analysis by X-ray diffraction X-ray diffractometer (D8 advanced: Bruker) was used to determine the phases of nanosilica. The scanning rate was 10/min in the 2 diffraction angle between 10o and 60o.

3. RESULTS AND DISCUSSION

The rice husk ash (RHA) sample after being burnt at 700 oC for 6 h presented higher silica content compared to the other sample 700 oC for 3 h, as shown in Table 1. The rice husk ash (RHA) sample after being extracted by 2.5 N sodium hydroxide generated the yield of pure silica up to 90.3% as shown in Table 2. The concentration of sodium hydroxide had strongly effect on the dissolution of silica from as-received rice husk and it also removed some impurities which were not dissolved from the main product. The major chemical groups presented in silica were identified by the FTIR spectra shown in Figure 1. The broad band between 2800 and 3750 cm-1 was due to silinol OH

208

Chiang Mai J. Sci. 2008; 35(1)

Table 1. Chemical composition of RHA before after burning out at 700 oC for 3 and 6 h.

Components expressed as oxides SiO2 Al2O3 Fe2O3 CaO ZrO MgO P2O3 Mn2O3 SO3 LOI RHA as-received 96.51 0.15 0.17 0.66 0.05 0.77 0.21 0.21 0.04 n/a RHA after burning out at 700 oC for 3 h 97.86 n/a 0.07 0.52 0.01 0.29 n/a 0.16 0.07 0.01 RHA after burning out at 700 oC for 6 h 98.14 n/a 0.07 0.46 0.03 n/a n/a 0.16 0.07 0.02

Table 2. Effect of concentration of sodium hydroxide on the percent yield of pure silica. Concentration of sodium hydroxide (Normal/N) 2.0 2.5 3.0 64.2 90.3 91.1 Yield of pure silica (%)

Absorbance

Wavenumbers (cm-1)

Figure 1. Fourier transform infrared spectra of spectra of pure silica produced from RHA.

Chiang Mai J. Sci. 2008; 35(1)

209

groups and adsorbed water. The predominant absorbance peak at 1320 cm-1 was due to siloxane bonds (Si-O-Si). The peaks between 1200 and 700 cm-1 are attributed to vibration modes of the gel net work [4]. IR spectrums were not clearly show the difference between pure silica and commercial silica. The characteristic and position of the peaks are identical. 3.1. Effect of concentration of sodium hydroxide on nanosilica production The particles size of the nanosilica after

treated by 2.0, 2.5 and 3.0 N sodium hydroxide was determined by TEM. Sodium hydroxide had an effect on the particle size and specific surface area of the nanosilica particles, as summarized in Table 3. TEM micrographs showed that the particle sizes are in nanometer scale within agglomeration form. The shape of the particle was found to be uniform and agglomerated species. The diffuse ring pattern indicative of an amorphous phase of the main phase was shown in Figure 2.

(a)

(b)

(c) Figure 2. TEM micrograph and diffraction pattern of samples (a) treated by 2.0 N NaOH, (b) treated by 2.5 N NaOH (c) treated by 3.0 N NaOH.

210

Chiang Mai J. Sci. 2008; 35(1)

Table 3. Effect of sodium hydroxide on specific surface area and particle size of nanosilica.

Concentration of NaOH (Normal/N) 2.0 2.5 3.0 Particle size (nm) 15-20 5-10 20-50 Specific surface area (m2/g) 187 656 184

Figure 3. EDS of nanosilica particles. EDS profile (Figure 3) of nanosilica particles contained predominantly the elements of Si, O, C and Cu. Both Si and O peaks correspond to the silica. The dominant signals originate from copper and carbon due to TEM copper grid and carbon coating

Figure 4. XRD diffractograms of nanosilica after treated by different concentration of sodium hydroxide.

Chiang Mai J. Sci. 2008; 35(1)

211

XRD diffractograms of nanosilica (Figure 4) showed strong broad peaks between 22o and 23o (2). These strong broad peaks suggested characteristic of amorphous SiO2.

4. CONCLUSION

REFERENCES [1] Della V.P., Kuhn I. and Hotza D., Rice husk ash as an alternate source for active silica production, Materials Letters, 2000; 57: 818-821. [2] Kalapathy U., Proctor A. and Shultz J., A Simple method for production of pure silica from rice hull ash, Bioresource Technology, 2000; 73: 257-262. [3] Hui L., Hui-gang X., Jie Y., and Jinping O., Microstructure of cement mortar with nano particles, Composites part B : engineering, 2003; 35: 185-189. [4] Kalapathy U., Proctor A. and Shultz J., An Improved method for production of silica from rice hull ash, Bioresource Technology, 2000; 85: 285-289. [5] Qing Y., Zhang Z., Kong D., and Chen R., Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume, Contruction and Building Materials, 2007; 21: 539-545. [6] Jal P K., Sudarshan M., Saha A., Sabita P., and Mishra B.K., Synthesis and characterization of nanosilica prepared by precipitation method, Colloidals and Surface, 2004; 240: 173-178.

The study revealed that silica with 90.34% silica content could be produced from RHA using a simple heat treatment. The 2.5 N sodium hydroxide treatment resulted in the highest SiO2 content. Nanosilica particles which obtained from the rice husk ash were in the agglomerate form which dimension of 5-10 nm and specific surface area 656 m2g-1. The particle shape distribution is found to be uniform. The diffraction pattern of the particles showed a diffuse pattern which indicative of amorphous phase and supported by XRD patterns. ACKNOWLEDGEMENTS The author is grateful to the Thailand Research Found for fundings this research and financially supported by Grad Research Chiang Mai University.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- SM ECOSYS P3145dn P3150dn P3155dn-Rev.4Document289 pagesSM ECOSYS P3145dn P3150dn P3155dn-Rev.4ANDY100% (6)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Astm D5436Document4 pagesAstm D5436Canek Cañedo ChavezNo ratings yet

- Homemade Alarm System With PIC16F84A: ComponentsDocument8 pagesHomemade Alarm System With PIC16F84A: ComponentsalisamerflorinNo ratings yet

- Managing Abandonment Issues Through Recovery12562Document108 pagesManaging Abandonment Issues Through Recovery12562Vincent MalayaoNo ratings yet

- Some Factors Which Influence The Feathering of Cream in CoffeeDocument6 pagesSome Factors Which Influence The Feathering of Cream in CoffeeVincent MalayaoNo ratings yet

- 3 - Manole 8pagDocument8 pages3 - Manole 8pagVincent MalayaoNo ratings yet

- Strategies For Biomass UtilizationDocument216 pagesStrategies For Biomass UtilizationheckybrizuelaNo ratings yet

- BagasseDocument7 pagesBagasseVincent MalayaoNo ratings yet

- Acid and Alkaline Pretreatment of Lignocellulosic Biomass To Produce Ethanol As Biofuel PDFDocument8 pagesAcid and Alkaline Pretreatment of Lignocellulosic Biomass To Produce Ethanol As Biofuel PDFVincent MalayaoNo ratings yet

- "Blue" LaccasesDocument15 pages"Blue" LaccasesVincent MalayaoNo ratings yet

- E826 Service Quick GuideDocument1 pageE826 Service Quick GuideTxarlyHidalgoNo ratings yet

- WPQR SBM 029Document3 pagesWPQR SBM 029HoJienHauNo ratings yet

- How Do You LIGHT Up Your World ? Part I-Virginia SOL 5.3Document21 pagesHow Do You LIGHT Up Your World ? Part I-Virginia SOL 5.3jjaappeesshhNo ratings yet

- Leica M525 MC1 Bro enDocument10 pagesLeica M525 MC1 Bro en陈年No ratings yet

- Jurnal Optik Modern Baru PDFDocument10 pagesJurnal Optik Modern Baru PDFEndang SetianingsihNo ratings yet

- Military Handbook Mil HDBK 415aDocument231 pagesMilitary Handbook Mil HDBK 415athomas.bhatiaNo ratings yet

- A054 Absorption Coefficient of Various Semiconducting MaterialsDocument4 pagesA054 Absorption Coefficient of Various Semiconducting MaterialsSulaiman Rabbaa سليمان رباعNo ratings yet

- K9000 3D Spare PartsDocument13 pagesK9000 3D Spare PartsendaNo ratings yet

- Brochure DVE Laser Film 201505Document2 pagesBrochure DVE Laser Film 201505RDII YANMEDRSDSNo ratings yet

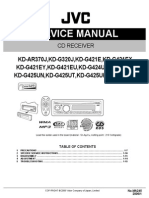

- JVC - KD Ar370 - KD g320 - KD g421 - KD g424 - KD g425 - KD g427 Ma245Document63 pagesJVC - KD Ar370 - KD g320 - KD g421 - KD g424 - KD g425 - KD g427 Ma245Póka István-ZsoltNo ratings yet

- A Comparative Study of Different Printed Documents PDFDocument7 pagesA Comparative Study of Different Printed Documents PDFsandeep yadavNo ratings yet

- Centrifugal Pumps: A World of Steady and Dependable Flow ControlDocument14 pagesCentrifugal Pumps: A World of Steady and Dependable Flow ControlYimmy Alexander Parra MarulandaNo ratings yet

- ONT Troubleshooting ALUDocument120 pagesONT Troubleshooting ALUszejkdudi100% (1)

- VideoDocument19 pagesVideoPurna Suresh PedamalluNo ratings yet

- Introduction To WeldingDocument16 pagesIntroduction To WeldingcfcshakerNo ratings yet

- UT MathDocument86 pagesUT MathDibyendu Bera100% (1)

- BOSCH AC IN enDocument22 pagesBOSCH AC IN enVasu DevanNo ratings yet

- Optics Chap. 3Document46 pagesOptics Chap. 3Gébrè SîllãsíêNo ratings yet

- Ehs6-Theodolite, Transit & Total Station (Without Videos)Document19 pagesEhs6-Theodolite, Transit & Total Station (Without Videos)Ariane Vince Gutierrez TuliaoNo ratings yet

- Optical Sources LED FOCDocument49 pagesOptical Sources LED FOCALNo ratings yet

- Electromagnetic Waves 3Document20 pagesElectromagnetic Waves 3anjanaNo ratings yet

- Mini Project CarbonDocument44 pagesMini Project Carbonisirajudeen17No ratings yet

- Julia Zugby Masters ReportDocument40 pagesJulia Zugby Masters ReportElena AnghelNo ratings yet

- Chapter 6Document136 pagesChapter 6vinothNo ratings yet

- S Af1060Document490 pagesS Af1060Hasim BaharuddinNo ratings yet

- BODOR User Manual of Fiber Metal Cutting MachineDocument50 pagesBODOR User Manual of Fiber Metal Cutting Machinesebastian carreño67% (3)

- Lens and Sensor Compatibility by ScorpionVisionDocument10 pagesLens and Sensor Compatibility by ScorpionVisionFakhri GhrairiNo ratings yet