Professional Documents

Culture Documents

Roh Boxn

Roh Boxn

Uploaded by

arun13Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roh Boxn

Roh Boxn

Uploaded by

arun13Copyright:

Available Formats

Major activities for ROH of BOXN wagon

1. All activities of Intensive examination 2. Check & rectify corrosions of the side wall skirting

3. Check & rectify cracks in side pillar

4. Patch body, roof, door, floor plate etc 5. Straighten buldged ends 6. Repair Angle irons, stanchions, crib angles etc 7. Maintain CASNUB bogie dimensions

8. Check airbrake system with SWTR

9. Clean dirt collector

10. Change rubber seal of angle cock, dirt collector 11. Change MU washer 12. Change rubber seals in main pipes and branch pipes 13. Check coupler body 14. Check CBC contour

15. Check Knuckle nose

16. Check Knuckle stretch 17. Examine lock in coupler mechanism

18. Check draft gear for stucking

19. Check draft gear pocket clearance

MAINTAINING CASNUB BOGIE COMPONENT DIMENSION

BOLSTER Check slope pocket liner, replace when < 5 mm Check rotation stop lug, replace liner when < 514 mm Check Inner column gib, replace liner when >142 mm

Check land surface, replace liner when < 442 mm

Check outer column, renew by welding >241 mm

Maintaining CASNUB bogie component dimension contd 2. SIDE FRAME Check friction column, replace liner when > 455 mm Check column side, replace liner when < 209 mm Check anti rotation lug, replace liner when > 426 mm

Check key seat to pedestal, replace liner when > 276 mm

Check Crown roof, replace liner when for

22WM > 321 mm

22NL > 321 mm

Maintaining CASNUB bogie component dimension contd

Check Pedestal crown, renew by welding when > 147 mm Check pedestal jaw, replace liner when for

22W > 275 mm

22WM > 283 mm NLS > 195 mm NLL > 241 mm Check pedestal sides, replace liner when for

22W & 22WM < 102 mm

NL < 78mm

Maintaining CASNUB bogie component dimension contd

WEDGE Check slope surface, renew by welding < 7 mm

Check vertical surface from center line of spigot, replace liner when< 56 mm

CENTER PIVOT BOTTOM

Check vertical side, renew by welding when wear for

22W > 4mm 22WM, NL > 3 mm Check seat side, renew by welding when wear > 3 mm

Maintaining CASNUB bogie component dimension contd

ADAPTER Check crown surface, replace if worn reaches to relief depth

Check side lug

Check thrust shoulder, replace if depth > 0.7mm Check machined relief, replace if depth > 0.8mm

COIL SPRING

Replace Outer spring when free height < 245 mm Replace Inner spring when free height < 247 mm Replace Snubber spring when free height < 279 mm

Maintaining CASNUB bogie component dimension contd WHEEL &AXLE and BEARING Check axle by ultrasonic test Clean & lubricate axle end holes Turn wheel to WWP Check bearing for unusual sound, external damage, loose backing ring, vent plug Replace locking plate Clean & lubricate axle end cap screw Change load zone area of cup

You might also like

- 2 - Ford Bantam Wiring DiagramsDocument296 pages2 - Ford Bantam Wiring DiagramsLouis Lion63% (16)

- Service Manual 157QMJDocument60 pagesService Manual 157QMJGeert Verfaillie67% (3)

- Z 18 XerDocument34 pagesZ 18 XerGlbrt Elizondo100% (3)

- Vauxhall Workshop Manuals Astra H J Engine and Engine Aggregates DOHC Petrol Engine Cylinder Head Repair Instructions Valve Lash - Petrol Engine Check and Adjust PDFDocument26 pagesVauxhall Workshop Manuals Astra H J Engine and Engine Aggregates DOHC Petrol Engine Cylinder Head Repair Instructions Valve Lash - Petrol Engine Check and Adjust PDFSean Osborne0% (1)

- Kiwiprop K4 Boss Assembly v2.4Document15 pagesKiwiprop K4 Boss Assembly v2.4adul sungkatinNo ratings yet

- Omm BW211D-40Document146 pagesOmm BW211D-40Jaybs GregorioNo ratings yet

- Engine Overhauling AssignmentDocument11 pagesEngine Overhauling AssignmentSabeeh Safdar100% (1)

- GSX1400 Manual Section 2 Periodic MaintenanceDocument28 pagesGSX1400 Manual Section 2 Periodic MaintenanceDeaferrant100% (1)

- Purifier OverhaulDocument27 pagesPurifier OverhaulMedha Jog KatdareNo ratings yet

- J Valve MaintenanceDocument76 pagesJ Valve Maintenancepatriarca28No ratings yet

- Bs Genuine Parts CatalogueDocument114 pagesBs Genuine Parts Cataloguearies2006100% (1)

- Reciprocating Compressor ? MaintenanceDocument54 pagesReciprocating Compressor ? MaintenancemanavjamespunnokaranNo ratings yet

- Exhaust Valve Overhaul (Two Stroke Engine)Document19 pagesExhaust Valve Overhaul (Two Stroke Engine)غازي عليNo ratings yet

- Quality Audit Check Sheet For Wagon DepotDocument32 pagesQuality Audit Check Sheet For Wagon Depotmukesh_singh_16100% (2)

- SIHI Thermal Fluid Circulating PumpDocument11 pagesSIHI Thermal Fluid Circulating Pumpwilmer fernando lopez galeanoNo ratings yet

- Prop Rem & InstallDocument20 pagesProp Rem & InstallamilaNo ratings yet

- HYDRO Inspection SM 0052 Power Point 11-12-2015Document28 pagesHYDRO Inspection SM 0052 Power Point 11-12-2015EdsonLuizPoleselloNo ratings yet

- Cy - Head 2strokeDocument33 pagesCy - Head 2strokeغازي عليNo ratings yet

- 1113 Maintenance of PRVDocument63 pages1113 Maintenance of PRVhardito sussatrioNo ratings yet

- Inspection of Heat ExchangerDocument82 pagesInspection of Heat ExchangerBalaji VenkatesanNo ratings yet

- Project Title-Design &fabrication of Compressed Air EngineDocument11 pagesProject Title-Design &fabrication of Compressed Air EngineTitus KPNo ratings yet

- Bha and Drilling Parameters Design For Deviation Control in Menengai Directional WellsDocument20 pagesBha and Drilling Parameters Design For Deviation Control in Menengai Directional WellsJose Manuel Lezama SantaellaNo ratings yet

- Well CompletionDocument40 pagesWell CompletionSunny ChaubeyNo ratings yet

- Chapter 7 DisassemblyDocument16 pagesChapter 7 DisassemblyVermel ColiNo ratings yet

- Clutch Overhaul: Group 21BDocument12 pagesClutch Overhaul: Group 21BChris TrivettNo ratings yet

- Sasiu2 Suzuki VL800Document20 pagesSasiu2 Suzuki VL800Crisan SorinNo ratings yet

- Trial Assembly and Erection of Open Web GirdersDocument35 pagesTrial Assembly and Erection of Open Web GirdersJeyakumar JamesNo ratings yet

- Inspection of Heat ExchangerDocument83 pagesInspection of Heat ExchangerRaghavan100% (2)

- Sop Consolidated (Revision 2019)Document456 pagesSop Consolidated (Revision 2019)Siddhartha ChakradharNo ratings yet

- Tomoe General CatalogDocument508 pagesTomoe General CatalogArianto SutarnioNo ratings yet

- Headstock Bearing Adjustment "Read Carefully"Document2 pagesHeadstock Bearing Adjustment "Read Carefully"scimtecNo ratings yet

- Workshop ProcedureDocument29 pagesWorkshop ProcedureAnil GhagreNo ratings yet

- PEM ManualDocument52 pagesPEM Manualagkrishnaroop007No ratings yet

- Maintenance Operating and Service ManualDocument16 pagesMaintenance Operating and Service ManualsaritasohamNo ratings yet

- ST - MaintenanceDocument26 pagesST - MaintenanceHayderr Hass100% (1)

- Manual Repair Nissan QuestDocument18 pagesManual Repair Nissan QuestALONDRA NATALI GONAZLEZ CANCHENo ratings yet

- Maintenance of Piston, Piston Rings & Cyl HeadDocument12 pagesMaintenance of Piston, Piston Rings & Cyl HeadAnik Das 8040No ratings yet

- Valves SpecsDocument38 pagesValves Specsprabhu_jay23No ratings yet

- Engine construction2Document68 pagesEngine construction2Hemanth SNo ratings yet

- S.No Remarks Description of WorkDocument21 pagesS.No Remarks Description of Workrizviabbas2012No ratings yet

- Fabrication SetupDocument47 pagesFabrication SetupGamble100% (2)

- Camshaft Inspection (4JJ1 (Euro4 Specification) )Document4 pagesCamshaft Inspection (4JJ1 (Euro4 Specification) )Edwin GilNo ratings yet

- An Introduction To Drilling: Akshat Tarate Summer Trainee New Builds Division - EOSILDocument54 pagesAn Introduction To Drilling: Akshat Tarate Summer Trainee New Builds Division - EOSILAkshat Tarate100% (1)

- ZAMA Carburetor ServiceDocument5 pagesZAMA Carburetor ServiceJEF GRAY100% (1)

- Lecture On Workshops in Industry Rev 1Document60 pagesLecture On Workshops in Industry Rev 1Anoop SharmaNo ratings yet

- Ball Valves: Sharma MVSRK 15 October 2013Document49 pagesBall Valves: Sharma MVSRK 15 October 2013Jay Ganta100% (2)

- Pistons and Conrods Skoda PetrolDocument3 pagesPistons and Conrods Skoda Petrolfrancismci92No ratings yet

- Third Engineer To Second Engineer Mentoring Program: Name:Abhijith Sreevalsan PillaiDocument42 pagesThird Engineer To Second Engineer Mentoring Program: Name:Abhijith Sreevalsan PillaiAbhijith Sreevalsan PillaiNo ratings yet

- Third Engineer To Second Engineer Mentoring Program: Name:Abhijith Sreevalsan PillaiDocument42 pagesThird Engineer To Second Engineer Mentoring Program: Name:Abhijith Sreevalsan PillaiAbhijith Sreevalsan PillaiNo ratings yet

- Cylinder Block - Repair ProcedurDocument34 pagesCylinder Block - Repair Procedurfebri yulianto100% (1)

- Tube Bending SeminarDocument48 pagesTube Bending Seminarhopkhtn100% (1)

- Maintenance of Machine Tools: Dr.K.ElangovanDocument15 pagesMaintenance of Machine Tools: Dr.K.ElangovanHaitham MohammadNo ratings yet

- Icf BogieDocument50 pagesIcf BogieCbabu Pull100% (1)

- Pedestal Crane Student ManualDocument25 pagesPedestal Crane Student ManualDangtrinh Nguyen100% (1)

- Injection Nozzels PDFDocument25 pagesInjection Nozzels PDFMoaed KanbarNo ratings yet

- Fabrication of Gates & Hoists PDFDocument242 pagesFabrication of Gates & Hoists PDFshy_foeNo ratings yet

- Thaioil WOOD High Pressure Heat Exchangers - Conventional 'D' Type Channel V Breech LockDocument29 pagesThaioil WOOD High Pressure Heat Exchangers - Conventional 'D' Type Channel V Breech LockPranpath NarupantawartNo ratings yet

- Maintenance On Unit 5Document10 pagesMaintenance On Unit 5Mazhar UddeenNo ratings yet

- PumpmaintenanceDocument35 pagesPumpmaintenanceAltamash TamboliNo ratings yet

- 150 Carburetor Service GuideDocument5 pages150 Carburetor Service GuideGustavo RodríguezNo ratings yet

- Tech RefDocument188 pagesTech RefJithin Rajan JosephNo ratings yet

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Track BookDocument4 pagesTrack Bookarun13No ratings yet

- Aaurved Ka Brihad ItihasDocument719 pagesAaurved Ka Brihad Itihasarun13No ratings yet

- DefectsInWheelsAndAxlesAndDetection (176 180) PDFDocument5 pagesDefectsInWheelsAndAxlesAndDetection (176 180) PDFarun13No ratings yet

- Revised IRCA Part-III FinalDocument296 pagesRevised IRCA Part-III Finalarun13100% (7)

- English Books ExcellDocument190 pagesEnglish Books Excellarun130% (1)

- 1 Development of An Innovative Wheel Material For High Speed Service - Andrea Ghidini, Francesco LomDocument14 pages1 Development of An Innovative Wheel Material For High Speed Service - Andrea Ghidini, Francesco Lomarun13No ratings yet

- Master Circular 67Document24 pagesMaster Circular 67arun13No ratings yet

- Revised Wagon Maintenance ManualDocument604 pagesRevised Wagon Maintenance Manualarun1389% (9)

- Al Wisk Acca YanaDocument287 pagesAl Wisk Acca Yanaarun13No ratings yet

- Peer Nabalik (1953) PDFDocument125 pagesPeer Nabalik (1953) PDFarun13No ratings yet

- Homeopathy P F CurieDocument300 pagesHomeopathy P F Curiearun13No ratings yet

- Loco GuideDocument444 pagesLoco Guidearun13No ratings yet

- Nawab NankuDocument237 pagesNawab Nankuarun13No ratings yet

- DAV Dharam ShikshakDocument740 pagesDAV Dharam Shikshakarun13No ratings yet

- Sanjiivanii VidyaDocument134 pagesSanjiivanii Vidyaarun1375% (4)

- Havan MantrDocument70 pagesHavan Mantrarun13100% (1)

- Vendor Directory - July 2013Document206 pagesVendor Directory - July 2013arun13No ratings yet

- Francis CrickDocument5 pagesFrancis Crickarun13No ratings yet

- DAV Dharam ShikshakDocument740 pagesDAV Dharam Shikshakarun13No ratings yet

- Functional Requirement Specification For C P Liner - EOI WD-04-2012Document6 pagesFunctional Requirement Specification For C P Liner - EOI WD-04-2012arun13No ratings yet

- Investigation DerailmentDocument353 pagesInvestigation Derailmentarun130% (1)

- Rail Business Issue March 11Document40 pagesRail Business Issue March 11arun13100% (1)

- 10 Facts You Must Know BeforeDocument13 pages10 Facts You Must Know Beforearun13100% (1)

- Assistance Required For M&P Installed at WMU/ WCC/TKDDocument2 pagesAssistance Required For M&P Installed at WMU/ WCC/TKDarun13No ratings yet

- 16 Facts StrengthenyourlifeDocument20 pages16 Facts Strengthenyourlifearun13No ratings yet

- DS404 5PDocument44 pagesDS404 5PAntony Moreno100% (1)

- 7 November 2014Document15 pages7 November 2014syamsuri samNo ratings yet

- HC110Document13 pagesHC110rustamriyadiNo ratings yet

- 4 - Storey Residential Building Pandacan ManilaDocument2 pages4 - Storey Residential Building Pandacan ManilaFlorido MolejonNo ratings yet

- 10 Mechanical Equipment, Attachment PDFDocument8 pages10 Mechanical Equipment, Attachment PDFPeter BrickNo ratings yet

- 4058 Manufacturing Lab IIDocument15 pages4058 Manufacturing Lab IIBiswadeep Roy ChoudhuryNo ratings yet

- Annual Book of ASTM Standards Vol 1003 ElectricalDocument2 pagesAnnual Book of ASTM Standards Vol 1003 ElectricalminhyNo ratings yet

- J-UnitCryogenicSealingSystem E00623 PDFDocument4 pagesJ-UnitCryogenicSealingSystem E00623 PDF백종수No ratings yet

- SSL & CTLDocument27 pagesSSL & CTLSergio GabrielNo ratings yet

- Climatronic 1.6 ltr.-74 KW Simos, Engine Code AEH, 1.6 ltr.-74 KW Simos, Engine Code AKL PDFDocument8 pagesClimatronic 1.6 ltr.-74 KW Simos, Engine Code AEH, 1.6 ltr.-74 KW Simos, Engine Code AKL PDFAlex SinatoviciNo ratings yet

- RAV2001-BE1009 0 1 ElectricalWiringDiagramCLA20Document58 pagesRAV2001-BE1009 0 1 ElectricalWiringDiagramCLA20Roberto Bianconi100% (1)

- Power Steering Pump, Reservoir & Related Parts, 3400, 3500, 4400 & 4410 (65!4!70)Document6 pagesPower Steering Pump, Reservoir & Related Parts, 3400, 3500, 4400 & 4410 (65!4!70)Denzil JeanesNo ratings yet

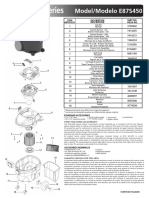

- E87 Series: Model/Modelo E87S450Document1 pageE87 Series: Model/Modelo E87S450José Luis Gómez JiménezNo ratings yet

- 7042 GL SpecDocument1 page7042 GL Specbkprice14No ratings yet

- History: Single-Stage Gear ReducerDocument3 pagesHistory: Single-Stage Gear ReducerZanbeelNo ratings yet

- FS1325A-R CNC RouterDocument6 pagesFS1325A-R CNC RouterBengkel WojojoyoNo ratings yet

- Thunderbird 500 XDocument134 pagesThunderbird 500 XArjun SureshNo ratings yet

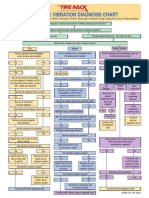

- Vibration ChartDocument1 pageVibration Chartairframer1981No ratings yet

- Workshopmanual - vf750 - Sabre Magna - 1982 1988 19022021 1225Document248 pagesWorkshopmanual - vf750 - Sabre Magna - 1982 1988 19022021 1225Grupo GatroNo ratings yet

- 42NQV050 060 SVMDocument102 pages42NQV050 060 SVMRob KoopmanNo ratings yet

- Flow Setari RegulatorDocument1 pageFlow Setari RegulatorMichael DavenportNo ratings yet

- 50 90ZV 2 - KCM600 08 2006 00 (9 07 830am)Document166 pages50 90ZV 2 - KCM600 08 2006 00 (9 07 830am)Halil Kara100% (1)

- Engine Repair ILT Participant GuideDocument15 pagesEngine Repair ILT Participant Guidejordan navarroNo ratings yet

- Bolt Tightening SolutionDocument64 pagesBolt Tightening SolutiondiahNo ratings yet

- Compressor System Control LogicDocument26 pagesCompressor System Control Logicman_y2kNo ratings yet

- Manual Godman Uidad PaqueteDocument24 pagesManual Godman Uidad PaqueteNaomi SandovalNo ratings yet

- Group 2 Main Control Valve: 1. StructureDocument23 pagesGroup 2 Main Control Valve: 1. StructureАлексейNo ratings yet