Professional Documents

Culture Documents

Pulsed Laser Deposition (PLD)

Pulsed Laser Deposition (PLD)

Uploaded by

Mohit YadavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pulsed Laser Deposition (PLD)

Pulsed Laser Deposition (PLD)

Uploaded by

Mohit YadavCopyright:

Available Formats

Pulsed Laser Deposition (PLD)

Outline

1. Thin film deposition

2. Pulsed Laser Deposition

a) Compared to other growth techniques

b) Experimental Setup

c) Advantages and Disadvantages

3. Basic Theory of PLD

4. Opportunities

Thin Film Deposition

Transfer atoms from a target to a vapor (or plasma) to a substrate

Thin Film Deposition

Transfer atoms from a target to a vapor (or plasma) to a substrate

After an atom is on surface, it diffuses according to: D=D

o

exp(-c

D

/kT)

c

D

is the activation energy for diffusion ~ 2-3 eV

kT is energy of atomic species.

Want sufficient diffusion for atoms to find best sites.

Either use energetic atoms, or heat the substrate.

target

substrate

Evaporation

(Molecular beam

epitaxy-MBE)

Ways to deposit thin films

target

substrate

Chemical

vapor

deposition-

CVD

Ar

+

substrate

gas

Sputtering

Low energy deposition

(MBE): ~0.1 eV

may get islanding unless

you pick right substrate or

heat substrate to high

temperatures

High energy deposition

(Sputtering ~ 1 eV)

smoother films at lower

substrate temperatures, but

may get intermixing

Low energy deposition

(MBE): ~0.1 eV

may get islanding unless

you pick right substrate or

heat substrate to high

temperatures

High energy deposition

(Sputtering ~ 1 eV)

smoother films at lower

substrate temperatures, but

may get intermixing

CCD /PMT

spectrometer

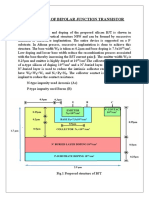

Target

Substrates

or Faraday

cup

laser beam

Pulsed Laser Deposition

CCD /PMT

spectrometer

Target

Substrates

or Faraday

cup

laser beam

Pulsed Laser Deposition

Target: Just about anything! (metals, semiconductors)

Laser: Typically excimer (UV, 10 nanosecond pulses)

Vacuum: Atmospheres to ultrahigh vacuum

Advantages of PLD

- Flexible, easy to implement

- Growth in any environment

- Exact transfer of complicated materials (YBCO)

- Variable growth rate

- Epitaxy at low temperature

- Resonant interactions possible (i.e., plasmons in metals,

absorption peaks in dielectrics and semiconductors)

- Atoms arrive in bunches, allowing for much more

controlled deposition

- Greater control of growth (e.g., by varying laser

parameters)

Disadvantages of PLD

Uneven coverage

High defect or particulate concentration

Not well suited for large-scale film growth

Mechanisms and dependence on parameters

not well understood

Processes in PLD

Laser pulse

Processes in PLD

e-

e-

e-

e- e-

e-

e-

e-

e-

e-

e-

e-

e-

e-

Electronic excitation

Processes in PLD

e-

e-

e-

e- e-

e-

e-

e-

e-

e-

e-

e-

e-

e-

Energy relaxation to lattice (~1 ps)

lattice

Processes in PLD

Heat diffusion (over microseconds)

lattice

Processes in PLD

Melting (tens of ns), Evaporation, Plasma

Formation (microseconds), Resolidification

lattice

Processes in PLD

lattice

If laser pulse is long (ns) or

repetition rate is high, laser may

continue interactions

Processes in Pulsed Laser Deposition

1. Absorption of laser pulse in material

Q

ab

=(1-R)I

o

e

-oL

(metals, absorption depths ~ 10 nm,

depends on )

2. Relaxation of energy (~ 1 ps) (electron-phonon interaction)

3. Heat transfer, Melting and Evaporation

when electrons and lattice at thermal equilibrium (long pulses)

use heat conduction equation:

(or heat diffusion model)

ab p

Q T K

t

T

C + V V =

c

c

) (

Processes in Pulsed Laser Deposition

4. Plasma creation

threshold intensity:

goverened by Saha equation:

5. Absorption of light by plasma, ionization

(inverse Bremsstrahlung)

6. I nteraction of target and ablated species with plasma

7. Cooling between pulses

(Resolidification between pulses)

pulse

threshold

t

cm Ws x

I

2 2 / 1 4

10 4

=

|

.

|

\

|

+

+

=

kT m m

m m

Q

Q Q

n

n n

ion

i e

i e

n

i e

n

i e

exp

Incredibly Non-Equilibrium!!!

At peak of laser pulse, temperatures on target can

reach >10

5

K (> 40 eV!)

Electric Fields > 10

5

V/cm, also high magnetic fields

Plasma Temperatures 3000-5000 K

Ablated Species with energies 1 100 eV

PLD with Ultrafast Pulses (< 1 picosecond)

see Stuart et al., Phys. Rev. B, 53 1749 (1996)

A new research area!

If the pulse width < electron lattice-relaxation time, heat diffusion, melting significantly

reduced! Means cleaner holes and cleaner ablation

Direct conversion of solid to vapor, less plasma formation

Reactive chemistry: energetic ions, ionized nitrogen, high charge states

Leads to less target damage (cleaner holes), and smoother films (less particulates)

PLD with Ultrafast Pulses (< 1 picosecond)

see Stuart et al., Phys. Rev. B, 53 1749 (1996)

A new research area!

If the pulse width < electron lattice-relaxation time, heat diffusion, melting significantly

reduced! Means cleaner holes and cleaner ablation

Direct conversion of solid to vapor, less plasma formation

Reactive chemistry: energetic ions, ionized nitrogen, high charge states

Leads to less target damage (cleaner holes), and smoother films (less particulates)

t> 50 ps

Conventional melting, boiling and fracture

Threshold fluence for ablation scales as t

1/2

t < 10 ps

Electrons photoionized, collisional

and multiphoton ionization

Plasma formation with no melting

Deviation from t

1/2

scaling

20 ns EXCIMER versus 1 ps TJNAF-FEL

Cobalt ~20 mJ/pulse, 20 ns, 308 nm,

25 Hz, 1 x 10

-5

Torr

Steel, ~20 J/pulse, 18 MHz, 3.1 micron

1 x 10

-2

Torr, 60 Hz pulsed, rastered beam

Less melting!

Few

particulates!

for Nb: < 1 per cm

-2

SEMs by B. Robertson, T. Wang, TJNAF

Opportunities

Ultrahigh quality films

Circuit writing

Isotope Enrichment

New Materials

Nanoparticle production

Magnetic Moment of fcc Fe(111) Ultrathin Films

by Ultrafast Deposition on Cu(111)

J. Shen et al., Phys. Rev. Lett., 80, pp. 1980-1983

MBE PLD

Higher quality films, better

magnetic properties

MICE

Direct writing of electronic components- in air!

Rapid process refinement

No masks, preforms, or long cycle times

True 3-D structure fabrication possible

Single laser does surface pretreatment, spatially selective material deposition,

surface annealing ,component trimming, ablative micromachining, dicing and

via-drilling

Isotope Enrichment in Laser-Ablation Plumes and Commensurately

Deposited Thin Films

P. P. Pronko, et al. Phys Rev. Lett., 83, pp. 2596-2599

Over twice the natural enrichment of

B

10

/B

11

, Ga

69

/Ga

71

in BN and GaN films

Plasma centrifuge by toroidal and axial

magnetic fields of 0.6MG!

Transient States of Matter during Short Pulse Laser Ablation

K. Sokolowski-Tinten et al., Phys. Rev. Lett., 81, pp. 224-227

Fluid material state of high index of

refraction, optically flat surface

http://www.ornl.gov/~odg/#nanotubes

New Materials and Nanoparticles

D.B. Geohegan-ORNL

Carbon/carbon collisons-

buckyballs

Fast carbon ions-

diamond films

Study of plasma plume and deposition of carbon materials

References

Pulsed Laser Vaporization and Deposition, Wilmott and

Huber, Reviews of Modern Physics, Vol. 72, 315 (2000)

Pulsed Laser Deposition of Thin Films, Chrisey and

Hubler (Wiley, New York, 1994)

Laser Ablation and Desorption, Miller and Haglund

(Academic Press, San Diego, 1998)

You might also like

- R. J. Singh - Solid State Physics-Pearson Education (2011)Document609 pagesR. J. Singh - Solid State Physics-Pearson Education (2011)saisasikumar26No ratings yet

- Tcad - BJTDocument10 pagesTcad - BJTram_786No ratings yet

- Physics and Applications of Terahertz RadiationDocument257 pagesPhysics and Applications of Terahertz RadiationShivanta Sahoo100% (2)

- PLDlecture 2Document32 pagesPLDlecture 2Ashok GargNo ratings yet

- Ferroelectric Thin Films Obtained by Pulsed Laser DepositionDocument7 pagesFerroelectric Thin Films Obtained by Pulsed Laser Depositioncbs78No ratings yet

- Dr. Marc Madou, Winter 2011 UCI Class 6Document30 pagesDr. Marc Madou, Winter 2011 UCI Class 6nomi59No ratings yet

- Makalah Thin Film (Fahril)Document46 pagesMakalah Thin Film (Fahril)fahril abdjanNo ratings yet

- (8 2) Film Preparation PVDDocument25 pages(8 2) Film Preparation PVDkenyaengNo ratings yet

- DR Nadeem Sabir 2Document88 pagesDR Nadeem Sabir 2Muhammad RizwanNo ratings yet

- 2017 Thin Film GrowthDocument70 pages2017 Thin Film GrowthPankaj Kumar100% (1)

- Fundamentals of Pulsed Laser Deposition First Age (1975-1995)Document5 pagesFundamentals of Pulsed Laser Deposition First Age (1975-1995)gyirgaNo ratings yet

- Pulse Laser DepositionDocument34 pagesPulse Laser DepositionankitjauramNo ratings yet

- Class6.CVD and PVDDocument30 pagesClass6.CVD and PVDSaquib HeshamNo ratings yet

- Role of The Cesium Antimonide Layer in The Na 2 Ksb/Cs 3 SB PhotocathodeDocument7 pagesRole of The Cesium Antimonide Layer in The Na 2 Ksb/Cs 3 SB PhotocathodeDayti JuniorNo ratings yet

- Low Cost, High Efficiency Solar Cell Based On Dye-Sensitized Colloidal TiO2 FilmDocument4 pagesLow Cost, High Efficiency Solar Cell Based On Dye-Sensitized Colloidal TiO2 FilmWildan MocholladNo ratings yet

- Chapter 2: Basic Concepts and Parameters of Plasma Physics: KT T T Ne NDocument13 pagesChapter 2: Basic Concepts and Parameters of Plasma Physics: KT T T Ne NRoy VeseyNo ratings yet

- Introduction To The Phenomenology of Hitc Superconductors. Patrick Lee and T. Senthil MitDocument54 pagesIntroduction To The Phenomenology of Hitc Superconductors. Patrick Lee and T. Senthil MitBrandon StephensNo ratings yet

- Definitions & FormulaeDocument7 pagesDefinitions & FormulaeAlex AntiaNo ratings yet

- Letters To Nature: Femtosecond Time-Resolved X-Ray Diffraction From Laser-Heated Organic FilmsDocument3 pagesLetters To Nature: Femtosecond Time-Resolved X-Ray Diffraction From Laser-Heated Organic FilmsZia Ur RehmanNo ratings yet

- Systematic Study of The RF Induced EvapoDocument5 pagesSystematic Study of The RF Induced Evapoluigy8509No ratings yet

- Short-Pulse Laser-Plasma Interactions PDFDocument25 pagesShort-Pulse Laser-Plasma Interactions PDFAjit UpadhyayNo ratings yet

- T. Shutt Et Al - The XENON Dark Matter ExperimentDocument4 pagesT. Shutt Et Al - The XENON Dark Matter ExperimentUmav24No ratings yet

- Phonons DiamondDocument3 pagesPhonons DiamondMaximo LopezNo ratings yet

- 02 Prog Dv2Document49 pages02 Prog Dv2deboline mitraNo ratings yet

- Introduction To Superconductivity in The: Jules Carbotte Mcmaster and CifarDocument69 pagesIntroduction To Superconductivity in The: Jules Carbotte Mcmaster and CifarFrancine SolalNo ratings yet

- SaaDocument41 pagesSaaAbdur RahmanNo ratings yet

- 1999, Tokyo, JJAP - Electrical Properties of A Semiconducting Layer Formed On SrTiO3 Single Crystal by Excimer Laser IrradiationDocument6 pages1999, Tokyo, JJAP - Electrical Properties of A Semiconducting Layer Formed On SrTiO3 Single Crystal by Excimer Laser IrradiationHaribabu PalneediNo ratings yet

- Mechanical Alloying and Photo Acoustic For CD Te - BrasilDocument7 pagesMechanical Alloying and Photo Acoustic For CD Te - BrasilFabricio FaitaNo ratings yet

- Plasma Physics in The CurriculumDocument10 pagesPlasma Physics in The Curriculumal hurtadoNo ratings yet

- Perovskite Solar Cell With CeO2 Based ETLDocument23 pagesPerovskite Solar Cell With CeO2 Based ETLrahulpelectronics100% (2)

- Basics of Vaccume and SputtringDocument87 pagesBasics of Vaccume and SputtringlavNo ratings yet

- Lecture 6 Thin Film Deposition, Physical Vapour DepositionDocument44 pagesLecture 6 Thin Film Deposition, Physical Vapour DepositionHari HarryNo ratings yet

- TemDocument31 pagesTemWilliam FullerNo ratings yet

- EXPERIMENT 8. Monolayer Characterization: Contact Angles, Reflection Infrared Spectroscopy, and EllipsometryDocument9 pagesEXPERIMENT 8. Monolayer Characterization: Contact Angles, Reflection Infrared Spectroscopy, and EllipsometryavniNo ratings yet

- Observation of Collapsing Radiative Shocks in Laboratory ExperimentsDocument5 pagesObservation of Collapsing Radiative Shocks in Laboratory ExperimentsNrapen SipaniNo ratings yet

- Ablation ThresholdDocument9 pagesAblation Thresholdanon-228152100% (2)

- 10.1007@s10854 019 00665 XDocument9 pages10.1007@s10854 019 00665 XchanveerNo ratings yet

- Lecture 5 - Photodetectors and Noise: 1.1 Thermoelectric DetectorsDocument23 pagesLecture 5 - Photodetectors and Noise: 1.1 Thermoelectric DetectorsArindam SenNo ratings yet

- 0906 5558 PDFDocument16 pages0906 5558 PDFFadhil AlwanNo ratings yet

- BioMEMSLecture 6Document29 pagesBioMEMSLecture 6varundbNo ratings yet

- 2010 - Sanchez de Armas - J Chem Theory Comput 2856Document10 pages2010 - Sanchez de Armas - J Chem Theory Comput 2856Tomas Delgado MontielNo ratings yet

- 2003 Broadband Dielectric Spectroscopy of BS PTDocument4 pages2003 Broadband Dielectric Spectroscopy of BS PTAnaghaNo ratings yet

- Statistical Mechanics Lasers and Fiber OpticsDocument35 pagesStatistical Mechanics Lasers and Fiber OpticsJAITHOMSONo ratings yet

- Photon Bubble Turbulence in Cold Atomic Gases: Joaodmrodrigues@tecnico - Ulisboa.ptDocument5 pagesPhoton Bubble Turbulence in Cold Atomic Gases: Joaodmrodrigues@tecnico - Ulisboa.ptbase1No ratings yet

- XRF Lecture NotesDocument19 pagesXRF Lecture Notesmundela4986No ratings yet

- Burda 1999Document6 pagesBurda 1999LAVI TYAGINo ratings yet

- Red Luminescence With Controlled Rise Time in La 2 MgTiO 6: Eu 3þDocument8 pagesRed Luminescence With Controlled Rise Time in La 2 MgTiO 6: Eu 3þRaul BuenoNo ratings yet

- Thin FilmDocument5 pagesThin FilmDipender SinghNo ratings yet

- Synchrotron and NeutronDocument9 pagesSynchrotron and NeutronNEMI CHAND SOODNo ratings yet

- Absorption in One-Dimensional Metallic-Dielectric Photonic CrystalsDocument7 pagesAbsorption in One-Dimensional Metallic-Dielectric Photonic CrystalsDana PopescuNo ratings yet

- Experiments and Simulations For Optical Controlled Thermal Management On The Nanometer Length ScalaDocument6 pagesExperiments and Simulations For Optical Controlled Thermal Management On The Nanometer Length Scala김영규No ratings yet

- Bulgakova ApplPhysA 2001Document10 pagesBulgakova ApplPhysA 2001norbNo ratings yet

- Nanofluidic Dielectrophoresis Single Molecules Holzel PRL 2005Document4 pagesNanofluidic Dielectrophoresis Single Molecules Holzel PRL 2005Vasu ManchesterNo ratings yet

- Short Pulse Laser Plasma Interactions PDFDocument25 pagesShort Pulse Laser Plasma Interactions PDFmorganNo ratings yet

- 4.1 Basics and Kirchoff's LawsDocument38 pages4.1 Basics and Kirchoff's LawsdkbradleyNo ratings yet

- Cdse Nanoparticles Synthesized by Laser Ablation: Epla, 2008Document6 pagesCdse Nanoparticles Synthesized by Laser Ablation: Epla, 2008Krishna PrasadNo ratings yet

- 강의7-Atomic Spect 호환 모드Document39 pages강의7-Atomic Spect 호환 모드Abdoul RahimNo ratings yet

- Experimentalphyslk III, Unwerszt T Diisseldorf. D-4000 Diisseldorf I, FRGDocument6 pagesExperimentalphyslk III, Unwerszt T Diisseldorf. D-4000 Diisseldorf I, FRGHeo Toàn TậpNo ratings yet

- Photoacoustic Studies of Annealed Cdsxse1-X (X 0.26) Nanocrystals in A Glass MatrixDocument6 pagesPhotoacoustic Studies of Annealed Cdsxse1-X (X 0.26) Nanocrystals in A Glass MatrixVigneshwaran MuruganNo ratings yet

- Tem SemDocument2 pagesTem Semkarthikeyan5000No ratings yet

- Spintronics for Next Generation Innovative DevicesFrom EverandSpintronics for Next Generation Innovative DevicesKatsuaki SatoNo ratings yet

- Physics NotesDocument1 pagePhysics NotesJohn ManciaNo ratings yet

- Coulomb BlockadeDocument21 pagesCoulomb BlockadepraveenNo ratings yet

- Tutorial 3 - Particle PhysicsDocument4 pagesTutorial 3 - Particle PhysicsWKQNo ratings yet

- Physics Innovation Project: The Quantum BITDocument6 pagesPhysics Innovation Project: The Quantum BITheywNo ratings yet

- Caie As Level Chemistry 9701 Theory v1Document37 pagesCaie As Level Chemistry 9701 Theory v1beracosiNo ratings yet

- 1) Bansal 1 (Resonance)Document11 pages1) Bansal 1 (Resonance)govindrajaram693No ratings yet

- Crystal Structure PresentationDocument10 pagesCrystal Structure PresentationTheresa TuliaoNo ratings yet

- Tips For CSIR NET For Physical SciencesDocument24 pagesTips For CSIR NET For Physical SciencesboltuNo ratings yet

- CM II - Part IDocument221 pagesCM II - Part IZeynep CihanNo ratings yet

- IOCAssignment-3 42Document5 pagesIOCAssignment-3 42Sanjit mourya Sanjit mouryavanshiNo ratings yet

- Solidification of Single-Phase Alloys - 2007Document12 pagesSolidification of Single-Phase Alloys - 2007pkn_pnt9950No ratings yet

- Essentials of The Living World 4th Edition by Johnson ISBN Test BankDocument22 pagesEssentials of The Living World 4th Edition by Johnson ISBN Test Bankpaul100% (23)

- Many Body LocalizationDocument125 pagesMany Body LocalizationAhmad SaleheenNo ratings yet

- Solar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaDocument40 pagesSolar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaMr. K.S. Raghul Asst Prof MECHNo ratings yet

- CUET 2023 Physics Question Paper 1Document8 pagesCUET 2023 Physics Question Paper 1snehawasthi222No ratings yet

- Appendix: Fundamental Physical ConstantsDocument3 pagesAppendix: Fundamental Physical ConstantsAndré OliveiraNo ratings yet

- Lecture 1 InorganicDocument20 pagesLecture 1 InorganicNaveen KumarNo ratings yet

- 13Document12 pages13MEOW41No ratings yet

- Tunnel Current in Mim SystemDocument5 pagesTunnel Current in Mim SystemSimón MejíaNo ratings yet

- Bohr Model and Atomic SpectraDocument18 pagesBohr Model and Atomic Spectrarajas0% (1)

- Atomic Structure 1Document27 pagesAtomic Structure 1Mamdooh AlqathamiNo ratings yet

- L28 Viscoelasticity ClassDocument18 pagesL28 Viscoelasticity ClassSuiajNo ratings yet

- General Relativistic Quantum MechanicsDocument5 pagesGeneral Relativistic Quantum MechanicsFarhad HossainNo ratings yet

- LoloDocument6 pagesLoloapi-26570979No ratings yet

- Ajc H2 Chem P2 MSDocument11 pagesAjc H2 Chem P2 MSclarissa yeoNo ratings yet

- Nano 1212Document13 pagesNano 1212azkayounas74No ratings yet

- Magnetic Materials - Chapter 18 - 2022Document10 pagesMagnetic Materials - Chapter 18 - 2022batrouni.elioNo ratings yet