Professional Documents

Culture Documents

Microstructure-Properties: II Martensitic Transformations

Microstructure-Properties: II Martensitic Transformations

Uploaded by

notsofarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microstructure-Properties: II Martensitic Transformations

Microstructure-Properties: II Martensitic Transformations

Uploaded by

notsofarCopyright:

Available Formats

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

1

Microstructure-Properties: II

Martensitic Transformations

27-302

Lecture 6

Fall, 2002

Prof. A. D. Rollett

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

2

Materials Tetrahedron

Microstructure Properties

Processing

Performance

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

3

Objective

The objective of this lecture is to explain the basic features of

martensitic transformations.

Martensitic transformations are the most important type of

military transformations, i.e. transformations that do not require

diffusion for the change in crystal structure to occur.

Why study martensitic transformations?! They occur in many

different metal, ceramic & polymer systems, and are generally

important to understand. Steels represent the classical

example (and a rate case of a mechanically hard martensite).

Also, there are remarkable devices that exploit the shape

memory effect (a consequence of martensitic transformation)

such as stents that open up once at body temperature. The

martensites in this case are generally soft, mechanically

speaking.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

4

References

Phase transformations in metals and alloys, D.A.

Porter, & K.E. Easterling, Chapman & Hall. Porter

& Easterling concentrate on the geometrical and

crystallographic characteristics of Fe-based

martensites.

Materials Principles & Practice, Butterworth

Heinemann, Edited by C. Newey & G. Weaver.

Otsuka, K. and C. M. Wayman (1998). Shape

Memory Materials. Cambridge, England,

Cambridge University Press. This book provides a

very thorough description of the scientific and

technological basis for the shape memory effect.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

5

Notation

T

0

:= Eq. Temp. for 2 phases at same

composition

T := undercooling

S := entropy of transformation

H := enthalpy of transformation

G := Gibbs free energy

e := transformation strain

g := Interface energy

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

6

Military Transformations

What is a martensitic transformation?

Most phase transformations studied in this course

have been diffusional transformations where long

range diffusion is required for the (nucleation and)

growth of the new phase(s).

There is a whole other class of military

transformations which are diffusionless

transformations in which the atoms move only short

distances in order to join the new phase (on the

order of the interatomic spacing).

These transformations are also subject to the

constraints of nucleation and growth. They are

(almost invariably) associated with allotropic

transformations.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

7

Massive vs. Martensitic Transformations

There are two basic types of diffusionless transformations.

One is the massive transformation. In this type, a diffusionless

transformation takes place without a definite orientation

relationship. The interphase boundary (between parent and

product phases) migrates so as to allow the new phase to

grow. It is, however, a civilian transformation because the

atoms move individually.

The other is the martensitic transformation. In this type, the

change in phase involves a definite orientation relationship

because the atoms have to move in a coordinated manner.

There is always a change in shape which means that there is a

strain associated with the transformation. The strain is a

general one, meaning that all six (independent) coefficients

can be different.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

8

Classification of Transformations

Civilian Military

Diffusion

Required

Precipitation,

Spinodal

Decomposition

?

Diffusionless Massive

Transformations

Martensitic

Transformations

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

9

Driving Forces

These transformations require larger driving forces

than for diffusional transformations.

Why? In order for a transformation to occur without

long range diffusion, it must take place without a

change in composition.

This leads to the so-called T

0

concept, which is the

temperature at which the new phase can appear

with a net decrease in free energy at the same

composition as the parent (matrix) phase.

As the following diagram demonstrates, the

temperature, T

0

, at which segregation-less

transformation becomes possible (i.e. a decrease in

free energy would occur), is always less than the

solvus (liquidus) temperature.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

10

Free Energy - Composition: T

0

g,

parent

a,

product

G

X

Common

tangent

G

ga

G

ga

T

1

T

2

T

1

>T

2

Diffusionless transformation impossible at T

1

,

Diffusionless transformation possible at T

2

;

T

0

is defined by no difference in free

energy between the phases, G=0.

T

2

corresponds to

figure 6.3b in P&E.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

11

Driving Force Estimation

The driving force for a martensitic transformation

can be estimated in exactly the same way as for

other transformations such as solidification.

Provided that an enthalpy (latent heat of

transformation) is known for the transformation, the

driving force can be estimated as proportional to the

latent heat and the undercooling below T

0

.

G

ga

= H

ga

T/T

0

.

Thus P&E estimate the driving force at the

temperature at which martensite formation starts in

Eq. 6.1 using this relationship.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

12

Phase

relationships

Note that the M

s

line is horizontal

in the TTT diagram;

also, the M

f

line.

T near T

0

diffusionless

equilibrium

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

13

Heterogeneous Nucleation

Why does martensite not form until well below the

T

0

temperature? The reason is that a finite driving

force is required to supply the energy needed for (a)

the interfacial energy of the nucleus and (b) the

elastic energy associated with the transformation

strain. The former is a small quantity (estimated at

0.02 J.m

-2

) but the elastic strain is large (estimated

at 0.2 in the Fe-C system), see section 6.3.1 for

details. Therefore the following (standard) equation

applies.

G* = 16g

3

/ 3(G

V

- G

S

)

2

Why does martensite require heterogeneous

nucleation? The reason is the large critical free

energy for nucleation outlined above.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

14

Microstructure of Martensite

The microstructural characteristics of martensite are:

- the product (martensite) phase has a well defined

crystallographic relationship with the parent (matrix).

- martensite forms as platelets within grains.

- each platelet is accompanied by a shape change

- the shape change appears to be a simple shear

parallel to a habit plane (the common, coherent

plane between the phases) and a uniaxial expansion

(dilatation) normal to the habit plane. The habit

plane in plain-carbon steels is close to (225), for

example (see P&E fig. 6.11).

- successive sets of platelets form, each generation

forming between pairs of the previous set.

- the transformation rarely goes to completion.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

15

Microstructures

Martensite formation

rarely goes to

completion because

of the strain associated

with the product

that leads to back

stresses in the

parent phase.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

16

Self-accommodation by variants

A typical feature of martensitic transformations is

that each colony of martensite laths/plates consists

of a stack in which different variants alternate. This

allows large shears to be accommodated with

minimal macroscopic shear.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

17

Mechanisms

The mechanisms of military transformations are not

entirely clear. The small length scales mean that

the reactions propagate at high rates - close to the

speed of sound. The high rates are possible

because of the absence of long range atomic

movement (via diffusion).

Possible mechanisms for martensitic

transformations include

(a) dislocation based

(b) shear based

Martensitic transformations strongly constrained by

crystallography of the parent and product phases.

This is analogous to slip (dislocation glide) and

twinning, especially the latter.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

18

Atomic model - the Bain Model

For the case of fcc Fe transforming to bct ferrite

(Fe-C martensite), there is a basic model known as

the Bain model.

The essential point of the Bain model is that it

accounts for the structural transformation with a

minimum of atomic motion.

Start with two fcc unit cells: contract by 20% in the z

direction, and expand by 12% along the x and y

directions.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

19

Bain model

Orientation relationships in the Bain model are:

(111)

g

<=> (011)

a

[101]

g

<=> [111]

a

[110]

g

<=> [100]

a

[112]

g

<=> [011]

a

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

20

Crystallography, contd.

Although the Bain model explains several basic

aspects of martensite formation, additional features

must be added for complete explanations (not

discussed here).

The missing component of the transformation strain

is an additional shear that changes the character of

the strain so that an invariant plane exists. This is

explained in fig. 6.8.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

21

Role of Dislocations

Dislocations play an important, albeit hard to define

role in martensitic transformations.

Dislocations in the parent phase (austenite) clearly

provide sites for heterogeneous nucleation.

Dislocation mechanisms are thought to be important

for propagation/growth of martensite platelets or

laths. Unfortunately, the transformation strain (and

invariant plane) does not correspond to simple

lattice dislocations in the fcc phase. Instead, more

complex models of interfacial dislocations are

required.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

22

Why tetragonal Fe-C martensite?

At this point, it is worth stopping to ask why a tetragonal

martensite forms in iron. The answer has to do with the

preferred site for carbon as an interstitial impurity in bcc Fe.

Remember: Fe-C martensites are unusual for being so strong

(& brittle). Most martensites are not significantly stronger than

their parent phases.

Interstitial sites:

fcc: octahedral sites radius= 0.052 nm

tetrahedral sites radius= 0.028 nm

bcc: octahedral sites radius= 0.019 nm

tetrahedral sites radius= 0.036 nm

Carbon atom radius = 0.08 nm.

Surprisingly, it occupies the octahedral site in the bcc Fe

structure, despite the smaller size of this site (compared to the

tetrahedral sites) presumably because of the low modulus in

the <100> directions.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

23

Interstitial

sites for C in

Fe

fcc: carbon

occupies the

octahedral sites

bcc: carbon

occupies the

octahedral sites

[Leslie]

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

24

Carbon in ferrite

One consequence of the occupation

of the octahedral site in ferrite is that

the carbon atom has only two

nearest neighbors.

Each carbon atom therefore distorts

the iron lattice in its vicinity.

The distortion is a tetragonal

distortion.

If all the carbon atoms occupy the

same type of site then the entire

lattice becomes tetragonal, as in the

martensitic structure.

Switching of the carbon atom

between adjacent sites leads to

strong internal friction peaks at

characteristic temperatures and

frequencies.

[P&E]

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

25

Shape Memory Effect (SME)

General phenomenon associated with martensitic

transformations.

Characteristic feature = strain induced martensite

(SIM), capable of thermal reversion.

Ferroelasticity and Superelasticity also possible.

M

d

,A

f

,A

s

,A

d

,M

s

,M

f

temperatures.

[Shape

Memory

Materials]

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

26

Temperatures

M

d

T

0

A

d

M

f

A

f

A

s

M

s

The M

d

and A

d

temperatures bracket T

0

because they define the on-

cooling and on-heating temperatures at which the transformation is

possible with allowance for the effect of strain energy.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

27

SME Definitions

M

d

: SIM possible below M

d

.

A

f

: reversion of SIM complete above A

f

(heating).

A

s

: reversion of SIM starts above A

s

(heating).

A

d

: formation of parent phase possible

above A

d

.

M

s

: martensite start temperature (cooling).

M

f

: martensite finish temperature (cooling).

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

28

SME, contd.

Classic alloy = Nitinol = NiTi

alloying for control of Ms.

Stress for SIM must be less than yield stress for

plastic deformation.

SME depends on incomplete transformation and

elastic back stresses to provide memory (>M

S

).

SME more effective in single xtals.

Alloying permits variations in the equilibrium

transformation temperature, for example (critical for

bio applications, for example). Also variations in the

maximum strain that can be recovered are possible.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

29

Super-elasticity

Super-elasticity is simply reversible (therefore

elastic) deformation over very large strain ranges

(many %).

Example: Ti-50.2%Ni.

[Shape

Memory

Materials]

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

30

Role of Ordering

A key feature of the Ni-Ti alloys for shape memory

applications is that their compositions are all in the

vicinity of 50Ni-50Ti and that the high temperature

phase is an ordered B2 structure. The low

temperature B19 monoclinic structure is therefore

also ordered (as is the other, intermediate R phase

which is trigonal).

The ordered structure (recall the discussion of

ordered particle strengthening) means that there is

an appreciable resistance to dislocation motion.

This is critical for favoring strain accommodation via

transformation and twinning as opposed to

dislocation glide.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

31

Self-accommodation

Micrograph with

diagram shows how

different variants of

a given martensitic

phase form so as to

minimize

macroscopic shear

strains in a given

region.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

32

Shape Memory

Effect

Demonstration of

shape memory effect

(SME) in a spring

Mechanism of SME:

1) transformation;

2) martensite, self-

accommodated;

3) deformation by

variant growth;

4) heating causes

re-growth of parent

phase in original

orientation

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

33

Surface

Relief

Micrographs

show a sequence

of temperatures

with surface

relief from the

martensite plates.

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

34

Stress versus Temperature

The stress applied to the material must be less than

the critical resolved shear stress for dislocation

motion, because the latter is not recoverable;

SME= Shape Memory Effect; SE = Superelasticity

Stress

Temperature

Critical

Stress for

Martensite

Formation

Critical

Stress for

Slip

A

f

A

s

M

f

M

s

SME

SE

d/dT = S/e = H/(T

e

e

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

35

Ni-Ti Alloys

X M

s

M

f

A

s

A

f

V > 25 < -140 < -64 > 25

Cr -100 < -180 < -58 > 25

Mn -116 < -180 < -63 > 10

Fe No

information

< -180 -30 > 25

Co No

information

No

information

0 > 25

Cu > 25 < -100 ? > 25

TiNi

0.95

70 60 108 113

TiNi 60 52 71 77

Ti

0.95

Ni -50 < -180 ? 20 (?)

[Wasilewski, SME in Alloys, p245]

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

36

SME Requirements

For achieving a strong or technologically useful

SME, the following characteristics are required.

High resistance to dislocation slip (to avoid

irreversible deformation).

Easy twin motion in the martensitic state so that

variants can exchange volume at low stresses.

Crystallographically reversible transformation from

product phase back to parent phase. Ordered

structures have this property (whereas for a

disordered parent phase, e.g. most Fe-alloys,

multiple routes back to the parent structure exist.)

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

37

Photo-

stimulated SME!

Objective

Basics

T

0

concept

Micro-

structures

Bain

model

Carbon

in Fe

SME

38

Summary

Martensitic transformations are characterized by a

diffusionless change in crystal structure.

The lack of change in composition means that larger

driving forces and undercoolings are required in

order for this type of transformation to occur.

The temperature below which a diffusionless

transformation is possible is known as T

0

.

Martensitic transformations invariably result in

significant strains with well defined (if irrational, in

terms of Miller indices) crystallography.

Technological applications abound - quenched and

tempered steels, Nitinol shape memory alloys etc.

You might also like

- TTT and CCT Continuous Cooling TransformationDocument6 pagesTTT and CCT Continuous Cooling TransformationurcojNo ratings yet

- Metallurgy For DummiesDocument6 pagesMetallurgy For DummiesTalha Bin TahirNo ratings yet

- Astm A500Document6 pagesAstm A500notsofar100% (4)

- Astm C 473-03 Standard Test Methods For Physical Testing ofDocument13 pagesAstm C 473-03 Standard Test Methods For Physical Testing ofCharwin Picao100% (1)

- Konica Minolta Production Print Products For 2018Document22 pagesKonica Minolta Production Print Products For 201824x7first100% (1)

- Martensitic TransformationsDocument38 pagesMartensitic TransformationsquitzlcoatlNo ratings yet

- Microstructure Properties: II Martensitic TransformationsDocument38 pagesMicrostructure Properties: II Martensitic TransformationsRecep VatanseverNo ratings yet

- Microstructure-Properties: II Martensitic Transformations: 27-302 Fall, 2002 Prof. A. D. RollettDocument38 pagesMicrostructure-Properties: II Martensitic Transformations: 27-302 Fall, 2002 Prof. A. D. RollettMukesh MehtaNo ratings yet

- Chapter Outline: Phase Transformations. KineticsDocument23 pagesChapter Outline: Phase Transformations. Kineticsmpcd07No ratings yet

- Towards An Austenite Decomposition Model For TRIP Steels: Physical PropertiesDocument6 pagesTowards An Austenite Decomposition Model For TRIP Steels: Physical PropertiesbluecreteNo ratings yet

- DiffusionlessTransformation KTF 2018Document40 pagesDiffusionlessTransformation KTF 2018Arif PasaditaNo ratings yet

- Part IV: Solid-Solid Phase Transformations I Module 5. Martensitic TransformationsDocument8 pagesPart IV: Solid-Solid Phase Transformations I Module 5. Martensitic TransformationsAmanpreet Singh ParhwaggaNo ratings yet

- Computational Materials Science: R. Mahnken, A. Schneidt, S. Tschumak, H.J. MaierDocument7 pagesComputational Materials Science: R. Mahnken, A. Schneidt, S. Tschumak, H.J. MaierJames HaidoNo ratings yet

- A Kinetics Model For Martensite Transformation in Plain Carbon and Low Alloyed SteelsDocument7 pagesA Kinetics Model For Martensite Transformation in Plain Carbon and Low Alloyed SteelsfdcarazoNo ratings yet

- The Mechanism of Multistage Martensitic Transformations in Aged Ni-Rich Niti Shape Memory AlloysDocument11 pagesThe Mechanism of Multistage Martensitic Transformations in Aged Ni-Rich Niti Shape Memory AlloysjimakosjpNo ratings yet

- Chapter Outline:: Heat Treatment (And Temperature)Document24 pagesChapter Outline:: Heat Treatment (And Temperature)DSGNo ratings yet

- A Case Study ReportDocument18 pagesA Case Study ReportRoshan Pasupathi100% (1)

- Complete Calculation of Steel Microstructure For Strong AlloysDocument12 pagesComplete Calculation of Steel Microstructure For Strong AlloysmkozinNo ratings yet

- Effects of Martensitic Phase Transformation On Advancing Cracks in Austenitic SteelDocument6 pagesEffects of Martensitic Phase Transformation On Advancing Cracks in Austenitic SteelIvanovka03No ratings yet

- Deformation-Induced Transformation of Retained Austenite in Transformation Induced Plasticity-Aided Steels: A Thermodynamic ModelDocument10 pagesDeformation-Induced Transformation of Retained Austenite in Transformation Induced Plasticity-Aided Steels: A Thermodynamic ModelAhmed El-SaiedNo ratings yet

- Diffusionless (Non-Diffusive) Transformation: Dr. Deni Ferdian, M.SCDocument40 pagesDiffusionless (Non-Diffusive) Transformation: Dr. Deni Ferdian, M.SCDimas Agung SetiajiNo ratings yet

- ExaminationDocument2 pagesExaminationoarappaNo ratings yet

- Morphological Evolution of MartensiteDocument17 pagesMorphological Evolution of MartensiteadarshNo ratings yet

- MatterDocument2 pagesMatterTapas Kumar DeNo ratings yet

- Very Strong Bainite: Current Opinion in Solid State and Materials Science 8 (2004) 251-257Document16 pagesVery Strong Bainite: Current Opinion in Solid State and Materials Science 8 (2004) 251-257asif hameedNo ratings yet

- Shape Memory Alloys PPT EditedDocument58 pagesShape Memory Alloys PPT EditedSaurav Kumar40% (5)

- Martensite and Bainite in Steels-UcamDocument10 pagesMartensite and Bainite in Steels-UcamEddyWangNo ratings yet

- Phase Transformation in Metals: Dr. Aneela WakeelDocument29 pagesPhase Transformation in Metals: Dr. Aneela WakeelmazharNo ratings yet

- Phase Transformation in Metals1Document3 pagesPhase Transformation in Metals1sridharan.engineer01No ratings yet

- Unified Model For Plate and Lath Martensite With Athermal KineticsDocument10 pagesUnified Model For Plate and Lath Martensite With Athermal KineticsHan Hisyam PratamaNo ratings yet

- TTT N AvramiDocument40 pagesTTT N AvramiAmirul AminNo ratings yet

- Hypoeutectoid Carbon SteelsDocument12 pagesHypoeutectoid Carbon SteelsCho BhoNo ratings yet

- Chmt3021 Lecture+Notes 1+Phase+DiagramsDocument22 pagesChmt3021 Lecture+Notes 1+Phase+DiagramslebogangmarobaneNo ratings yet

- Time-Temperature-Transformation Diagram Within The Bainitic Temperature Range in A Medium Carbon SteelDocument10 pagesTime-Temperature-Transformation Diagram Within The Bainitic Temperature Range in A Medium Carbon SteelAnonymous Fty6OOHlNo ratings yet

- MME-18-14 - Afnan Sadaqat - Physical MetallurgyDocument19 pagesMME-18-14 - Afnan Sadaqat - Physical MetallurgyMuhammed AfnanNo ratings yet

- The Bainite ControversyDocument46 pagesThe Bainite ControversyCoca CocaNo ratings yet

- Qubs 04 00001 v3Document17 pagesQubs 04 00001 v3Lorena LeonNo ratings yet

- Platinum Alloys For Shape Memory ApplicationsDocument15 pagesPlatinum Alloys For Shape Memory ApplicationsKursalNo ratings yet

- Tracking Solute Atoms During Bainite ReaDocument21 pagesTracking Solute Atoms During Bainite ReamirosekNo ratings yet

- Articol Carburi in Inele de RulmeniDocument9 pagesArticol Carburi in Inele de RulmeniBuluc GheorgheNo ratings yet

- Crystalstructure Handout10 PDF 19544 PDFDocument16 pagesCrystalstructure Handout10 PDF 19544 PDFRojy SaikiaNo ratings yet

- Ferrocelectric 1Document16 pagesFerrocelectric 1Minhaj MunshiNo ratings yet

- Cambridge PDFDocument6 pagesCambridge PDFArush SinhalNo ratings yet

- NiTiPillar Acta 2009Document13 pagesNiTiPillar Acta 2009sivom01No ratings yet

- Phase Transformation in Metals and AlloysDocument31 pagesPhase Transformation in Metals and AlloysSyafiqah RusdiNo ratings yet

- High-Strength Bainitic SteelsDocument9 pagesHigh-Strength Bainitic SteelsabanzabalNo ratings yet

- Heat Treatment of 1045 Steel PDFDocument17 pagesHeat Treatment of 1045 Steel PDFH_DEBIANENo ratings yet

- Fe CDocument34 pagesFe CZaza ArifinNo ratings yet

- Shape - Memory - Alloy - Actuators - 1Document8 pagesShape - Memory - Alloy - Actuators - 1numbrNo ratings yet

- Lecture 2, 3Document25 pagesLecture 2, 3Mohamed MoawadNo ratings yet

- Ko 2015Document22 pagesKo 2015Mudavath Babu RamNo ratings yet

- Probing The Mott Physics in - (BEDT-TTF) 2X Salts Via Thermal ExpansionDocument28 pagesProbing The Mott Physics in - (BEDT-TTF) 2X Salts Via Thermal ExpansionFelipeSilveiraNo ratings yet

- Sample Questions For Phase DiagramDocument5 pagesSample Questions For Phase DiagramMohaiminul Islam TalhaNo ratings yet

- Martensitic TransformationDocument3 pagesMartensitic TransformationnewteamNo ratings yet

- EMAT 10 (2k21)Document41 pagesEMAT 10 (2k21)Kumail AbbasNo ratings yet

- IpmmmmDocument6 pagesIpmmmmAshok PradhanNo ratings yet

- On The Bainitic and Martensitic Phase Transformation Behavior and The Mechanical Properties of Low Alloy 51Crv4 SteelDocument13 pagesOn The Bainitic and Martensitic Phase Transformation Behavior and The Mechanical Properties of Low Alloy 51Crv4 SteelTaha TalbiNo ratings yet

- Shape Memory ShubhamDocument11 pagesShape Memory Shubhamtimroddick24No ratings yet

- An Introduction To Shape Memory AlloysDocument8 pagesAn Introduction To Shape Memory AlloysJayabharath GuredyNo ratings yet

- Module #25Document28 pagesModule #25kamel touilebNo ratings yet

- Tempering ReviewDocument34 pagesTempering ReviewAleš Nagode100% (1)

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Hypoeutectiod Steel Alloys - SteelDocument52 pagesHypoeutectiod Steel Alloys - SteelnotsofarNo ratings yet

- 02 - STRUCTURE - 01 - European Fitness For Service Network (FITNET) Fatigue Module DevelopmentDocument10 pages02 - STRUCTURE - 01 - European Fitness For Service Network (FITNET) Fatigue Module DevelopmentnotsofarNo ratings yet

- NHSS6 Issue7 June 2013Document45 pagesNHSS6 Issue7 June 2013notsofarNo ratings yet

- Map of Mount Druitt TAFEDocument2 pagesMap of Mount Druitt TAFEnotsofar0% (1)

- Lincoln GMAW Welding GuideDocument96 pagesLincoln GMAW Welding GuideМич БјукенонNo ratings yet

- Machine Learning Inspired Sound-Based Amateur Drone Detection For Public Safety ApplicationsDocument9 pagesMachine Learning Inspired Sound-Based Amateur Drone Detection For Public Safety ApplicationsKhurram AzizNo ratings yet

- 0100CT1501 Sec-05Document4 pages0100CT1501 Sec-05João Carlos AlmeidaNo ratings yet

- Wheel Weight SizeDocument56 pagesWheel Weight SizeHerciu FlavianNo ratings yet

- Cad 1133 Powersupply FinalreportDocument47 pagesCad 1133 Powersupply Finalreportapi-300000636No ratings yet

- Kebutuhan Beton - Update 080922Document1 pageKebutuhan Beton - Update 080922daraNo ratings yet

- (Certificate and Survey Status) : No Certificate Issued by RemarksDocument32 pages(Certificate and Survey Status) : No Certificate Issued by RemarksPankajShukla100% (1)

- Is:4926 RMCDocument21 pagesIs:4926 RMCRamesh100% (7)

- Jackson 11.14 Homework Problem SolutionDocument4 pagesJackson 11.14 Homework Problem SolutionPero PericNo ratings yet

- Informe DialuxDocument134 pagesInforme DialuxSFERNo ratings yet

- Pakistan International School (English Section) : Subject: Physics Grade: 7 Answer Key Chapter 31: CircuitsDocument2 pagesPakistan International School (English Section) : Subject: Physics Grade: 7 Answer Key Chapter 31: CircuitsAHK GAMERNo ratings yet

- Iso 11795 2018 en PDFDocument3 pagesIso 11795 2018 en PDFYAHYAWINo ratings yet

- Mosfet 100 VoltDocument9 pagesMosfet 100 Voltnithinmundackal3623No ratings yet

- GC2 Q4 Week-5bDocument11 pagesGC2 Q4 Week-5bfrancise keith sionaNo ratings yet

- The Offshore Oil and Gas Decommissioning Market 2013-2023 PDFDocument22 pagesThe Offshore Oil and Gas Decommissioning Market 2013-2023 PDFVisiongainGlobal100% (1)

- NodefluxDocument16 pagesNodefluxNuswantoro Gading AlfaNo ratings yet

- Cebex 100 PDFDocument2 pagesCebex 100 PDFBijaya RaulaNo ratings yet

- 7 - Woson Tanda PDFDocument16 pages7 - Woson Tanda PDFNassima BelilNo ratings yet

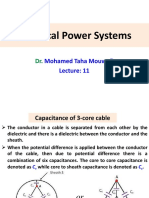

- Electrical Power Systems: Mohamed Taha MouwafiDocument18 pagesElectrical Power Systems: Mohamed Taha MouwafiAHMED BAKRNo ratings yet

- Laboratory Manual 4: Discrete Time Fourier Transform & Discrete Fourier TransformDocument10 pagesLaboratory Manual 4: Discrete Time Fourier Transform & Discrete Fourier TransformHassanNo ratings yet

- DPPS - Tutorial QuestionsDocument3 pagesDPPS - Tutorial QuestionsraviciviltNo ratings yet

- Testing and Commissioning of Fire Fighting System Hosereel and Sprinkler SystemDocument4 pagesTesting and Commissioning of Fire Fighting System Hosereel and Sprinkler SystemHumaid ShaikhNo ratings yet

- BIOS Keys For All BrandsDocument2 pagesBIOS Keys For All BrandsmugavaidineshNo ratings yet

- Geothermal Energy Materials and Process IssuesDocument8 pagesGeothermal Energy Materials and Process IssuesmattkidoNo ratings yet

- ERP Cloud Financials Fusion Cash Management R11 (8) SecurityDocument88 pagesERP Cloud Financials Fusion Cash Management R11 (8) SecurityELOUSOUANINo ratings yet

- Manual Utilizare Sistem Garaj - SPIDODocument78 pagesManual Utilizare Sistem Garaj - SPIDOTheodora GherdanNo ratings yet

- MT-Card 3DS V1.3 Firmware Upgrade To Support Eshop, Solve Memory Card ProblemDocument13 pagesMT-Card 3DS V1.3 Firmware Upgrade To Support Eshop, Solve Memory Card ProblemSandyDuNo ratings yet

- Aggregates DiscussionDocument90 pagesAggregates DiscussionJames PleñosNo ratings yet

- JSA ScaffoldingDocument10 pagesJSA ScaffoldingLo Roque100% (1)