Professional Documents

Culture Documents

Kunalsinh Mechanical Dept Lecture On Lathe Machines-1

Kunalsinh Mechanical Dept Lecture On Lathe Machines-1

Uploaded by

Kunalsinh88Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kunalsinh Mechanical Dept Lecture On Lathe Machines-1

Kunalsinh Mechanical Dept Lecture On Lathe Machines-1

Uploaded by

Kunalsinh88Copyright:

Available Formats

KUNALSINH MECHANICAL DEPT LECTURE ON LATHE MACHINES-1

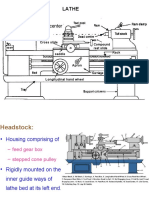

INTRODUCTION OF LATHE. GENERAL LAYOUT OF LATHE LATHE PARTS. DESCRIPTION OF LATHE PARTS.

Kunalsinh [Mechanical dept]

Lathe is one of the most versatile and widely used machine tools all over the world. It is commonly known as the mother of all other machine tool. The main function of a lathe is to remove metal from a job to give it the required shape and size. The job is secure1y and rigid1y held in the chuck or in between centers on the lathe machine and then turn it against a single point cutting tool which wi1l remove meta1 from the job in the form of chips.

Kunalsinh [Mechanical dept]

An engine lathe is the most basic and simplest form of the lathe. It derives its name from the early lathes, which obtained their power from engines. Besides the simple turning operation as described above, lathe can be used to carry out other operations also, such as drilling, reaming, boring, taper turning, knurling, screw- thread cutting, grinding etc.

Kunalsinh [Mechanical dept]

Kunalsinh [Mechanical dept]

Kunalsinh [Mechanical dept]

Kunalsinh [Mechanical dept]

1. 2. 3. 4. 5. 6.

Bed Head stock Tailstock Carriage Feed mechanism Thread cutting mechanism.

Kunalsinh [Mechanical dept]

The bed of a lathe machine is the base on which all other parts of lathe are mounted. It is massive and rigid single piece casting made to support other active parts of lathe. On left end of the bed, headstock of lathe machine is located while on right side tailstock is located. The carriage of the machine rests over the bed and slides on it. On the top of the bed there are two sets of guidewaysinnerways and outerways. The innerways provide sliding surfaces for the tailstock and the outerways for the carriage. The guideways of the lathe bed may be flat and inverted V shape. Generally cast iron alloyed with nickel and chromium material is used for manufacturing of the lathe bed.

Kunalsinh [Mechanical dept]

The main function of headstock is to transmit power to the different parts of a lathe. It comprises of the headstock casting to accommodate all the parts within it including gear train arrangement. The main spindle is adjusted in it, which possesses live centre to which the work can be attached. It supports the work and revolves with the work, fitted into the main spindle of the headstock. The cone pulley is also attached with this arrangement, which is used to get various spindle speed through electric motor. The back gear arrangement is used for obtaining a wide range of slower speeds. Some gears called change wheels are used to produce different velocity ratio required for thread cutting.

Kunalsinh [Mechanical dept]

Kunalsinh [Mechanical dept]

shows the tail stock of central lathe, which is commonly used for the objective of primarily giving an outer bearing and support the circular job being turned on centers. Tail stock can be easily set or adjusted for alignment or non-alignment with respect to the spindle centre and carries a centre called dead centre for supporting one end of the work. Both live and dead centers have 60 conical points to fit centre holes in the circular job, the other end tapering to allow for good fitting into the spindles. The dead centre can be mounted in ball bearing so that it rotates with the job avoiding friction of the job with dead centre as it important to hold heavy jobs.

Kunalsinh [Mechanical dept]

Kunalsinh [Mechanical dept]

Carriage is mounted on the outer guide ways of lathe bed and it can move in a direction parallel to the spindle axis. It comprises of important parts such as apron, cross-slide, saddle, compound rest, and tool post. The lower part of the carriage is termed the apron in which there are gears to constitute apron mechanism for adjusting the direction of the feed using clutch mechanism and the split half nut for automatic feed. The cross-slide is basically mounted on the carriage, which generally travels at right angles to the spindle axis. On the cross-slide, a saddle is mounted in which the compound rest is adjusted which can rotate and fix to any desired angle. The compound rest slide is actuated by a screw, which rotates in a nut fixed to the saddle.

Kunalsinh [Mechanical dept]

Carriage is mounted on the outer guide ways of lathe bed and it can move in a direction parallel to the spindle axis. It comprises of important parts such as apron, cross-slide, saddle, compound rest, and tool post. The lower part of the carriage is termed the apron in which there are gears to constitute apron mechanism for adjusting the direction of the feed using clutch mechanism and the split half nut for automatic feed. The cross-slide is basically mounted on the carriage, which generally travels at right angles to the spindle axis. On the cross-slide, a saddle is mounted in which the compound rest is adjusted which can rotate and fix to any desired angle. The compound rest slide is actuated by a screw, which rotates in a nut fixed to the saddle.

Kunalsinh [Mechanical dept]

Feed mechanism is the combination of different units through which motion of headstock spindle is transmitted to the carriage of lathe machine. Following units play role in feed mechanism of a lathe machine. 1. End of bed gearing 2. Feed gear box 3. Lead screw and feed rod 4. Apron mechanism

Kunalsinh [Mechanical dept]

The half nut or split nut is used for thread cutting in a lathe. It engages or disengages the carriage with the lead screw so that the rotation of the leadscrew is used to traverse the tool along the workpiece to cut screw threads. The direction in which the carriage moves depends upon the position of the feed reverse lever on the headstock.

Kunalsinh [Mechanical dept]

WHAT IS LATHE? WORKING OF LATHE? BLOCK DIAGRAM OF LATHE. PARTS OF LATHE MACHINE. LATHE MACHINE EACH AND EVERY PARTS DESCRIPTION IN SHORT.

Kunalsinh [Mechanical dept]

DEFINE LATHE MACHINE. DRAW A NEAT AND SUITABLE DIAGRAM OF ENGINE LATHE AND DESCRIBE THERE EACH PARTS. WHAT IS LATHE? HOW IT CAN BE USED IN DIFFERENT OPERATIONS?

Kunalsinh [Mechanical dept]

ANY QUESTIONS?

Kunalsinh [Mechanical dept]

You might also like

- Shell Welding ProcedureDocument7 pagesShell Welding ProcedurePravesh Modi100% (3)

- Lathe MachineDocument41 pagesLathe MachineRohit GhulanavarNo ratings yet

- Cbe-241rev Quad Processing MachineDocument12 pagesCbe-241rev Quad Processing MachineVigneshMurugesh ANo ratings yet

- Tornillo Bolas PDFDocument104 pagesTornillo Bolas PDFAndres PuertaNo ratings yet

- JIS (Japanese) Standards For Steel MaterialsDocument2 pagesJIS (Japanese) Standards For Steel MaterialsLG Nguyen100% (1)

- ConnectionsDocument82 pagesConnectionsseabrake83% (12)

- Department of Mechanical Engineering ME1030-Basic Workshop Practice Lab (1 0 0 2)Document17 pagesDepartment of Mechanical Engineering ME1030-Basic Workshop Practice Lab (1 0 0 2)Devansh MathurNo ratings yet

- Naya Nangal UnitDocument24 pagesNaya Nangal UnitprabhjotbhangalNo ratings yet

- LatheDocument68 pagesLatheregistrarNo ratings yet

- Abhay TiwariDocument17 pagesAbhay Tiwaridabangg Siddharth mishraNo ratings yet

- Lathes and Lathe Machining OperationsDocument11 pagesLathes and Lathe Machining OperationsJunayed HasanNo ratings yet

- Lathe Types, Parts, Specification, Operations, PrecautionsDocument15 pagesLathe Types, Parts, Specification, Operations, PrecautionsnNo ratings yet

- Module 5 PDFDocument28 pagesModule 5 PDFkaushal shivaprakashNo ratings yet

- Lathe Machine: MaterialDocument10 pagesLathe Machine: MaterialKishan ParmarNo ratings yet

- Chapter Two Traditional Material Removal Processes MachiningDocument21 pagesChapter Two Traditional Material Removal Processes MachiningkidusNo ratings yet

- Lab ManualDocument60 pagesLab Manualshahid_ahmed_28No ratings yet

- Lab 7 Workshop Teacher VersionDocument4 pagesLab 7 Workshop Teacher Versionumar272No ratings yet

- Chapter 4 LatheDocument10 pagesChapter 4 LatheDipayan DasNo ratings yet

- Mto Module 1 NotesDocument41 pagesMto Module 1 NotesSandeshNo ratings yet

- Mini Lathe Machine-AbstractDocument5 pagesMini Lathe Machine-AbstractVivace SystmNo ratings yet

- 1 TurningDocument2 pages1 Turningsampatd444No ratings yet

- Lathe PresentationDocument11 pagesLathe PresentationChandresh KulshresthaNo ratings yet

- Lathe Machine PrinciplesDocument15 pagesLathe Machine Principlesscratch89No ratings yet

- Lathe Machine: SpecificationsDocument4 pagesLathe Machine: SpecificationsTanish VermaNo ratings yet

- Machine Tools Lab Manual (13-14)Document39 pagesMachine Tools Lab Manual (13-14)Krishna Murthy100% (1)

- Machine ToolsDocument22 pagesMachine ToolsSankalpRaiNo ratings yet

- LatheDocument39 pagesLatheDominador Lozano Jr.No ratings yet

- TurningDocument6 pagesTurningShivshankar Singh0% (1)

- Lab ManualDocument43 pagesLab ManualTech OriginNo ratings yet

- Layout of Mechanical Work ShopkkkkDocument7 pagesLayout of Mechanical Work ShopkkkkChaudhary Rizwan MeoNo ratings yet

- BMEDocument23 pagesBMELawanbha LyngdohNo ratings yet

- Lathe MachineDocument12 pagesLathe MachineEmy SyazlindaNo ratings yet

- MM Presentation Gear and TumblerDocument24 pagesMM Presentation Gear and Tumblersachin prajapatiNo ratings yet

- Lathe MachineDocument5 pagesLathe MachineJeremiah NayosanNo ratings yet

- Project PPT-2Document43 pagesProject PPT-2vennasrinivasrao4No ratings yet

- Chapter 7 (Turning - Lathe Work)Document58 pagesChapter 7 (Turning - Lathe Work)Munashe ZharareNo ratings yet

- BME 513 Lecture NotesDocument31 pagesBME 513 Lecture Noteschibuzorosinachi21No ratings yet

- Lab Session Introduction To Lathe MachineDocument5 pagesLab Session Introduction To Lathe MachineAqib ZamanNo ratings yet

- LATHE - WriteupDocument21 pagesLATHE - WriteupMERISH GURU100% (1)

- Lathe Machine: SpecificationsDocument28 pagesLathe Machine: SpecificationsTanish VermaNo ratings yet

- Module 2Document10 pagesModule 2Shamanth M BabuNo ratings yet

- Machining Process - I: Lathe MachineDocument48 pagesMachining Process - I: Lathe MachineNajshhsNo ratings yet

- Unit-II The LatheDocument14 pagesUnit-II The LatheThulasi RamNo ratings yet

- Metal Cutting Lab ManualDocument54 pagesMetal Cutting Lab ManualAbhay Sharma 2K20PE02No ratings yet

- Chapter 11Document32 pagesChapter 11Mark Angelo M. BubanNo ratings yet

- Slotting MachineDocument30 pagesSlotting MachineUsman Zubair100% (1)

- Lab 2 TurningDocument12 pagesLab 2 TurningLuqman HakimNo ratings yet

- Lathe Machine: Trade: Turning (Workshop Practices)Document1 pageLathe Machine: Trade: Turning (Workshop Practices)Sanjay GhejiNo ratings yet

- Lathe Machine: DR A R M Harunur RashidDocument30 pagesLathe Machine: DR A R M Harunur RashidAHMAD MUSANo ratings yet

- A Dissertation Report On "Hydraulic System"Document15 pagesA Dissertation Report On "Hydraulic System"hunny280889No ratings yet

- Lathe Machine: Definition, Introduction, Parts, Types, Operations, and Specifications (With PDFDocument22 pagesLathe Machine: Definition, Introduction, Parts, Types, Operations, and Specifications (With PDFMrTurner HoodNo ratings yet

- 2 - Machining Processes and Machine ToolsDocument69 pages2 - Machining Processes and Machine ToolsWajih HasnainNo ratings yet

- Product Realization by Manufacturing: Lab ManualDocument75 pagesProduct Realization by Manufacturing: Lab ManualjasvindersinghsagguNo ratings yet

- Lathe Machine 1sDocument10 pagesLathe Machine 1sMrTurner HoodNo ratings yet

- IME - Module 2 NotesDocument27 pagesIME - Module 2 Noteskdshakuntala40No ratings yet

- Lathe MachineDocument13 pagesLathe Machinemboniface763No ratings yet

- 06 Gear Changing of Center LatheDocument4 pages06 Gear Changing of Center Lathekabbirhossain100% (1)

- Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFDocument20 pagesLathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFMark Angelo M. BubanNo ratings yet

- Advance Manufacturing Process (Amp) Project FinalDocument12 pagesAdvance Manufacturing Process (Amp) Project FinalAyyan Gaonkhadkar100% (3)

- Lathe Machine Parts and FunctionDocument58 pagesLathe Machine Parts and Functionjas081603No ratings yet

- Lathe, Milling Machine, Computer Numerical Control (CNC) and RobotsDocument25 pagesLathe, Milling Machine, Computer Numerical Control (CNC) and RobotsLAKSH RAMASWAMYNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- NADCAP Quoation FormDocument12 pagesNADCAP Quoation FormAnkurNo ratings yet

- Theory of Metal CuttingDocument69 pagesTheory of Metal Cuttingprof_panneer0% (1)

- Manufacturing Process Plan Commercial Aircraft Nose Radome Delivery IIDocument42 pagesManufacturing Process Plan Commercial Aircraft Nose Radome Delivery II100506402No ratings yet

- LatheClass1 3dupDocument20 pagesLatheClass1 3dupomkardashetwarNo ratings yet

- Drylin - Lead Screw Technology - Product RangeDocument4 pagesDrylin - Lead Screw Technology - Product RangeLeandro SoaresNo ratings yet

- Hiwin Ballscrew CatalogueDocument174 pagesHiwin Ballscrew Catalogueskooba84No ratings yet

- HY80 Alloy Steels PDFDocument3 pagesHY80 Alloy Steels PDFLuis GarciaNo ratings yet

- Edm AssignmentDocument8 pagesEdm Assignmentfarahin_selamatNo ratings yet

- Manufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesDocument5 pagesManufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesMiguel Rodriguez100% (1)

- Gambar 21 Side Cover: Nomor Refere Nomor Part Nama Part KeteranganDocument2 pagesGambar 21 Side Cover: Nomor Refere Nomor Part Nama Part KeteranganRohaizad SallehNo ratings yet

- 12 Machinery Ebook PDFDocument135 pages12 Machinery Ebook PDFTeuku Andy Nur IsaNo ratings yet

- Manufacturing Processes PrimaryDocument2 pagesManufacturing Processes PrimaryKodok SuperNo ratings yet

- Notes On CNCDocument27 pagesNotes On CNCKaushalendra Kumar SinghNo ratings yet

- 45 Manufacturing ProcessDocument45 pages45 Manufacturing ProcessOtunba Olakunle Sunday AjayiNo ratings yet

- MCTD LabDocument38 pagesMCTD LabnidhidarklordNo ratings yet

- Guide To Milling Tool InsertsDocument46 pagesGuide To Milling Tool InsertsCristian FuentesNo ratings yet

- Ar Cutting OperationDocument7 pagesAr Cutting OperationNandakrishnan S LNo ratings yet

- B737 Ch70 STD PracticesDocument21 pagesB737 Ch70 STD PracticesAhmed Abdoul ZaherNo ratings yet

- Engraver Tool To MakeDocument15 pagesEngraver Tool To MakeDave Bass100% (7)

- Fabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)Document58 pagesFabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)johnknight000No ratings yet

- Solid Round Micro Cutting Tools CatalogDocument315 pagesSolid Round Micro Cutting Tools Catalogdon-donnolaNo ratings yet

- Hyrel 30M Instructions (Rough Draft)Document2 pagesHyrel 30M Instructions (Rough Draft)Juan Camilo VelasquezNo ratings yet

- EURODIMA Catalogue - 3-3Document1 pageEURODIMA Catalogue - 3-3Music NetNo ratings yet

- FORGINGDocument55 pagesFORGINGhadiNo ratings yet

- Hand ToolsDocument33 pagesHand ToolsNan OoNo ratings yet

- Ridgeway GaDDocument1 pageRidgeway GaDalpogaltreeNo ratings yet