Professional Documents

Culture Documents

Fire Resistive Materials: Adhesion

Fire Resistive Materials: Adhesion

Uploaded by

Chethan RaviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Resistive Materials: Adhesion

Fire Resistive Materials: Adhesion

Uploaded by

Chethan RaviCopyright:

Available Formats

Fire Resistive Materials:

Adhesion

Performance Assessment and Optimization

of Fire Resistive Materials

NIST

July 14, 2005

Microstructure

Experimental

3-D Tomography

2-D optical, SEM

Confocal microscopy

Modeling

3-D Reconstruction

Parameters

Porosity

Pore Sizes

Contact Areas

Properties

(all as a function of T)

Thermal

Heat Capacity

Conductivity

Density

Heats of Reaction

Adhesion

Pull-off strength

Peel strength

Adhesion energy

Fracture toughness

Equipment

TGA/DSC/STA

Slug calorimeter

Dilatometer

Blister apparatus

Materials Science-Based Studies

of Fire Resistive Materials

Environmental

Interior

Temperature, RH, load

Exterior

Temperature, RH, UV, load

Performance Prediction

Lab scale testing

ASTM E119 Test

Real structures (WTC)

Adhesive Performance of FRMs

Why should we care?

Opportunity: Recent events have

demonstrated the importance of in-service

adhesive performance in the ability of

FRM to protect steel.

What can we learn about existing adhesive

properties of FRM?

How do we measure adhesion?

Want a geometry independent property.

Adhesive Fracture energy, Gc

How do we measure Gc?

energy to create

a unit of surface area

units: J/m

2

What is Gc

Experimental: Schematic and Theory

4

16

|

.

|

\

|

=

a

w Eh

G

2

2

1

|

.

|

\

|

=

w

P

Eh t

G

3 / 4 3 / 1

4

16

1

|

.

|

\

|

|

.

|

\

|

=

a

P

Eh t

G

P

w

2a

2

4

1

a

Pw

t

= G

Assumptions: Thin, stretching membrane,

loaded elastically and at a point

Eh: Film Tensile Rigidity (modulus, E, thickness, h)

a

U

b width c

c

=

,

1

G

Experimental: Schematic and Theory

4

16

|

.

|

\

|

=

a

w Eh

G

3 / 4 3 / 1

4

16

1

|

.

|

\

|

|

.

|

\

|

=

a

P

Eh t

G

P

w

2a

Load-based equation (P)

displacement-based equation (w)

Experimental Set-Up:

N kg

Load suspended

from center of

specimen

3 / 4 3 / 1

4

16

1

|

.

|

\

|

|

.

|

\

|

=

a

P

Eh t

G

2

4

1

a

Pw

t

= G

WTC Material

Experimental: Shaft-Loaded Blister Test

for WTC Material

2

2

1

|

.

|

\

|

=

w

P

Eh

G

t

P

h

Kai Tak Wan and Yiu-Wing Mai,

International Journal of Fracture, 74, 181-197 (1995)

E: Youngs Modulus

coating

Rigid substrate

Mechanically driven

shaft attached

to Instron

Shaft attached

To instron

Stand to hold sample

Film is on the

underside

Of stand

Mirror to view

film

w

WTC Sample

P

Fire Retardant Material (3/4)

Primer

2 mil steel

For a bending plate:

2

2

2

|

.

|

\

|

=

w

P

Eh

G

t

The mechanical properties of the film

are estimated from:

Steel E (Pa) = 2 * 10^11

h (m) = 0.05 *10^-3

Adhesion Promotor

E (Pa) = 3 * 10^9

h (m) = 0.20 *10^-3

and:

E

composite

= v

2

E

1

+v

2

E

2

y = 8.7337x - 1.2149

R

2

= 0.9965

-0.5

0

0.5

1

1.5

2

2.5

3

3.5

4

0 0.2 0.4 0.6

w (mm)

P

(

N

)

0

1

2

3

4

5

0 0.2 0.4 0.6 0.8 1

w (mm)

P

(

N

)

54 % of the

samples were

entirely

debonded

when received

Experimental: Shaft-Loaded Blister Test

G = 17.3 +/- 12.8 J/m

2

Fire Retardant Coatings

Testing of Adhesive Joints:

Introduction to Sub-Critical Adhesive Fracture Testing

and the Wedge Test

Wedge Test:

a (t > 0)

a (t = 0)

4

3 2

16

3

ba

Eh BA

= G

v-G curves will tell you:

-rank order of adhesive

-failure mechanisms

-engineering design parameters

L

o

g

C

r

a

c

k

V

e

l

o

c

i

t

y

,

v

(

m

/

s

)

Crack Driving Energy, (J/m )

v

(

m

/

s

)

(J/m

v

(

m

/

s

)

G

(J/m

2

10

-10

v-G Curve Reveals Mechanisms of Adhesive Failure at the Crack-

Tip: Regions I, II, III

v*

Region II: diffusion to crack tip

Region III:

stress

controlled

G

Th

Region I: stress-dependent

chemical reaction

Crack Driving Energy, (J/m )

I

Crack Driving Energy, (J/m )

I

II

L

o

g

C

r

a

c

k

V

e

l

o

c

i

t

y

,

v

(

m

/

s

)

Crack Driving Energy,

G

(J/m

2

)

I

III

Increasing

Aggressiveness of

Environment

C

r

a

c

k

V

e

l

o

c

i

t

y

,

v

(

m

/

s

)

Crack Driving Energy, G (J/m

2

)

Region II

Application of Sub-Critical Adhesion Testing: Residual

Stress (

r

) in Coatings

E

v h

Z

r

) 1 (

2

=

o

G

r

arise due to

CTE mismatch or processing

G

Th

L

o

g

C

r

a

c

k

V

e

l

o

c

i

t

y

,

v

(

m

/

s

)

Crack Driving Energy, (J/m )

v

(

m

/

s

)

(J/m

v

(

m

/

s

)

G

(J/m

2

T

E

r

A A

= o

v

o

) 1 (

Data from wedge test

Constant-Load Subcritical Blister Test

4/40 screw

wire

nut and washer(s)

epoxy sealant

wafer substrate

adhesive film

weight

4/40 screw

wire

nut and washer(s)

epoxy sealant

wafer substrate

adhesive film

weight

Constant load Constant load

3 / 4 3 / 1

4

16

1

|

.

|

\

|

|

.

|

\

|

=

a

P

Eh t

G

i i

i i

t t

a a

v

=

+

+

1

1

*

Measure debond easily with micrometer!

Borofloat

glass substrate

P

1.

Kapton PSA pre-crack

2. Spin coat PMMA

3. RT cure epoxy adhesive and Kapton backing

Fire Resistive Coating

Cold Rolled Steel

Substrate

1.E-10

1.E-09

1.E-08

1.E-07

1.E-06

1.E-05

1 10 100 1000

debond energy (J/m

2

)

d

e

b

o

n

d

v

e

l

o

c

i

t

y

(

m

/

s

)

Epoxy DCB

Screening Tool for Different Coatings

Bonded to Cold Rolled Steel at 100% r.h. & RT

A SLBT

B SLBT

A DCB

D

C

1.E-10

1.E-09

1.E-08

1.E-07

1.E-06

1.E-05

1.0 10.0 100.0

debond energy (J/m

2

)

d

e

b

o

n

d

v

e

l

o

c

i

t

y

(

m

/

s

)

Soft vs. Hard Coating,

low humidity vs. high humidity

Hard coating performs better than Soft coating!

Coatings perform better at low humidity

High (95%) RH

Low (1%)

RH

FRC DCB :

1.E-10

1.E-09

1.E-08

1.E-07

1.E-06

1.0 10.0 100.0 1000.0

debond energy (J/m

2

)

d

e

b

o

n

d

v

e

l

o

c

i

t

y

(

m

/

s

)

Increase humidity and reduced residual stress

Tensile Residual Stress is reduced by moisture absorption

Reduction in residual stress leads to improved durability

FRMs.

Modern Adhesion testing methods can give

LRFD parameters.

These parameters are environmentally

sensitive.

(increasing RH can either increase or decrease performance.)

What about Temp and UV? Rate effects?

What about the existing test methods?

Can we modify existing test methods?

Adhesion Tests: Ideal

Ideal Adhesion Test:

Simple, cheap, fast, easy to perform

Grounded in fundamental mechanics and material

science- LFRD guidance

Includes modes- opening, in-plane shear, torsion, mixed,

Could include environmental and rate dependence.

How far are the test from idea?

Current FRM Standards:

ASTM E759 (Effect of Deflection)

12 Ft

Deflect 1/120 or 1 inch.

ASTM E760 (Effect of Impact)

12 Ft

Concrete

60 lb from 4 ft.

ASTM E736 (Cohesive/Adhesive)

Current Empirical Methods:

Advantages:

Quick, easy, Cheap

Practical

Pass/Fail guidance

Disadvantages:

Highly dependent on sample preparation

Specific to situation tested (geometry, speed, etc)

Little or no design guidance

Quantitative Adhesive Test Methods:

Beam, JKR and Peel Measure G and E

JKR Test

2 / 1

2

3

3 6 3

1

(

(

|

.

|

\

|

+ + + =

P

WR

P

WR

P

WR

K

PR

a

t t t

At equilibrium G =W

A

P

P

a

) 4 6 5 ( 2

) 2 3 2 ( 2

8

3

2 2 4 2 2 4 2 2

2 2 4 2 2 4 2 2

4

3 2

h th t th BwEE h E w t E B

h th t th BwEE h E w t E B

w a

BEt

a a

a a

+ + + +

+ + + + A

= G

Beam Test, ex. Wedge Test

Blister Test

2

4

1

a

Pw

t

= G

P

w

2a

P

Peel Test(s)

w

P

= G

Fundamental Mechanics

Advantages:

Link to fundamental mechanics and material science

properties G

Results are independent of geometry/sample

preparation.

Gives LFRD guidance

Disadvantages:

Expensive

Require equipment

Time consuming

Current Methods:

Fundamental Mechanics

DCLB

Peel Tests

Blister Tests

JKR

Empirical, Practical

Pull off

Lap Shear

Impact

Deflection

A

P

P

a

P

w

General Approach:

Simple Test,

Fast, easy, inexpensive to perform

Calibrate.

Can be calibrated against fundamental

mechanics and material science

Rate, strain and environmental dependence

Round robin

Prototype:

Steel

FRM

Bending, twisting, stretching will

produce known strains at the

interface (different modes)

Stress can be calculated from first

principles and calibrated with known

adhesion geometries.

Visually evaluated, or calibrated.

Can give both rate and environmental

performance.

Never have to touch the

material

Summary

Current methods for evaluating the adhesion

performance are pass/fail.

Modern adhesion testing methods present the

ability to give design guidance for FRMs.

It appears possible to build a close to ideal

adhesion test for FRMs.

Simple, cheap, fast, based in mechanics, calibrated by

NIST.

You might also like

- Understanding of TWI J-R CurvesDocument21 pagesUnderstanding of TWI J-R CurvespcastlesmithNo ratings yet

- Week-4 - Properties and BehaviourDocument34 pagesWeek-4 - Properties and BehaviourEncik MaaNo ratings yet

- The Impact Resistance of Composite Materials PDFDocument16 pagesThe Impact Resistance of Composite Materials PDFSergio A. Ardila ParraNo ratings yet

- Cantwell 91Document16 pagesCantwell 91Dave BakerNo ratings yet

- Charpy Impact TestDocument3 pagesCharpy Impact TestRamana IkkurthiNo ratings yet

- Alumunium A 7075Document6 pagesAlumunium A 7075Diaz XboyNo ratings yet

- Ship Collition Rr220Document85 pagesShip Collition Rr220francisNo ratings yet

- Fracture Toughness Testing - TwiDocument5 pagesFracture Toughness Testing - TwiSergio MunhosNo ratings yet

- Astm e 399 - 90Document53 pagesAstm e 399 - 90Edgar LopezNo ratings yet

- Charpy Impact TestDocument3 pagesCharpy Impact TestKajal KhanNo ratings yet

- Plain Bearings Made From Engineering PlasticsDocument44 pagesPlain Bearings Made From Engineering PlasticsJani LahdelmaNo ratings yet

- DraftDocument27 pagesDraftisaudkNo ratings yet

- 2005 Polym Composite 01Document16 pages2005 Polym Composite 01Ali FahemNo ratings yet

- Ultimate Strength and Failure Process of Composite Laminated Plates Subjected To Low-Velocity ImpactDocument23 pagesUltimate Strength and Failure Process of Composite Laminated Plates Subjected To Low-Velocity ImpactHossein RashediNo ratings yet

- Fracture Properties of Glass Fiber Composite Laminates and Size Effect EGYPTDocument14 pagesFracture Properties of Glass Fiber Composite Laminates and Size Effect EGYPTRajaneesh AnantharajuNo ratings yet

- Dropped Object To Using The Non-Linear Dynamic AnalysisDocument18 pagesDropped Object To Using The Non-Linear Dynamic AnalysisRaghu MahadevappaNo ratings yet

- Highway Engineering PDFDocument54 pagesHighway Engineering PDFKreesthu ReddyNo ratings yet

- EXP 7 - MaterialsDocument18 pagesEXP 7 - MaterialsLeslie CatindigNo ratings yet

- Experiment:-To Determine The Tensile Properties of Given Material. Theory:-The Tensile Test Consists of Clamping One and of The Specimen and AnDocument11 pagesExperiment:-To Determine The Tensile Properties of Given Material. Theory:-The Tensile Test Consists of Clamping One and of The Specimen and AnGurmeet MehmaNo ratings yet

- Testing of Plastics: Instrumented Charpy Impact Test (ICIT)Document19 pagesTesting of Plastics: Instrumented Charpy Impact Test (ICIT)faisalNo ratings yet

- Fatigue Residual Strength of Circular Laminate Graphite-Epoxy Composite PlatesDocument6 pagesFatigue Residual Strength of Circular Laminate Graphite-Epoxy Composite PlatestommasobrugoNo ratings yet

- Fatigue Behavior of Foreign Object Damaged 7075 Heat Treated Aluminum Alloy Coated With PVD WC/CDocument6 pagesFatigue Behavior of Foreign Object Damaged 7075 Heat Treated Aluminum Alloy Coated With PVD WC/CFrancesco MontagnoliNo ratings yet

- Figueiredo 2015Document9 pagesFigueiredo 2015Ana Emily PrentissNo ratings yet

- Testing Methods For CompositesDocument26 pagesTesting Methods For CompositesRupayan RoyNo ratings yet

- SHAPES Network Meeting PenstockDocument9 pagesSHAPES Network Meeting PenstockPEJU0007No ratings yet

- Bolted Composite JointDocument28 pagesBolted Composite JointHitesh Parghi50% (2)

- Optimization of Composite Bonded Joints and Repairs: Maria Victoria Castro FernándezDocument27 pagesOptimization of Composite Bonded Joints and Repairs: Maria Victoria Castro FernándezMaria Victoria FernandezNo ratings yet

- A3 DeterminationofElasticPlasticDocument9 pagesA3 DeterminationofElasticPlastic2557630582No ratings yet

- Segarra 2008Document10 pagesSegarra 2008felipeqbrasilNo ratings yet

- ReviewDocument24 pagesReviewhunters eNo ratings yet

- Adams Testing Module August 29 PDFDocument46 pagesAdams Testing Module August 29 PDFSubbalakshmi Yeleswarapu 010311No ratings yet

- Use of Split-Disk Tests For The Process Parameters-Kaynak2005Document8 pagesUse of Split-Disk Tests For The Process Parameters-Kaynak2005houcinejNo ratings yet

- Fad Analytic PDFDocument13 pagesFad Analytic PDFMalik Beta100% (1)

- Materials Selection and Design Design & Selection: Materials IndicesDocument9 pagesMaterials Selection and Design Design & Selection: Materials IndicesTeguh SulistiyonoNo ratings yet

- 17 Experimental Determination of Freezethaw Resistance in Selfcompacting Concretes2019IOP Conference Series Materials Science and EngineeringDocument8 pages17 Experimental Determination of Freezethaw Resistance in Selfcompacting Concretes2019IOP Conference Series Materials Science and EngineeringВладиславNo ratings yet

- Mechanical TestingDocument24 pagesMechanical Testinggaurav503050No ratings yet

- Damage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingDocument8 pagesDamage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingMa RcoNo ratings yet

- Charpy Impact Test: An Overview of Mechanical and Physical Testing of Composite MaterialsDocument11 pagesCharpy Impact Test: An Overview of Mechanical and Physical Testing of Composite MaterialswaniNo ratings yet

- Drop Test and Finite Element Analysis of Test BoarDocument6 pagesDrop Test and Finite Element Analysis of Test BoarBIKASHNo ratings yet

- Fibre Carbon - Tensile Test (Unidirection)Document5 pagesFibre Carbon - Tensile Test (Unidirection)AlsonChinNo ratings yet

- CCC2008 PaperBarrosGlauciaElisaAlessandraDocument11 pagesCCC2008 PaperBarrosGlauciaElisaAlessandraGlaucia DalfreNo ratings yet

- Finite Element Modeling of SnAgCu Alloy On 3D Package-on-Package (POP) Subjected To Board Level Drop TestDocument8 pagesFinite Element Modeling of SnAgCu Alloy On 3D Package-on-Package (POP) Subjected To Board Level Drop TestSEP-PublisherNo ratings yet

- Cyclic Behavior of Steel Gusset Plate Connections PDFDocument165 pagesCyclic Behavior of Steel Gusset Plate Connections PDFliron4349No ratings yet

- V003t05a002 Ipc2018 78097Document15 pagesV003t05a002 Ipc2018 78097c885ffmfrrNo ratings yet

- Exp 3 ErianeDocument16 pagesExp 3 ErianeEriane GarciaNo ratings yet

- BioRes 07 2 B Popil Overview Edge Compression Buckling 1006Document30 pagesBioRes 07 2 B Popil Overview Edge Compression Buckling 1006SubtabNo ratings yet

- Crupi Et Al. - 2015 - Experimental Analyses of SFRP Material Under StatiDocument10 pagesCrupi Et Al. - 2015 - Experimental Analyses of SFRP Material Under StatitjuliuyjNo ratings yet

- Comparaison NormesDocument64 pagesComparaison NormesCAILLAULT100% (1)

- New Method To Measure The Adhesion Capability of Metallic Surface Under Shear Loading Using A Modified Arcan TestDocument31 pagesNew Method To Measure The Adhesion Capability of Metallic Surface Under Shear Loading Using A Modified Arcan TestMatt LABNo ratings yet

- Damage Evolution in Nakajima Tests of DP800 Dual PDocument7 pagesDamage Evolution in Nakajima Tests of DP800 Dual PĐạt TriệuNo ratings yet

- Three-Point Flexural TestDocument3 pagesThree-Point Flexural TestBassey Okon100% (1)

- Material Testing TechniquesDocument66 pagesMaterial Testing Techniquesrakamew442.epevaNo ratings yet

- 234567890Document37 pages234567890erppibuNo ratings yet

- D 5528 - 94 Rdu1mjgtukveDocument15 pagesD 5528 - 94 Rdu1mjgtukveJuanNo ratings yet

- Lightweight Design and Crash Analysis of Composite Frontal Impact Energy Absorbing Structures 2012 Composite StructuresDocument8 pagesLightweight Design and Crash Analysis of Composite Frontal Impact Energy Absorbing Structures 2012 Composite Structuressalman husainNo ratings yet

- 7 Ijcmes PDFDocument8 pages7 Ijcmes PDFInfogain publicationNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Compressor Station InspectionDocument8 pagesCompressor Station InspectionWelkin SkyNo ratings yet

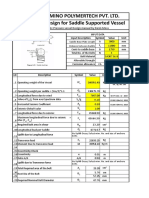

- Saddle DesignDocument6 pagesSaddle DesignPankajDhobleNo ratings yet

- Module 1 - The Plumbing ProfessionDocument19 pagesModule 1 - The Plumbing Professionnicholas yeo chun ekNo ratings yet

- 1 Prestressed ConcreteDocument8 pages1 Prestressed ConcreteWiy Guom0% (1)

- Fisa Tehnica Enkamat® 7010 - 1Document4 pagesFisa Tehnica Enkamat® 7010 - 1Andreea AndreiNo ratings yet

- Fisher Big Joe Type 630 321 ManualDocument11 pagesFisher Big Joe Type 630 321 ManualAbigail Lupe Aguilar YapuraNo ratings yet

- Louvre Abu DhabiDocument13 pagesLouvre Abu DhabieliasmehannausaNo ratings yet

- Jadual MPI - Sem II 20132014Document3 pagesJadual MPI - Sem II 20132014phyrdowsNo ratings yet

- Steel Grades and StandardsDocument22 pagesSteel Grades and Standardsmorning starNo ratings yet

- Cutting Tools by R EdwardsDocument214 pagesCutting Tools by R EdwardsRyan MiningNo ratings yet

- Wood Plastic Composites Made From Corn Husk Fiber and Recycled Polystyrene FoamDocument12 pagesWood Plastic Composites Made From Corn Husk Fiber and Recycled Polystyrene FoamPedro AlbanNo ratings yet

- District Cooling Case Study - James Cook University, TownsvilleDocument10 pagesDistrict Cooling Case Study - James Cook University, TownsvilleAnonymous I7MUd3mCNo ratings yet

- Electrical Technical SpecificationDocument37 pagesElectrical Technical SpecificationKamal KhanNo ratings yet

- PB Single Multi Dfs Systems Sracscac (Uslineup) 2020Document23 pagesPB Single Multi Dfs Systems Sracscac (Uslineup) 2020RaulNo ratings yet

- Hydrolic Transportation Tailing SlurryDocument7 pagesHydrolic Transportation Tailing SlurryBagus Tjahjoko Nugroho100% (1)

- Homemade Mini Coaxial AirgunDocument9 pagesHomemade Mini Coaxial Airgunnfk100% (1)

- Conductive Black CP1™ Polyimide: Lower RF Loss Than Other Black and Conductive Black PolyimidesDocument2 pagesConductive Black CP1™ Polyimide: Lower RF Loss Than Other Black and Conductive Black PolyimidesRoad BlasterNo ratings yet

- Sample PaperDocument7 pagesSample Paperbhooshan japeNo ratings yet

- Introduction Heat ExchangerDocument11 pagesIntroduction Heat ExchangerLorna AhlaamiNo ratings yet

- Thermodynamics MCQDocument83 pagesThermodynamics MCQChristian RoxasNo ratings yet

- Interface Mass TraDocument26 pagesInterface Mass TraWahid AliNo ratings yet

- Aw StandartsDocument12 pagesAw StandartsKiukStaksNo ratings yet

- 50 Chemical Injection System Access Fitting Assemblies - 50-DS RevcDocument19 pages50 Chemical Injection System Access Fitting Assemblies - 50-DS RevcChemkhiNo ratings yet

- Antivibradores Castel 1Document4 pagesAntivibradores Castel 1charly541No ratings yet

- Elbi Press Exp TanksDocument2 pagesElbi Press Exp TanksMinela NedžadNo ratings yet

- MaterialsDocument23 pagesMaterialsMuhammad Hussain BilalNo ratings yet

- Paint Matrix - NPE ProjectDocument2 pagesPaint Matrix - NPE Projectridwan muhammadNo ratings yet

- Ritemix Blocksave - Docx 0Document2 pagesRitemix Blocksave - Docx 0Roemaric AguasNo ratings yet

- IV Validación de ProcesosDocument1,194 pagesIV Validación de Procesosalejandromfunes1749No ratings yet

- 506 Steel Sheet BracingDocument2 pages506 Steel Sheet BracingAira A. ParallagNo ratings yet