Professional Documents

Culture Documents

Flow Measuring Devices

Flow Measuring Devices

Uploaded by

Abdul Moeed KalsonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Measuring Devices

Flow Measuring Devices

Uploaded by

Abdul Moeed KalsonCopyright:

Available Formats

FLOW MEASURING DEVICES

Prepared by!

ABDUL MOEED KALSON

Why accurate measurement of fluid flow is

important?

To obtain specific proportions is necessary.

The maintenance of definite rates of flow is

important for maximum efficiency and

production.

Precise quality control is impossible.

Costs which are based on flow measurements will

be incorrect if the measurements are erroneous.

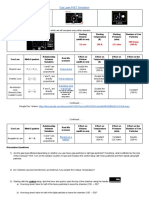

FLOW MEASUREMENT

Primary Measuring Devices

Secondary Measuring Devices

RRIMARY MEASURING

DEVICES

Devices which create a difference in

pressure in a flowing fluid.

For Example:-

Orifice plates,Venturi tubes,

Flow nozzles etc.

SECODARY MEASURING

DEVICES

The devices which measure the pressure

differential to determine the flow velocity or

flow rate of a fluid.

For Example:-

Manometer,Bellows meter,

Pressure differential transmitter etc.

IMPORTANT FLOW METERS

Orifice meter.

Venturi meter.

Turbine meter.

Magnetic flow meter.

Pitot tube.

Rota meter.

ORIFICE METER

Principle:-

On flowing the fluid through the

meter (construction), there will be an

increase in the velocity (i.e. kinetic

energy) and the decrease in the pressure .

The rate of flow is then measured at the

expense of this pressure drop.

ORIFICE METER

Construction:-

It consists of a thin shell of

metal having a hole drilled of the required size.

The plate is made enough strong to withstand the

high pressure on its surface, more it made of the

material which is not to be corroded. This plate is

fitted between two pipe flanges and suitable

pressure holes are drilled to measure the

differential pressure.

ORIFICE METER

Working:-

Fluid enters the orifice, its velocity

suddenly increases and its pressure falls. Upto the

point called vena contracta pressure is minimum

and the cross section of the fluid is also minimum.

After this the pressure of the fluid increases

gradually and the velocity decreases, the fluid

once again as previously however with the

permanent pressure drop.

ORIFICE METER

Working Equation:-

O O D

gh A C G 2 =

Where

ho = difference in head across the orifice expressed in terms of

the fluid in work.

CD = Coefficient of discharge.

Ao = Area of cross section of orifice

ORIFICE METER

Advantages:-

Due to its smallest form it is easy to manufacture.

It is cheap in comparison with other primary ones.

If the maximum flow is charged a great deal, plate

can be replaced with other orifice diameter, thus flow

is measured on a new scale with in the same geometry.

It occupies very less space and easy to install.

A carrier ring containing pressure taps can be fitted

easily between the space available in flanges.

ORIFICE METER

Disadvantages:-

Pressure recovery in orifice meter is poor,

thus resulting power loss is one of the

disadvantages of this meter.

ORIFICE METER

Applications and Limitations:-

An orifice plate may be used for measuring

the flow of gases , liquids or vapours.

However not suitable for measuring the

flow of viscous fluids.

VENTURI METER

Principle:-

On flowing the fluid

through the meter (constriction) , there will

be an increase in the velocity (i.e. K.E.)

and a decrease in pressure. The rate of flow

is then measured at the expense of this

pressure drop.

VENTURI METER

Construction:-

In construction it consists of

following points.

The short cylinder inlet having same dia as the

upstream pipe, with a side hole or several side

holes for measuring static pressures.

The entrance cone including an angle of 15-20

degree joined to the inlet by smooth curve.

VENTURI METER

The short cylinderical throat fitted with

single hole, or servel holes to measure the

pressure at the throat.

The exit cone including an angle from 5-7

degree.

The end of exit cone the outlet flange.

VENTURI METER

Working:-

The fluid enters into the converging

cone its velocity increases , and pressure is

decreased, after passes through the throat the fluid

is retarted gradually and much of original pressure

is recovered (i.e. much K.E. is converted back to

pressure energy). Due to the gradual reduction in

the area of flow there is no vena-contracta and the

flow area is this minimum at the throat thus it is

why the second piezometer is placed at the throat.

VENTURI METER

Working Equation:-

v D

gh C C G 2

'

=

Where

hv = difference in head across the

converging cone.

C =constant for venturi meter.

VENTURI METER

Advantages:-

In venturi meter the overall loss of pressure is less

than nozzles or orifice.This is extrmely important

where overall head of pressure is small .

A venturi meter unlike orifice can be used for flow

of slurries,suspensios etc,and unilike orifice can be

used for gases and liquids etc.

VENTURI METER

Disadvantages:-

It has high initial cost.

Due to its length it is difficult to install.

Once manufactured and installed it is

impossible to vary the range of flow as

orifice may do.

PITOT TUBE

Principle:-

It operates on the principle

that a pressure differential exists in the fluid

between the spot where the flow impinges

on the front opening (P2) and the place

where higher velocity fluid speeds past the

lateral openings (P1) , the faster the fluid

flows, the greater the difference in pressure.

PITOT TUBE

Construction:-

It normally

consists of two concentric tubes arranged parallel

to the flow . The outer tube of greater dia

perforated i.e. having small holes (static holes)

prependicular to the direction of flow .The inner

tube has a small opening pointed into the flow.

Both these tubes are connected to the manometeter

PITOT TUBE

Working:-

A simple U-tube manometer

(filled with water of mercury) attached to the

pitot tube act as a secondary device. One side of

the tube connects to the inner tube (P2), and the

other side connects to the outer tube (P1) . The

difference between the two levels of manometer

fluid can be calibrated in velocity units to give

flow ate readings directly from the glass U-tube.

The greater the difference in levels, the greater

the rate of fluid flow.

PITOT TUBE

Working Equation:-

Where

C = Coefficient for the meter.

for well designed tube C=1

gh C U 2 =

PITOT TUBE

Advantages:-

They are inexpensive.

They have no moving parts.

They cause minimal pressure drop.

PITOT TUBE

Applications and Limitations:-

The Pitot tube must be used in relatively clean

liquids, free of solid contaminants, or its openings

will clog.

It must be properly positioned within the

pipe where fluid velocity is average.

Pitot tubes are often used in hospitals , where

fluids are usually cleaner than in industry.

ROTAMETER

Principle:-

In such meters the drop in

pressure is constant and the flow rate is a

function of the area . The quantity of fluid

flowing per unit of time varies directly with

the area in this instrument.

ROTAMETER

Construction:-

The rotameter is a long

graduated , uniform tapered vertical tube.

The tube is smallest at the bottom and

larges at the top. There is freely moving

unidirectional marker called float .This float

is at rest at the base of the tube, when no

flow is occuring.

ROTAMETER

Working:-

Fluid enters the bottom of the tube and as

it flows upward it exerts a force on the bottom of the float.

When the upward force on the float is equal to the

gravitational force acting downward the float becomes

stationary at some point in the tube. The float position

gives the reading. Now when more of the fluid passed

upward, i.e. a greater force is exerted on the bottom of the

float and float then moves more upwardly and stops at

some higher level. Area available for flow increases,

allowig more liquid or gas to flow. Constant pressure drop

arises due to the change in kinetic energy, i.e. due to

greater area less velocity ,also from liquid friction.

ROTAMETER

Working Equation:-

(

|

.

|

\

|

=

2

1

2

2

1

) ( 2

A

A

Af

V g

A C G

f f

D

where

Af = Max. Area of float.

A1 = Cross sectional area of the tube

A2 = Area of the annulus between the float and tube

CD = Coefficient of discharge

Vf = Volume of float.

ROTAMETER

Advantages:-

The range of the meter can be varied by the use of

floats of different densities.

Direct reading is available not pressure measuring

installments are required.

Pressure drop remains constant.

It can be arranged to give an indication in weights

thus independent of small changes in the sp.

gravity.

ROTAMETER

Disadvantages:-

The major disadvantage is the its expensivity.It is

expensive specially in larger sizes, thus it is often

used in installations with pipe sizes less than 2 in.

The flow rate reading must be read at the

instrument places, rather than at the control room .

The quantity of liquid that can be measured by

a rotameter is small when compared with

capacities of some of the other methods.

REFERENCES

COULSON, J.M. and RICHARDSON, J.F.

Chemical Engineering Vol.1, 5

th

ed.

McCABE, W.L. and SMITH, J.C. :Unit

Operation of Chemical Engineering, 5

th

ed.

AUSTIN E. FRIBANCE : Industrial

Instrumentation Fundamentals.

Perry Chemical Engineers Handbook.

TPC training System (U-275).

THANKS

U

TO

ALL!!!

You might also like

- Pneumatic Conveyor Sizing CalculationsDocument3 pagesPneumatic Conveyor Sizing Calculationsm_nassif100% (1)

- Gas Laws Phet Simulation: 5.0 NM 300 K 23.3 Atm 100 Heavy (100 H)Document3 pagesGas Laws Phet Simulation: 5.0 NM 300 K 23.3 Atm 100 Heavy (100 H)ferpuc16No ratings yet

- Level HE6: RAS AL Khaimah CampusDocument6 pagesLevel HE6: RAS AL Khaimah CampusUmer RaufNo ratings yet

- Dual-Pot Sand Filter Type B (DSF-B)Document2 pagesDual-Pot Sand Filter Type B (DSF-B)kanchanabalajiNo ratings yet

- PTRT 2323assignments 9-10 PDFDocument1 pagePTRT 2323assignments 9-10 PDFAlmotsem0% (1)

- Thermodynamics 2Document52 pagesThermodynamics 2joe125675% (4)

- Flow Measurement: 6 November 2012 PMI Revision 00 1Document57 pagesFlow Measurement: 6 November 2012 PMI Revision 00 1narendra_nucleusNo ratings yet

- FLOWDocument31 pagesFLOWHassan HaiderNo ratings yet

- Storage and Measurement in Crude Oil E&PDocument16 pagesStorage and Measurement in Crude Oil E&PSaurabh SharmaNo ratings yet

- Flow Measurement: - Introduced By: Taha Safi Ahmad Habbas Essa Qaisi Abdel Rahman AlnatourDocument29 pagesFlow Measurement: - Introduced By: Taha Safi Ahmad Habbas Essa Qaisi Abdel Rahman AlnatourAbd Al-NatourNo ratings yet

- Basic Flow MeasurementDocument50 pagesBasic Flow MeasurementSaishankar L NarayananNo ratings yet

- Flow Measurement BasicDocument87 pagesFlow Measurement BasicSri100% (2)

- Crude Oil Properties (Laboratory)Document15 pagesCrude Oil Properties (Laboratory)gshdavidNo ratings yet

- Bernoulli'S Theorem: Eesha Agarwal 1741018011 Mechanical - D 5 SemesterDocument19 pagesBernoulli'S Theorem: Eesha Agarwal 1741018011 Mechanical - D 5 SemesterEESHA AGARWALNo ratings yet

- Gauge Gauge Tank Body:: FunctionsDocument9 pagesGauge Gauge Tank Body:: FunctionsMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Gas Density MeasurementDocument31 pagesGas Density MeasurementJamesh Babu100% (1)

- Static Pitot Tube: Flow MeasurementDocument23 pagesStatic Pitot Tube: Flow MeasurementMuthu KarthikNo ratings yet

- Fluid Mechanics LabDocument12 pagesFluid Mechanics LabRonald Muñez BadicNo ratings yet

- Specific Gravity of Crude OilDocument3 pagesSpecific Gravity of Crude OilAteeq Ul Rehman100% (1)

- Ideal Gas Equation of StateDocument18 pagesIdeal Gas Equation of StateOssama BohamdNo ratings yet

- VSD Affinity Laws and ApplicationsDocument32 pagesVSD Affinity Laws and Applicationsram_river808100% (2)

- Pressure Loss CorrelationsDocument57 pagesPressure Loss Correlationseandresmar100% (1)

- ABB-733-WPO Understanding Coriolis Mass FlowmeterDocument3 pagesABB-733-WPO Understanding Coriolis Mass FlowmetercarlosmandopintoNo ratings yet

- Marine Cargo Deepwell PumpsDocument3 pagesMarine Cargo Deepwell PumpsRickey PanwarNo ratings yet

- Vortex Pilot Gas Heater Over Temperature ProtectionDocument17 pagesVortex Pilot Gas Heater Over Temperature ProtectionDon BettonNo ratings yet

- API Gravity FormulasDocument2 pagesAPI Gravity FormulasCH PurnimaRajesh100% (1)

- Summer Internship Report On: Training Undertaken atDocument41 pagesSummer Internship Report On: Training Undertaken atJaydeep MulchandaniNo ratings yet

- Dynamic, Absolute and Kinematic ViscosityDocument5 pagesDynamic, Absolute and Kinematic ViscosityDeidra CadeNo ratings yet

- Properties of Petroleum (Oil and Gas) and Petroleum ProductsDocument21 pagesProperties of Petroleum (Oil and Gas) and Petroleum ProductsHadi H. HussenNo ratings yet

- Group B ReportDocument47 pagesGroup B ReportFINAL YEAR PETROLEUM 2020 BATCH100% (1)

- Classification of Hydrocarbon Reservoir: Chapter OneDocument19 pagesClassification of Hydrocarbon Reservoir: Chapter OneWanambwa SilagiNo ratings yet

- Maintenance Manual FOR Turbine Flow Meter: Shanghai Cowell Machinery Co., LTDDocument29 pagesMaintenance Manual FOR Turbine Flow Meter: Shanghai Cowell Machinery Co., LTDasmoosa_scribdNo ratings yet

- API GravityDocument3 pagesAPI Gravityargon sanjayaNo ratings yet

- 1 - Intro + Basic ConceptsDocument48 pages1 - Intro + Basic ConceptsShawki BsatNo ratings yet

- Abstract Lab 6Document12 pagesAbstract Lab 6adib assoliNo ratings yet

- MPFM-050 PresentationDocument19 pagesMPFM-050 Presentationrocket-vtNo ratings yet

- Meter Linearity Turbine Meter PerspectiveDocument3 pagesMeter Linearity Turbine Meter PerspectiveraminNo ratings yet

- Learning For Oil and Gas PlantDocument93 pagesLearning For Oil and Gas Plantlucky yadavNo ratings yet

- Drilling Mud CalculationDocument12 pagesDrilling Mud Calculationaditya imansyahNo ratings yet

- Design 2P Separators in Rigth LimitsDocument8 pagesDesign 2P Separators in Rigth Limitsedgardiaz5519No ratings yet

- GT-Turbine Flowmeter ManualDocument16 pagesGT-Turbine Flowmeter Manualedgarcoo100% (1)

- Problems Crude Oil Weight Calculation: N.G. Domostroeva, A.V. DomostroevDocument5 pagesProblems Crude Oil Weight Calculation: N.G. Domostroeva, A.V. DomostroevstvadimNo ratings yet

- Introductiontocustodytransfer 161204083749Document58 pagesIntroductiontocustodytransfer 161204083749NguyễnTrườngNo ratings yet

- Advanced Techniques For Acoustic Liquid Level DeterminationDocument14 pagesAdvanced Techniques For Acoustic Liquid Level Determinationmáté_galambosiNo ratings yet

- Losses in Bends FittingsDocument26 pagesLosses in Bends FittingsKunalNo ratings yet

- Fundamentals of Natural Gas Liquid MeasurementsDocument9 pagesFundamentals of Natural Gas Liquid Measurementsmakasad26No ratings yet

- Porosity by Saturation Method-150731201424-Lva1-App6891Document16 pagesPorosity by Saturation Method-150731201424-Lva1-App6891Mohammed AL-sharafiNo ratings yet

- Unit Conversion Related To Oil and Gas IndustryDocument20 pagesUnit Conversion Related To Oil and Gas IndustryNavin KumarNo ratings yet

- 04 Flow MeasurementDocument10 pages04 Flow MeasurementVo Dang Gia PhatNo ratings yet

- Gas Lift On Improving TPR and Oil ProductionDocument24 pagesGas Lift On Improving TPR and Oil Productionyimam aliNo ratings yet

- FlowDocument54 pagesFlowsourajpatelNo ratings yet

- Application of Water Alaternating Gas (Wag) Injection For Heavy Oil Recovery in Niger DeltaDocument71 pagesApplication of Water Alaternating Gas (Wag) Injection For Heavy Oil Recovery in Niger DeltaNdifreke Nsima WilliamsNo ratings yet

- Liquid Flowmeters: Reynolds NumbersDocument12 pagesLiquid Flowmeters: Reynolds NumbersAsaithambi DorairajNo ratings yet

- Gas-Solid Flows: 2004 by Marcel Dekker, Inc. All Rights ReservedDocument36 pagesGas-Solid Flows: 2004 by Marcel Dekker, Inc. All Rights ReservedGustavo Hernandez100% (1)

- Flare Gas Recovery - Olefin Plants PDFDocument5 pagesFlare Gas Recovery - Olefin Plants PDFChem.EnggNo ratings yet

- Orifice Sizing Guidelines and Thumb RulesDocument11 pagesOrifice Sizing Guidelines and Thumb RulesBsd Fareed100% (1)

- Vertical Multiphase Flow: Instructional ObjectivesDocument23 pagesVertical Multiphase Flow: Instructional ObjectivesIksan Adityo MulyoNo ratings yet

- Petroleum Refinery Lab. Kinematic ViscosityDocument11 pagesPetroleum Refinery Lab. Kinematic ViscositySiyar SaleemNo ratings yet

- Measurement of Fluid FlowDocument13 pagesMeasurement of Fluid FlowDahiru Muhammed DanbarebariNo ratings yet

- Flow Measurement Unit 4Document94 pagesFlow Measurement Unit 4Ajith AdityaNo ratings yet

- قياسات نموذجيDocument11 pagesقياسات نموذجيMohammed KasimNo ratings yet

- Head Flow MetersDocument27 pagesHead Flow Metersvashu patelNo ratings yet

- Folds, Faults, and Other Records of Rock DeformationDocument90 pagesFolds, Faults, and Other Records of Rock DeformationAbdul Moeed KalsonNo ratings yet

- Structural Geology: R. B. SchultzDocument17 pagesStructural Geology: R. B. SchultzAbdul Moeed KalsonNo ratings yet

- Stratigraphic PrinciplesDocument39 pagesStratigraphic PrinciplesAbdul Moeed Kalson100% (1)

- Sedimentary Rocks: Rocks Made of Bits & Pieces of Other RocksDocument28 pagesSedimentary Rocks: Rocks Made of Bits & Pieces of Other RocksAbdul Moeed KalsonNo ratings yet

- Welcome To The Glendale Community College: Mineral Identification ProgramDocument55 pagesWelcome To The Glendale Community College: Mineral Identification ProgramAbdul Moeed KalsonNo ratings yet

- Sedimentary RockDocument65 pagesSedimentary RockAbdul Moeed KalsonNo ratings yet

- Rocks: Dr. Michael J. PassowDocument21 pagesRocks: Dr. Michael J. PassowAbdul Moeed Kalson100% (1)

- Structure Contour MapsDocument49 pagesStructure Contour MapsAbdul Moeed Kalson50% (2)

- Weathering and Mass WastingDocument52 pagesWeathering and Mass WastingAbdul Moeed KalsonNo ratings yet

- Classification of FaultsDocument3 pagesClassification of FaultsAbdul Moeed KalsonNo ratings yet

- Fold - Geometry, Classification & MechanicsDocument24 pagesFold - Geometry, Classification & MechanicsAbdul Moeed KalsonNo ratings yet

- Geology Literally Means "Study of The Earth."Document49 pagesGeology Literally Means "Study of The Earth."Abdul Moeed KalsonNo ratings yet

- Historical Geology SlidesDocument21 pagesHistorical Geology SlidesAbdul Moeed KalsonNo ratings yet

- What Is A Topographic MapDocument36 pagesWhat Is A Topographic MapAbdul Moeed KalsonNo ratings yet

- Topo MapDocument47 pagesTopo MapAbdul Moeed Kalson100% (2)

- Confined SpaceDocument35 pagesConfined SpaceAbdul Moeed Kalson100% (8)

- Remote Field Technique (RFT)Document2 pagesRemote Field Technique (RFT)Abdul Moeed KalsonNo ratings yet

- Water Boiling Temperature Vs Pressure in Vacuum Table Chart - Engineers EdgeDocument1 pageWater Boiling Temperature Vs Pressure in Vacuum Table Chart - Engineers Edgeinterkesselgmail0% (1)

- Monte Carlo Simulation For Statistical Physics Coddington P PDFDocument164 pagesMonte Carlo Simulation For Statistical Physics Coddington P PDFjgonzalezsanz8914No ratings yet

- Ensembles NotesDocument5 pagesEnsembles NotesParamita HaldarNo ratings yet

- Engineering Technology ComputerScienceDocument138 pagesEngineering Technology ComputerScienceprateek vyasNo ratings yet

- MP, FP & BPDocument3 pagesMP, FP & BPammuluhai333No ratings yet

- 460 Question PaperDocument2 pages460 Question PaperMounish PathanNo ratings yet

- Some Solved QuestionsDocument16 pagesSome Solved QuestionsShashwat ChakrabortiNo ratings yet

- Dry and Atmospheric Air: Specific and Relative HumidityDocument6 pagesDry and Atmospheric Air: Specific and Relative HumidityHassan JalilNo ratings yet

- Definition:: DistillationDocument2 pagesDefinition:: DistillationAirah De JesusNo ratings yet

- Department Chemistry PG SyllabusDocument40 pagesDepartment Chemistry PG Syllabusrihana yadavNo ratings yet

- Chapter 6 - EntropyDocument46 pagesChapter 6 - EntropyNor HidayahNo ratings yet

- Compressibility Z FactorDocument14 pagesCompressibility Z FactorosbertodiazNo ratings yet

- Stanley I. Sandler: Equations of State For Phase Equilibrium ComputationsDocument29 pagesStanley I. Sandler: Equations of State For Phase Equilibrium ComputationscsandrasNo ratings yet

- Introduction To Chemical Engineering For Lecture 5: Flash DistillationDocument10 pagesIntroduction To Chemical Engineering For Lecture 5: Flash DistillationAkmalNo ratings yet

- Train-1 Process Flow DiagramDocument1 pageTrain-1 Process Flow DiagramHtoo Htoo KyawNo ratings yet

- CorrectionsDocument7 pagesCorrectionskarimNo ratings yet

- Appendices D: Problems: EtohDocument4 pagesAppendices D: Problems: EtohJensen Myles CollasNo ratings yet

- Equation of State of Ideal Gases With Cobra3Document1 pageEquation of State of Ideal Gases With Cobra3Jose GalvanNo ratings yet

- Behavior of GasesDocument4 pagesBehavior of GasesDuaneNo ratings yet

- 2 Fluid Mechanics I ReviewDocument11 pages2 Fluid Mechanics I ReviewAmjad AliNo ratings yet

- States of Matter Grade - IV 2021-2022 UnsolvedDocument6 pagesStates of Matter Grade - IV 2021-2022 UnsolvedManisha Thakur100% (1)

- Gibbs Reactor: GBR-100: Stream NameDocument3 pagesGibbs Reactor: GBR-100: Stream NameJamesNo ratings yet

- R & AC Lab ManualDocument30 pagesR & AC Lab ManualShashankNo ratings yet

- Convert Ion MeasurementDocument2 pagesConvert Ion MeasurementSayed MachfudNo ratings yet

- Fluid Mechanics ApplicationsDocument29 pagesFluid Mechanics ApplicationsHASSAN ARSHADNo ratings yet

- PPE ME321 Steam NozzleDocument15 pagesPPE ME321 Steam Nozzlemuhammad umarNo ratings yet

- 2Ch404-Chemical Engineering Thermodynamics: Tutorial-1 21BCH021Document6 pages2Ch404-Chemical Engineering Thermodynamics: Tutorial-1 21BCH021Harvin PatelNo ratings yet