Professional Documents

Culture Documents

NPSH1

NPSH1

Uploaded by

koyasrujanaCopyright:

Available Formats

You might also like

- Handbook of Ultrasonics and Sonochemistry-C.backesDocument1,485 pagesHandbook of Ultrasonics and Sonochemistry-C.backesDouglas Ribeiro100% (1)

- Pumps (Questions & Answers)Document14 pagesPumps (Questions & Answers)SriRaman Pathakgaru100% (5)

- How To Find Pump Size and Pump Head CalculationDocument8 pagesHow To Find Pump Size and Pump Head CalculationprosperNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- FLARESDocument10 pagesFLARESkoyasrujanaNo ratings yet

- Pumps Design and PerformanceDocument27 pagesPumps Design and PerformanceJefferson SmithNo ratings yet

- Pumps OverviewDocument12 pagesPumps OverviewHesham ZaghloulNo ratings yet

- Centrifugal Pump: Net Positive Suction Head (NPSH)Document4 pagesCentrifugal Pump: Net Positive Suction Head (NPSH)Sohibul Burhan Ar-RosyidNo ratings yet

- Centrifugal PumpsDocument5 pagesCentrifugal PumpsNimesh GunasekeraNo ratings yet

- Pump ReportDocument12 pagesPump ReportHesham Zaghloul100% (1)

- Net Positive Suction HeadDocument2 pagesNet Positive Suction Headanwerosama0% (1)

- Natalie Portmans Shaved Head Glossary of Firefighting Equipment#n Talk PageDocument34 pagesNatalie Portmans Shaved Head Glossary of Firefighting Equipment#n Talk PageMikelaNo ratings yet

- NPSH Is An: Acronym Hydraulic Vapor PressureDocument5 pagesNPSH Is An: Acronym Hydraulic Vapor PressureSantosh Yellappa SulebhavikarNo ratings yet

- PumpsDocument24 pagesPumpsDeva RajNo ratings yet

- Pumping TerminologyDocument3 pagesPumping TerminologymyravganacNo ratings yet

- NPSHDocument5 pagesNPSHmbakhshi2No ratings yet

- PumpDocument196 pagesPumprahul kumar75% (4)

- Pump ADocument172 pagesPump AAdithya VKNo ratings yet

- Pid Presentation 1Document11 pagesPid Presentation 1SahilNo ratings yet

- NPSHA For PumpDocument11 pagesNPSHA For PumpHariharan KandasamyNo ratings yet

- Pump Suction CharacteristicsDocument10 pagesPump Suction Characteristicsvermaakash22No ratings yet

- NPSHDocument1 pageNPSHssabih75No ratings yet

- Boiler Feed PumpDocument46 pagesBoiler Feed Pumppratapsingh12100% (2)

- GPM RevDocument138 pagesGPM RevJuan Cortes TorizNo ratings yet

- NPSH and Specific SpeedDocument16 pagesNPSH and Specific SpeedmyravganacNo ratings yet

- Pump Classifications:: Transportation of FluidsDocument2 pagesPump Classifications:: Transportation of FluidsAvinash GarikapatiNo ratings yet

- ME Lab Activity 2 FinalsDocument3 pagesME Lab Activity 2 FinalsTheo AlapanNo ratings yet

- Libro de BombasDocument260 pagesLibro de BombasBoris SalazarNo ratings yet

- Me151 MidtermsDocument18 pagesMe151 MidtermsJohnNo ratings yet

- Chapter Fluid Machinery - PART 2Document27 pagesChapter Fluid Machinery - PART 2Winter NaiNo ratings yet

- Pump NPSH (Net Positive Suction Head)Document8 pagesPump NPSH (Net Positive Suction Head)farhan_katpar1838No ratings yet

- Basic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)Document42 pagesBasic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)RaduIon100% (2)

- Pumps and CompressorsDocument16 pagesPumps and CompressorsAbc AbcNo ratings yet

- Functions of A PumpDocument178 pagesFunctions of A PumpKetan Sarmalkar50% (2)

- Centrifugal Pumps: What Is A Centrifugal Pump?Document10 pagesCentrifugal Pumps: What Is A Centrifugal Pump?kenoly123No ratings yet

- Net Positive Suction Head or NPSHDocument4 pagesNet Positive Suction Head or NPSHSathish LingamNo ratings yet

- Understanding Net Positive Suction Head - Short Notes For GATE Mechanical EngineeringDocument4 pagesUnderstanding Net Positive Suction Head - Short Notes For GATE Mechanical EngineeringBharat BhushanNo ratings yet

- NPSH For Metering PumpsDocument7 pagesNPSH For Metering PumpsRahul S. ChandrawarNo ratings yet

- Choice of PumpsDocument5 pagesChoice of PumpsShaikh Muhammad WaqasNo ratings yet

- NPSHDocument24 pagesNPSHneerajtrip123100% (1)

- Function of A PumpDocument178 pagesFunction of A Pumpmostafa nabilNo ratings yet

- Melab Act2Document2 pagesMelab Act2Theo AlapanNo ratings yet

- How Does Pump Suction Limit The FlowDocument6 pagesHow Does Pump Suction Limit The FlowNilesh GohelNo ratings yet

- FluidDocument6 pagesFluidMoosa NaseerNo ratings yet

- Pump & Pump PipingDocument55 pagesPump & Pump PipingManan100% (2)

- Pump Head CalculationsDocument4 pagesPump Head CalculationsPrabhjot Singh SahiNo ratings yet

- Classifications of PumpsDocument25 pagesClassifications of PumpsdanishshoaibNo ratings yet

- Fluid Moving MachineriesDocument37 pagesFluid Moving MachineriesJeetendra YadavNo ratings yet

- NPSHDocument3 pagesNPSHsasi636974No ratings yet

- PumpsDocument6 pagesPumpsSalehAfadlehNo ratings yet

- A Centrifugal Pump Converts The Input Power To Kinetic Energy in The Liquid by Accelerating The Liquid by A Revolving DeviceDocument2 pagesA Centrifugal Pump Converts The Input Power To Kinetic Energy in The Liquid by Accelerating The Liquid by A Revolving DeviceAshutosh SharmaNo ratings yet

- 1) Hi Everyone. Today We Start A New Chapter Which Is Dedicated To Pumps. in ThisDocument4 pages1) Hi Everyone. Today We Start A New Chapter Which Is Dedicated To Pumps. in ThisIdris IbrahimovNo ratings yet

- An Introduction To Centrifugal PumpsDocument3 pagesAn Introduction To Centrifugal PumpsCaiyun LimNo ratings yet

- Pressure and Head: Bernoulli EquationDocument2 pagesPressure and Head: Bernoulli EquationAKSHAY AGALAVENo ratings yet

- PumpsDocument36 pagesPumpsIbrahim DewaliNo ratings yet

- Pressure and Head: Bernoulli Equation Affinity LawsDocument3 pagesPressure and Head: Bernoulli Equation Affinity LawsAna Bailey DioNo ratings yet

- Net Positive Suction HeadDocument16 pagesNet Positive Suction HeadpandiangvNo ratings yet

- How To Size A PumpDocument6 pagesHow To Size A PumpSoe T. HtunNo ratings yet

- Npsha Calculations: Liquids Line Sizing CriteriaDocument4 pagesNpsha Calculations: Liquids Line Sizing CriteriaDejan KovačNo ratings yet

- Basics of Centrifugal PumpsDocument60 pagesBasics of Centrifugal PumpsMajid Sattar100% (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Singapore Maths Problem SolutionDocument1 pageSingapore Maths Problem SolutionkoyasrujanaNo ratings yet

- Neem Coated UreaDocument1 pageNeem Coated UreakoyasrujanaNo ratings yet

- Age Limit May Be Raised To 60 YearsDocument2 pagesAge Limit May Be Raised To 60 YearskoyasrujanaNo ratings yet

- 1 Overview of State Public Sector UndertakingsDocument17 pages1 Overview of State Public Sector UndertakingskoyasrujanaNo ratings yet

- Bharata NatyamDocument9 pagesBharata NatyamkoyasrujanaNo ratings yet

- Stress Corrosion Cracking-PTADocument1 pageStress Corrosion Cracking-PTAkoyasrujanaNo ratings yet

- Basis For Emission Calculation From Flare Systems: Scot SmithDocument9 pagesBasis For Emission Calculation From Flare Systems: Scot SmithkoyasrujanaNo ratings yet

- Chemcon 2000Document9 pagesChemcon 2000koyasrujanaNo ratings yet

- General Service (GS) Control ValvesDocument8 pagesGeneral Service (GS) Control ValvesGỗ MộcNo ratings yet

- Ampco Mold Design Guidelines PDFDocument39 pagesAmpco Mold Design Guidelines PDFAjay RaiNo ratings yet

- Pumps and Cooling TowersDocument51 pagesPumps and Cooling TowersMikho SaligueNo ratings yet

- Technological Advancements in Meat Tenderization-A Review: April 2020Document10 pagesTechnological Advancements in Meat Tenderization-A Review: April 2020Noice NoiceNo ratings yet

- Hydraulics I ModuleDocument170 pagesHydraulics I ModuleBiruk AkliluNo ratings yet

- Googlepreview PDFDocument89 pagesGooglepreview PDFFaris FadliNo ratings yet

- Trash Racks Best PracticeDocument17 pagesTrash Racks Best Practicesanbarun100% (2)

- 04 150 MM Borewell Submersible PumpsetDocument23 pages04 150 MM Borewell Submersible PumpsetN ANITHANo ratings yet

- Sistema de Traslado - TextoDocument32 pagesSistema de Traslado - Textolalo11715100% (2)

- Tutorial 17. Modeling Cavitation: PreparationDocument24 pagesTutorial 17. Modeling Cavitation: PreparationVirendra PawarNo ratings yet

- Mechanical Seal Troubleshooting GuideDocument10 pagesMechanical Seal Troubleshooting Guideempswook100% (2)

- Thermal Fluid HeatersDocument166 pagesThermal Fluid Heatersbornluky100% (1)

- (Ed01-2019) M2000-M3000 Main ValveDocument24 pages(Ed01-2019) M2000-M3000 Main ValveMirhad PjanićNo ratings yet

- Handout 4b Alat Transfer Fluida 1 PompaDocument51 pagesHandout 4b Alat Transfer Fluida 1 PompadeniNo ratings yet

- 2018catalogue PDFDocument44 pages2018catalogue PDFRahman RahmmanNo ratings yet

- PumpsDocument80 pagesPumpsMuhammad Nursalam100% (1)

- SchineiderDocument12 pagesSchineiderguipimentelNo ratings yet

- Main Principles of Pumps SelectionDocument20 pagesMain Principles of Pumps SelectionRaj KamalNo ratings yet

- Propeller Fitting InstructionsDocument7 pagesPropeller Fitting Instructionsrubens0001No ratings yet

- Ultrasonics Sonochemistry: Xiangning Bu, Muidh AlheshibriDocument11 pagesUltrasonics Sonochemistry: Xiangning Bu, Muidh AlheshibriatulhbariNo ratings yet

- All System Pump Head LoosDocument33 pagesAll System Pump Head LoosEngFaisal Alrai100% (1)

- Transient - Chapter 11 - Advanced TopicsDocument181 pagesTransient - Chapter 11 - Advanced TopicsPasquale CutriNo ratings yet

- Cavitation NotesDocument12 pagesCavitation NotesrajeevNo ratings yet

- 4 Forensic Engineering - Metallurgical Failure AnalysisDocument30 pages4 Forensic Engineering - Metallurgical Failure AnalysisJOSE ANTONIO FRAUSTO ESPARZANo ratings yet

- 325 Lanzhou 3NB1300C Instruction Manual PDFDocument21 pages325 Lanzhou 3NB1300C Instruction Manual PDFOilGasManNo ratings yet

- 3D Numerical Simulation of Horizontal Split Casing Pump: Conference PaperDocument11 pages3D Numerical Simulation of Horizontal Split Casing Pump: Conference PaperAhmed ShawkiNo ratings yet

- Centrifugal Pump PipingDocument22 pagesCentrifugal Pump PipingBhupender Sharma100% (3)

- Ship Hydrodynamics Lecture Notes Part 8 Propeller TestsDocument12 pagesShip Hydrodynamics Lecture Notes Part 8 Propeller TestsManoj NalliNo ratings yet

- BS 6683 (1985) Installation and Use of ValvesDocument18 pagesBS 6683 (1985) Installation and Use of Valves김창배No ratings yet

NPSH1

NPSH1

Uploaded by

koyasrujanaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NPSH1

NPSH1

Uploaded by

koyasrujanaCopyright:

Available Formats

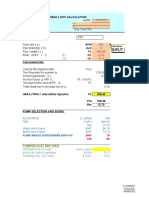

It is a function of the pump design and is determined based on actual pump test by the vendor.

As the liquid passes from the pump suction to the eye of the impeller, the velocity increases and the pressure decreases. There are also pressure losses due to shock and turbulence as the liquid strikes the impeller. The centrifugal force of the impeller vanes further increases the velocity and decreases the pressure of the liquid. The NPSH required is the positive head in feet absolute required at the pump suction to overcome these pressure drops in the pump and maintain the majority of the liquid above its vapor pressure.

The NPSH required varies with speed and capacity within any particular pump. The NPSH required increase as the capacity is increasing because the velocity of the liquid is increasing, and as anytime the velocity of a liquid goes up, the pressure or head comes down. Pump manufacturer's curves normally provide this information.

Net Positive Suction Head Available is a function of the system in which the pump operates. It is the excess pressure of the liquid absolute over its vapor pressure as it arrives at the pump suction, to be sure that the pump selected does not cavitate. It is calculated based on system or process conditions NPSHa must be greater than NPSHr to avoid CAVITATION

Understanding the significance of NPSH is very much essential during installation as well as operation of the pumps. Rise in temperature and fall in pressure induces vaporization NPSH Is a measure to prevent liquid vaporization Net Positive Suction Head (NPSH) is the total head at the suction flange of the pump less the vapor pressure converted to fluid column height of the liquid.

NPSH AVAILABLE=Fluid surface pressure + positive head pipework friction loss fluid vapour pressure

or

=Fluid surface pressure - negative head pipework friction loss fluid vapour pressure

Redesign the suction pipework to eliminate bends, valves and fittings where possible. Raise the height of the fluid container. Control the temperature to make sure the vapor pressure doesnt get too high. Often tanks and pipes holding high vapor pressure liquids are painted light colors to avoid the sun heating them and raising the vapor pressure.

As the liquid flows onto the impeller of the pump it is accelerated and initially its pressure falls (Bernoulli). The pressure subsequently increases as the fluid leaves the impeller and as the kinetic energy is recovered in the volute chamber. If the pressure of the liquid falls below the vapour pressure, Pv, the liquid boils, generating vapour bubbles or cavities-cavitation. The bubbles are swept into higher pressure regions by the liquid flow, where they collapse creating pressure waves and cause mechanical damage to solid surfaces. Moreover, pump discharge head is reduced at flow rates above the cavitation point. Operation under these conditions is not desirable and damages the equipment.

You might also like

- Handbook of Ultrasonics and Sonochemistry-C.backesDocument1,485 pagesHandbook of Ultrasonics and Sonochemistry-C.backesDouglas Ribeiro100% (1)

- Pumps (Questions & Answers)Document14 pagesPumps (Questions & Answers)SriRaman Pathakgaru100% (5)

- How To Find Pump Size and Pump Head CalculationDocument8 pagesHow To Find Pump Size and Pump Head CalculationprosperNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- FLARESDocument10 pagesFLARESkoyasrujanaNo ratings yet

- Pumps Design and PerformanceDocument27 pagesPumps Design and PerformanceJefferson SmithNo ratings yet

- Pumps OverviewDocument12 pagesPumps OverviewHesham ZaghloulNo ratings yet

- Centrifugal Pump: Net Positive Suction Head (NPSH)Document4 pagesCentrifugal Pump: Net Positive Suction Head (NPSH)Sohibul Burhan Ar-RosyidNo ratings yet

- Centrifugal PumpsDocument5 pagesCentrifugal PumpsNimesh GunasekeraNo ratings yet

- Pump ReportDocument12 pagesPump ReportHesham Zaghloul100% (1)

- Net Positive Suction HeadDocument2 pagesNet Positive Suction Headanwerosama0% (1)

- Natalie Portmans Shaved Head Glossary of Firefighting Equipment#n Talk PageDocument34 pagesNatalie Portmans Shaved Head Glossary of Firefighting Equipment#n Talk PageMikelaNo ratings yet

- NPSH Is An: Acronym Hydraulic Vapor PressureDocument5 pagesNPSH Is An: Acronym Hydraulic Vapor PressureSantosh Yellappa SulebhavikarNo ratings yet

- PumpsDocument24 pagesPumpsDeva RajNo ratings yet

- Pumping TerminologyDocument3 pagesPumping TerminologymyravganacNo ratings yet

- NPSHDocument5 pagesNPSHmbakhshi2No ratings yet

- PumpDocument196 pagesPumprahul kumar75% (4)

- Pump ADocument172 pagesPump AAdithya VKNo ratings yet

- Pid Presentation 1Document11 pagesPid Presentation 1SahilNo ratings yet

- NPSHA For PumpDocument11 pagesNPSHA For PumpHariharan KandasamyNo ratings yet

- Pump Suction CharacteristicsDocument10 pagesPump Suction Characteristicsvermaakash22No ratings yet

- NPSHDocument1 pageNPSHssabih75No ratings yet

- Boiler Feed PumpDocument46 pagesBoiler Feed Pumppratapsingh12100% (2)

- GPM RevDocument138 pagesGPM RevJuan Cortes TorizNo ratings yet

- NPSH and Specific SpeedDocument16 pagesNPSH and Specific SpeedmyravganacNo ratings yet

- Pump Classifications:: Transportation of FluidsDocument2 pagesPump Classifications:: Transportation of FluidsAvinash GarikapatiNo ratings yet

- ME Lab Activity 2 FinalsDocument3 pagesME Lab Activity 2 FinalsTheo AlapanNo ratings yet

- Libro de BombasDocument260 pagesLibro de BombasBoris SalazarNo ratings yet

- Me151 MidtermsDocument18 pagesMe151 MidtermsJohnNo ratings yet

- Chapter Fluid Machinery - PART 2Document27 pagesChapter Fluid Machinery - PART 2Winter NaiNo ratings yet

- Pump NPSH (Net Positive Suction Head)Document8 pagesPump NPSH (Net Positive Suction Head)farhan_katpar1838No ratings yet

- Basic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)Document42 pagesBasic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)RaduIon100% (2)

- Pumps and CompressorsDocument16 pagesPumps and CompressorsAbc AbcNo ratings yet

- Functions of A PumpDocument178 pagesFunctions of A PumpKetan Sarmalkar50% (2)

- Centrifugal Pumps: What Is A Centrifugal Pump?Document10 pagesCentrifugal Pumps: What Is A Centrifugal Pump?kenoly123No ratings yet

- Net Positive Suction Head or NPSHDocument4 pagesNet Positive Suction Head or NPSHSathish LingamNo ratings yet

- Understanding Net Positive Suction Head - Short Notes For GATE Mechanical EngineeringDocument4 pagesUnderstanding Net Positive Suction Head - Short Notes For GATE Mechanical EngineeringBharat BhushanNo ratings yet

- NPSH For Metering PumpsDocument7 pagesNPSH For Metering PumpsRahul S. ChandrawarNo ratings yet

- Choice of PumpsDocument5 pagesChoice of PumpsShaikh Muhammad WaqasNo ratings yet

- NPSHDocument24 pagesNPSHneerajtrip123100% (1)

- Function of A PumpDocument178 pagesFunction of A Pumpmostafa nabilNo ratings yet

- Melab Act2Document2 pagesMelab Act2Theo AlapanNo ratings yet

- How Does Pump Suction Limit The FlowDocument6 pagesHow Does Pump Suction Limit The FlowNilesh GohelNo ratings yet

- FluidDocument6 pagesFluidMoosa NaseerNo ratings yet

- Pump & Pump PipingDocument55 pagesPump & Pump PipingManan100% (2)

- Pump Head CalculationsDocument4 pagesPump Head CalculationsPrabhjot Singh SahiNo ratings yet

- Classifications of PumpsDocument25 pagesClassifications of PumpsdanishshoaibNo ratings yet

- Fluid Moving MachineriesDocument37 pagesFluid Moving MachineriesJeetendra YadavNo ratings yet

- NPSHDocument3 pagesNPSHsasi636974No ratings yet

- PumpsDocument6 pagesPumpsSalehAfadlehNo ratings yet

- A Centrifugal Pump Converts The Input Power To Kinetic Energy in The Liquid by Accelerating The Liquid by A Revolving DeviceDocument2 pagesA Centrifugal Pump Converts The Input Power To Kinetic Energy in The Liquid by Accelerating The Liquid by A Revolving DeviceAshutosh SharmaNo ratings yet

- 1) Hi Everyone. Today We Start A New Chapter Which Is Dedicated To Pumps. in ThisDocument4 pages1) Hi Everyone. Today We Start A New Chapter Which Is Dedicated To Pumps. in ThisIdris IbrahimovNo ratings yet

- An Introduction To Centrifugal PumpsDocument3 pagesAn Introduction To Centrifugal PumpsCaiyun LimNo ratings yet

- Pressure and Head: Bernoulli EquationDocument2 pagesPressure and Head: Bernoulli EquationAKSHAY AGALAVENo ratings yet

- PumpsDocument36 pagesPumpsIbrahim DewaliNo ratings yet

- Pressure and Head: Bernoulli Equation Affinity LawsDocument3 pagesPressure and Head: Bernoulli Equation Affinity LawsAna Bailey DioNo ratings yet

- Net Positive Suction HeadDocument16 pagesNet Positive Suction HeadpandiangvNo ratings yet

- How To Size A PumpDocument6 pagesHow To Size A PumpSoe T. HtunNo ratings yet

- Npsha Calculations: Liquids Line Sizing CriteriaDocument4 pagesNpsha Calculations: Liquids Line Sizing CriteriaDejan KovačNo ratings yet

- Basics of Centrifugal PumpsDocument60 pagesBasics of Centrifugal PumpsMajid Sattar100% (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Singapore Maths Problem SolutionDocument1 pageSingapore Maths Problem SolutionkoyasrujanaNo ratings yet

- Neem Coated UreaDocument1 pageNeem Coated UreakoyasrujanaNo ratings yet

- Age Limit May Be Raised To 60 YearsDocument2 pagesAge Limit May Be Raised To 60 YearskoyasrujanaNo ratings yet

- 1 Overview of State Public Sector UndertakingsDocument17 pages1 Overview of State Public Sector UndertakingskoyasrujanaNo ratings yet

- Bharata NatyamDocument9 pagesBharata NatyamkoyasrujanaNo ratings yet

- Stress Corrosion Cracking-PTADocument1 pageStress Corrosion Cracking-PTAkoyasrujanaNo ratings yet

- Basis For Emission Calculation From Flare Systems: Scot SmithDocument9 pagesBasis For Emission Calculation From Flare Systems: Scot SmithkoyasrujanaNo ratings yet

- Chemcon 2000Document9 pagesChemcon 2000koyasrujanaNo ratings yet

- General Service (GS) Control ValvesDocument8 pagesGeneral Service (GS) Control ValvesGỗ MộcNo ratings yet

- Ampco Mold Design Guidelines PDFDocument39 pagesAmpco Mold Design Guidelines PDFAjay RaiNo ratings yet

- Pumps and Cooling TowersDocument51 pagesPumps and Cooling TowersMikho SaligueNo ratings yet

- Technological Advancements in Meat Tenderization-A Review: April 2020Document10 pagesTechnological Advancements in Meat Tenderization-A Review: April 2020Noice NoiceNo ratings yet

- Hydraulics I ModuleDocument170 pagesHydraulics I ModuleBiruk AkliluNo ratings yet

- Googlepreview PDFDocument89 pagesGooglepreview PDFFaris FadliNo ratings yet

- Trash Racks Best PracticeDocument17 pagesTrash Racks Best Practicesanbarun100% (2)

- 04 150 MM Borewell Submersible PumpsetDocument23 pages04 150 MM Borewell Submersible PumpsetN ANITHANo ratings yet

- Sistema de Traslado - TextoDocument32 pagesSistema de Traslado - Textolalo11715100% (2)

- Tutorial 17. Modeling Cavitation: PreparationDocument24 pagesTutorial 17. Modeling Cavitation: PreparationVirendra PawarNo ratings yet

- Mechanical Seal Troubleshooting GuideDocument10 pagesMechanical Seal Troubleshooting Guideempswook100% (2)

- Thermal Fluid HeatersDocument166 pagesThermal Fluid Heatersbornluky100% (1)

- (Ed01-2019) M2000-M3000 Main ValveDocument24 pages(Ed01-2019) M2000-M3000 Main ValveMirhad PjanićNo ratings yet

- Handout 4b Alat Transfer Fluida 1 PompaDocument51 pagesHandout 4b Alat Transfer Fluida 1 PompadeniNo ratings yet

- 2018catalogue PDFDocument44 pages2018catalogue PDFRahman RahmmanNo ratings yet

- PumpsDocument80 pagesPumpsMuhammad Nursalam100% (1)

- SchineiderDocument12 pagesSchineiderguipimentelNo ratings yet

- Main Principles of Pumps SelectionDocument20 pagesMain Principles of Pumps SelectionRaj KamalNo ratings yet

- Propeller Fitting InstructionsDocument7 pagesPropeller Fitting Instructionsrubens0001No ratings yet

- Ultrasonics Sonochemistry: Xiangning Bu, Muidh AlheshibriDocument11 pagesUltrasonics Sonochemistry: Xiangning Bu, Muidh AlheshibriatulhbariNo ratings yet

- All System Pump Head LoosDocument33 pagesAll System Pump Head LoosEngFaisal Alrai100% (1)

- Transient - Chapter 11 - Advanced TopicsDocument181 pagesTransient - Chapter 11 - Advanced TopicsPasquale CutriNo ratings yet

- Cavitation NotesDocument12 pagesCavitation NotesrajeevNo ratings yet

- 4 Forensic Engineering - Metallurgical Failure AnalysisDocument30 pages4 Forensic Engineering - Metallurgical Failure AnalysisJOSE ANTONIO FRAUSTO ESPARZANo ratings yet

- 325 Lanzhou 3NB1300C Instruction Manual PDFDocument21 pages325 Lanzhou 3NB1300C Instruction Manual PDFOilGasManNo ratings yet

- 3D Numerical Simulation of Horizontal Split Casing Pump: Conference PaperDocument11 pages3D Numerical Simulation of Horizontal Split Casing Pump: Conference PaperAhmed ShawkiNo ratings yet

- Centrifugal Pump PipingDocument22 pagesCentrifugal Pump PipingBhupender Sharma100% (3)

- Ship Hydrodynamics Lecture Notes Part 8 Propeller TestsDocument12 pagesShip Hydrodynamics Lecture Notes Part 8 Propeller TestsManoj NalliNo ratings yet

- BS 6683 (1985) Installation and Use of ValvesDocument18 pagesBS 6683 (1985) Installation and Use of Valves김창배No ratings yet