Professional Documents

Culture Documents

Unit-3-Statistical Process Control and Process Capability

Unit-3-Statistical Process Control and Process Capability

Uploaded by

suraj_suri890 ratings0% found this document useful (0 votes)

21 views11 pagesStatistical Process Control (SPC) uses statistical methods to monitor and improve processes over time. Control charts graphically display process data to distinguish between normal variation due to chance ("common causes") and abnormal variation due to assignable factors ("special causes"). The goal of SPC is to eliminate variability in processes and help them perform consistently by detecting and removing assignable causes of variation. Commonly used control charts include X, R, and sigma charts for continuous variables and P and C charts for attributes. Control charts indicate whether a process meets specifications and can provide information for improving inspection procedures and tolerances.

Original Description:

Original Title

tqm

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStatistical Process Control (SPC) uses statistical methods to monitor and improve processes over time. Control charts graphically display process data to distinguish between normal variation due to chance ("common causes") and abnormal variation due to assignable factors ("special causes"). The goal of SPC is to eliminate variability in processes and help them perform consistently by detecting and removing assignable causes of variation. Commonly used control charts include X, R, and sigma charts for continuous variables and P and C charts for attributes. Control charts indicate whether a process meets specifications and can provide information for improving inspection procedures and tolerances.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

21 views11 pagesUnit-3-Statistical Process Control and Process Capability

Unit-3-Statistical Process Control and Process Capability

Uploaded by

suraj_suri89Statistical Process Control (SPC) uses statistical methods to monitor and improve processes over time. Control charts graphically display process data to distinguish between normal variation due to chance ("common causes") and abnormal variation due to assignable factors ("special causes"). The goal of SPC is to eliminate variability in processes and help them perform consistently by detecting and removing assignable causes of variation. Commonly used control charts include X, R, and sigma charts for continuous variables and P and C charts for attributes. Control charts indicate whether a process meets specifications and can provide information for improving inspection procedures and tolerances.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 11

UNIT-3-STATISTICAL PROCESS CONTROL AND PROCESS CAPABILITY

Statistical Process Control

Statistical Process Control (SPC) can be thought of as the application of statistical methods for the purposes of quality control and improvement. Quality Improvement is perhaps foremost among all areas in business for application of statistical methods.

Control Charts: Recognizing Sources of Variation Why Use a Control Chart?

To monitor, control, and improve process performance over time by studying variation and its source.

What Does a Control Chart Do?

Focuses attention on detecting and monitoring process variation over time; Distinguishes special from common causes of variation, as a guide to local or management action; Serves as a tool for ongoing control of a process; Helps improve a process to perform consistently and predictably for higher quality, lower cost, and higher effective capacity; Provides a common language for discussing process performance.

Introduction to Control Charts

Basic Principles

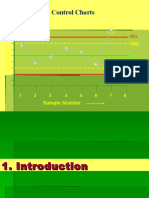

A typical control chart has control limits set at values such that if the process is in control, nearly all points will lie within the upper control limit (UCL) and the lower control limit (LCL).

Introduction to Control Charts

Basic Principles

Introduction to Control Charts

Basic Principles A process that is operating with only chance causes of variation present is said to be in out of control. A process that is operating in the presence of assignable causes is said to be statistical control- easily traced/detected The eventual goal of SPC is the elimination of variability in the process.

Control Chart- Variations

It is a graphical representation of the collected information. Control chart is a device which specifies the state of statistical control, second a device for attaining statistical control, and third a device to judge whether statistical control has been attained.

Commonly used Control charts

Control charts for variablesX, R and sigma charts Control charts for attributes Control charts for fraction defective- P chart Control charts for number of defects per unitC chart.

Objectives of Control Charts

X chart shows the centering of the process R chart show variation in the ranges of samples Sigma chart shows variation of the process Control charts shows whether a given process can meet the existing specifications without a fundamental change in the production process

Objectives of Control Charts

To secure information when it is needed to widen the tolerances To secure information when it is needed to widen the tolerances To secure information to be used in establishing or changing inspection procedure To familiarize personnel with the use of control charts

Important uses of the control chart 1. Most processes do not operate in a state of statistical control 2. Consequently, the routine and attentive use of control charts will identify assignable causes. If these causes can be eliminated from the process, variability will be reduced and the process will be improved 3. The control chart only detects assignable causes. Management, operator, and engineering action will be necessary to eliminate the assignable causes.

You might also like

- Quality ControlDocument41 pagesQuality ControlPrashantNo ratings yet

- Chapter-3 Control ChartsDocument44 pagesChapter-3 Control ChartsComputer Maintainance Hardware and softwareNo ratings yet

- Quality Control & Control ChartsDocument23 pagesQuality Control & Control ChartsEdelyn AgadNo ratings yet

- A Presentation On: Control ChartsDocument30 pagesA Presentation On: Control ChartsAnonymous FW5PVUpNo ratings yet

- 7.1 Statistical Quality ControlDocument3 pages7.1 Statistical Quality Controlboddarambabu100% (1)

- Certification Course On Quality Assurance and Statistical Quality Techniques Course Level A Statistical Process Control Concepts & Control ChartsDocument28 pagesCertification Course On Quality Assurance and Statistical Quality Techniques Course Level A Statistical Process Control Concepts & Control Chartsrchandra2473No ratings yet

- A Presentation On: Control ChartsDocument30 pagesA Presentation On: Control Chartsanil gautamNo ratings yet

- By, Pradeep Nayar (Roll No-24/2009) - Abhishek Kumar (Roll No-13/2009) Rohit Siddhu (Roll No-18/2009)Document22 pagesBy, Pradeep Nayar (Roll No-24/2009) - Abhishek Kumar (Roll No-13/2009) Rohit Siddhu (Roll No-18/2009)Abhishek KumarNo ratings yet

- Unit - V IemDocument19 pagesUnit - V IemG Hitesh ReddyNo ratings yet

- Total Quality Management - CIM 1115Document28 pagesTotal Quality Management - CIM 1115Raunak GuptaNo ratings yet

- Statistical Process Control SPCDocument3 pagesStatistical Process Control SPCtintucinNo ratings yet

- 4.statistical Process ContorlDocument47 pages4.statistical Process ContorlMinhajul Haque SarkarNo ratings yet

- TQM Unit-3 SQCDocument7 pagesTQM Unit-3 SQCVinayak goswamiNo ratings yet

- Chapter Four Statistical Quality Control (SQC)Document31 pagesChapter Four Statistical Quality Control (SQC)fekadeNo ratings yet

- Statistical Process ControlDocument66 pagesStatistical Process Controlanshuldce50% (2)

- Chapter 5. Methods and Philosophy of Statistical Process ControlDocument36 pagesChapter 5. Methods and Philosophy of Statistical Process ControlBouslaDI Projects TeamNo ratings yet

- In This SectionDocument3 pagesIn This SectionNhư VũNo ratings yet

- Statistical Process ControlDocument29 pagesStatistical Process ControlTushar NaikNo ratings yet

- Rocess Ontrol Tatistical: C C I P P S E EDocument71 pagesRocess Ontrol Tatistical: C C I P P S E EalwaleedrNo ratings yet

- SQCDocument36 pagesSQCMandeep SinghNo ratings yet

- Control ChartsDocument15 pagesControl ChartsArivanandanNo ratings yet

- Control ChartDocument10 pagesControl Chartamelia99No ratings yet

- Operation Management: Role of Statistical Process Control in BusinessDocument9 pagesOperation Management: Role of Statistical Process Control in BusinessSheikh IkramNo ratings yet

- Statistical Quality ControlDocument56 pagesStatistical Quality ControlcmukherjeeNo ratings yet

- SPC Quality OneDocument9 pagesSPC Quality OneElanthendral GNo ratings yet

- Statistical Quality ControlDocument6 pagesStatistical Quality ControlAtish JitekarNo ratings yet

- 5 3 QC Automated Inspection AbkDocument45 pages5 3 QC Automated Inspection Abkfree0332hNo ratings yet

- Chapter 3 - Philosophy of The Shewhart ChartDocument48 pagesChapter 3 - Philosophy of The Shewhart Chartgeletaw mitawNo ratings yet

- Lecture Control Charts 1558081780Document49 pagesLecture Control Charts 1558081780Dahn NguyenNo ratings yet

- Quality Management System DocumentsDocument8 pagesQuality Management System Documentsselinasimpson371No ratings yet

- Control Chart P, NP, C, UDocument64 pagesControl Chart P, NP, C, USakthi Tharan SNo ratings yet

- Assignment 3Document9 pagesAssignment 3api-265324689No ratings yet

- Seven Basic Quality Control ToolDocument7 pagesSeven Basic Quality Control ToolAhmed M. HashimNo ratings yet

- Topic 9.0: Statistical Process Control For Variables DataDocument115 pagesTopic 9.0: Statistical Process Control For Variables Datawong6804No ratings yet

- 21b. Quality AssuranceDocument19 pages21b. Quality AssurancePrashantNo ratings yet

- 4.statistical Process ControlDocument40 pages4.statistical Process ControlTalha Imran100% (1)

- SPC ChartsDocument6 pagesSPC ChartsMichael PhungNo ratings yet

- PPT3-Quality in ProductionDocument55 pagesPPT3-Quality in ProductionK3L PLN WKSKTNo ratings yet

- QC 2 (Control Chart)Document12 pagesQC 2 (Control Chart)Lks ANo ratings yet

- Tedco SPCDocument83 pagesTedco SPCselvamNo ratings yet

- Control ChartsDocument136 pagesControl ChartsSowmya VisinigiriNo ratings yet

- Statistical Process ControlDocument8 pagesStatistical Process ControlSaurabh MishraNo ratings yet

- Control Charts3Document103 pagesControl Charts3Emad EmadNo ratings yet

- O o o O: Control ChartsDocument2 pagesO o o O: Control ChartssusansNo ratings yet

- Lec 5 Variables Control ChartDocument48 pagesLec 5 Variables Control ChartAldwin Angelo Culing MontañezNo ratings yet

- 7 Tools of Statistical Process ControlDocument3 pages7 Tools of Statistical Process ControlSachin Methree100% (1)

- Statistical Process Control: Fqa Lec 5Document31 pagesStatistical Process Control: Fqa Lec 5Shaira Madiline M. GelvezonNo ratings yet

- Statistical Quality ControlDocument23 pagesStatistical Quality Controljoan dueroNo ratings yet

- Control ChartDocument50 pagesControl ChartAnand Dubey0% (1)

- Control Charts: by Praveen GuptaDocument4 pagesControl Charts: by Praveen GuptaKlemen StrušnikNo ratings yet

- Statistical Process ControlDocument24 pagesStatistical Process ControlAnoopa Narayan100% (1)

- Quality Control in Analytical ProcessDocument14 pagesQuality Control in Analytical ProcessFrancis Oche AdahNo ratings yet

- Retail Service Quality ManagementDocument8 pagesRetail Service Quality Managementselinasimpson331No ratings yet

- Unit VDocument130 pagesUnit VJoJa JoJaNo ratings yet

- TQM 8Document22 pagesTQM 8Shahrul AzriNo ratings yet

- Quality Control Tools: ChecksheetDocument3 pagesQuality Control Tools: Checksheetd_senatorNo ratings yet

- Software ProjectDocument5 pagesSoftware ProjectSumana NanjundaiahNo ratings yet

- Process Capability and Statistical Process ControlDocument8 pagesProcess Capability and Statistical Process ControlDeepakh ArunNo ratings yet

- Modeling & System HandoutDocument4 pagesModeling & System HandoutAntelopeNo ratings yet

- Feedback Control of Dynamic Bipedal Robot LocomotionDocument9 pagesFeedback Control of Dynamic Bipedal Robot Locomotiongusaleman100% (1)

- CDS 101/110a: Lecture 9-1 PID Control: Richard M. Murray 24 November 2008Document14 pagesCDS 101/110a: Lecture 9-1 PID Control: Richard M. Murray 24 November 2008cooldoubtlessNo ratings yet

- Slides Powerpoint SCRUM StandardDocument20 pagesSlides Powerpoint SCRUM StandardPatrícia SodréNo ratings yet

- Interacting and Non-Interacting System 18BEI0004: Experiment-1 AimDocument32 pagesInteracting and Non-Interacting System 18BEI0004: Experiment-1 AimGoutham KrishnaNo ratings yet

- Course Outline Handout Soen6481 w2016Document2 pagesCourse Outline Handout Soen6481 w2016picalaNo ratings yet

- Unit 6 SW TestingDocument49 pagesUnit 6 SW TestingPrasad Patil100% (1)

- Process Dynamics and Control PREV PAPERDocument9 pagesProcess Dynamics and Control PREV PAPERNisha TNNo ratings yet

- Dispersive Flies Optimisation PDFDocument6 pagesDispersive Flies Optimisation PDFalgeioNo ratings yet

- Fundamentals of TestingDocument95 pagesFundamentals of TestingAlexandru Si Larisa Serb-Alexe100% (1)

- 6-1LTI Frequency ResponseDocument7 pages6-1LTI Frequency ResponseAhmed RashedNo ratings yet

- Eee 362 (2022) Assignment 2Document4 pagesEee 362 (2022) Assignment 2Chinenye GraceNo ratings yet

- Thermo Module 6Document29 pagesThermo Module 6Royce SumagaysayNo ratings yet

- 2016-1 Advanced Automatic Control Final Exam PDFDocument2 pages2016-1 Advanced Automatic Control Final Exam PDFIslam Saqr67% (3)

- Systems Verification Guide eDocument67 pagesSystems Verification Guide eJim HawkinsNo ratings yet

- Real Time Application of Ants Colony Optimization: Dr.S.M.Girirajkumar Dr.K.Ramkumar Sanjay Sarma O.VDocument13 pagesReal Time Application of Ants Colony Optimization: Dr.S.M.Girirajkumar Dr.K.Ramkumar Sanjay Sarma O.VKarthik BalajiNo ratings yet

- LQR Tuning of Power System Stabilizer For Damping OscillationsDocument18 pagesLQR Tuning of Power System Stabilizer For Damping Oscillations●●●●●●●1100% (1)

- Compensator For Control SystemDocument56 pagesCompensator For Control SystembhaskarNo ratings yet

- Chapter-2 Literature ReviewDocument3 pagesChapter-2 Literature Reviewvscs.1982100% (3)

- Pattern Classification SlideDocument45 pagesPattern Classification SlideTiến QuảngNo ratings yet

- Abhijeet Savkar Software TestingDocument41 pagesAbhijeet Savkar Software TestingAbhijeet SavkarNo ratings yet

- Ee PemdDocument22 pagesEe PemdShovan DeyNo ratings yet

- Controls YsDocument17 pagesControls Ysbamboo shackNo ratings yet

- The Family and Family HealthDocument52 pagesThe Family and Family HealthBhie BhieNo ratings yet

- Software Project Management: Dr. Chaitali Biswas Dutta CSE, SSIPMT, RaipurDocument82 pagesSoftware Project Management: Dr. Chaitali Biswas Dutta CSE, SSIPMT, RaipurAdity chandrakarNo ratings yet

- Se Unit-4-PsuDocument67 pagesSe Unit-4-PsuSpSukumaranNo ratings yet

- Ia Assignment SolutionDocument7 pagesIa Assignment SolutionARJUN SOMAIYANo ratings yet

- Sheet - 01 - Thermodynamics-1Document110 pagesSheet - 01 - Thermodynamics-1IITIANNo ratings yet

- di V iR R L L Mi dt = + + + + ω T Mi =: a a a a se a se a mDocument33 pagesdi V iR R L L Mi dt = + + + + ω T Mi =: a a a a se a se a mMedo SabahNo ratings yet