Professional Documents

Culture Documents

Clump System

Clump System

Uploaded by

Priyanka SinghCopyright:

Available Formats

You might also like

- Ethylene Oxide Sterilization Validation ProtocolDocument26 pagesEthylene Oxide Sterilization Validation ProtocolPhạm Quang Huy83% (24)

- Garments. Answer To The Question No: 01 Garment Production/Garment AssemblyDocument33 pagesGarments. Answer To The Question No: 01 Garment Production/Garment AssemblyMoklesur RahmanNo ratings yet

- PBS & UpsDocument17 pagesPBS & UpsSRI PRAGATHINo ratings yet

- Support MaterialsDocument27 pagesSupport MaterialsndkrajNo ratings yet

- Balloon Debates: Lost!Document3 pagesBalloon Debates: Lost!Patricia ZghibartaNo ratings yet

- Progressive Bundle SystemDocument4 pagesProgressive Bundle SystemMeeta Arora100% (1)

- Production System in Garment IndustryDocument12 pagesProduction System in Garment Industryyasin husenNo ratings yet

- Garment Sewing Production SystemsDocument27 pagesGarment Sewing Production SystemsCool JugglerNo ratings yet

- Garments Production SystemDocument21 pagesGarments Production SystemMd. Taufikul ArifNo ratings yet

- Apparel Production SystemDocument8 pagesApparel Production Systemghosh7171No ratings yet

- Session 2 - Apparel Production SystemsDocument25 pagesSession 2 - Apparel Production SystemsPuja PrasadNo ratings yet

- Denimfabricstextile Cottontrbrush: APPAREL PRODUCTION SYSTEMS (Wholesale Denim Fabrics in CHINA)Document6 pagesDenimfabricstextile Cottontrbrush: APPAREL PRODUCTION SYSTEMS (Wholesale Denim Fabrics in CHINA)Thamara Dananjaya GunarathnaNo ratings yet

- Manufacturing SystemsDocument8 pagesManufacturing Systemstheriteshtiwari100% (1)

- Apparel Production System Analysis Discussion Handout Introduction To Different Production SystemDocument32 pagesApparel Production System Analysis Discussion Handout Introduction To Different Production SystemFahima RashidNo ratings yet

- 10b..apparel Production SystemDocument5 pages10b..apparel Production SystemAbhinav VermaNo ratings yet

- Production System: Features of A Progressive Bundle Unit SystemDocument3 pagesProduction System: Features of A Progressive Bundle Unit SystemdivyaNo ratings yet

- Apparel Production SystemsDocument49 pagesApparel Production SystemstajalaNo ratings yet

- Conventional Bundle SytemDocument14 pagesConventional Bundle SytemAnshu Raj100% (3)

- 15) Pressing & FinishingDocument16 pages15) Pressing & FinishingMd. Asiqul AlamNo ratings yet

- Marker EfficiencyDocument2 pagesMarker EfficiencyGaurav ShakyaNo ratings yet

- Knits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDocument23 pagesKnits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. LakshmanakanthNo ratings yet

- 2 Fashion Designer PDFDocument8 pages2 Fashion Designer PDFraiyandu100% (1)

- Whole Garment Production SystemDocument61 pagesWhole Garment Production SystemKriti Singh50% (4)

- Fabric CuttingDocument10 pagesFabric CuttingRatul HasanNo ratings yet

- Typs of MarkerDocument2 pagesTyps of MarkerarunkadveNo ratings yet

- Fusing TechnologyDocument17 pagesFusing Technologyjonalee100% (1)

- Sewing DefectsDocument2 pagesSewing Defectsbsrastogi100% (1)

- Marker EfficiencyDocument8 pagesMarker EfficiencyMeeta Arora100% (1)

- Fabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessDocument2 pagesFabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessSubrata Mahapatra100% (2)

- A Training Report ON Introduction and An Overview of The Garment IndustryDocument55 pagesA Training Report ON Introduction and An Overview of The Garment IndustrykaalNo ratings yet

- Clothing ConstructionDocument1 pageClothing ConstructionJoseph Fayomi0% (1)

- 9 Ways To Increase Sewing Operator EfficiencyDocument47 pages9 Ways To Increase Sewing Operator EfficiencyNitta MallikNo ratings yet

- Finishing and PressingDocument42 pagesFinishing and PressingKushagra Jain100% (1)

- A Conceptual Framework For Apparel DesignDocument7 pagesA Conceptual Framework For Apparel DesignIvana Skoko100% (1)

- Make Through Production SystemDocument9 pagesMake Through Production Systemshrutiagarwal9229100% (1)

- Introduction To StitchingDocument25 pagesIntroduction To StitchingAbid Hussain100% (2)

- Presentation On Application of Ergonomics in The GarmentDocument27 pagesPresentation On Application of Ergonomics in The GarmentVishakha Chopra100% (1)

- Capacity in Apparel IndustryDocument23 pagesCapacity in Apparel IndustryVishwanath KrNo ratings yet

- Woven FabricsDocument73 pagesWoven Fabricsgizex20130% (1)

- Marker MakingDocument12 pagesMarker MakingsachipalNo ratings yet

- Ae L04Document29 pagesAe L04Md. Riasat Arifin TanimNo ratings yet

- GMTDocument22 pagesGMTEusha NightangelNo ratings yet

- Anti Treatment Knits PrintDocument22 pagesAnti Treatment Knits Printn.tNo ratings yet

- Cost Control Apparel IndustryDocument20 pagesCost Control Apparel IndustryjitinsharmanewNo ratings yet

- Fabric Handle and Drape: by E-MailDocument26 pagesFabric Handle and Drape: by E-MailGurumurthy B RNo ratings yet

- Garments Terms & DefinitionDocument3 pagesGarments Terms & Definitionsatex100% (2)

- Cutting DepartmentDocument8 pagesCutting Departmentjohnchristy2002100% (1)

- Method Study of Cuff AttachmentDocument12 pagesMethod Study of Cuff AttachmentKshitij LauNo ratings yet

- IE UpdatedDocument58 pagesIE Updateddinhlap237100% (1)

- Productivity Improvement in Apparel Industry .PPT PesentationDocument14 pagesProductivity Improvement in Apparel Industry .PPT Pesentationsudincr100% (3)

- Automation in Garment ManufacturingDocument43 pagesAutomation in Garment ManufacturingvagueNo ratings yet

- Label & MotifDocument16 pagesLabel & MotifnahidNo ratings yet

- Cut Order PlanningDocument2 pagesCut Order Planningarunkadve100% (1)

- Various Technique of Production in Sewing RoomDocument22 pagesVarious Technique of Production in Sewing RoomMansha sharma100% (2)

- Strategic Management in The Garment IndustryDocument3 pagesStrategic Management in The Garment IndustryGordana ČolovićNo ratings yet

- 20 Ways To Improve Productivity in Garment Production and Planning CapacityDocument8 pages20 Ways To Improve Productivity in Garment Production and Planning CapacityCucak RowoNo ratings yet

- TLS PDFDocument36 pagesTLS PDFAmrita KhatriNo ratings yet

- Industrial EngineeringDocument32 pagesIndustrial Engineeringpradeep_vsp1077100% (1)

- Industrial Sewing Machine ClassificationsDocument3 pagesIndustrial Sewing Machine ClassificationsHumaun KabirNo ratings yet

- Marker Making ModesDocument15 pagesMarker Making ModessamchikkuNo ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Garment Production SystemDocument22 pagesGarment Production SystemNaveen Tatawat100% (1)

- BY-Aakash Abhimanyu Faraz Hina Manjeet Priyanka Pulkit ShivaniDocument15 pagesBY-Aakash Abhimanyu Faraz Hina Manjeet Priyanka Pulkit ShivaniPriyanka SinghNo ratings yet

- Fujitsu Lean Supply ChainDocument2 pagesFujitsu Lean Supply ChainPriyanka SinghNo ratings yet

- Idea For Workshop On Soft Skills/Entrepreneurship: Mapping Consumer Profile and PreferencesDocument6 pagesIdea For Workshop On Soft Skills/Entrepreneurship: Mapping Consumer Profile and PreferencesPriyanka SinghNo ratings yet

- History of T - ShirtDocument3 pagesHistory of T - ShirtPriyanka SinghNo ratings yet

- Gender Inequality, Concerned Problems & Education: Dr. Pranita Singh (A.N.D.T.T.C. SITAPUR)Document4 pagesGender Inequality, Concerned Problems & Education: Dr. Pranita Singh (A.N.D.T.T.C. SITAPUR)Priyanka SinghNo ratings yet

- BT điền từ - KeyDocument4 pagesBT điền từ - KeyLam Thúy100% (1)

- 5 Secrets To Grow Your Following: (And Convert That Following Into Paying Clients!)Document8 pages5 Secrets To Grow Your Following: (And Convert That Following Into Paying Clients!)jane100% (1)

- Triangle CongruenceDocument7 pagesTriangle CongruenceJay UsNo ratings yet

- Sarah Chapter IvDocument29 pagesSarah Chapter IvSarahNo ratings yet

- QP ScriptDocument57 pagesQP ScriptRitesh SharmaNo ratings yet

- R&W (Notes)Document21 pagesR&W (Notes)Louise Bea ValbuenaNo ratings yet

- Coupling and Constraint EquationsDocument19 pagesCoupling and Constraint EquationstripathijohnNo ratings yet

- Creating Axi-Lite Custom IP' in Vivado: Lab For COMP4601Document33 pagesCreating Axi-Lite Custom IP' in Vivado: Lab For COMP4601wwahib2100% (1)

- The Origin and Status of The Arrhenius EquationDocument3 pagesThe Origin and Status of The Arrhenius Equationleizar_death64No ratings yet

- 1 Nature of Inquiry and ResearchDocument7 pages1 Nature of Inquiry and ResearchInna Sanvictores67% (3)

- Debre Markos University Institute of Technology School of Mechanical and Industrial EngineeringDocument5 pagesDebre Markos University Institute of Technology School of Mechanical and Industrial Engineeringanon_293092329No ratings yet

- Perfect Match: Application To Adopt or Foster A Cat or KittenDocument2 pagesPerfect Match: Application To Adopt or Foster A Cat or KittenChichinete MadalinaNo ratings yet

- Mastering Change For Effective Leadership - Monterrey, MexicoDocument2 pagesMastering Change For Effective Leadership - Monterrey, MexicoAdizes InstituteNo ratings yet

- Sartor Concept MisinformationDocument22 pagesSartor Concept MisinformationhealinghumanityNo ratings yet

- 2013 Metodine Priemone Comparative Politics PDFDocument150 pages2013 Metodine Priemone Comparative Politics PDFmirhafeez100% (2)

- Windows 10 Upgrade Guide PDFDocument8 pagesWindows 10 Upgrade Guide PDFCélim GheribNo ratings yet

- Cambridge IGCSE Mathematics Core and Extended by Ric Pimental Terry WallDocument2 pagesCambridge IGCSE Mathematics Core and Extended by Ric Pimental Terry WallKishani SarmilanNo ratings yet

- Business Continuity Management Sop PDFDocument21 pagesBusiness Continuity Management Sop PDFdexiNo ratings yet

- Participants GuideDocument17 pagesParticipants GuideMarcela Reinoso JayaNo ratings yet

- Travels To Discover The Source of The Nile, in The Years 1768, 1769, 1770, 1771, 1772, A PDFDocument678 pagesTravels To Discover The Source of The Nile, in The Years 1768, 1769, 1770, 1771, 1772, A PDFsyliusNo ratings yet

- European Computer Driving Licence (ECDL) and International Computer Driving Licence (ICDL) European Question and Test Base (EQTB)Document36 pagesEuropean Computer Driving Licence (ECDL) and International Computer Driving Licence (ICDL) European Question and Test Base (EQTB)liakonstNo ratings yet

- DSP Engineer, Systems Engineer, Wireless Design EngineerDocument3 pagesDSP Engineer, Systems Engineer, Wireless Design Engineerapi-72678201No ratings yet

- Colors and Their Effect On The MoodDocument33 pagesColors and Their Effect On The MoodMalakNo ratings yet

- Vle SolteqDocument3 pagesVle SolteqFarhan AhmadNo ratings yet

- MotivatieDocument10 pagesMotivatieDaniela ParapiruNo ratings yet

- 12 Ways To Ask PermissionDocument2 pages12 Ways To Ask PermissionNico Pérez CamoteNo ratings yet

- Liceo de Cagayan University: Human Histology (Laboratory)Document2 pagesLiceo de Cagayan University: Human Histology (Laboratory)Fatimah TambilawanNo ratings yet

- Population Policies of IndiaDocument3 pagesPopulation Policies of IndiaAmit KumarNo ratings yet

Clump System

Clump System

Uploaded by

Priyanka SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clump System

Clump System

Uploaded by

Priyanka SinghCopyright:

Available Formats

BY- ANU MAHTO PRIYANKA SINGH SAMIRAN HAZARIKA

In clump system ,a worker collects a clump of materials from the worktable and carries out the first operation. After he has completed his part of the work, he returns it to the table. A worker for the second operation then continues the work and so on.

The process is ' collection - work -return' continues until the whole garment has been assembled.

It has the same characteristics as the conventional bundle system

STORE

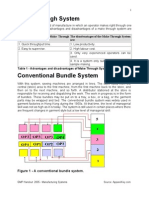

OPERATOR

With this system, sewing machines are arranged in lines. The work flows from the central (store) area to the first machine, from the first machine back to the store, and then on to the next machine, and so forth. A distributor stationed at the store is responsible for receiving and dispatching the work

In Clump system , product is manufactured section by section with the component units sewn together at end of manufacturing process. A clump bundle contains only a single part of the garment such as sleeve, body, cuff or collar. Etc. that means this system not only divide the work, but also divide up the garment. Machines of similar operations are clubbed together instead of spreading over in all lines. For example, when a mans formal shirt is being made in a section layout collars, cuffs and sleeves are in the preparatory sections and then send to the assembly section.

Specific quantity of parts in the bundle is determined by number of fabric plies and weight of bundle. Operators of specialized skills are independently working at own pace and paid by piece rates.

The system is flexible, as it can cope with frequent style changes.

Absenteeism and machine breakdown problems will not cause serious problems., as the controller can control the amount of work received and dispatched

The system is easy to operate and supervise. Specialization and rhythm of operation increase productivity. As the WIP is high in this system, this is stable system. It is easier to obtain a uniform level of quality, as the controller can check the quality control. The labor cost is less compared with individual system.

It requires excessive handling of the materials by the operators, as they have to carry their work back to the central inventory. Operators who are compensated by piece rates become extremely efficient at one operation and may not be willing to learn a new operation because it reduces their efficiency and earnings. It is difficult to control the inventory. It is difficult to see the work in progress at the various stages of manufacture. High level of WIP extends throughput time Engineering of work places is difficult because machines are arranged in the limited capacity. High level of work-in-progress. Large storage space is required to cope with the large volume of work-in-progress

The system is used in industries where there are frequent changes in garment style but a low level of managerial skill. This system is very efficient for producing a variety of styles in reasonable quantities. Orders in low to medium volume.

Difference from other manufacturing system

System attributes Clump system Work flow Method of retrieval to work station push Brought to operator or self retrieved by operator from store High level( racks or carts of bundles) Single task Production systems Progressive system push Brought to operator from operator by cart or conveyor Moderate level (enough to balance the lines) Single task No teamwork Modular system pull Hand off

WIP inventory

Zero to minimal

Number of task per operator

Multiple task Teamwork

Interaction No teamwork between operators

http://ojs.cnr.ncsu.edu www.indiantextilejournal.com www.onlineclothingstudy.com www.monozukuri.co.in

You might also like

- Ethylene Oxide Sterilization Validation ProtocolDocument26 pagesEthylene Oxide Sterilization Validation ProtocolPhạm Quang Huy83% (24)

- Garments. Answer To The Question No: 01 Garment Production/Garment AssemblyDocument33 pagesGarments. Answer To The Question No: 01 Garment Production/Garment AssemblyMoklesur RahmanNo ratings yet

- PBS & UpsDocument17 pagesPBS & UpsSRI PRAGATHINo ratings yet

- Support MaterialsDocument27 pagesSupport MaterialsndkrajNo ratings yet

- Balloon Debates: Lost!Document3 pagesBalloon Debates: Lost!Patricia ZghibartaNo ratings yet

- Progressive Bundle SystemDocument4 pagesProgressive Bundle SystemMeeta Arora100% (1)

- Production System in Garment IndustryDocument12 pagesProduction System in Garment Industryyasin husenNo ratings yet

- Garment Sewing Production SystemsDocument27 pagesGarment Sewing Production SystemsCool JugglerNo ratings yet

- Garments Production SystemDocument21 pagesGarments Production SystemMd. Taufikul ArifNo ratings yet

- Apparel Production SystemDocument8 pagesApparel Production Systemghosh7171No ratings yet

- Session 2 - Apparel Production SystemsDocument25 pagesSession 2 - Apparel Production SystemsPuja PrasadNo ratings yet

- Denimfabricstextile Cottontrbrush: APPAREL PRODUCTION SYSTEMS (Wholesale Denim Fabrics in CHINA)Document6 pagesDenimfabricstextile Cottontrbrush: APPAREL PRODUCTION SYSTEMS (Wholesale Denim Fabrics in CHINA)Thamara Dananjaya GunarathnaNo ratings yet

- Manufacturing SystemsDocument8 pagesManufacturing Systemstheriteshtiwari100% (1)

- Apparel Production System Analysis Discussion Handout Introduction To Different Production SystemDocument32 pagesApparel Production System Analysis Discussion Handout Introduction To Different Production SystemFahima RashidNo ratings yet

- 10b..apparel Production SystemDocument5 pages10b..apparel Production SystemAbhinav VermaNo ratings yet

- Production System: Features of A Progressive Bundle Unit SystemDocument3 pagesProduction System: Features of A Progressive Bundle Unit SystemdivyaNo ratings yet

- Apparel Production SystemsDocument49 pagesApparel Production SystemstajalaNo ratings yet

- Conventional Bundle SytemDocument14 pagesConventional Bundle SytemAnshu Raj100% (3)

- 15) Pressing & FinishingDocument16 pages15) Pressing & FinishingMd. Asiqul AlamNo ratings yet

- Marker EfficiencyDocument2 pagesMarker EfficiencyGaurav ShakyaNo ratings yet

- Knits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDocument23 pagesKnits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. LakshmanakanthNo ratings yet

- 2 Fashion Designer PDFDocument8 pages2 Fashion Designer PDFraiyandu100% (1)

- Whole Garment Production SystemDocument61 pagesWhole Garment Production SystemKriti Singh50% (4)

- Fabric CuttingDocument10 pagesFabric CuttingRatul HasanNo ratings yet

- Typs of MarkerDocument2 pagesTyps of MarkerarunkadveNo ratings yet

- Fusing TechnologyDocument17 pagesFusing Technologyjonalee100% (1)

- Sewing DefectsDocument2 pagesSewing Defectsbsrastogi100% (1)

- Marker EfficiencyDocument8 pagesMarker EfficiencyMeeta Arora100% (1)

- Fabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessDocument2 pagesFabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessSubrata Mahapatra100% (2)

- A Training Report ON Introduction and An Overview of The Garment IndustryDocument55 pagesA Training Report ON Introduction and An Overview of The Garment IndustrykaalNo ratings yet

- Clothing ConstructionDocument1 pageClothing ConstructionJoseph Fayomi0% (1)

- 9 Ways To Increase Sewing Operator EfficiencyDocument47 pages9 Ways To Increase Sewing Operator EfficiencyNitta MallikNo ratings yet

- Finishing and PressingDocument42 pagesFinishing and PressingKushagra Jain100% (1)

- A Conceptual Framework For Apparel DesignDocument7 pagesA Conceptual Framework For Apparel DesignIvana Skoko100% (1)

- Make Through Production SystemDocument9 pagesMake Through Production Systemshrutiagarwal9229100% (1)

- Introduction To StitchingDocument25 pagesIntroduction To StitchingAbid Hussain100% (2)

- Presentation On Application of Ergonomics in The GarmentDocument27 pagesPresentation On Application of Ergonomics in The GarmentVishakha Chopra100% (1)

- Capacity in Apparel IndustryDocument23 pagesCapacity in Apparel IndustryVishwanath KrNo ratings yet

- Woven FabricsDocument73 pagesWoven Fabricsgizex20130% (1)

- Marker MakingDocument12 pagesMarker MakingsachipalNo ratings yet

- Ae L04Document29 pagesAe L04Md. Riasat Arifin TanimNo ratings yet

- GMTDocument22 pagesGMTEusha NightangelNo ratings yet

- Anti Treatment Knits PrintDocument22 pagesAnti Treatment Knits Printn.tNo ratings yet

- Cost Control Apparel IndustryDocument20 pagesCost Control Apparel IndustryjitinsharmanewNo ratings yet

- Fabric Handle and Drape: by E-MailDocument26 pagesFabric Handle and Drape: by E-MailGurumurthy B RNo ratings yet

- Garments Terms & DefinitionDocument3 pagesGarments Terms & Definitionsatex100% (2)

- Cutting DepartmentDocument8 pagesCutting Departmentjohnchristy2002100% (1)

- Method Study of Cuff AttachmentDocument12 pagesMethod Study of Cuff AttachmentKshitij LauNo ratings yet

- IE UpdatedDocument58 pagesIE Updateddinhlap237100% (1)

- Productivity Improvement in Apparel Industry .PPT PesentationDocument14 pagesProductivity Improvement in Apparel Industry .PPT Pesentationsudincr100% (3)

- Automation in Garment ManufacturingDocument43 pagesAutomation in Garment ManufacturingvagueNo ratings yet

- Label & MotifDocument16 pagesLabel & MotifnahidNo ratings yet

- Cut Order PlanningDocument2 pagesCut Order Planningarunkadve100% (1)

- Various Technique of Production in Sewing RoomDocument22 pagesVarious Technique of Production in Sewing RoomMansha sharma100% (2)

- Strategic Management in The Garment IndustryDocument3 pagesStrategic Management in The Garment IndustryGordana ČolovićNo ratings yet

- 20 Ways To Improve Productivity in Garment Production and Planning CapacityDocument8 pages20 Ways To Improve Productivity in Garment Production and Planning CapacityCucak RowoNo ratings yet

- TLS PDFDocument36 pagesTLS PDFAmrita KhatriNo ratings yet

- Industrial EngineeringDocument32 pagesIndustrial Engineeringpradeep_vsp1077100% (1)

- Industrial Sewing Machine ClassificationsDocument3 pagesIndustrial Sewing Machine ClassificationsHumaun KabirNo ratings yet

- Marker Making ModesDocument15 pagesMarker Making ModessamchikkuNo ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Garment Production SystemDocument22 pagesGarment Production SystemNaveen Tatawat100% (1)

- BY-Aakash Abhimanyu Faraz Hina Manjeet Priyanka Pulkit ShivaniDocument15 pagesBY-Aakash Abhimanyu Faraz Hina Manjeet Priyanka Pulkit ShivaniPriyanka SinghNo ratings yet

- Fujitsu Lean Supply ChainDocument2 pagesFujitsu Lean Supply ChainPriyanka SinghNo ratings yet

- Idea For Workshop On Soft Skills/Entrepreneurship: Mapping Consumer Profile and PreferencesDocument6 pagesIdea For Workshop On Soft Skills/Entrepreneurship: Mapping Consumer Profile and PreferencesPriyanka SinghNo ratings yet

- History of T - ShirtDocument3 pagesHistory of T - ShirtPriyanka SinghNo ratings yet

- Gender Inequality, Concerned Problems & Education: Dr. Pranita Singh (A.N.D.T.T.C. SITAPUR)Document4 pagesGender Inequality, Concerned Problems & Education: Dr. Pranita Singh (A.N.D.T.T.C. SITAPUR)Priyanka SinghNo ratings yet

- BT điền từ - KeyDocument4 pagesBT điền từ - KeyLam Thúy100% (1)

- 5 Secrets To Grow Your Following: (And Convert That Following Into Paying Clients!)Document8 pages5 Secrets To Grow Your Following: (And Convert That Following Into Paying Clients!)jane100% (1)

- Triangle CongruenceDocument7 pagesTriangle CongruenceJay UsNo ratings yet

- Sarah Chapter IvDocument29 pagesSarah Chapter IvSarahNo ratings yet

- QP ScriptDocument57 pagesQP ScriptRitesh SharmaNo ratings yet

- R&W (Notes)Document21 pagesR&W (Notes)Louise Bea ValbuenaNo ratings yet

- Coupling and Constraint EquationsDocument19 pagesCoupling and Constraint EquationstripathijohnNo ratings yet

- Creating Axi-Lite Custom IP' in Vivado: Lab For COMP4601Document33 pagesCreating Axi-Lite Custom IP' in Vivado: Lab For COMP4601wwahib2100% (1)

- The Origin and Status of The Arrhenius EquationDocument3 pagesThe Origin and Status of The Arrhenius Equationleizar_death64No ratings yet

- 1 Nature of Inquiry and ResearchDocument7 pages1 Nature of Inquiry and ResearchInna Sanvictores67% (3)

- Debre Markos University Institute of Technology School of Mechanical and Industrial EngineeringDocument5 pagesDebre Markos University Institute of Technology School of Mechanical and Industrial Engineeringanon_293092329No ratings yet

- Perfect Match: Application To Adopt or Foster A Cat or KittenDocument2 pagesPerfect Match: Application To Adopt or Foster A Cat or KittenChichinete MadalinaNo ratings yet

- Mastering Change For Effective Leadership - Monterrey, MexicoDocument2 pagesMastering Change For Effective Leadership - Monterrey, MexicoAdizes InstituteNo ratings yet

- Sartor Concept MisinformationDocument22 pagesSartor Concept MisinformationhealinghumanityNo ratings yet

- 2013 Metodine Priemone Comparative Politics PDFDocument150 pages2013 Metodine Priemone Comparative Politics PDFmirhafeez100% (2)

- Windows 10 Upgrade Guide PDFDocument8 pagesWindows 10 Upgrade Guide PDFCélim GheribNo ratings yet

- Cambridge IGCSE Mathematics Core and Extended by Ric Pimental Terry WallDocument2 pagesCambridge IGCSE Mathematics Core and Extended by Ric Pimental Terry WallKishani SarmilanNo ratings yet

- Business Continuity Management Sop PDFDocument21 pagesBusiness Continuity Management Sop PDFdexiNo ratings yet

- Participants GuideDocument17 pagesParticipants GuideMarcela Reinoso JayaNo ratings yet

- Travels To Discover The Source of The Nile, in The Years 1768, 1769, 1770, 1771, 1772, A PDFDocument678 pagesTravels To Discover The Source of The Nile, in The Years 1768, 1769, 1770, 1771, 1772, A PDFsyliusNo ratings yet

- European Computer Driving Licence (ECDL) and International Computer Driving Licence (ICDL) European Question and Test Base (EQTB)Document36 pagesEuropean Computer Driving Licence (ECDL) and International Computer Driving Licence (ICDL) European Question and Test Base (EQTB)liakonstNo ratings yet

- DSP Engineer, Systems Engineer, Wireless Design EngineerDocument3 pagesDSP Engineer, Systems Engineer, Wireless Design Engineerapi-72678201No ratings yet

- Colors and Their Effect On The MoodDocument33 pagesColors and Their Effect On The MoodMalakNo ratings yet

- Vle SolteqDocument3 pagesVle SolteqFarhan AhmadNo ratings yet

- MotivatieDocument10 pagesMotivatieDaniela ParapiruNo ratings yet

- 12 Ways To Ask PermissionDocument2 pages12 Ways To Ask PermissionNico Pérez CamoteNo ratings yet

- Liceo de Cagayan University: Human Histology (Laboratory)Document2 pagesLiceo de Cagayan University: Human Histology (Laboratory)Fatimah TambilawanNo ratings yet

- Population Policies of IndiaDocument3 pagesPopulation Policies of IndiaAmit KumarNo ratings yet