Professional Documents

Culture Documents

Chapter 1

Chapter 1

Uploaded by

tafere99Copyright:

Available Formats

You might also like

- Mckinsey - Style Practice Case #8: Ronald ChocolatesDocument12 pagesMckinsey - Style Practice Case #8: Ronald ChocolatesHiếu LươngNo ratings yet

- Supply Chain Management PresentationDocument71 pagesSupply Chain Management Presentationabir1986100% (1)

- Supply Chain and IT - Impact...Document39 pagesSupply Chain and IT - Impact...Praveen ChoudharyNo ratings yet

- Basics of Supply Chain ManagementDocument34 pagesBasics of Supply Chain ManagementBhuvanes KumarNo ratings yet

- Basics of Supply Chain ManagementDocument43 pagesBasics of Supply Chain ManagementsriramNo ratings yet

- 17.supply Chain ManagementDocument22 pages17.supply Chain ManagementNivedita Misra100% (1)

- Supply ChainDocument32 pagesSupply ChainAkhil SardaNo ratings yet

- Supply Chain Management-1Document57 pagesSupply Chain Management-1Amit AgarwalNo ratings yet

- 3 Supply Chain Strategies (Integration Distribution) (Moodle) (Compatibility Mode)Document33 pages3 Supply Chain Strategies (Integration Distribution) (Moodle) (Compatibility Mode)Tamarai Selvi ArumugamNo ratings yet

- C CCCC C CCCCCCCCCC CCCCCCCCCCCCCCCC C: CC CCCCCCCC C CCC CCC C CCDocument8 pagesC CCCC C CCCCCCCCCC CCCCCCCCCCCCCCCC C: CC CCCCCCCC C CCC CCC C CCSanna SalimNo ratings yet

- Distribution Supply Chain Management - Sourcing & ProcurementDocument39 pagesDistribution Supply Chain Management - Sourcing & Procurementshoaibnadir100% (1)

- Demand Chain ManagementDocument134 pagesDemand Chain ManagementVivek Sarmal100% (3)

- T8 Distribution StrategiesDocument3 pagesT8 Distribution StrategiesAnna Vidal AribauNo ratings yet

- Designing & Managing The Supply Chain: Introduction To Supply Chain Management Dr. A. K. DeyDocument61 pagesDesigning & Managing The Supply Chain: Introduction To Supply Chain Management Dr. A. K. DeyPriya DattaNo ratings yet

- Supply Management NewDocument4 pagesSupply Management NewMurugan SaravananNo ratings yet

- Supply Chain Management 7Document45 pagesSupply Chain Management 7Abhi KeshwaniNo ratings yet

- Supply Chain MGTDocument42 pagesSupply Chain MGTYash RoxsNo ratings yet

- Overview of Logistics and Supply ChainDocument23 pagesOverview of Logistics and Supply ChainZaa ZaNo ratings yet

- SCM in GeneralDocument22 pagesSCM in GeneralMartin JohnNo ratings yet

- Supply Chain ManagementDocument9 pagesSupply Chain ManagementRupesh SinghNo ratings yet

- Supply Chain TerminologyDocument5 pagesSupply Chain TerminologyMehroz KhanNo ratings yet

- 1.0 Introduction To Supply Chain Management (SCM)Document69 pages1.0 Introduction To Supply Chain Management (SCM)Anchal BaggaNo ratings yet

- Supply ChainDocument38 pagesSupply ChainMk YapNo ratings yet

- Introduction To Supply Chain ManagementDocument19 pagesIntroduction To Supply Chain ManagementSneha Karpe100% (1)

- Introduction To Supply Chain ManagementDocument42 pagesIntroduction To Supply Chain Managementsoumyarm942No ratings yet

- Supply Chain Risk ManagementDocument45 pagesSupply Chain Risk ManagementSabir AliNo ratings yet

- Demand Management and Customer Service-4 - Supply Chain ManagementDocument22 pagesDemand Management and Customer Service-4 - Supply Chain ManagementPooja ShahNo ratings yet

- Corporate Strategy - Supply Chain Management - Dell Case StudyDocument22 pagesCorporate Strategy - Supply Chain Management - Dell Case StudyDr Rushen Singh100% (1)

- Origin of Supply Chain ManagementDocument4 pagesOrigin of Supply Chain ManagementMurugan SaravananNo ratings yet

- Session 2 - Nsupply Chain Design and Linkage To Corporate StrategyDocument39 pagesSession 2 - Nsupply Chain Design and Linkage To Corporate Strategypulkit khandelwalNo ratings yet

- Importance of Supply-Chain Management (SCM), Purchasing Strategies and Purchasing ManagementDocument20 pagesImportance of Supply-Chain Management (SCM), Purchasing Strategies and Purchasing ManagementLaian MaligNo ratings yet

- Notes For Supply Chain ManagementDocument18 pagesNotes For Supply Chain ManagementDanny GloverNo ratings yet

- Lifeline - Supply ChainDocument41 pagesLifeline - Supply Chainvnewaskar_1No ratings yet

- Designing Supply Chain NetworkDocument4 pagesDesigning Supply Chain NetworkendeshawNo ratings yet

- Introduction To Supply Chain ManagementDocument96 pagesIntroduction To Supply Chain ManagementGaurav SainiNo ratings yet

- SCM Udemy NotesDocument6 pagesSCM Udemy NotesPraphulNo ratings yet

- Integrating The Supply Chain - RKSDocument25 pagesIntegrating The Supply Chain - RKSRksingal SingalNo ratings yet

- Supply Chain Management Research Paper OutlineDocument4 pagesSupply Chain Management Research Paper Outlinegz7vxzyz100% (1)

- SCM SummaryDocument47 pagesSCM SummaryEmanuelle BakuluNo ratings yet

- Supply Chain MnagementDocument5 pagesSupply Chain MnagementDanish AhsanNo ratings yet

- An Assignment On Supply Chain Practice & ProcedureDocument29 pagesAn Assignment On Supply Chain Practice & ProcedurePankaj AgarwalNo ratings yet

- 8 - Integrating The Supply ChainDocument31 pages8 - Integrating The Supply ChainArunkumarNo ratings yet

- Emailing SCM PPTs - CompressedDocument458 pagesEmailing SCM PPTs - CompressedRahul PandeyNo ratings yet

- E - Supply Chain ManagementDocument45 pagesE - Supply Chain Managementayman hindiehNo ratings yet

- SCM Chapter 1Document34 pagesSCM Chapter 1Sneha KadamNo ratings yet

- Supply Chain ManagementDocument23 pagesSupply Chain ManagementNeha GuptaNo ratings yet

- 1.1 What Is A Supply Chain?Document5 pages1.1 What Is A Supply Chain?chitraNo ratings yet

- Supply Chain Version 2Document37 pagesSupply Chain Version 2Abdelhamid Harakat100% (1)

- IT in Supply Chain ManagementDocument62 pagesIT in Supply Chain Managementrohitsingh17No ratings yet

- SC & OS - FinalDocument20 pagesSC & OS - FinalPrasad ChamaraNo ratings yet

- Demand ManagementDocument22 pagesDemand Managementmushtaque61No ratings yet

- SCM Test 3 Q&ADocument9 pagesSCM Test 3 Q&AnarinebalasubramaniNo ratings yet

- WK 6 Supply ChainDocument8 pagesWK 6 Supply ChainpthavNo ratings yet

- Managing Supply Chains: Session 2Document25 pagesManaging Supply Chains: Session 2Malik Muhammad SufyanNo ratings yet

- Ssupply Chain 1Document53 pagesSsupply Chain 1Tedros AbrehamNo ratings yet

- Supply Chain Management: Mid-Semester ReviewDocument42 pagesSupply Chain Management: Mid-Semester ReviewKaran BhatiaNo ratings yet

- Sap SCMDocument21 pagesSap SCMAffizul AzuwarNo ratings yet

- Submitted To: Submitted By:: Mr. N.S Uppal SUDEEP JANA (80062) Chitrangda Thakur (80081) 4 MAY, 2009Document56 pagesSubmitted To: Submitted By:: Mr. N.S Uppal SUDEEP JANA (80062) Chitrangda Thakur (80081) 4 MAY, 2009fun_maduraiNo ratings yet

- Military Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceFrom EverandMilitary Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceNo ratings yet

- Marketing Managaement: by A. Sandhya Rani Asst. ProfDocument45 pagesMarketing Managaement: by A. Sandhya Rani Asst. Proftafere99100% (1)

- 7 Quality Control ToolsDocument1 page7 Quality Control Toolstafere99No ratings yet

- Production and Operations ManagementDocument13 pagesProduction and Operations Managementtafere99No ratings yet

- Introduction To OMDocument30 pagesIntroduction To OMtafere99No ratings yet

- Approches To Customer Analysis-31!12!2010 Friday ClassDocument118 pagesApproches To Customer Analysis-31!12!2010 Friday Classtafere99No ratings yet

- Textile Inspections in Asia Textile Inspections in AsiaDocument1 pageTextile Inspections in Asia Textile Inspections in Asiatafere99No ratings yet

- A Power Point Presentation On TQMDocument46 pagesA Power Point Presentation On TQMtafere99No ratings yet

- Final ReportDocument8 pagesFinal ReportZack GroothouseNo ratings yet

- Intermittent Battery Drain: Ymms: Dec 4, 2019 Engine: 3.5L Eng License: Vin: Odometer: 2014 Acura MDX BaseDocument2 pagesIntermittent Battery Drain: Ymms: Dec 4, 2019 Engine: 3.5L Eng License: Vin: Odometer: 2014 Acura MDX Basebyungchul kimNo ratings yet

- Nuvance Health Strategic PlanDocument7 pagesNuvance Health Strategic Planfranjo bacicNo ratings yet

- List Obat ApotekDocument17 pagesList Obat ApotekAnonymous NIuKdo2xqtNo ratings yet

- Mix Design C 35A - 50%Document1 pageMix Design C 35A - 50%cecbNo ratings yet

- Entrep - Product ProposalDocument4 pagesEntrep - Product ProposalPrincess ArabelaNo ratings yet

- PED 5 Heat ExchangersDocument74 pagesPED 5 Heat ExchangersDiogo EstevesNo ratings yet

- Yasnac J300 Connecting Manual (Type B)Document186 pagesYasnac J300 Connecting Manual (Type B)sunhuynh100% (1)

- CV - ModelDocument5 pagesCV - ModeldanzeluNo ratings yet

- Competitors Analysis 1Document2 pagesCompetitors Analysis 1rajaroma45No ratings yet

- Swimming Pool BoqDocument5 pagesSwimming Pool Boqfelix sowah-laryeaNo ratings yet

- So Too Either NeitherDocument4 pagesSo Too Either NeitherJos Nguyễn Công DươngNo ratings yet

- Automated Coiled Tubing Integrity Monitoring (ACIM) : TechnologyDocument4 pagesAutomated Coiled Tubing Integrity Monitoring (ACIM) : TechnologyArgonauta_navegadorNo ratings yet

- Echo Core LabsDocument11 pagesEcho Core LabsSundara Rami ReddyNo ratings yet

- Karakteristik Ekosistem Mangrove Di Kawasan Pesisi PDFDocument7 pagesKarakteristik Ekosistem Mangrove Di Kawasan Pesisi PDFAdilNo ratings yet

- Network Engineer - L3 Noida - Noida - CYFUTURE INDIA PRIVATE LIMITED - 4 To 8 Years of ExperienceDocument3 pagesNetwork Engineer - L3 Noida - Noida - CYFUTURE INDIA PRIVATE LIMITED - 4 To 8 Years of Experiencemanish0202No ratings yet

- Integrated Watershed ApproachDocument3 pagesIntegrated Watershed ApproachSuhas KandeNo ratings yet

- SP1100 50HZ Perkins GeneratorDocument4 pagesSP1100 50HZ Perkins GeneratorsunshinemachineryNo ratings yet

- COSH Module 2 - 1A Safety Hazards (Synerquest) - CompressedDocument61 pagesCOSH Module 2 - 1A Safety Hazards (Synerquest) - Compressedalmiraraiza bustamanteNo ratings yet

- 432 OSCE Revision File PDFDocument20 pages432 OSCE Revision File PDFReza Affandi MohamadNo ratings yet

- KatalogDocument3 pagesKatalogJosua Sahat Parulian SinagaNo ratings yet

- Morphology McqsDocument8 pagesMorphology McqsHiba Shah100% (2)

- IP0497 Sandvik EDocument15 pagesIP0497 Sandvik EGary LopezNo ratings yet

- Test Bank For Williams Basic Nutrition and Diet Therapy 14th Edition Staci NixDocument24 pagesTest Bank For Williams Basic Nutrition and Diet Therapy 14th Edition Staci Nixdavidjonescrjeagtnwp100% (38)

- Subsea PE RoleDocument3 pagesSubsea PE RoleBen OjemsNo ratings yet

- Voucher (Pre-Paid Booking) : ST - Havel ResidenceDocument2 pagesVoucher (Pre-Paid Booking) : ST - Havel ResidenceAlena KolesnykNo ratings yet

- Weflo 3129 Cast Iron Gate Valve Flanged Table EDocument1 pageWeflo 3129 Cast Iron Gate Valve Flanged Table EMOHD HAIDARNo ratings yet

- Delhi Gang Rape CaseDocument3 pagesDelhi Gang Rape CasePriyesha MaliNo ratings yet

- Low Cost Mechatronics Prototype Prosthesis For Transfemoral Amputation Controled by Myolectric SignalsDocument6 pagesLow Cost Mechatronics Prototype Prosthesis For Transfemoral Amputation Controled by Myolectric SignalsElizabeth CominaNo ratings yet

Chapter 1

Chapter 1

Uploaded by

tafere99Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 1

Chapter 1

Uploaded by

tafere99Copyright:

Available Formats

Basics of Supply Chain Management

Definitions

What Is the Supply Chain?

Also referred to as the logistics network Suppliers, manufacturers, warehouses, distribution centers and retail outlets facilities

Suppliers Manufacturers Warehouses & Customers Distribution Centers

and the

Raw materials Work-in-process (WIP) inventory Finished products

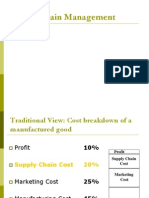

Material Costs Transportation Costs Transportation Costs Transportation Manufacturing Costs Inventory Costs Costs

that flow between the facilities

The Supply Chain

Suppliers Manufacturers Warehouses & Distribution Centers Customers

Transportation Costs Material Costs

Transportation Costs

Manufacturing Costs

Transportation Costs Inventory Costs

The Supply Chain Another View

Plan Source Make Deliver Buy

Suppliers

Manufacturers

Warehouses & Distribution Centers

Customers

Material Costs

Transportation Transportation Costs Transportation Costs Manufacturing Costs Inventory Costs Costs 5

What Is Supply Chain Management (SCM)?

Plan Source Make Deliver Buy

A set of approaches used to efficiently integrate

Suppliers Manufacturers Warehouses Distribution centers In the right quantities To the right locations And at the right time

So that the product is produced and distributed

System-wide costs are minimized and Service level requirements are satisfied

History of Supply Chain Management

1960s - Inventory Management Focus, Cost Control 1970s - MRP & BOM - Operations Planning 1980s - MRPII, JIT - Materials Management, Logistics 1990s - SCM - ERP - Integrated Purchasing, Financials, Manufacturing, Order Entry 2000s - Optimized Value Network with Real-Time Decision Support; Synchronized & Collaborative Extended Network

Why Is SCM Difficult?

Plan Source Make Deliver Buy

Uncertainty is inherent to every supply chain

Travel times Breakdowns of machines and vehicles Weather, natural catastrophe, war Local politics, labor conditions, border issues

The complexity of the problem to globally optimize a supply chain is significant

Minimize internal costs Minimize uncertainty Deal with remaining uncertainty

The Importance of Supply Chain Management Dealing with uncertain environments matching supply and

demand

Boeing announced a $2.6 billion write-off in 1997 due to raw materials shortages, internal and supplier parts shortages and productivity inefficiencies U.S Surgical Corporation announced a $22 million loss in 1993 due to larger than anticipated inventories on the shelves of hospitals IBM sold out its supply of its new Aptiva PC in 1994 costing it millions in potential revenue Hewlett-Packard and Dell found it difficult to obtain important components for its PCs from Taiwanese suppliers in 1999 due to a massive earthquake

U.S. firms spent $898 billion (10% of GDP) on supply-chain related activities in 1998

The Importance of Supply Chain Management Shorter product life cycles of high-technology products

Less opportunity to accumulate historical data on customer demand Wide choice of competing products makes it difficult to predict demand

The growth of technologies such as the Internet enable greater collaboration between supply chain trading partners

If you dont do it, your competitor will Major buyers such as Wal-Mart demand a level of supply chain maturity of its suppliers Firms have access to multiple products (e.g., SAP, Baan, Oracle, JD Edwards) with which to integrate internal processes

Availability of SCM technologies on the market

10

Supply Chain Management and Uncertainty

Inventory and back-order levels fluctuate considerably across the supply chain even when customer demand doesnt vary The variability worsens as we travel up the supply chain Forecasting doesnt help!

Wholesale Distributors

Multi-tier Suppliers

Manufacturer

Retailers

Consumers

Sales

Sales

Time

Sales

Time

Time

Sales Time

Bullwhip Effect

11

Factors Contributing to the Bullwhip

Demand forecasting practices

Min-max inventory management (reorder points to bring inventory up to predicted levels) Longer lead times lead to greater variability in estimates of average demand, thus increasing variability and safety stock costs Peaks and valleys in orders Fixed ordering costs Impact of transportation costs (e.g., fuel costs) Sales quotas Promotion and discount policies

Lead time

Batch ordering

Price fluctuations

Lack of centralized information

12

Todays Marketplace Requires:

Personalized content and services for their customers Collaborative planning with design partners,

distributors, and suppliers

Real-time commitments for design, production, inventory, and transportation capacity Flexible logistics options to ensure timely fulfillment Order tracking & reporting across multiple vendors and carriers

Shared visibility for trading partners

13

Supply Chain Management Key Issues

Forecasts are never right

Very unlikely that actual demand will exactly equal forecast demand

The longer the forecast horizon, the worse the forecast

A forecast for a year from now will never be as accurate as a forecast for 3 months from now

Aggregate forecasts are more accurate

A demand forecast for all CV therapeutics will be more accurate than a forecast for a specific CV-related product

Nevertheless, forecasts (or plans, if you prefer) are important management tools when some methods are applied to reduce uncertainty

14

Supply Chain Management Key Issues

Overcoming functional silos with conflicting goals

Purchasing Manufacturing Distribution Customer Service/ Sales

High inventories

Low purchase price Multiple vendors

Few changeovers Stable schedules Long run lengths

Low inventories

High service levels Regional stocks

Low transportation

SOURCE

MAKE

DELIVER

SELL

15

Supply Chain Management Key Issues

ISSUE Network Planning

CONSIDERATIONS

Warehouse locations and capacities Plant locations and production levels Transportation flows between facilities to minimize cost and time How should inventory be managed? Why does inventory fluctuate and what strategies minimize this? Impact of volume discount and revenue sharing Pricing strategies to reduce order-shipment variability Selection of distribution strategies (e.g., direct ship vs. cross-docking) How many cross-dock points are needed? Cost/Benefits of different strategies How can integration with partners be achieved? What level of integration is best? What information and processes can be shared? What partnerships should be implemented and in which situations? What are our core supply chain capabilities and which are not? Does our product design mandate different outsourcing approaches? Risk management How are inventory holding and transportation costs affected by product design? How does product design enable mass customization?

Inventory Control Supply Contracts Distribution Strategies

Integration and Strategic Partnering

Outsourcing & Procurement Strategies Product Design

Source: Simchi-Levi

16

Supply Chain Management Operations Strategies

STRATEGY WHEN TO CHOOSE BENEFITS Make to Stock

standardized products, relatively predictable demand customized products, many variations many variations on finished product; infrequent demand Low manufacturing costs; meet customer demands quickly Customization; reduced inventory; improved service levels Low inventory levels; wide range of product offerings; simplified planning

Make to Order

Configure to Order

Engineer to Order

complex products, unique customer specifications

Enables response to specific customer requirements

Source: Simchi-Levi

17

Supply Chain Management Benefits

A 1997 PRTM Integrated Supply Chain Benchmarking Survey of 331 firms found significant benefits to integrating the supply chain

Delivery Performance Inventory Reduction Fulfillment Cycle Time Forecast Accuracy Overall Productivity Lower Supply-Chain Costs Fill Rates Improved Capacity Realization

Source: Cohen & Roussel

16%-28% Improvement 25%-60% Improvement 30%-50% Improvement 25%-80% Improvement 10%-16% Improvement 25%-50% Improvement 20%-30% Improvement 10%-20% Improvement

18

You might also like

- Mckinsey - Style Practice Case #8: Ronald ChocolatesDocument12 pagesMckinsey - Style Practice Case #8: Ronald ChocolatesHiếu LươngNo ratings yet

- Supply Chain Management PresentationDocument71 pagesSupply Chain Management Presentationabir1986100% (1)

- Supply Chain and IT - Impact...Document39 pagesSupply Chain and IT - Impact...Praveen ChoudharyNo ratings yet

- Basics of Supply Chain ManagementDocument34 pagesBasics of Supply Chain ManagementBhuvanes KumarNo ratings yet

- Basics of Supply Chain ManagementDocument43 pagesBasics of Supply Chain ManagementsriramNo ratings yet

- 17.supply Chain ManagementDocument22 pages17.supply Chain ManagementNivedita Misra100% (1)

- Supply ChainDocument32 pagesSupply ChainAkhil SardaNo ratings yet

- Supply Chain Management-1Document57 pagesSupply Chain Management-1Amit AgarwalNo ratings yet

- 3 Supply Chain Strategies (Integration Distribution) (Moodle) (Compatibility Mode)Document33 pages3 Supply Chain Strategies (Integration Distribution) (Moodle) (Compatibility Mode)Tamarai Selvi ArumugamNo ratings yet

- C CCCC C CCCCCCCCCC CCCCCCCCCCCCCCCC C: CC CCCCCCCC C CCC CCC C CCDocument8 pagesC CCCC C CCCCCCCCCC CCCCCCCCCCCCCCCC C: CC CCCCCCCC C CCC CCC C CCSanna SalimNo ratings yet

- Distribution Supply Chain Management - Sourcing & ProcurementDocument39 pagesDistribution Supply Chain Management - Sourcing & Procurementshoaibnadir100% (1)

- Demand Chain ManagementDocument134 pagesDemand Chain ManagementVivek Sarmal100% (3)

- T8 Distribution StrategiesDocument3 pagesT8 Distribution StrategiesAnna Vidal AribauNo ratings yet

- Designing & Managing The Supply Chain: Introduction To Supply Chain Management Dr. A. K. DeyDocument61 pagesDesigning & Managing The Supply Chain: Introduction To Supply Chain Management Dr. A. K. DeyPriya DattaNo ratings yet

- Supply Management NewDocument4 pagesSupply Management NewMurugan SaravananNo ratings yet

- Supply Chain Management 7Document45 pagesSupply Chain Management 7Abhi KeshwaniNo ratings yet

- Supply Chain MGTDocument42 pagesSupply Chain MGTYash RoxsNo ratings yet

- Overview of Logistics and Supply ChainDocument23 pagesOverview of Logistics and Supply ChainZaa ZaNo ratings yet

- SCM in GeneralDocument22 pagesSCM in GeneralMartin JohnNo ratings yet

- Supply Chain ManagementDocument9 pagesSupply Chain ManagementRupesh SinghNo ratings yet

- Supply Chain TerminologyDocument5 pagesSupply Chain TerminologyMehroz KhanNo ratings yet

- 1.0 Introduction To Supply Chain Management (SCM)Document69 pages1.0 Introduction To Supply Chain Management (SCM)Anchal BaggaNo ratings yet

- Supply ChainDocument38 pagesSupply ChainMk YapNo ratings yet

- Introduction To Supply Chain ManagementDocument19 pagesIntroduction To Supply Chain ManagementSneha Karpe100% (1)

- Introduction To Supply Chain ManagementDocument42 pagesIntroduction To Supply Chain Managementsoumyarm942No ratings yet

- Supply Chain Risk ManagementDocument45 pagesSupply Chain Risk ManagementSabir AliNo ratings yet

- Demand Management and Customer Service-4 - Supply Chain ManagementDocument22 pagesDemand Management and Customer Service-4 - Supply Chain ManagementPooja ShahNo ratings yet

- Corporate Strategy - Supply Chain Management - Dell Case StudyDocument22 pagesCorporate Strategy - Supply Chain Management - Dell Case StudyDr Rushen Singh100% (1)

- Origin of Supply Chain ManagementDocument4 pagesOrigin of Supply Chain ManagementMurugan SaravananNo ratings yet

- Session 2 - Nsupply Chain Design and Linkage To Corporate StrategyDocument39 pagesSession 2 - Nsupply Chain Design and Linkage To Corporate Strategypulkit khandelwalNo ratings yet

- Importance of Supply-Chain Management (SCM), Purchasing Strategies and Purchasing ManagementDocument20 pagesImportance of Supply-Chain Management (SCM), Purchasing Strategies and Purchasing ManagementLaian MaligNo ratings yet

- Notes For Supply Chain ManagementDocument18 pagesNotes For Supply Chain ManagementDanny GloverNo ratings yet

- Lifeline - Supply ChainDocument41 pagesLifeline - Supply Chainvnewaskar_1No ratings yet

- Designing Supply Chain NetworkDocument4 pagesDesigning Supply Chain NetworkendeshawNo ratings yet

- Introduction To Supply Chain ManagementDocument96 pagesIntroduction To Supply Chain ManagementGaurav SainiNo ratings yet

- SCM Udemy NotesDocument6 pagesSCM Udemy NotesPraphulNo ratings yet

- Integrating The Supply Chain - RKSDocument25 pagesIntegrating The Supply Chain - RKSRksingal SingalNo ratings yet

- Supply Chain Management Research Paper OutlineDocument4 pagesSupply Chain Management Research Paper Outlinegz7vxzyz100% (1)

- SCM SummaryDocument47 pagesSCM SummaryEmanuelle BakuluNo ratings yet

- Supply Chain MnagementDocument5 pagesSupply Chain MnagementDanish AhsanNo ratings yet

- An Assignment On Supply Chain Practice & ProcedureDocument29 pagesAn Assignment On Supply Chain Practice & ProcedurePankaj AgarwalNo ratings yet

- 8 - Integrating The Supply ChainDocument31 pages8 - Integrating The Supply ChainArunkumarNo ratings yet

- Emailing SCM PPTs - CompressedDocument458 pagesEmailing SCM PPTs - CompressedRahul PandeyNo ratings yet

- E - Supply Chain ManagementDocument45 pagesE - Supply Chain Managementayman hindiehNo ratings yet

- SCM Chapter 1Document34 pagesSCM Chapter 1Sneha KadamNo ratings yet

- Supply Chain ManagementDocument23 pagesSupply Chain ManagementNeha GuptaNo ratings yet

- 1.1 What Is A Supply Chain?Document5 pages1.1 What Is A Supply Chain?chitraNo ratings yet

- Supply Chain Version 2Document37 pagesSupply Chain Version 2Abdelhamid Harakat100% (1)

- IT in Supply Chain ManagementDocument62 pagesIT in Supply Chain Managementrohitsingh17No ratings yet

- SC & OS - FinalDocument20 pagesSC & OS - FinalPrasad ChamaraNo ratings yet

- Demand ManagementDocument22 pagesDemand Managementmushtaque61No ratings yet

- SCM Test 3 Q&ADocument9 pagesSCM Test 3 Q&AnarinebalasubramaniNo ratings yet

- WK 6 Supply ChainDocument8 pagesWK 6 Supply ChainpthavNo ratings yet

- Managing Supply Chains: Session 2Document25 pagesManaging Supply Chains: Session 2Malik Muhammad SufyanNo ratings yet

- Ssupply Chain 1Document53 pagesSsupply Chain 1Tedros AbrehamNo ratings yet

- Supply Chain Management: Mid-Semester ReviewDocument42 pagesSupply Chain Management: Mid-Semester ReviewKaran BhatiaNo ratings yet

- Sap SCMDocument21 pagesSap SCMAffizul AzuwarNo ratings yet

- Submitted To: Submitted By:: Mr. N.S Uppal SUDEEP JANA (80062) Chitrangda Thakur (80081) 4 MAY, 2009Document56 pagesSubmitted To: Submitted By:: Mr. N.S Uppal SUDEEP JANA (80062) Chitrangda Thakur (80081) 4 MAY, 2009fun_maduraiNo ratings yet

- Military Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceFrom EverandMilitary Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceNo ratings yet

- Marketing Managaement: by A. Sandhya Rani Asst. ProfDocument45 pagesMarketing Managaement: by A. Sandhya Rani Asst. Proftafere99100% (1)

- 7 Quality Control ToolsDocument1 page7 Quality Control Toolstafere99No ratings yet

- Production and Operations ManagementDocument13 pagesProduction and Operations Managementtafere99No ratings yet

- Introduction To OMDocument30 pagesIntroduction To OMtafere99No ratings yet

- Approches To Customer Analysis-31!12!2010 Friday ClassDocument118 pagesApproches To Customer Analysis-31!12!2010 Friday Classtafere99No ratings yet

- Textile Inspections in Asia Textile Inspections in AsiaDocument1 pageTextile Inspections in Asia Textile Inspections in Asiatafere99No ratings yet

- A Power Point Presentation On TQMDocument46 pagesA Power Point Presentation On TQMtafere99No ratings yet

- Final ReportDocument8 pagesFinal ReportZack GroothouseNo ratings yet

- Intermittent Battery Drain: Ymms: Dec 4, 2019 Engine: 3.5L Eng License: Vin: Odometer: 2014 Acura MDX BaseDocument2 pagesIntermittent Battery Drain: Ymms: Dec 4, 2019 Engine: 3.5L Eng License: Vin: Odometer: 2014 Acura MDX Basebyungchul kimNo ratings yet

- Nuvance Health Strategic PlanDocument7 pagesNuvance Health Strategic Planfranjo bacicNo ratings yet

- List Obat ApotekDocument17 pagesList Obat ApotekAnonymous NIuKdo2xqtNo ratings yet

- Mix Design C 35A - 50%Document1 pageMix Design C 35A - 50%cecbNo ratings yet

- Entrep - Product ProposalDocument4 pagesEntrep - Product ProposalPrincess ArabelaNo ratings yet

- PED 5 Heat ExchangersDocument74 pagesPED 5 Heat ExchangersDiogo EstevesNo ratings yet

- Yasnac J300 Connecting Manual (Type B)Document186 pagesYasnac J300 Connecting Manual (Type B)sunhuynh100% (1)

- CV - ModelDocument5 pagesCV - ModeldanzeluNo ratings yet

- Competitors Analysis 1Document2 pagesCompetitors Analysis 1rajaroma45No ratings yet

- Swimming Pool BoqDocument5 pagesSwimming Pool Boqfelix sowah-laryeaNo ratings yet

- So Too Either NeitherDocument4 pagesSo Too Either NeitherJos Nguyễn Công DươngNo ratings yet

- Automated Coiled Tubing Integrity Monitoring (ACIM) : TechnologyDocument4 pagesAutomated Coiled Tubing Integrity Monitoring (ACIM) : TechnologyArgonauta_navegadorNo ratings yet

- Echo Core LabsDocument11 pagesEcho Core LabsSundara Rami ReddyNo ratings yet

- Karakteristik Ekosistem Mangrove Di Kawasan Pesisi PDFDocument7 pagesKarakteristik Ekosistem Mangrove Di Kawasan Pesisi PDFAdilNo ratings yet

- Network Engineer - L3 Noida - Noida - CYFUTURE INDIA PRIVATE LIMITED - 4 To 8 Years of ExperienceDocument3 pagesNetwork Engineer - L3 Noida - Noida - CYFUTURE INDIA PRIVATE LIMITED - 4 To 8 Years of Experiencemanish0202No ratings yet

- Integrated Watershed ApproachDocument3 pagesIntegrated Watershed ApproachSuhas KandeNo ratings yet

- SP1100 50HZ Perkins GeneratorDocument4 pagesSP1100 50HZ Perkins GeneratorsunshinemachineryNo ratings yet

- COSH Module 2 - 1A Safety Hazards (Synerquest) - CompressedDocument61 pagesCOSH Module 2 - 1A Safety Hazards (Synerquest) - Compressedalmiraraiza bustamanteNo ratings yet

- 432 OSCE Revision File PDFDocument20 pages432 OSCE Revision File PDFReza Affandi MohamadNo ratings yet

- KatalogDocument3 pagesKatalogJosua Sahat Parulian SinagaNo ratings yet

- Morphology McqsDocument8 pagesMorphology McqsHiba Shah100% (2)

- IP0497 Sandvik EDocument15 pagesIP0497 Sandvik EGary LopezNo ratings yet

- Test Bank For Williams Basic Nutrition and Diet Therapy 14th Edition Staci NixDocument24 pagesTest Bank For Williams Basic Nutrition and Diet Therapy 14th Edition Staci Nixdavidjonescrjeagtnwp100% (38)

- Subsea PE RoleDocument3 pagesSubsea PE RoleBen OjemsNo ratings yet

- Voucher (Pre-Paid Booking) : ST - Havel ResidenceDocument2 pagesVoucher (Pre-Paid Booking) : ST - Havel ResidenceAlena KolesnykNo ratings yet

- Weflo 3129 Cast Iron Gate Valve Flanged Table EDocument1 pageWeflo 3129 Cast Iron Gate Valve Flanged Table EMOHD HAIDARNo ratings yet

- Delhi Gang Rape CaseDocument3 pagesDelhi Gang Rape CasePriyesha MaliNo ratings yet

- Low Cost Mechatronics Prototype Prosthesis For Transfemoral Amputation Controled by Myolectric SignalsDocument6 pagesLow Cost Mechatronics Prototype Prosthesis For Transfemoral Amputation Controled by Myolectric SignalsElizabeth CominaNo ratings yet