Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

271 viewsProject Management by CPM & PERT

Project Management by CPM & PERT

Uploaded by

engr_misbahullahThe document discusses the history and development of the Critical Path Method (CPM) and Program Evaluation and Review Technique (PERT) project management tools. It was created in the 1950s out of the need for Western industrial and military establishments to plan, schedule, and control complex projects. CPM was developed by DuPont to reduce downtime on plant maintenance, while PERT was created by the US Navy for the Polaris missile program. The document then outlines the framework for using CPM and PERT to define activities, durations, dependencies, and critical paths to help plan, schedule, monitor and control projects.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You might also like

- UasfntitledDocument3 pagesUasfntitledSivekiNo ratings yet

- Extended Essay Draft 1Document15 pagesExtended Essay Draft 1Eli MuellerNo ratings yet

- Chpater 6 - Continous Random Variables and The Normal DistributionDocument11 pagesChpater 6 - Continous Random Variables and The Normal Distributionbishoy sefinNo ratings yet

- Ieee STD 730 Sqa PlansDocument17 pagesIeee STD 730 Sqa PlansPatricia LlallicoNo ratings yet

- Benefits of FMEADocument9 pagesBenefits of FMEAbaranirajsalem100% (2)

- Phys 181Document2 pagesPhys 181sophiecaiNo ratings yet

- Im Unit 5 NotesDocument34 pagesIm Unit 5 NotessunitaNo ratings yet

- Project Management - CPM-PERTDocument49 pagesProject Management - CPM-PERTAbu BasharNo ratings yet

- Principles of ManagementDocument36 pagesPrinciples of ManagementNISTHA KUMARINo ratings yet

- Unit - 6 Projet Management (Pert/Cpm) : Net Work Analysis: It Is Refers To A Number of Techniques For The Planning andDocument40 pagesUnit - 6 Projet Management (Pert/Cpm) : Net Work Analysis: It Is Refers To A Number of Techniques For The Planning andSuneelKumarNo ratings yet

- Project Planning, Appraisal and Control - 1 PDFDocument117 pagesProject Planning, Appraisal and Control - 1 PDFArchna RaiNo ratings yet

- Draft Model Panchayat and Gram Swaraj ActDocument200 pagesDraft Model Panchayat and Gram Swaraj ActChantal FoleriNo ratings yet

- PM Notes WordDocument257 pagesPM Notes Wordgkvimal nathanNo ratings yet

- Public System ManagementDocument7 pagesPublic System ManagementOlusegun Olasunkanmi PatNo ratings yet

- Construction Scheduling Cost Optimization and Management A New Model Based On Neurocomputing and Object TechnologiesDocument15 pagesConstruction Scheduling Cost Optimization and Management A New Model Based On Neurocomputing and Object TechnologiesEviaNo ratings yet

- CPM - PertDocument48 pagesCPM - Pertrocklife008No ratings yet

- Difference Between PERT & CPMDocument1 pageDifference Between PERT & CPMChandra Sekhar ChittineniNo ratings yet

- Pert and CPMDocument11 pagesPert and CPMbotchNo ratings yet

- 02.levels of ManagementDocument18 pages02.levels of Managementgosaye desalegn0% (1)

- Values & Ethics - POMDocument16 pagesValues & Ethics - POMNirmal100% (1)

- Management Theory Chapter 5 & 6Document41 pagesManagement Theory Chapter 5 & 6Addi100% (1)

- Town Planning ActsDocument14 pagesTown Planning ActsGurleen KaurNo ratings yet

- Difference Between PERT and CPMDocument4 pagesDifference Between PERT and CPMRohit SethNo ratings yet

- Chapter No. 1 Nature and Scope of EconomicsDocument28 pagesChapter No. 1 Nature and Scope of Economicsmohammad muzamilNo ratings yet

- DepartmentalizationDocument19 pagesDepartmentalizationSwami MishraNo ratings yet

- The Origins of Modern Project ManagementDocument22 pagesThe Origins of Modern Project ManagementEmdad YusufNo ratings yet

- Meaning, Purpose and Problems of Cost Benefit Analysis MeaningDocument4 pagesMeaning, Purpose and Problems of Cost Benefit Analysis MeaningAzizul ActivitiesNo ratings yet

- Course FM 10Document149 pagesCourse FM 10Gregg AaronNo ratings yet

- Unit - Ii Creativity and Entrepreneurial Plan Idea Generation, Screening and Project IdentificationDocument9 pagesUnit - Ii Creativity and Entrepreneurial Plan Idea Generation, Screening and Project Identificationmba departmentNo ratings yet

- 14 Principles of ManagementDocument5 pages14 Principles of ManagementVictoria Beltran SubaranNo ratings yet

- Project ManagementDocument43 pagesProject Managementalp_ganNo ratings yet

- Project Management Theory and Practice - MBA 7023Document30 pagesProject Management Theory and Practice - MBA 7023Tharshi100% (1)

- Unit I Office System & ProceduresDocument7 pagesUnit I Office System & ProceduresVishal PatelNo ratings yet

- Review of Solid Waste Management For Smart Cities in IndiaDocument5 pagesReview of Solid Waste Management For Smart Cities in IndiaGJESRNo ratings yet

- Capital BudgetingDocument42 pagesCapital BudgetingPiyush ChitlangiaNo ratings yet

- Project Management Introduction To Project ManagementDocument36 pagesProject Management Introduction To Project ManagementwyfwongNo ratings yet

- CHAPTER 1 Introduction To Organizational BehaviourDocument14 pagesCHAPTER 1 Introduction To Organizational Behaviourirumawan94% (17)

- Housing FinanceDocument22 pagesHousing FinanceMitesh DhoriyaNo ratings yet

- CPM and PertDocument34 pagesCPM and PertFata Hirzi Abi KaramiNo ratings yet

- Difference Between General Management and Project ManagementDocument2 pagesDifference Between General Management and Project ManagementTadele DandenaNo ratings yet

- Government Information Quarterly: Jean Damascene Twizeyimana, Annika Andersson TDocument12 pagesGovernment Information Quarterly: Jean Damascene Twizeyimana, Annika Andersson TRachit MunjalNo ratings yet

- Project Direction & ControlDocument57 pagesProject Direction & ControlMeeta Murarka50% (2)

- Classification of IndustriesDocument11 pagesClassification of IndustriesAppan Kandala Vasudevachary100% (3)

- Chapter Three: Project Evaluation and Analysis (Project Preparation) 3.1 Meaning of Feasibility StudyDocument37 pagesChapter Three: Project Evaluation and Analysis (Project Preparation) 3.1 Meaning of Feasibility Studymekibib fisihaNo ratings yet

- Unit3 MBADocument156 pagesUnit3 MBAAman Roxx100% (1)

- 32 Project ManagementDocument252 pages32 Project ManagementAjay MalikNo ratings yet

- Lecture 1,2Document126 pagesLecture 1,2armyfreak007No ratings yet

- Organizational BehaviourDocument55 pagesOrganizational BehaviourRuchi AgarwallNo ratings yet

- Fayol's 14 Principles of ManagementDocument12 pagesFayol's 14 Principles of Managementkandukurisandeep0188% (17)

- CPM PertDocument18 pagesCPM PertJunaid YNo ratings yet

- 18CS51 MODULE IV NotesDocument19 pages18CS51 MODULE IV NotesSathwik Rao KNo ratings yet

- Land Use-Transport ModelDocument31 pagesLand Use-Transport ModelPriti BhujbalNo ratings yet

- Project Management: A Managerial Approach 4/e: by Jack R. Meredith and Samuel J. Mantel, JRDocument19 pagesProject Management: A Managerial Approach 4/e: by Jack R. Meredith and Samuel J. Mantel, JRQasim RehmanNo ratings yet

- ATP Question Bank - 1Document3 pagesATP Question Bank - 1sn jadhavNo ratings yet

- Town Planning Unit 1-2Document37 pagesTown Planning Unit 1-2Sujaysinh Patil100% (1)

- IGBC Green Townships Rating SystemDocument64 pagesIGBC Green Townships Rating SystemAmit MendirattaNo ratings yet

- GomathiDocument19 pagesGomathiGomathiNo ratings yet

- Earnest Burgess Concentric Zone ModelDocument22 pagesEarnest Burgess Concentric Zone ModelKejal50% (2)

- Cyber LawDocument16 pagesCyber LawAmrit Raz100% (1)

- Regional PlanningDocument73 pagesRegional Planningaditi kaviwala0% (1)

- Scheduling: Network Techniques: Graphic Representation of Project Activities, Network AnalysisDocument62 pagesScheduling: Network Techniques: Graphic Representation of Project Activities, Network AnalysisInderjeet Singh Toor100% (1)

- PERT and CPMDocument26 pagesPERT and CPMmathi sivaNo ratings yet

- O.R Unit 5 NewDocument32 pagesO.R Unit 5 NewSaif Ali KhanNo ratings yet

- Chapter 3 Part 2Document54 pagesChapter 3 Part 2mussab ababnehNo ratings yet

- History of Project ManagementDocument16 pagesHistory of Project ManagementCassandri LabuschagneNo ratings yet

- I Denti FI Cati ON OF Acti VI TI ESDocument7 pagesI Denti FI Cati ON OF Acti VI TI ESengr_misbahullahNo ratings yet

- CAPM Questions PDFDocument4 pagesCAPM Questions PDFengr_misbahullahNo ratings yet

- Basic Change Document Instructions To RMSDocument32 pagesBasic Change Document Instructions To RMSengr_misbahullahNo ratings yet

- Contract MGT AssignmentDocument5 pagesContract MGT Assignmentengr_misbahullahNo ratings yet

- Contract MGT - 2.1 - Contract Types 1Document24 pagesContract MGT - 2.1 - Contract Types 1engr_misbahullahNo ratings yet

- Conduct Training Needs Analysis: Step 1Document20 pagesConduct Training Needs Analysis: Step 1engr_misbahullahNo ratings yet

- US Army Corps of EngineersDocument28 pagesUS Army Corps of Engineersengr_misbahullahNo ratings yet

- Introduction To Project ManagementDocument36 pagesIntroduction To Project Managementengr_misbahullahNo ratings yet

- Microsoft® Office Excel ShortcutDocument64 pagesMicrosoft® Office Excel Shortcutengr_misbahullahNo ratings yet

- Project Management Concepts: Academic Computing Services 2009 Academic Computing Services 2009Document62 pagesProject Management Concepts: Academic Computing Services 2009 Academic Computing Services 2009Hamis Rabiam MagundaNo ratings yet

- Information Technology Project Management, Seventh EditionDocument57 pagesInformation Technology Project Management, Seventh Editionengr_misbahullahNo ratings yet

- Software and Software Engineering: Software Engineering: A Practitioner's Approach, 6th EditionDocument19 pagesSoftware and Software Engineering: Software Engineering: A Practitioner's Approach, 6th Editiongopi_meruguNo ratings yet

- Course Exit Survey EE3071Document2 pagesCourse Exit Survey EE3071Bharath PulavarthiNo ratings yet

- L12 Fractional Knapsack GreedyDocument13 pagesL12 Fractional Knapsack GreedyShivansh RagNo ratings yet

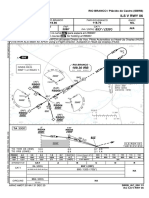

- SBRB Ils-V-Rwy-06 Iac 20201231Document1 pageSBRB Ils-V-Rwy-06 Iac 20201231Matheus GuerraNo ratings yet

- RELIABILITYrev2 Jan17 - Version 2Document18 pagesRELIABILITYrev2 Jan17 - Version 2Ainan SyabilNo ratings yet

- ControlDocument59 pagesControlTuan Anh Nguyen HuuNo ratings yet

- Gr. 5 - Why Does The Future Does Not Need UsDocument2 pagesGr. 5 - Why Does The Future Does Not Need UsBrian CastañedaNo ratings yet

- Quiz Ch1. Intro Deadline Fri 27 Aug 21 - 00 - Attempt ReviewDocument4 pagesQuiz Ch1. Intro Deadline Fri 27 Aug 21 - 00 - Attempt ReviewNgô Hữu ĐangNo ratings yet

- UML Diagram: By: Lona Mohammed Lava Nadr Lava KareemDocument28 pagesUML Diagram: By: Lona Mohammed Lava Nadr Lava KareemKosar AbdullaNo ratings yet

- Sahana ResumeDocument2 pagesSahana ResumeAmith VishwanathNo ratings yet

- BSMAC 2019 FlowchartDocument1 pageBSMAC 2019 FlowchartMikaela SamonteNo ratings yet

- Use of Combined ARX - NARX Model in Identification of Neuromuscular SystemDocument7 pagesUse of Combined ARX - NARX Model in Identification of Neuromuscular SystemDavid AndresNo ratings yet

- Iv. Single Layer Structures: 4.1. PerceptronsDocument26 pagesIv. Single Layer Structures: 4.1. PerceptronsYunus KoçNo ratings yet

- Zeroth Law of ThermodynamicspptDocument20 pagesZeroth Law of ThermodynamicspptCherry Mae Miranda VillabasNo ratings yet

- 2.004 Dynamics and Control Ii: Mit OpencoursewareDocument7 pages2.004 Dynamics and Control Ii: Mit OpencoursewareVishay RainaNo ratings yet

- Chapter 2 - SQA - Conceptes and Standards - STQADocument23 pagesChapter 2 - SQA - Conceptes and Standards - STQASambhav KapoorNo ratings yet

- 1.1 - Computational Intelligence PDFDocument31 pages1.1 - Computational Intelligence PDFpancawawanNo ratings yet

- 5G Network (Prospects and Applications)Document8 pages5G Network (Prospects and Applications)Eriharemien Emmanuel OsaregueNo ratings yet

- Course Description: Introduction, Modeling of Dynamical Systems, Time-Domain Analysis, FrequencyDocument2 pagesCourse Description: Introduction, Modeling of Dynamical Systems, Time-Domain Analysis, FrequencyCoalescence BITSNo ratings yet

- 24.378 Signal Processing I Laboratory 2: U (T-A), HDocument2 pages24.378 Signal Processing I Laboratory 2: U (T-A), HRodrigoNo ratings yet

- Lecture3 CPS RequirementsDocument14 pagesLecture3 CPS RequirementszahraNo ratings yet

- FMSE Lecture 1Document35 pagesFMSE Lecture 1Muhammad BilalNo ratings yet

- Unit 5 2marksDocument2 pagesUnit 5 2marksSINNAPPARAJ SNo ratings yet

- Inverted Pendulum Control: A Brief OverviewDocument4 pagesInverted Pendulum Control: A Brief OverviewIJMERNo ratings yet

- UntitledDocument4 pagesUntitled9710190524No ratings yet

Project Management by CPM & PERT

Project Management by CPM & PERT

Uploaded by

engr_misbahullah0 ratings0% found this document useful (0 votes)

271 views18 pagesThe document discusses the history and development of the Critical Path Method (CPM) and Program Evaluation and Review Technique (PERT) project management tools. It was created in the 1950s out of the need for Western industrial and military establishments to plan, schedule, and control complex projects. CPM was developed by DuPont to reduce downtime on plant maintenance, while PERT was created by the US Navy for the Polaris missile program. The document then outlines the framework for using CPM and PERT to define activities, durations, dependencies, and critical paths to help plan, schedule, monitor and control projects.

Original Description:

Project Management through CPM & PERT

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the history and development of the Critical Path Method (CPM) and Program Evaluation and Review Technique (PERT) project management tools. It was created in the 1950s out of the need for Western industrial and military establishments to plan, schedule, and control complex projects. CPM was developed by DuPont to reduce downtime on plant maintenance, while PERT was created by the US Navy for the Polaris missile program. The document then outlines the framework for using CPM and PERT to define activities, durations, dependencies, and critical paths to help plan, schedule, monitor and control projects.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

271 views18 pagesProject Management by CPM & PERT

Project Management by CPM & PERT

Uploaded by

engr_misbahullahThe document discusses the history and development of the Critical Path Method (CPM) and Program Evaluation and Review Technique (PERT) project management tools. It was created in the 1950s out of the need for Western industrial and military establishments to plan, schedule, and control complex projects. CPM was developed by DuPont to reduce downtime on plant maintenance, while PERT was created by the US Navy for the Polaris missile program. The document then outlines the framework for using CPM and PERT to define activities, durations, dependencies, and critical paths to help plan, schedule, monitor and control projects.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 18

Project Management by CPM & PERT

SML 740 Quantitative Methods in Management

Course Coordinator Prof. D.K.Banwet

Presented by :-

Neha Thapliyal 2005SMF6544 Kumar Gaurav 2005SMF6615

Ashish Kumar Singh 2005SMF6648 Saurabh Vajpayee 2005SMT6671

Department of Management Studies

Indian Institute of Technology, Delhi

History of CPM & PERT

Project planning with CPM/PERT

CPM (Critical Path Method)

PERT (Programme Evaluation Review Technique)

Project management techniques

Created out of the need of Western industrial and

military establishments to plan, schedule and control

complex projects.

Developed along two parallel streams, one industrial and

the other military.

History of CPM & PERT

CPM was the discovery of M.R.Walker of E.I.Du Pont

de Nemours & Co. and J.E.Kelly of Remington Rand,

1957

First test was made in 1958, when CPM was applied

to the construction of a new chemical plant

In 1959, the method was applied to maintenance

shutdown at the Du Pont works - Unproductive time

was reduced from 125 to 93 hours

PERT was devised in 1958 for the POLARIS missile

program by the Program Evaluation Branch of the

Special Projects office of the U.S.Navy

Planning, Scheduling & Control

Planning, Scheduling (or organizing) and Control

are considered to be basic Managerial functions

PERT/CPM provided a focus around which

managers could brainstorm and put their ideas

together.

Proved to be a great communication medium by

which thinkers and planners at one level could

communicate their ideas, their doubts and fears to

another level.

Planning, Scheduling & Control

CPM/PERT can answer the following important

questions:

How long will the entire project take to be

completed? What are the risks involved?

Which are the critical activities or tasks in the

project, which could delay the entire project if they

were not completed on time?

Is the project on schedule, behind schedule or

ahead of schedule?

If the project has to be finished earlier than

planned, what is the best way to do this at the least

cost?

Framework for PERT & CPM

1. Define the Project and all of its significant

activities or tasks.

2. Develop the relationships among the activities

3. Draw the "Network" connecting all the activities

4. Assign time and/or cost estimates to each activity

5. Compute the longest time path through the

network CRITICAL PATH

6. Use the Network to help plan, schedule, monitor

and control the project

Framework for PERT & CPM

Five useful questions to ask when preparing an

activity network are:

Is this a Start Activity?

Is this a Finish Activity?

What Activity Precedes this?

What Activity Follows this?

What Activity is Concurrent with this?

Activity-on-Node Network Diagrams

AON

Each activity is represented by a node in the network.

A precedence relationship between two activities is

represented by an arc or link between the two.

AON may be less error prone because it does not

need dummy activities or arcs

Figure2: Activity on node representation

Figure 3: Activity on arc representation

AOA

Each activity is represented by an arc in the network.

If activity X must precede activity Y, there are X leads into arc Y.

Thus, the nodes represent events or milestones (e.g., finished

activity X). Dummy activities of zero length may be required to

properly represent precedence relationships.

AOA historically has been more popular, perhaps because of its

similarity to Gantt charts used in scheduling.

Activity-on-Arc Network Diagrams

Crashing, Resource Constraints

and Uncertainty

Some peculiar situations that may arise in a current

day project are :

Speeding up the completion of a project by speeding

up or crashing some of the activities in the project.

Ability to finish a project quickly is hindered by limited

resources.

Given the uncertainty of each activity, what can be

said about the probability that the entire project

will finish by a given target date.

Thus, we get a crashing cost curve for the activity as shown in Figure 4:

Normal time

Figure 4 Activity Crash Cost Curve

Cost

Crashing, Resource Constraints and

Uncertaintycontd.

Crashing and the cost of crashing

Crashing of Project Networks

Once the critical path length for a project has been identified, the

next question invariably asked is: can we shorten the project? The

process of decreasing the duration of a project or activity is

commonly called crashing.

The Cost and Value of Crashing

There is value in crashing a project. In order to crash a project, we

must crash one or more activities. Crashing an activity costs

money.

The Cost of Crashing an Activity

An activity is typically crashed by applying more labor to it.

CPM PERT in building construction

Construction activities and their time & start constraints

CPM in construction

C

The Value of Crashing a Project

There are two approaches to deciding upon the amount of project

crashing:

We simply specify a project duration time and crash enough to

achieve this duration, or

We estimate the value of crashing it for various days.

Figure 6 Gantt chart for House Project

Thank You !!

You might also like

- UasfntitledDocument3 pagesUasfntitledSivekiNo ratings yet

- Extended Essay Draft 1Document15 pagesExtended Essay Draft 1Eli MuellerNo ratings yet

- Chpater 6 - Continous Random Variables and The Normal DistributionDocument11 pagesChpater 6 - Continous Random Variables and The Normal Distributionbishoy sefinNo ratings yet

- Ieee STD 730 Sqa PlansDocument17 pagesIeee STD 730 Sqa PlansPatricia LlallicoNo ratings yet

- Benefits of FMEADocument9 pagesBenefits of FMEAbaranirajsalem100% (2)

- Phys 181Document2 pagesPhys 181sophiecaiNo ratings yet

- Im Unit 5 NotesDocument34 pagesIm Unit 5 NotessunitaNo ratings yet

- Project Management - CPM-PERTDocument49 pagesProject Management - CPM-PERTAbu BasharNo ratings yet

- Principles of ManagementDocument36 pagesPrinciples of ManagementNISTHA KUMARINo ratings yet

- Unit - 6 Projet Management (Pert/Cpm) : Net Work Analysis: It Is Refers To A Number of Techniques For The Planning andDocument40 pagesUnit - 6 Projet Management (Pert/Cpm) : Net Work Analysis: It Is Refers To A Number of Techniques For The Planning andSuneelKumarNo ratings yet

- Project Planning, Appraisal and Control - 1 PDFDocument117 pagesProject Planning, Appraisal and Control - 1 PDFArchna RaiNo ratings yet

- Draft Model Panchayat and Gram Swaraj ActDocument200 pagesDraft Model Panchayat and Gram Swaraj ActChantal FoleriNo ratings yet

- PM Notes WordDocument257 pagesPM Notes Wordgkvimal nathanNo ratings yet

- Public System ManagementDocument7 pagesPublic System ManagementOlusegun Olasunkanmi PatNo ratings yet

- Construction Scheduling Cost Optimization and Management A New Model Based On Neurocomputing and Object TechnologiesDocument15 pagesConstruction Scheduling Cost Optimization and Management A New Model Based On Neurocomputing and Object TechnologiesEviaNo ratings yet

- CPM - PertDocument48 pagesCPM - Pertrocklife008No ratings yet

- Difference Between PERT & CPMDocument1 pageDifference Between PERT & CPMChandra Sekhar ChittineniNo ratings yet

- Pert and CPMDocument11 pagesPert and CPMbotchNo ratings yet

- 02.levels of ManagementDocument18 pages02.levels of Managementgosaye desalegn0% (1)

- Values & Ethics - POMDocument16 pagesValues & Ethics - POMNirmal100% (1)

- Management Theory Chapter 5 & 6Document41 pagesManagement Theory Chapter 5 & 6Addi100% (1)

- Town Planning ActsDocument14 pagesTown Planning ActsGurleen KaurNo ratings yet

- Difference Between PERT and CPMDocument4 pagesDifference Between PERT and CPMRohit SethNo ratings yet

- Chapter No. 1 Nature and Scope of EconomicsDocument28 pagesChapter No. 1 Nature and Scope of Economicsmohammad muzamilNo ratings yet

- DepartmentalizationDocument19 pagesDepartmentalizationSwami MishraNo ratings yet

- The Origins of Modern Project ManagementDocument22 pagesThe Origins of Modern Project ManagementEmdad YusufNo ratings yet

- Meaning, Purpose and Problems of Cost Benefit Analysis MeaningDocument4 pagesMeaning, Purpose and Problems of Cost Benefit Analysis MeaningAzizul ActivitiesNo ratings yet

- Course FM 10Document149 pagesCourse FM 10Gregg AaronNo ratings yet

- Unit - Ii Creativity and Entrepreneurial Plan Idea Generation, Screening and Project IdentificationDocument9 pagesUnit - Ii Creativity and Entrepreneurial Plan Idea Generation, Screening and Project Identificationmba departmentNo ratings yet

- 14 Principles of ManagementDocument5 pages14 Principles of ManagementVictoria Beltran SubaranNo ratings yet

- Project ManagementDocument43 pagesProject Managementalp_ganNo ratings yet

- Project Management Theory and Practice - MBA 7023Document30 pagesProject Management Theory and Practice - MBA 7023Tharshi100% (1)

- Unit I Office System & ProceduresDocument7 pagesUnit I Office System & ProceduresVishal PatelNo ratings yet

- Review of Solid Waste Management For Smart Cities in IndiaDocument5 pagesReview of Solid Waste Management For Smart Cities in IndiaGJESRNo ratings yet

- Capital BudgetingDocument42 pagesCapital BudgetingPiyush ChitlangiaNo ratings yet

- Project Management Introduction To Project ManagementDocument36 pagesProject Management Introduction To Project ManagementwyfwongNo ratings yet

- CHAPTER 1 Introduction To Organizational BehaviourDocument14 pagesCHAPTER 1 Introduction To Organizational Behaviourirumawan94% (17)

- Housing FinanceDocument22 pagesHousing FinanceMitesh DhoriyaNo ratings yet

- CPM and PertDocument34 pagesCPM and PertFata Hirzi Abi KaramiNo ratings yet

- Difference Between General Management and Project ManagementDocument2 pagesDifference Between General Management and Project ManagementTadele DandenaNo ratings yet

- Government Information Quarterly: Jean Damascene Twizeyimana, Annika Andersson TDocument12 pagesGovernment Information Quarterly: Jean Damascene Twizeyimana, Annika Andersson TRachit MunjalNo ratings yet

- Project Direction & ControlDocument57 pagesProject Direction & ControlMeeta Murarka50% (2)

- Classification of IndustriesDocument11 pagesClassification of IndustriesAppan Kandala Vasudevachary100% (3)

- Chapter Three: Project Evaluation and Analysis (Project Preparation) 3.1 Meaning of Feasibility StudyDocument37 pagesChapter Three: Project Evaluation and Analysis (Project Preparation) 3.1 Meaning of Feasibility Studymekibib fisihaNo ratings yet

- Unit3 MBADocument156 pagesUnit3 MBAAman Roxx100% (1)

- 32 Project ManagementDocument252 pages32 Project ManagementAjay MalikNo ratings yet

- Lecture 1,2Document126 pagesLecture 1,2armyfreak007No ratings yet

- Organizational BehaviourDocument55 pagesOrganizational BehaviourRuchi AgarwallNo ratings yet

- Fayol's 14 Principles of ManagementDocument12 pagesFayol's 14 Principles of Managementkandukurisandeep0188% (17)

- CPM PertDocument18 pagesCPM PertJunaid YNo ratings yet

- 18CS51 MODULE IV NotesDocument19 pages18CS51 MODULE IV NotesSathwik Rao KNo ratings yet

- Land Use-Transport ModelDocument31 pagesLand Use-Transport ModelPriti BhujbalNo ratings yet

- Project Management: A Managerial Approach 4/e: by Jack R. Meredith and Samuel J. Mantel, JRDocument19 pagesProject Management: A Managerial Approach 4/e: by Jack R. Meredith and Samuel J. Mantel, JRQasim RehmanNo ratings yet

- ATP Question Bank - 1Document3 pagesATP Question Bank - 1sn jadhavNo ratings yet

- Town Planning Unit 1-2Document37 pagesTown Planning Unit 1-2Sujaysinh Patil100% (1)

- IGBC Green Townships Rating SystemDocument64 pagesIGBC Green Townships Rating SystemAmit MendirattaNo ratings yet

- GomathiDocument19 pagesGomathiGomathiNo ratings yet

- Earnest Burgess Concentric Zone ModelDocument22 pagesEarnest Burgess Concentric Zone ModelKejal50% (2)

- Cyber LawDocument16 pagesCyber LawAmrit Raz100% (1)

- Regional PlanningDocument73 pagesRegional Planningaditi kaviwala0% (1)

- Scheduling: Network Techniques: Graphic Representation of Project Activities, Network AnalysisDocument62 pagesScheduling: Network Techniques: Graphic Representation of Project Activities, Network AnalysisInderjeet Singh Toor100% (1)

- PERT and CPMDocument26 pagesPERT and CPMmathi sivaNo ratings yet

- O.R Unit 5 NewDocument32 pagesO.R Unit 5 NewSaif Ali KhanNo ratings yet

- Chapter 3 Part 2Document54 pagesChapter 3 Part 2mussab ababnehNo ratings yet

- History of Project ManagementDocument16 pagesHistory of Project ManagementCassandri LabuschagneNo ratings yet

- I Denti FI Cati ON OF Acti VI TI ESDocument7 pagesI Denti FI Cati ON OF Acti VI TI ESengr_misbahullahNo ratings yet

- CAPM Questions PDFDocument4 pagesCAPM Questions PDFengr_misbahullahNo ratings yet

- Basic Change Document Instructions To RMSDocument32 pagesBasic Change Document Instructions To RMSengr_misbahullahNo ratings yet

- Contract MGT AssignmentDocument5 pagesContract MGT Assignmentengr_misbahullahNo ratings yet

- Contract MGT - 2.1 - Contract Types 1Document24 pagesContract MGT - 2.1 - Contract Types 1engr_misbahullahNo ratings yet

- Conduct Training Needs Analysis: Step 1Document20 pagesConduct Training Needs Analysis: Step 1engr_misbahullahNo ratings yet

- US Army Corps of EngineersDocument28 pagesUS Army Corps of Engineersengr_misbahullahNo ratings yet

- Introduction To Project ManagementDocument36 pagesIntroduction To Project Managementengr_misbahullahNo ratings yet

- Microsoft® Office Excel ShortcutDocument64 pagesMicrosoft® Office Excel Shortcutengr_misbahullahNo ratings yet

- Project Management Concepts: Academic Computing Services 2009 Academic Computing Services 2009Document62 pagesProject Management Concepts: Academic Computing Services 2009 Academic Computing Services 2009Hamis Rabiam MagundaNo ratings yet

- Information Technology Project Management, Seventh EditionDocument57 pagesInformation Technology Project Management, Seventh Editionengr_misbahullahNo ratings yet

- Software and Software Engineering: Software Engineering: A Practitioner's Approach, 6th EditionDocument19 pagesSoftware and Software Engineering: Software Engineering: A Practitioner's Approach, 6th Editiongopi_meruguNo ratings yet

- Course Exit Survey EE3071Document2 pagesCourse Exit Survey EE3071Bharath PulavarthiNo ratings yet

- L12 Fractional Knapsack GreedyDocument13 pagesL12 Fractional Knapsack GreedyShivansh RagNo ratings yet

- SBRB Ils-V-Rwy-06 Iac 20201231Document1 pageSBRB Ils-V-Rwy-06 Iac 20201231Matheus GuerraNo ratings yet

- RELIABILITYrev2 Jan17 - Version 2Document18 pagesRELIABILITYrev2 Jan17 - Version 2Ainan SyabilNo ratings yet

- ControlDocument59 pagesControlTuan Anh Nguyen HuuNo ratings yet

- Gr. 5 - Why Does The Future Does Not Need UsDocument2 pagesGr. 5 - Why Does The Future Does Not Need UsBrian CastañedaNo ratings yet

- Quiz Ch1. Intro Deadline Fri 27 Aug 21 - 00 - Attempt ReviewDocument4 pagesQuiz Ch1. Intro Deadline Fri 27 Aug 21 - 00 - Attempt ReviewNgô Hữu ĐangNo ratings yet

- UML Diagram: By: Lona Mohammed Lava Nadr Lava KareemDocument28 pagesUML Diagram: By: Lona Mohammed Lava Nadr Lava KareemKosar AbdullaNo ratings yet

- Sahana ResumeDocument2 pagesSahana ResumeAmith VishwanathNo ratings yet

- BSMAC 2019 FlowchartDocument1 pageBSMAC 2019 FlowchartMikaela SamonteNo ratings yet

- Use of Combined ARX - NARX Model in Identification of Neuromuscular SystemDocument7 pagesUse of Combined ARX - NARX Model in Identification of Neuromuscular SystemDavid AndresNo ratings yet

- Iv. Single Layer Structures: 4.1. PerceptronsDocument26 pagesIv. Single Layer Structures: 4.1. PerceptronsYunus KoçNo ratings yet

- Zeroth Law of ThermodynamicspptDocument20 pagesZeroth Law of ThermodynamicspptCherry Mae Miranda VillabasNo ratings yet

- 2.004 Dynamics and Control Ii: Mit OpencoursewareDocument7 pages2.004 Dynamics and Control Ii: Mit OpencoursewareVishay RainaNo ratings yet

- Chapter 2 - SQA - Conceptes and Standards - STQADocument23 pagesChapter 2 - SQA - Conceptes and Standards - STQASambhav KapoorNo ratings yet

- 1.1 - Computational Intelligence PDFDocument31 pages1.1 - Computational Intelligence PDFpancawawanNo ratings yet

- 5G Network (Prospects and Applications)Document8 pages5G Network (Prospects and Applications)Eriharemien Emmanuel OsaregueNo ratings yet

- Course Description: Introduction, Modeling of Dynamical Systems, Time-Domain Analysis, FrequencyDocument2 pagesCourse Description: Introduction, Modeling of Dynamical Systems, Time-Domain Analysis, FrequencyCoalescence BITSNo ratings yet

- 24.378 Signal Processing I Laboratory 2: U (T-A), HDocument2 pages24.378 Signal Processing I Laboratory 2: U (T-A), HRodrigoNo ratings yet

- Lecture3 CPS RequirementsDocument14 pagesLecture3 CPS RequirementszahraNo ratings yet

- FMSE Lecture 1Document35 pagesFMSE Lecture 1Muhammad BilalNo ratings yet

- Unit 5 2marksDocument2 pagesUnit 5 2marksSINNAPPARAJ SNo ratings yet

- Inverted Pendulum Control: A Brief OverviewDocument4 pagesInverted Pendulum Control: A Brief OverviewIJMERNo ratings yet

- UntitledDocument4 pagesUntitled9710190524No ratings yet