Professional Documents

Culture Documents

Two Liquid Phase Partitioning Bioreactor System For Biodegradation of Pyrene by

Two Liquid Phase Partitioning Bioreactor System For Biodegradation of Pyrene by

Uploaded by

Elkin Dario Mantilla MejiaCopyright:

Available Formats

You might also like

- 000504242-Microwave Ephedrine From LpacDocument4 pages000504242-Microwave Ephedrine From LpacPaul BrownNo ratings yet

- Astm E34-2011Document3 pagesAstm E34-2011Makarius YanuantoNo ratings yet

- Exp 1 Physical Refining of Crude Palm OilDocument13 pagesExp 1 Physical Refining of Crude Palm Oilaffeena100% (1)

- Palm Oil Mill EffluentDocument6 pagesPalm Oil Mill Effluentankitsaxena123100% (2)

- Ijaesv11n4 19Document10 pagesIjaesv11n4 19Dimas PhilipinantoNo ratings yet

- International Journal of Engineering Research and Development (IJERD)Document4 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- The Effect of Co-Solvents On The Antibacterial Activity of ParabenDocument10 pagesThe Effect of Co-Solvents On The Antibacterial Activity of ParabenDamariscpNo ratings yet

- Bioresource Technology: Soham Chattopadhyay, Ramkrishna SenDocument6 pagesBioresource Technology: Soham Chattopadhyay, Ramkrishna SenSriArthiNo ratings yet

- Comparison Study of Two Procedures For Determination of Emamectin Benzoate in Medicated Fish FeedDocument4 pagesComparison Study of Two Procedures For Determination of Emamectin Benzoate in Medicated Fish FeedSV_TokanNo ratings yet

- Lin 05 FoodadditcontamDocument9 pagesLin 05 Foodadditcontamforward websiteNo ratings yet

- 113 115 Extraction Hitesh PatelDocument4 pages113 115 Extraction Hitesh PatelAxcel Ann MacasocolNo ratings yet

- Objective 1 Part 2Document5 pagesObjective 1 Part 2Revanth VennuNo ratings yet

- JMB025-11-21 Fdoc 1Document8 pagesJMB025-11-21 Fdoc 1tsing takNo ratings yet

- PIIS0022030267874186Document3 pagesPIIS0022030267874186Jose Carlos Diaz de sandi Megalith Increasing PowerNo ratings yet

- Archive of SID: Total Phenolic Contents and Antioxidant Activity of Pomegranate (Punica Granatum L.) Peel ExtractsDocument7 pagesArchive of SID: Total Phenolic Contents and Antioxidant Activity of Pomegranate (Punica Granatum L.) Peel ExtractsVida Faith GalvezNo ratings yet

- Benzene Recovery 1Document12 pagesBenzene Recovery 1Student 80No ratings yet

- Direct Ecotox Testing of Leachates As An Alternative To PEC/PNEC ComparisonDocument7 pagesDirect Ecotox Testing of Leachates As An Alternative To PEC/PNEC ComparisonNgoc NguyenNo ratings yet

- Iso 11348 1Document18 pagesIso 11348 1amirNo ratings yet

- Selective Extraction of Carotenoids From The Microalga Dunaliella Salina With Retention of ViabilityDocument8 pagesSelective Extraction of Carotenoids From The Microalga Dunaliella Salina With Retention of ViabilityYellow MarmotNo ratings yet

- Enzymatic Pre-Hydrolysis of High Fat Content Dairy Wastewater As A Pretreatment For Anaerobic DigestionDocument6 pagesEnzymatic Pre-Hydrolysis of High Fat Content Dairy Wastewater As A Pretreatment For Anaerobic DigestionlucasNo ratings yet

- Torulaspora Delbrueckii and Conversion To Ephedrine byDocument4 pagesTorulaspora Delbrueckii and Conversion To Ephedrine bysalvia1025100% (1)

- Supercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYDocument7 pagesSupercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYGuillermo Serralde PaezNo ratings yet

- 22 PDFDocument7 pages22 PDFWidya Dwi Arini100% (1)

- The Biological Purification of Waste Products From Olive Oil ExtractionDocument5 pagesThe Biological Purification of Waste Products From Olive Oil ExtractionRicardo Rafael Garcia MirandaNo ratings yet

- Engineering Safer Bulk Cooking Oil by Increasing oDocument9 pagesEngineering Safer Bulk Cooking Oil by Increasing oLaboratorium KimiaNo ratings yet

- Esterification of Fatty Acids Using Partially Purified Dvl-2 LipaseDocument44 pagesEsterification of Fatty Acids Using Partially Purified Dvl-2 Lipaseakashgoyal1992100% (1)

- Physical and Chemical Analysis of Composting in Cephalosporium Residue and Chicken ManureDocument6 pagesPhysical and Chemical Analysis of Composting in Cephalosporium Residue and Chicken ManureNaztovenNo ratings yet

- Exp 1 Physical Refining of Crude Palm OilDocument13 pagesExp 1 Physical Refining of Crude Palm OilMUHAMMAD LUQMAN IZZUDDIN BIN SUHAIMINo ratings yet

- Thavasi2011 Article BiosurfactantProductionByPseudDocument7 pagesThavasi2011 Article BiosurfactantProductionByPseudLina Maria Ospina NuñezNo ratings yet

- CONICET Digital Nro.7cc5afb8 1375 4b75 b937 F2be2eec9ac6 SDocument10 pagesCONICET Digital Nro.7cc5afb8 1375 4b75 b937 F2be2eec9ac6 SRey MuhamadNo ratings yet

- 1 PBDocument6 pages1 PBjaka djNo ratings yet

- Articulo 6.Document8 pagesArticulo 6.sara_tabares_2No ratings yet

- Self-Emulsifying Formulation of Indomethacin With Improved Dissolution and Oral AbsorptionDocument12 pagesSelf-Emulsifying Formulation of Indomethacin With Improved Dissolution and Oral AbsorptionKietNo ratings yet

- Bio-Scouring Process Optimization of Wool Fiber and Wastewater UtilizationDocument8 pagesBio-Scouring Process Optimization of Wool Fiber and Wastewater UtilizationcenotakNo ratings yet

- Solubility and Dissolution Improvement of Ketoprofen by Emulsification Ionic GelationDocument7 pagesSolubility and Dissolution Improvement of Ketoprofen by Emulsification Ionic GelationAfifah Dwi CahyaniNo ratings yet

- Research Rev A04Document9 pagesResearch Rev A04MohamadDanielBinYaacobNo ratings yet

- Journal of Advanced Scientific ResearchDocument5 pagesJournal of Advanced Scientific Researchzulaika22No ratings yet

- Application Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerDocument4 pagesApplication Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerPrianurraufikachmadNo ratings yet

- Experiment 2: Purification: Fumio Kumakura, Cedric RentierDocument1 pageExperiment 2: Purification: Fumio Kumakura, Cedric RentierHiroaki IkedaNo ratings yet

- Experiment 2: Purification: Fumio Kumakura, Cedric RentierDocument1 pageExperiment 2: Purification: Fumio Kumakura, Cedric RentierHiroaki IkedaNo ratings yet

- Quantitative Analyses of Ricinoleic Acid and RicinDocument5 pagesQuantitative Analyses of Ricinoleic Acid and RicinHajar HadisNo ratings yet

- 1 s2.0 S2214785316303583 MainDocument6 pages1 s2.0 S2214785316303583 MainMaría Camila GonzalezNo ratings yet

- Aqueous Two Phase Extraction For Purification of C-PhycocyaninDocument9 pagesAqueous Two Phase Extraction For Purification of C-PhycocyaninRuxandra SimionNo ratings yet

- 1generation of Biogas Via Organic MaterialsDocument13 pages1generation of Biogas Via Organic MaterialsOKORIENo ratings yet

- Development of Chemically Modified Pectin Based Extended Release Tablets of NifedipineDocument16 pagesDevelopment of Chemically Modified Pectin Based Extended Release Tablets of NifedipineMurali Krishna ReddyNo ratings yet

- Extracción Verde de Aceite Vegetal de Ajonjolí Mediante EnzimasDocument7 pagesExtracción Verde de Aceite Vegetal de Ajonjolí Mediante EnzimasJ LakesNo ratings yet

- A New and Unique Tool For Shrimp Feed Producers: Kristin Weel SundbyDocument8 pagesA New and Unique Tool For Shrimp Feed Producers: Kristin Weel SundbyrsuertoNo ratings yet

- HPLC Analysis of AP and BHA (Antioxidants)Document5 pagesHPLC Analysis of AP and BHA (Antioxidants)Sarala TantirimudaligeNo ratings yet

- Extraction of Caffeine, Theobromine, and Cocoa Butter From Cocoa BeansDocument8 pagesExtraction of Caffeine, Theobromine, and Cocoa Butter From Cocoa Beansmurdanetap957No ratings yet

- Wafa MS ThesisDocument59 pagesWafa MS ThesisnomanhaimourNo ratings yet

- Ansolin Et Al 2013Document9 pagesAnsolin Et Al 2013Francielly StechiNo ratings yet

- Lutein Extraction An CVDocument22 pagesLutein Extraction An CVSacra PsyntergiaNo ratings yet

- 16234-Article Text-55935-3-10-20220117Document17 pages16234-Article Text-55935-3-10-20220117AJ ManurungNo ratings yet

- 2 PBDocument6 pages2 PBbangtan loversNo ratings yet

- Biomethanation of Banana Peel and Pineapple WasteDocument4 pagesBiomethanation of Banana Peel and Pineapple WasteolieNo ratings yet

- An Enzymatic Approach To The Cleaning of Ultrafiltration PDFDocument8 pagesAn Enzymatic Approach To The Cleaning of Ultrafiltration PDFsamrickyNo ratings yet

- Chapter 4 Exp. WorkDocument14 pagesChapter 4 Exp. WorkSAI ASSOCIATENo ratings yet

- An Efficient Method For Extraction, Separation and PurificationDocument5 pagesAn Efficient Method For Extraction, Separation and PurificationE Gustiasih MaulidantiNo ratings yet

- 1 PBDocument7 pages1 PBleonlovebernardNo ratings yet

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.From EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Rating: 4 out of 5 stars4/5 (1)

- 2016 Fall Midterm 1 OChem 1 KeyDocument20 pages2016 Fall Midterm 1 OChem 1 KeyAlex LeungNo ratings yet

- June 2017 (v1) QP - Paper 1 CIE Biology A-LevelDocument20 pagesJune 2017 (v1) QP - Paper 1 CIE Biology A-LevelFadhilNo ratings yet

- BoilersDocument5 pagesBoilersSafety professionalNo ratings yet

- SOP - Standard Operating Procedure For Manual Dispensing SystemsDocument82 pagesSOP - Standard Operating Procedure For Manual Dispensing Systemsrsmbgss575No ratings yet

- Protective Coatings ManualDocument127 pagesProtective Coatings ManualQudri SaufiNo ratings yet

- Date Time Internal Temperature Total Radiation Uva Uvb °C W/M2 Microw/Cm2 Microw/Cm2Document8 pagesDate Time Internal Temperature Total Radiation Uva Uvb °C W/M2 Microw/Cm2 Microw/Cm2Bilel KrayniNo ratings yet

- PT Procedure Rev01EDocument14 pagesPT Procedure Rev01ETrương Ngọc SơnNo ratings yet

- Multiple ShoyshesDocument2 pagesMultiple ShoyshesJonathan Roy BombitaNo ratings yet

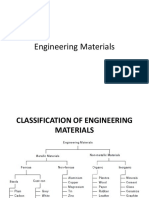

- Engineering MaterialsDocument18 pagesEngineering MaterialsAhmed ElkomyNo ratings yet

- AREA Introduction To EN 378 - For Publication - 0Document27 pagesAREA Introduction To EN 378 - For Publication - 0jorge rodriguezNo ratings yet

- Reviews of Environmental Contamination and ToxicologyDocument239 pagesReviews of Environmental Contamination and ToxicologyRetal MohamedNo ratings yet

- Dow RSC 155Document6 pagesDow RSC 155icfcfciNo ratings yet

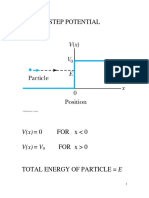

- Step Potential PDFDocument34 pagesStep Potential PDFRomi Necq S. AbuelNo ratings yet

- Chem273 Take Home LabDocument12 pagesChem273 Take Home LabMentari Permata HatiNo ratings yet

- Jurnal Nutri3Document11 pagesJurnal Nutri3Winda SariNo ratings yet

- Altig 316L PDFDocument1 pageAltig 316L PDFgst ajahNo ratings yet

- Strategies To Improve The Production of Secondary MetabolitesDocument6 pagesStrategies To Improve The Production of Secondary Metabolitesdennis leeNo ratings yet

- Cookery 9 LO1 Clean, Sanitize, and Store Kitchen Tools and EquipmentDocument16 pagesCookery 9 LO1 Clean, Sanitize, and Store Kitchen Tools and EquipmentSteffi ToringNo ratings yet

- Liquid Distribution and Falling Film Wetting in Dairy EvaporatorsDocument227 pagesLiquid Distribution and Falling Film Wetting in Dairy Evaporatorsyadavmihir63No ratings yet

- Flawed Specimen Kit - API-K1, UT-1Qualification Kit (FlawTech) - Welding Store - Weldperfect, Weld Inspection, Weld ToolsDocument2 pagesFlawed Specimen Kit - API-K1, UT-1Qualification Kit (FlawTech) - Welding Store - Weldperfect, Weld Inspection, Weld ToolsAnonymous DXCsjJNo ratings yet

- FLUOR-lesson04 VesselOrientationDocument146 pagesFLUOR-lesson04 VesselOrientationHernâni CruzNo ratings yet

- Asme B31.3 2018 30PDocument7 pagesAsme B31.3 2018 30PKim JungdaeNo ratings yet

- MDCAT-Physics - Key Points PDFDocument15 pagesMDCAT-Physics - Key Points PDFFarhad Ali50% (2)

- 38 Daily Tutorial SheetDocument7 pages38 Daily Tutorial SheetMeera SarangapaniNo ratings yet

- 17th Exam P2 PDFDocument16 pages17th Exam P2 PDFLuthfansyah MohammadNo ratings yet

- Oil SpillsDocument12 pagesOil SpillsmartuaNo ratings yet

- Determination of Vitamin C Concentration by TitrationDocument2 pagesDetermination of Vitamin C Concentration by Titration17roopa2010100% (1)

- Ultra Frac TraysDocument4 pagesUltra Frac TraysAhmed Al-HashmiNo ratings yet

- Formation of The Heavy ElementsDocument17 pagesFormation of The Heavy ElementsSheiloiNo ratings yet

Two Liquid Phase Partitioning Bioreactor System For Biodegradation of Pyrene by

Two Liquid Phase Partitioning Bioreactor System For Biodegradation of Pyrene by

Uploaded by

Elkin Dario Mantilla MejiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Two Liquid Phase Partitioning Bioreactor System For Biodegradation of Pyrene by

Two Liquid Phase Partitioning Bioreactor System For Biodegradation of Pyrene by

Uploaded by

Elkin Dario Mantilla MejiaCopyright:

Available Formats

Chapter 3

TWO LIQUID PHASE PARTITIONING BIOREACTOR SYSTEM FOR BIODEGRADATION OF PYRENE BY MYCOBACTERIUM FREDERIKSBERGENSE

Biswanath Mahanty, Kannan Pakshirajan & Veeranki Venkata Dasu

Department of Biotechnology, Indian Institute of Technology Guwahati, Guwahati, India

ABSTRACT Biodegradation of pyrene by Mycobacterium frederiksbergense was evaluated in a two liquid phase partitioning bioreactor (TPPB) containing 20% v/v silicone oil in an aqueous phase medium. At an initial concentration of 400 mg l1 in silicone oil, the mycobacterium could completely degrade pyrene within 6 d with a rate of 140 mg l1 d1. When compared to the results of slurry phase and surfactant aided systems, the TPPB system was found superior not only in terms of pyrene removal efficiency and rate but also in terms of cost effectiveness of the process.

INTRODUCTION Polycyclic aromatic hydrocarbons (PAHs) produced via natural and anthropogenic sources during the incomplete combustion of solid and liquid fuels in industrial activities are harmful to environment and human health.1 However, due to low aqueous solubility/bioavailability, bioremediation of PAHs is largely limited. Two-phase partitioning bioreactors (TPPBs) have gained considerable attention, in which PAHs dissolved in an organic phase partitions into the aqueous phase based on equilibrium considerations and real-time demand of the microorganisms.2,3 In this present study, an efficient TPPB system was investigated for pyrene biodegradation by M. frederiksbergense. Its performance in terms of pyrene degradation rate and efficiency, and cost benefit over slurry phase and surfactant aided systems was also compared.

14

Biotechniques for Air Pollution Control

MATERIALS AND METHODS CHEMICALS AND REAGENTS Analytical grade pyrene and silicone oil used in the study were purchased from Sigma-aldrich Chemicals, India, and Loba Chemie, India, respectively. Non-ionic surfactant (Tween 80) and media components were purchased from Himedia laboratory, India. MICROORGANISM AND CULTURE MEDIA M. frederiksbergense NRRL B-24126 was obtained from USDA, USA. While nutrient Broth was used for its routine growth and maintenance, Bushnell Hass media was used in the pyrene biodegradation experiments. SCREENING OF NON AQUEOUS PHASE LIQUID FOR USE IN TPPB SYSTEM For selecting a suitable non aqueous phase liquid (NAPL) that is biocompatible with the microorganism in TPPB system, isopropyl myristate, n-hexadecane and silicone oil were considered. Five 125 ml flasks each containing 40 ml of BH medium, 5 ml of M. frederiksbergense, 5 ml of any of the solvents and 2 ml of soybean oil were taken; an additional flask containing all the ingredients except the solvents served as the positive control in this experiment. All the flasks were incubated at 28C for 3 d, and at the end the biomass in the flasks were determined by the dry weight method. PYRENE BIODEGRADATION EXPERIMENTS TPPB system All pyrene biodegradation experiments in the TPPB system were carried out in a 3 l autoclavable glass fermenter (Applikon). Both the aqueous (1 L BH media) and organic phases (pyrene in silicone oil, 250 ml) were loaded together in the vessel, autoclaved in toto and allowed to cool down to room temperature. Thereafter 50 ml of overnight grown M. frederiksbergense culture was added as the inoculum, and the bioreactor operated at temperature 28C, pH 7.0, aeration rate 1.5 vvm and agitation rate 600 rpm. During its operation, duplicate samples of 1.5 ml each were withdrawn from the fermenter for 15 d and remaining pyrene in the silicone oil samples was extracted with methanol to monitor its degradation in the system. Slurry phase system Pyrene biodegradation experiments in this system were carried out using the same fermenter mentioned in experiments under TPPB system, but by taking

Two liquid phase bioreactor for biodegradation of pyrene 15

pyrene stock solution (25 g l1 in acetone) in the empty vessel to give final pyrene content of 50 mg l1, which is based on the final aqueous phase volume. Other experimental conditions in this system remained the same as that of the TPPB system. Samples (1 ml each) from this slurry phase reactor were extracted twice with equal volumes of ethyl acetate before final analysis of pyrene. Surfactant aided system Based on our earlier study,4 using Tween 80 as the surfactant , experiments in this system were carried out using the earlier mentioned 3 l fermenter with 1 l BH media containing pyrene (25 mg l1) that was solubilised by the surfactant. Again, the experimental conditions were maintained the same in this system as those of the two other systems. ANALYTICAL METHODS Pyrene analysis Pyrene concentrations in all the samples, with or without pretreatment as mentioned before, were quantified using synchronous fluorescence spectroscopy using a FluoroMax-3 (HORIBA Jobin Yvon, USA) fluorescence spectrometer with the detection condition of = 36.0 nm, excitation peak maximum = 335 nm. COST BENEFIT ANALYSIS OF THE THREE DIFFERENT SYSTEMS Cost analysis of the three biodegradation systems investigated in this work was performed considering the costs involved in the preparation of inoculum and media, and power required for running fermenter and shake incubator in the experiments. These are presented in Tables 1 and 2, respectively.

Table 1 Preparation costs of inoculums and media used in the biodegradation experiments. For inoculums (50 ml) Chemical/power input Nutrient broth Power consumption in shaker (12 h) BH media Trace element solution Total cost (in USD)

*All costs are represented in USD.

For media (1000 ml) Amount 3.27 g 2 ml Cost* 0.30 0.01 0.31

Amount 0.65 g 41.4 unit

Cost* 0.04 3.90 3.94

16

Biotechniques for Air Pollution Control

Table 2 Power requirements for running fermenter and shaker incubator in the experiments. System Fermenter Unit/Components (Power in kW) Bioconsole (1.6), Controller (0.07), Agitator (0.04), Chiller unit (0.9), Air compressor (1.5) Complete system (3.45) Total power (kW) 4.11 Cost/h 0.38

Shaker incubator

3.45

0.07

Cost in USD; 1 USD = 48.00 Indian rupees and Electricity charges are based on LT-commercial tariff of AERC.

RESULTS AND DISCUSSION Selection of NAPL for use in the TPPB system Solvent selection experiments were performed to choose a candidate solvent that is biocompatible but not bioavailable to M. frederiksbergense. Figure 1 presents the results in terms of relative metabolic activity (RMA) of the mycobacterium in presence of the different solvents, which clearly reveals that all except IPM (RMA = 1.7) were found non-bioavailable. It is also apparent from Fig. 1 that relative metabolic activity in presence of silicone oil was comparable to that due to hexadecane. Hence, based on these results and economic considerations, silicone oil was selected as the suitable solvent in the study. Silicone oil has traditionally been considered highly stable, hydrophobic and chemically resistant to oxidative attack, and has been employed successfully in several other TPPB studies3,5,6, as well. PYRENE BIODEGRADATION EXPERIMENTS TPPB system Pyrene biodegradation experiments employing the TPPB system was carried out at its initial concentration of 400 mg l1. Pyrene degradation profiles, shown in figure 2, reveal that pyrene was completely degraded in 6 d with a rate of 139 mg l1 d1 without any lag phase in this TPPB system. MacLeod and Daugulis reported complete degradation of pyrene (1 g) within 4 d at a rate of 138 mg l1 d1 by Mycobacterium PYR-1in a TPPB system containing bis(ethylhexyl) sebacate.7 In another study, Vandermeer and Daugulis observed only 26% degradation of pyrene after 120 h of TPPB operation by a defined Sphingomonas consortium using a very high initial pyrene concentration of 1 g l1 in dodecane.8 These results clearly indicate the superiority of the NAPL silicone oil M. frederiksbergense pair in biodegradation of pyrene over other TPPB systems reported in the literature.

Two liquid phase bioreactor for biodegradation of pyrene

17

2.0 1.8 1.6

Relative metabolic activity

1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0

il il l) tro no no on ea ea yb yb l (c o oi So +S +S an il + ne be IPM eo ca oy n S de ico xa Sil He b oy ea no il

IPM

ic Sil

on

il ne eo ca de xa He

Figure 1 Results of solvent selection experiments.

500 50

-1

Slurry phase system Tween 80 aided system TPPB system

400

Pyrene concentration, mg l

40 300 30

200 20

10

100

0 0 50 100 150 200

Time, h

Figure 2 Pyrene biodegradation profiles obtained using slurry phase, surfactant aided and TPPB systems.

Slurry phase and Tween 80 aided systems Results of pyrene biodegradation experiments in slurry phase system containing an initial concentration of 50 mg l1 revealed complete degradation of the compound within 200 h (Fig. 2) with an overall degradation rate of 6 mg l1 d1.

18

Biotechniques for Air Pollution Control

Table 3 Overall cost comparison of pyrene degradation employing the three different systems. Cost involved for (in USD) Cost per mg of pyrene removed (in USD) 1.10 0.73 0.62

System Slurry phase Surfactant aided TPPB

Inoculums Basic media Pyrene preparation preparation delivery 3.94 3.94 3.94 0.46 0.31 0.46 0.04 11.40

Power 77.51 13.95 46.51

Total cost 81.91 18.24 62.30

Amount of pyrene removed (mg) 75 25 100

On the other hand, pyrene degradation profile with Tween 80 indicated near complete degradation within 50 h without any lag period with a degradation rate of 17.7 mg l1 d1. It should be noted here that in both these two systems degradation of pyrene by the mycobacterium at initial concentrations above 50 mg l1 were not investigated owing to either of the two limitations associated with such high concentration levels in these systems: no change in effective aqueous concentration of pyrene (slurry phase system) or huge requirement of surfactant (surfactant aided system). The chosen pyrene concentration of 25 mg l1 in the present Tween 80 aided system was also based on our earlier study.4 COST BENEFIT ANALYSIS COMPARISON As described earlier, cost benefit analysis was conducted considering the costs for preparing inoculum and media ingredients, and for power required to run fermenter and shaker incubator in these experiments. Table 3 comparatively illustrates the combined cost for the three systems, which clearly indicate that the TPPB system was the most economical among the three, and in which case only $0.62 was required for biodegrading a unit weight of pyrene. REFERENCES

1 Mastral AM and Callen MS, A review on polycyclic aromatic hydrocarbon (PAH) emissions from energy generation. Environ Sci Technol 34:30513057 (2000). 2 Daugulis AJ, Two-phase partitioning bioreactors: a new technology platform for destroying xenobiotics. Trends Biotechnol 19:457462 (2001). 3 Mahanty B, Pakshirajan K and Dasu VV, Biodegradation of pyrene by Mycobacterium frederiksbergense in a two-phase partitioning bioreactor system. Bioresour Technol 99:26942698 (2008).

Two liquid phase bioreactor for biodegradation of pyrene 19

4 Mahanty B, Sarma SJ and Pakshirajan K, Evaluation of different surfactants for use in pyrene biodegradation by Mycobacterium frederiksbergense. Int J Chem Sci 5:15051512 (2007). 5 Vanneck P, Beeckman M, De Saeyer N, DHaene S and Verstraete W, Biodegradation of polycyclic aromatic hydrocarbons in a two-liquid-phase system. In Bioremediation of recalcitrant organics, ed by Hinchee RE, Anderson DB and Hoeppel RE. Battelle Press, Columbus, pp. 5562 (1995). 6 Muoz R, Guieysse B and Mattiasson B, Phenanthrene biodegradation by an algal-bacterial consortium in two-phase partitioning bioreactors. Appl Microbiol Biotechnol 61:261267 (2003). 7 MacLeod CT and Daugulis AJ, Biodegradation of polycyclic aromatic hydrocarbons in a two-phase partitioning bioreactor in the presence of a bioavailable solvent. Appl Microbiol Biotechnol 62:291296 (2003). 8 Vandermeer KD and Daugulis AJ, Enhanced degradation of a mixture of polycyclic aromatic hydrocarbons by a defined microbial consortium in a two-phase partitioning bioreactor. Biodegradation 18:211221 (2007).

You might also like

- 000504242-Microwave Ephedrine From LpacDocument4 pages000504242-Microwave Ephedrine From LpacPaul BrownNo ratings yet

- Astm E34-2011Document3 pagesAstm E34-2011Makarius YanuantoNo ratings yet

- Exp 1 Physical Refining of Crude Palm OilDocument13 pagesExp 1 Physical Refining of Crude Palm Oilaffeena100% (1)

- Palm Oil Mill EffluentDocument6 pagesPalm Oil Mill Effluentankitsaxena123100% (2)

- Ijaesv11n4 19Document10 pagesIjaesv11n4 19Dimas PhilipinantoNo ratings yet

- International Journal of Engineering Research and Development (IJERD)Document4 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- The Effect of Co-Solvents On The Antibacterial Activity of ParabenDocument10 pagesThe Effect of Co-Solvents On The Antibacterial Activity of ParabenDamariscpNo ratings yet

- Bioresource Technology: Soham Chattopadhyay, Ramkrishna SenDocument6 pagesBioresource Technology: Soham Chattopadhyay, Ramkrishna SenSriArthiNo ratings yet

- Comparison Study of Two Procedures For Determination of Emamectin Benzoate in Medicated Fish FeedDocument4 pagesComparison Study of Two Procedures For Determination of Emamectin Benzoate in Medicated Fish FeedSV_TokanNo ratings yet

- Lin 05 FoodadditcontamDocument9 pagesLin 05 Foodadditcontamforward websiteNo ratings yet

- 113 115 Extraction Hitesh PatelDocument4 pages113 115 Extraction Hitesh PatelAxcel Ann MacasocolNo ratings yet

- Objective 1 Part 2Document5 pagesObjective 1 Part 2Revanth VennuNo ratings yet

- JMB025-11-21 Fdoc 1Document8 pagesJMB025-11-21 Fdoc 1tsing takNo ratings yet

- PIIS0022030267874186Document3 pagesPIIS0022030267874186Jose Carlos Diaz de sandi Megalith Increasing PowerNo ratings yet

- Archive of SID: Total Phenolic Contents and Antioxidant Activity of Pomegranate (Punica Granatum L.) Peel ExtractsDocument7 pagesArchive of SID: Total Phenolic Contents and Antioxidant Activity of Pomegranate (Punica Granatum L.) Peel ExtractsVida Faith GalvezNo ratings yet

- Benzene Recovery 1Document12 pagesBenzene Recovery 1Student 80No ratings yet

- Direct Ecotox Testing of Leachates As An Alternative To PEC/PNEC ComparisonDocument7 pagesDirect Ecotox Testing of Leachates As An Alternative To PEC/PNEC ComparisonNgoc NguyenNo ratings yet

- Iso 11348 1Document18 pagesIso 11348 1amirNo ratings yet

- Selective Extraction of Carotenoids From The Microalga Dunaliella Salina With Retention of ViabilityDocument8 pagesSelective Extraction of Carotenoids From The Microalga Dunaliella Salina With Retention of ViabilityYellow MarmotNo ratings yet

- Enzymatic Pre-Hydrolysis of High Fat Content Dairy Wastewater As A Pretreatment For Anaerobic DigestionDocument6 pagesEnzymatic Pre-Hydrolysis of High Fat Content Dairy Wastewater As A Pretreatment For Anaerobic DigestionlucasNo ratings yet

- Torulaspora Delbrueckii and Conversion To Ephedrine byDocument4 pagesTorulaspora Delbrueckii and Conversion To Ephedrine bysalvia1025100% (1)

- Supercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYDocument7 pagesSupercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYGuillermo Serralde PaezNo ratings yet

- 22 PDFDocument7 pages22 PDFWidya Dwi Arini100% (1)

- The Biological Purification of Waste Products From Olive Oil ExtractionDocument5 pagesThe Biological Purification of Waste Products From Olive Oil ExtractionRicardo Rafael Garcia MirandaNo ratings yet

- Engineering Safer Bulk Cooking Oil by Increasing oDocument9 pagesEngineering Safer Bulk Cooking Oil by Increasing oLaboratorium KimiaNo ratings yet

- Esterification of Fatty Acids Using Partially Purified Dvl-2 LipaseDocument44 pagesEsterification of Fatty Acids Using Partially Purified Dvl-2 Lipaseakashgoyal1992100% (1)

- Physical and Chemical Analysis of Composting in Cephalosporium Residue and Chicken ManureDocument6 pagesPhysical and Chemical Analysis of Composting in Cephalosporium Residue and Chicken ManureNaztovenNo ratings yet

- Exp 1 Physical Refining of Crude Palm OilDocument13 pagesExp 1 Physical Refining of Crude Palm OilMUHAMMAD LUQMAN IZZUDDIN BIN SUHAIMINo ratings yet

- Thavasi2011 Article BiosurfactantProductionByPseudDocument7 pagesThavasi2011 Article BiosurfactantProductionByPseudLina Maria Ospina NuñezNo ratings yet

- CONICET Digital Nro.7cc5afb8 1375 4b75 b937 F2be2eec9ac6 SDocument10 pagesCONICET Digital Nro.7cc5afb8 1375 4b75 b937 F2be2eec9ac6 SRey MuhamadNo ratings yet

- 1 PBDocument6 pages1 PBjaka djNo ratings yet

- Articulo 6.Document8 pagesArticulo 6.sara_tabares_2No ratings yet

- Self-Emulsifying Formulation of Indomethacin With Improved Dissolution and Oral AbsorptionDocument12 pagesSelf-Emulsifying Formulation of Indomethacin With Improved Dissolution and Oral AbsorptionKietNo ratings yet

- Bio-Scouring Process Optimization of Wool Fiber and Wastewater UtilizationDocument8 pagesBio-Scouring Process Optimization of Wool Fiber and Wastewater UtilizationcenotakNo ratings yet

- Solubility and Dissolution Improvement of Ketoprofen by Emulsification Ionic GelationDocument7 pagesSolubility and Dissolution Improvement of Ketoprofen by Emulsification Ionic GelationAfifah Dwi CahyaniNo ratings yet

- Research Rev A04Document9 pagesResearch Rev A04MohamadDanielBinYaacobNo ratings yet

- Journal of Advanced Scientific ResearchDocument5 pagesJournal of Advanced Scientific Researchzulaika22No ratings yet

- Application Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerDocument4 pagesApplication Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerPrianurraufikachmadNo ratings yet

- Experiment 2: Purification: Fumio Kumakura, Cedric RentierDocument1 pageExperiment 2: Purification: Fumio Kumakura, Cedric RentierHiroaki IkedaNo ratings yet

- Experiment 2: Purification: Fumio Kumakura, Cedric RentierDocument1 pageExperiment 2: Purification: Fumio Kumakura, Cedric RentierHiroaki IkedaNo ratings yet

- Quantitative Analyses of Ricinoleic Acid and RicinDocument5 pagesQuantitative Analyses of Ricinoleic Acid and RicinHajar HadisNo ratings yet

- 1 s2.0 S2214785316303583 MainDocument6 pages1 s2.0 S2214785316303583 MainMaría Camila GonzalezNo ratings yet

- Aqueous Two Phase Extraction For Purification of C-PhycocyaninDocument9 pagesAqueous Two Phase Extraction For Purification of C-PhycocyaninRuxandra SimionNo ratings yet

- 1generation of Biogas Via Organic MaterialsDocument13 pages1generation of Biogas Via Organic MaterialsOKORIENo ratings yet

- Development of Chemically Modified Pectin Based Extended Release Tablets of NifedipineDocument16 pagesDevelopment of Chemically Modified Pectin Based Extended Release Tablets of NifedipineMurali Krishna ReddyNo ratings yet

- Extracción Verde de Aceite Vegetal de Ajonjolí Mediante EnzimasDocument7 pagesExtracción Verde de Aceite Vegetal de Ajonjolí Mediante EnzimasJ LakesNo ratings yet

- A New and Unique Tool For Shrimp Feed Producers: Kristin Weel SundbyDocument8 pagesA New and Unique Tool For Shrimp Feed Producers: Kristin Weel SundbyrsuertoNo ratings yet

- HPLC Analysis of AP and BHA (Antioxidants)Document5 pagesHPLC Analysis of AP and BHA (Antioxidants)Sarala TantirimudaligeNo ratings yet

- Extraction of Caffeine, Theobromine, and Cocoa Butter From Cocoa BeansDocument8 pagesExtraction of Caffeine, Theobromine, and Cocoa Butter From Cocoa Beansmurdanetap957No ratings yet

- Wafa MS ThesisDocument59 pagesWafa MS ThesisnomanhaimourNo ratings yet

- Ansolin Et Al 2013Document9 pagesAnsolin Et Al 2013Francielly StechiNo ratings yet

- Lutein Extraction An CVDocument22 pagesLutein Extraction An CVSacra PsyntergiaNo ratings yet

- 16234-Article Text-55935-3-10-20220117Document17 pages16234-Article Text-55935-3-10-20220117AJ ManurungNo ratings yet

- 2 PBDocument6 pages2 PBbangtan loversNo ratings yet

- Biomethanation of Banana Peel and Pineapple WasteDocument4 pagesBiomethanation of Banana Peel and Pineapple WasteolieNo ratings yet

- An Enzymatic Approach To The Cleaning of Ultrafiltration PDFDocument8 pagesAn Enzymatic Approach To The Cleaning of Ultrafiltration PDFsamrickyNo ratings yet

- Chapter 4 Exp. WorkDocument14 pagesChapter 4 Exp. WorkSAI ASSOCIATENo ratings yet

- An Efficient Method For Extraction, Separation and PurificationDocument5 pagesAn Efficient Method For Extraction, Separation and PurificationE Gustiasih MaulidantiNo ratings yet

- 1 PBDocument7 pages1 PBleonlovebernardNo ratings yet

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.From EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Rating: 4 out of 5 stars4/5 (1)

- 2016 Fall Midterm 1 OChem 1 KeyDocument20 pages2016 Fall Midterm 1 OChem 1 KeyAlex LeungNo ratings yet

- June 2017 (v1) QP - Paper 1 CIE Biology A-LevelDocument20 pagesJune 2017 (v1) QP - Paper 1 CIE Biology A-LevelFadhilNo ratings yet

- BoilersDocument5 pagesBoilersSafety professionalNo ratings yet

- SOP - Standard Operating Procedure For Manual Dispensing SystemsDocument82 pagesSOP - Standard Operating Procedure For Manual Dispensing Systemsrsmbgss575No ratings yet

- Protective Coatings ManualDocument127 pagesProtective Coatings ManualQudri SaufiNo ratings yet

- Date Time Internal Temperature Total Radiation Uva Uvb °C W/M2 Microw/Cm2 Microw/Cm2Document8 pagesDate Time Internal Temperature Total Radiation Uva Uvb °C W/M2 Microw/Cm2 Microw/Cm2Bilel KrayniNo ratings yet

- PT Procedure Rev01EDocument14 pagesPT Procedure Rev01ETrương Ngọc SơnNo ratings yet

- Multiple ShoyshesDocument2 pagesMultiple ShoyshesJonathan Roy BombitaNo ratings yet

- Engineering MaterialsDocument18 pagesEngineering MaterialsAhmed ElkomyNo ratings yet

- AREA Introduction To EN 378 - For Publication - 0Document27 pagesAREA Introduction To EN 378 - For Publication - 0jorge rodriguezNo ratings yet

- Reviews of Environmental Contamination and ToxicologyDocument239 pagesReviews of Environmental Contamination and ToxicologyRetal MohamedNo ratings yet

- Dow RSC 155Document6 pagesDow RSC 155icfcfciNo ratings yet

- Step Potential PDFDocument34 pagesStep Potential PDFRomi Necq S. AbuelNo ratings yet

- Chem273 Take Home LabDocument12 pagesChem273 Take Home LabMentari Permata HatiNo ratings yet

- Jurnal Nutri3Document11 pagesJurnal Nutri3Winda SariNo ratings yet

- Altig 316L PDFDocument1 pageAltig 316L PDFgst ajahNo ratings yet

- Strategies To Improve The Production of Secondary MetabolitesDocument6 pagesStrategies To Improve The Production of Secondary Metabolitesdennis leeNo ratings yet

- Cookery 9 LO1 Clean, Sanitize, and Store Kitchen Tools and EquipmentDocument16 pagesCookery 9 LO1 Clean, Sanitize, and Store Kitchen Tools and EquipmentSteffi ToringNo ratings yet

- Liquid Distribution and Falling Film Wetting in Dairy EvaporatorsDocument227 pagesLiquid Distribution and Falling Film Wetting in Dairy Evaporatorsyadavmihir63No ratings yet

- Flawed Specimen Kit - API-K1, UT-1Qualification Kit (FlawTech) - Welding Store - Weldperfect, Weld Inspection, Weld ToolsDocument2 pagesFlawed Specimen Kit - API-K1, UT-1Qualification Kit (FlawTech) - Welding Store - Weldperfect, Weld Inspection, Weld ToolsAnonymous DXCsjJNo ratings yet

- FLUOR-lesson04 VesselOrientationDocument146 pagesFLUOR-lesson04 VesselOrientationHernâni CruzNo ratings yet

- Asme B31.3 2018 30PDocument7 pagesAsme B31.3 2018 30PKim JungdaeNo ratings yet

- MDCAT-Physics - Key Points PDFDocument15 pagesMDCAT-Physics - Key Points PDFFarhad Ali50% (2)

- 38 Daily Tutorial SheetDocument7 pages38 Daily Tutorial SheetMeera SarangapaniNo ratings yet

- 17th Exam P2 PDFDocument16 pages17th Exam P2 PDFLuthfansyah MohammadNo ratings yet

- Oil SpillsDocument12 pagesOil SpillsmartuaNo ratings yet

- Determination of Vitamin C Concentration by TitrationDocument2 pagesDetermination of Vitamin C Concentration by Titration17roopa2010100% (1)

- Ultra Frac TraysDocument4 pagesUltra Frac TraysAhmed Al-HashmiNo ratings yet

- Formation of The Heavy ElementsDocument17 pagesFormation of The Heavy ElementsSheiloiNo ratings yet