Professional Documents

Culture Documents

Introducing Vapor Power Plants: Combustion of The Fuel

Introducing Vapor Power Plants: Combustion of The Fuel

Uploaded by

Ahmed M TOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introducing Vapor Power Plants: Combustion of The Fuel

Introducing Vapor Power Plants: Combustion of The Fuel

Uploaded by

Ahmed M TCopyright:

Available Formats

Introducing Vapor Power Plants

In fossil-fueled plants, the energy required for

vaporization originates in combustion of the fuel.

Power Cycle Review

in

cycle

Q

W

= q

The first law of thermodynamics

requires the net work developed by a

system undergoing a power cycle to

equal the net energy added by heat

transfer to the system:

The thermal efficiency of a power

cycle is

W

cycle

= Q

in

Q

out

Power Cycle Review

The second law of thermodynamics requires the thermal

efficiency to be less than 100%. Most of todays vapor power

plants have thermal efficiencies ranging up to about 40%.

Thermal efficiency tends to increase as the average

temperature at which energy is added by heat transfer

increases and/or the average temperature at which energy is

rejected by heat transfer decreases.

Improved thermodynamic performance of power cycles, as

measured by increased thermal efficiency, for example, also

accompanies the reduction of irreversibilities and losses.

The extent of improved power cycle performance is limited,

however, by constraints imposed by thermodynamics and

economics.

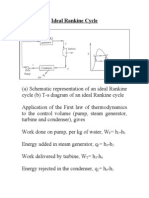

The Rankine Cycle

Each unit of mass of water circulating through the

interconnected components of Subsystem B of Fig. 8.1(a)

undergoes a thermodynamic cycle known as the Rankine cycle.

All energy transfers by work and heat are taken as positive in

the directions of the arrows on the schematic and energy

balances are written accordingly.

There are four principal

control volumes involving

these components:

Turbine

Condenser

Pump

Boiler

Turbine

Condenser

Pump

Boiler

The Rankine Cycle

3 4

p

h h

m

W

=

2 1

t

h h

m

W

=

4 1

in

h h

m

Q

=

(Eq. 8.3)

(Eq. 8.4)

(Eq. 8.2)

(Eq. 8.1)

3 2

out

h h

m

Q

=

Applying mass and energy rate balances

Thermal Efficiency

The Rankine Cycle

) (

) (

/

/

bwr

2 1

3 4

t

p

h h

h h

m W

m W

= =

(Eq. 8.6)

(Eq. 8.5a)

Performance parameters

) (

) ( ) (

/

/ /

4 1

3 4 2 1

in

p t

in

cycle

h h

h h h h

m Q

m W m W

Q

W

= =

q

Back Work Ratio

Back work ratio is characteristically low for vapor

power plants. For instance, in Example 8.1, the

power required by the pump is less than 1% of the

power developed by the turbine.

Ideal Rankine Cycle

Since the ideal Rankine cycle involves

internally reversible processes, results from

Sec. 6.13 apply.

Applying Eq. 6.51c, the pump work input per

unit of mass flowing is evaluated as follows

) (

3 4 3

s

p

p p

m

W

~

|

|

.

|

\

|

v

(Eq. 8.7b)

where v

3

is the specific volume at the pump

inlet and the subscript s signals the isentropic

process of the liquid flowing through the pump.

Ideal Reheat Cycle

When computing the

thermal efficiency of a reheat

cycle it is necessary to

account for the

Total work developed in

the two turbine stages:

processes 1-2 and 3-4.

Total heat added during

vaporization/superheating

and reheating: processes

6-1 and 2-3.

3 - 2 1 - 6

p

LP

t

HP

t

Q Q

W W W

+

+

= q

( ) ) (

) (

/

) / (

s 2 1

2 1

s

t

t

t

h h

h h

m W

m W

= =

q

Principal Irreversibilities

Isentropic turbine efficiency, introduced in Sec. 6.12.1,

accounts for the effects of irreversibilities within the turbine in

terms of actual and isentropic turbine work, each per unit of

mass flowing through the turbine.

(Eq. 8.9)

work developed in the actual

expansion from turbine inlet state

to the turbine exit pressure

work developed in an isentropic

expansion from turbine inlet

state to exit pressure

( ) ) (

) (

/

) / (

3 4

3 s 4

p

s p

p

h h

h h

m W

m W

= =

q

Principal Irreversibilities

While pump work input is much less than turbine work

output, irreversibilities in the pump affect net power output of

the vapor plant.

Isentropic pump efficiency, introduced in Sec. 6.12.3,

accounts for the effects of irreversibilities within the pump in

terms of actual and isentropic pump work input, each per unit

of mass flowing through the pump.

(Eq. 8.10a)

work input for the actual process from pump

inlet state to the pump exit pressure

work input for an isentropic process

from pump inlet state to exit pressure

With fraction y known, mass and energy rate

balances applied to control volumes around the

other components yield the following expressions,

each on the basis of a unit of mass entering the

first turbine stage.

Regenerative Vapor Power Cycle Using

an Open Feedwater Heater

Applying steady-state mass and energy rate

balances to a control volume enclosing the

feedwater heater, the fraction of the total flow y is

(Eq. 8.12)

Regenerative Vapor Power Cycle Using

an Open Feedwater Heater

For the pumps

(Eq. 8.14)

For the steam generator

(Eq. 8.15)

(Eq. 8.16)

For the condenser

For the turbine stages

(Eq. 8.13)

You might also like

- Explanatory Statement For The Amnesty CoalitionDocument8 pagesExplanatory Statement For The Amnesty CoalitionKai W100% (5)

- Oxford Advanced Learners Dictionary 10th EditionDocument2 pagesOxford Advanced Learners Dictionary 10th Editionpiyush50% (2)

- 06 791 1 - Rev2 PDFDocument94 pages06 791 1 - Rev2 PDFMaria Ignacia VasquezNo ratings yet

- 1968 - Feher - The Supercritical Thermodynamic Power CycleDocument6 pages1968 - Feher - The Supercritical Thermodynamic Power CycleDilipNo ratings yet

- Brayton Cycle Experiment - Jet EngineDocument10 pagesBrayton Cycle Experiment - Jet EngineAsif MohammedNo ratings yet

- Crane PartsDocument931 pagesCrane Partstecnicomanel100% (3)

- KE13N Upload of COPA Offline PlanningDocument6 pagesKE13N Upload of COPA Offline PlanningMOORTHYNo ratings yet

- Planta A Vapor Ciclo RankineDocument62 pagesPlanta A Vapor Ciclo Rankinelides fernandez saldivarNo ratings yet

- Faculty of Engineering: TutorialDocument13 pagesFaculty of Engineering: TutorialDavid ChikuseNo ratings yet

- ThermodynamicsDocument26 pagesThermodynamicsManikanta Reddy100% (1)

- Steam Power CycleDocument37 pagesSteam Power CycleAnamikaSharmaNo ratings yet

- Brayton CycleDocument103 pagesBrayton CycleRoosevelt SantosNo ratings yet

- Chapter8-MG2 Modifikasi Siklus RankineDocument30 pagesChapter8-MG2 Modifikasi Siklus RankineDefrianto PratamaNo ratings yet

- Ideal Rankine CycleDocument27 pagesIdeal Rankine Cycleslv_prasaadNo ratings yet

- ch09 pt2Document59 pagesch09 pt2Neil DalalNo ratings yet

- Internal Combustion Engines ME 4143: Dr. Saif Ur Rahman Department of Mechanical EngineeringDocument26 pagesInternal Combustion Engines ME 4143: Dr. Saif Ur Rahman Department of Mechanical EngineeringSyma ShaheenNo ratings yet

- Exp 4-Gas Turbine AnalysisDocument17 pagesExp 4-Gas Turbine AnalysisEdgar FigueroaNo ratings yet

- ch08 JmsDocument51 pagesch08 JmsGeçmiş GölgelerNo ratings yet

- Thermodynamics Steam TurbineDocument8 pagesThermodynamics Steam TurbineidhammenderoNo ratings yet

- Brayton Gas Turbine CycleDocument15 pagesBrayton Gas Turbine CycleJamshidNo ratings yet

- Ideal Gas Power Cycles: 13.1 Genera) IntroductionDocument5 pagesIdeal Gas Power Cycles: 13.1 Genera) IntroductionJahangir AliNo ratings yet

- MUCLecture 2022 123134814Document17 pagesMUCLecture 2022 123134814Raja ArifNo ratings yet

- Thermodynamics Project PDFDocument32 pagesThermodynamics Project PDFDaniyal NisarNo ratings yet

- Chap7 1Document10 pagesChap7 1Cm EtcmNo ratings yet

- Chapter 9Document84 pagesChapter 9ERCAN ÖZERDENNo ratings yet

- Lecture 3 Steam Power Plant Part I Rankine CycleDocument30 pagesLecture 3 Steam Power Plant Part I Rankine CycleMhd Donde Al HajNo ratings yet

- Thermal EngineeringDocument118 pagesThermal EngineeringSuresh RajuNo ratings yet

- Chap5 4Document8 pagesChap5 4Christopher EvanNo ratings yet

- Unit 3 Gas Turbines AND JET PROPULSIONDocument99 pagesUnit 3 Gas Turbines AND JET PROPULSIONSANTHOSH NAGARAJANo ratings yet

- Vapor Power CyclesDocument48 pagesVapor Power CyclesJames WankerNo ratings yet

- Mechanical Engineering Thermodynamics II - Lecture 03 - 27 SepDocument25 pagesMechanical Engineering Thermodynamics II - Lecture 03 - 27 SepThineshraaj Naidu Jaya RamanNo ratings yet

- Lecture 1 - Rankine Power CyclesDocument6 pagesLecture 1 - Rankine Power CyclesMuhammad IsmailNo ratings yet

- Chapter 3. Steam Power Plant Cycle PDFDocument31 pagesChapter 3. Steam Power Plant Cycle PDFJohn Carlo LEBRILLANo ratings yet

- Thermal EngineeringDocument118 pagesThermal EngineeringMukesh Kumar67% (6)

- Unit - 4 Vapour Power Cycles: H T L PDocument14 pagesUnit - 4 Vapour Power Cycles: H T L PMukesh MystNo ratings yet

- PpeDocument7 pagesPpeChristopher YsitNo ratings yet

- Chapter 8B - Gas Power Plant Brayton CycleDocument17 pagesChapter 8B - Gas Power Plant Brayton CycleBF3nobel100% (1)

- Unit - 2 Vapour Power Cycle - Theory - NotesDocument14 pagesUnit - 2 Vapour Power Cycle - Theory - Notes1DS19ME136-Shivam KumarNo ratings yet

- 0 S PP Chap6Document57 pages0 S PP Chap6Adib Nawawi100% (1)

- Adv Therm Week 10Document16 pagesAdv Therm Week 10Tegin Berkay BudakNo ratings yet

- Gas Power Cycles Study Guide in Powerpoint: To AccompanyDocument68 pagesGas Power Cycles Study Guide in Powerpoint: To AccompanyManjunatha TnNo ratings yet

- Thermodynamics 2 Rankine CycleDocument214 pagesThermodynamics 2 Rankine CycleDebbie Diane MarananNo ratings yet

- Thermodynamic CyclesDocument32 pagesThermodynamic CyclessunitbhaumikNo ratings yet

- Basic Cycle BraytonDocument15 pagesBasic Cycle BraytonMarin Andreea100% (2)

- Chapter RankineDocument32 pagesChapter RankineZack ZukhairiNo ratings yet

- Engineering Software: Brayton Cycle (Gas Turbine) For Propulsion Application AnalysisDocument16 pagesEngineering Software: Brayton Cycle (Gas Turbine) For Propulsion Application AnalysisagoezNo ratings yet

- Power PlantDocument63 pagesPower PlantSatheesh Sekar100% (4)

- Analysis of The Gpu-3 Stirling EngineDocument28 pagesAnalysis of The Gpu-3 Stirling EnginesbregoNo ratings yet

- Tarea U3Document2 pagesTarea U3mauricio omar enriquez martinezNo ratings yet

- Lecture 1 - Rankine Power CyclesDocument5 pagesLecture 1 - Rankine Power CyclesMuhammad Alam Zaib KhanNo ratings yet

- Gas Power Plant #1Document1 pageGas Power Plant #1Daniel KalderNo ratings yet

- Reciprocating CompressorDocument26 pagesReciprocating Compressorfaisalnadim100% (1)

- Chapter 9 LectureDocument29 pagesChapter 9 Lectureinam vf100% (6)

- 18me42 Atd Module 3Document23 pages18me42 Atd Module 3Shaik SulemanNo ratings yet

- 2nd Law of ThermoDocument13 pages2nd Law of ThermoTomiwa TolaseNo ratings yet

- EntropyDocument46 pagesEntropyAnonymous UqsAfi100% (1)

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Matlab HandoutsDocument6 pagesMatlab HandoutsAhmed M TNo ratings yet

- ST 371 (III) - Conditional Probability and IndependenceDocument18 pagesST 371 (III) - Conditional Probability and IndependenceAhmed M TNo ratings yet

- CH 02Document9 pagesCH 02Ahmed M TNo ratings yet

- CH 01Document10 pagesCH 01Ahmed M TNo ratings yet

- Due Date: Grade: July 24, 2014 Student Name (Print)Document1 pageDue Date: Grade: July 24, 2014 Student Name (Print)Ahmed M TNo ratings yet

- College of Engineering and Computer ScienceDocument1 pageCollege of Engineering and Computer ScienceAhmed M TNo ratings yet

- Homework AnasysDocument2 pagesHomework AnasysAhmed M TNo ratings yet

- Exam 1 Fall02Document5 pagesExam 1 Fall02Ahmed M TNo ratings yet

- Discrete Probability DistributionsDocument7 pagesDiscrete Probability DistributionsAhmed M TNo ratings yet

- Due Date: Grade: July 17, 2014 Student Name (Print)Document1 pageDue Date: Grade: July 17, 2014 Student Name (Print)Ahmed M TNo ratings yet

- Due: 9:30 Am, Thursday 06/19/2014 Student Name (Print) : GradeDocument2 pagesDue: 9:30 Am, Thursday 06/19/2014 Student Name (Print) : GradeAhmed M TNo ratings yet

- Press and Shrink FitsDocument11 pagesPress and Shrink FitsAhmed M TNo ratings yet

- Hardness ReportDocument23 pagesHardness ReportMohsin MunawarNo ratings yet

- Equipment List IrisDocument14 pagesEquipment List IrisTubagus DikaNo ratings yet

- Case 4Document2 pagesCase 4Harnam RainuNo ratings yet

- TF-FT With KidsDocument8 pagesTF-FT With KidsKeren MalchiNo ratings yet

- EQUATIONS OF STELLAR STRUCTURE - 7 Pages PDFDocument7 pagesEQUATIONS OF STELLAR STRUCTURE - 7 Pages PDFJohn BirdNo ratings yet

- Appendix 1,2,3 - Summer Internship Guideline For MMS & PGDM Batch 2019-21 & PGDM Exec Batch 2019-20Document3 pagesAppendix 1,2,3 - Summer Internship Guideline For MMS & PGDM Batch 2019-21 & PGDM Exec Batch 2019-20Punyak SatishNo ratings yet

- Staralfur (For Violin and Piano) PDFDocument5 pagesStaralfur (For Violin and Piano) PDFChavez AgniNo ratings yet

- Instrumentation Design EngineeringDocument4 pagesInstrumentation Design EngineeringAwneesh Kumar100% (1)

- Project CollegeDocument6 pagesProject CollegeDIPAK RAYCHURANo ratings yet

- Lecture - 15 Decoration of PlasticsDocument24 pagesLecture - 15 Decoration of PlasticsRoronoaNo ratings yet

- Access-Right The Future of Digital Copyright LawDocument633 pagesAccess-Right The Future of Digital Copyright LawRichard ShayNo ratings yet

- Bidriectional Lurking Jack-Up AGV Manual TZAGV-Q500Document23 pagesBidriectional Lurking Jack-Up AGV Manual TZAGV-Q500Vinaykumar PingaliNo ratings yet

- Amazon Things GraphDocument242 pagesAmazon Things GraphhabriwwoNo ratings yet

- PreviewpdfDocument36 pagesPreviewpdfOrkun TürkmenNo ratings yet

- EuroPHit Handbook Final OptimizedDocument124 pagesEuroPHit Handbook Final OptimizedBranescu FlorinNo ratings yet

- AGCDocument7 pagesAGCZarChiAyeNo ratings yet

- LG 2040T LED Monitor User GuideDocument38 pagesLG 2040T LED Monitor User GuideNikumbh RanaNo ratings yet

- Module-3 Metal CastingDocument100 pagesModule-3 Metal CastingAbdul KhadarNo ratings yet

- 3SK21221AA10 Datasheet enDocument7 pages3SK21221AA10 Datasheet enRodney PimentaNo ratings yet

- Quality Control and Robustness of SCC, Part 2: ACI Spring 2012 Convention March 18 - 21, Dallas, TXDocument5 pagesQuality Control and Robustness of SCC, Part 2: ACI Spring 2012 Convention March 18 - 21, Dallas, TXmasteriragaNo ratings yet

- Mathematics: Quarter 2 - Module 8Document24 pagesMathematics: Quarter 2 - Module 8Emmanuel M. Dela Cruz100% (1)

- Vmware Data Protection With Hitachi Data Protection Suite: Please Insert Your Hitachi Truenorth Partner Logo HereDocument21 pagesVmware Data Protection With Hitachi Data Protection Suite: Please Insert Your Hitachi Truenorth Partner Logo HereWildan AbdatNo ratings yet

- Fdocuments - in Low Power Vlsi Design PPT 250 259Document10 pagesFdocuments - in Low Power Vlsi Design PPT 250 259B VasuNo ratings yet

- EEE 231 - Lecture 9 PDFDocument9 pagesEEE 231 - Lecture 9 PDFMahfuj EmonNo ratings yet

- I. Person-Centered Theraphy Carl RogersDocument4 pagesI. Person-Centered Theraphy Carl RogersMaja Aira Bumatay100% (1)

- Benchmark Analysis Action Plan TemplateDocument39 pagesBenchmark Analysis Action Plan Templatem.hakmehNo ratings yet