Professional Documents

Culture Documents

3 Downstream Process Farmasi

3 Downstream Process Farmasi

Uploaded by

Naela RizqiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Downstream Process Farmasi

3 Downstream Process Farmasi

Uploaded by

Naela RizqiCopyright:

Available Formats

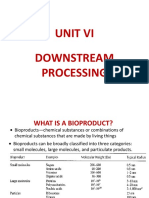

Downstream Processing in

Biopharmaceutical Fermentation

Alwani Hamad, ST, MSc.

Fakultas Farmasi

Universitas Muhammadiyah Purwokerto

Teknologi Fermentasi

MK: Bioteknologi

2

Course content

Persyaratan proses fermentasi

Kondisi dan variable fermentasi

Fermenter/ bioreaktor

Media dan optimasi media untuk fermentasi

Kinetika pertumbuhan bakteri untuk menghitung hasil

produk fermentasi

Downstream process hasil fermentasi (produk

biopharmacy)

Evaluasi : Ujian (closed book)

Buku rujukan:

G Rao.2007. Introduction to Biochemical Engineering. Tata Mc Graw- Hill Publishing

Company Limited

Stanbury, Whitaker and Hall, 2003. Principles of Fermentation Technology Butterworth

Typical Production Process Flow

(Feed 2)

(Feed 3)

(Feed 4)

Chrom 1

Chrom 3

Cryo-preservation

Concentration /

Diafiltration

Centrifuge

Viral Removal

Filtration

(Feed1)

Inoculum Expansion

(Spinner Bottles)

Ampule Thaw

Chrom 2

Media Prep

Working Cell

Bank

Sub-

Culture

Inoculum

Sub-

Culture

Sub-

Culture

Sub-

Culture

Sub-

Culture

Large Scale Bioreactor

Wave

Bag

Seed Bioreactors

Fermentation

150L

Bioreactor

750L

Bioreactor

5,000L

Bioreactor

26,000L

Bioreactor

Depth

Filtration

Collection

Centrifuge

Harvest/Recovery

Harvest

Collection

Tank

1,500L

Filter

Chromatography

Skid

Anion Exchange

Chromatography (QXL)

Column Eluate

Hold

Tank

8,000L

Eluate

Hold

Tank

6,000L

Filter

Chromatography

Skid

Protein A

Chromatography

Column

Chromatography

Skid

Column

Eluate

Hold

Tank

20,000L

Hydrophobic Interaction

Chromatography (HIC)

Eluate

Hold

Tank

20,000L

Viral

Inactivation

Eluate

Hold

Tank

5,000L

Filter

Chromatography

Skid

Anion Exchange

Chromatography

(QFF - Fast Flow)

Column

Post-viral

Hold

Vessel

3,000L

Viral Filtering Ultra Filtration

Diafiltration

Bulk

Fill

Purification

24 days 31 days

8 days

1 day

Upstream/Downstream Manufacturing Overview

Hasil proses fermentasi

Mikroorganisme

Product

Whole cells

Cell debris/fragments

Soluble and insoluble medium product

Proteins

Undissolved nutrient components

biomass

Downstream process dalam

Fermentasi

Langkah proses downstream merupakan salah satu langkah dalam proses

fermentasi yang sangat penting yaitu langkah setelah proses fermentasi

untuk menghasilkan bioproduk dengan menggunakan unit operation agar

diperoleh produk yang terpisah dari campuran yang lain

Dalam downstream process : cost 20 60% dari total cost proses. >90%

untuk produk rekombinant DNA

Downstream processing steps = operasi pemurnian produk hasil

fermentasi

Langkah langkah dalam downstream process

Initial isolation

Product recovery

Purification and concentration

Hal yang dipertimbangkan dalam rangka

pemilihan jenis unit operation dalam

downstream process

Lokasi produk : intracelluler atau ekstracelluler

Kestabilan terhadap panas

Jumlah produk di dalam broth

Cost product

Kegunaan produk

Minimal standar yang dapat diterima

Komposisi impuritas yang diijinkan dalam produk

Jenis unit operation yang digunakan

dalam downstream process

Lihat table 17.1 hal 158 Rao Introduction of biochemical engineering

Dapat dibagi sebagai berikut :

Pemisahan suspended solid

Filtrasi

Sedimentasi

Centrifugation

Foam separation

Precipitation

Cell Disruption

Pemisahan satu fasa

Ekstraksi

kromatografi

Cell disruption

Mechanical method

High speed agitation

Grinding with abrasives

High pressure pumping (homogenization)

Non-mechanical method

Osmotic shock

Treatment with solvent and detergents

Freezing and thawingf

Enzymatic digestion of cell walls

Know the Characteristics of

Your Protein

Green Fluorescent Protein

(GFP)

Sequence of Amino Acids

MSKGEELFTGVVPVLVELDGDVNGQKF

SVSGEGEGDATYGKLTLNFICTTGKL

PVPWPTLVTTFSYGVQCFSRYPDHM

KQHDFFKSAMPEGYVQERTIFYKDD

GNYKTRAEVKFEGDTLVNRIELKGID

FKEDGNILGHKMEYNYNSHNVYIMG

DKPKNGIKVNFKIRHNIKDGSVQLAD

HYQQNTPIGDGPVLLPDNHYLSTQS

ALSKDPNEKRDHMILLEFVTAARITH

GMDELYK

Tertiary Structure

Contoh downstream process dalam

industri biopharmacy

Know the Characteristics of Your Protein

Green Fluorescent Protein (GFP)

MW (molecular weight = 27,000 Daltons (27 kD)

pI (isoelectric point) = 4.8

Hydropathicity (=hydrophobicity) =

Tissue Plasminogen Activator

MW 60 kD pI: 8.04 Hydrophobicity -.516

Human Serum Albumin

mkwvtfisll llfssaysrg vfrrdthkse iahrfkdlge ehfkglvlia fsqylqqcpf

61 dehvklvnel tefaktcvad eshagceksl htlfgdelck vaslretygd madccekqep

121 ernecflshk ddspdlpklk pdpntlcdef kadekkfwgk ylyeiarrhp yfyapellyy

181 ankyngvfqe ccqaedkgac llpkietmre kvltssarqr lrcasiqkfg eralkawsva

241 rlsqkfpkae fvevtklvtd ltkvhkecch gdllecaddr adlakyicdn qdtissklke

301 ccdkplleks hciaevekda ipenlpplta dfaedkdvck nyqeakdafl gsflyeysrr

361 hpeyavsvll rlakeyeatl eeccakddph acystvfdkl khlvdepqnl ikqncdqfek

421 lgeygfqnal ivrytrkvpq vstptlvevs rslgkvgtrc ctkpesermp ctedylslil

481 nrlcvlhekt pvsekvtkcc teslvnrrpc fsaltpdety vpkafdeklf tfhadictlp

541 dtekqikkqt alvellkhkp kateeqlktv menfvafvdk ccaaddkeac favegpklvw

601 stqtala

MW 69 kD pI 5.82 Hydrophobicity -.395

1 rrgarsyqvi crdektqmiy qqhqswlrpv lrsnrveycw cnsgraqchs vpvkscsepr 61

cfnggtcqqa lyfsdfvcqc pegfagkcce idtratcyed qgisyrgtws taesgaectn 121

wnssalaqkp ysgrrpdair lglgnhnycr npdrdskpwc yvfkagkyss efcstpacse 181

gnsdcyfgng sayrgthslt esgasclpwn smiligkvyt aqnpsaqalg lgkhnycrnp 241

dgdakpwchv lknrrltwey cdvpscstcg lrqysqpqfr ikgglfadia shpwqaaifa 301

khrrspgerf lcggilissc wilsaahcfq erfpphhltv ilgrtyrvvp geeeqkfeve 361 kyivhkefdd

dtydndiall qlksdssrca qessvvrtvc lppadlqlpd wtecelsgyg 421 khealspfys

erlkeahvrl ypssrctsqh llnrtvtdnm lcagdtrsgg pqanlhdacq 481 gdsggplvcl

ndgrmtlvgi iswglgcgqk dvpgvytkvt nyldwirdnm rp

Some Other Proteins of Interest

Clarification or

Removal of Cells and Cell Debris

Using Centrifugation

Using Depth Filtration

Control Panel

Cut-away view

Protective enclosure

Basic components of a centrifuge

Door

Rotor

Drive

shaft

Motor

Centrifugal force

Sedimentatio

n

path of

particles

Pellet

deposited

at an angle

C

e

n

t

e

r

o

f

r

o

t

a

t

i

o

n

r

minimum

r

average

r

maximum

Centrifuge

An instrument that generates centrifugal force.

Commonly used to separate particles in a liquid from the liquid.

Continuous Centrifugation

Media and Cells In & Clarified Media Out

Separation of particles from liquid by applying

a pressure to the solution to force the solution through a

filter. Filters are materials with pores.

Particles larger than the pore size of the

filter are retained by the filter.

Particles smaller than the pore size of the filter pass

through the filter along with the liquid.

Filtration

Traps contaminants larger than the pore size on the top surface of the membrane.

Contaminants smaller than the specified pore size pass through the membrane.

Used for critical applications such as sterilizing and final filtration.

Normal Flow Filtration

Depth Filtration:

Equipment

Depth Filtration: Cells and Cellular Debris

Stick to Ceramic Encrusted Fibers in Pads

PROTEIN of INTEREST

Uses crossflow to reduce build up

of retained components on the

membrane surface

Allows filtration of high fouling

streams and high resolution

Tangential Flow Filtration

vs. Normal Flow Filtration

Tangential Flow Filtration

vs. Normal Flow Filtration

Tangential Flow Filtration TFF

Separation of Protein of Interest

Using TFF with the right cut off filters, the protein of interest

can be separated from other proteins and molecules in the

clarified medium.

HSA has a molecular weight of 69KD. To make sure that the

protein of interest is retained, a 10KD cut-off filter is used.

After we concentrate or ultrafilter our protein, we can

diafilter, adding the phosphate buffer at pH 7.1 that we will

use to equilibrate our affinity column to prepare for affinity

chromatography of HSA.

How TFF Concentrates and Purifies

a Protein of Interest

Downstream Processing Equipment

Lab-Scale TFF System

Large-Scale TFF System

Low Pressure Production

Chromatography

The System: Components and Processes

The Media: Affinity, Ion Exchange,

Hydrophobic Interaction Chromatography

and Gel Filtration

LP LC Components

Mixer for Buffers, Filtrate with Protein of

Interest, Cleaning Solutions

Peristaltic Pump

Injector to Inject Small Sample (in our case for

HETP Analysis)

Chromatography Column and Media (Beads)

Conductivity Meter

UV Detector

Peristaltic Pump

Creates a gentle

squeezing action to

move fluid through

flexible tubing.

Liquid Column Chromatography

Lonza, Portsmouth, NH

A Commercial LP LC

Chromatography Column

Downstream Processing Equipment

Lab Scale

Chromatography System

Large Scale

Chromatography System

Overview of LP LC Chromatography

The molecules of interest, in our case proteins, are adsorbed or

stuck to beads packed in the column. We are interested in the

equilibrium between protein free in solution and protein bound

to the column. The higher the affinity of a protein for the bead

the more protein will be bound to the column at any given time.

Proteins with a high affinity travel slowly through the column

because they are stuck a significant portion of the time.

Molecules with a lower affinity will not stick as often and will

elute more quickly. We can change the relative affinity of the

protein for the column (retention time) and mobile phase by

changing the mobile phase (the buffer). Hence the difference

between loading buffers and elution buffers. This is how proteins

are separated.

The most common type of adsorption chromatography is ion

exchange chromatography. The others used in commercial

biopharmaceutical production are affinity, hydrophobic

interaction and gel filtration.

Liquid Chromatography

Protein solution is applied to a

column

Column filled with matrix (stationary

phase) + liquid phase (mobile phase)

Proteins separated based on

differing affinity for the stationary

and mobile phases

1 2 3 4

Column Chromatography

Separates molecules by their chemical and

physical differences

Most common types:

Size exclusion (Gel filtration): separates by

molecular weight

Ion exchange: separates by charge

Affinity chromatography: specific binding

Hydrophobic Interaction: separates by

hydrophobic/hydrophilic characteristics

Component

Culture Harvest

Level

Final Product

Level

Conventional

Method

Therapeutic Antibody 0.1-1.5 g/l 1-10 g/l UF/Cromatography

Isoforms Various Monomer Chromatography

Serum and host proteins 0.1-3.0 g/l < 0.1-10 mg/l Chromatography

Cell debris and colloids 10

6

/ml None MF

Bacterial pathogens Various <10

-6

/dose MF

Virus pathogens Various

<10

-6

/dose (12

LRV)

virus filtration

DNA 1 mg/l 10 ng/dose Chromatography

Endotoxins Various <0.25 EU/ml Chromatography

Lipids, surfactants 0-1 g/l <0.1-10 mg/l Chromatography

Buffer Growth media Stability media UF

Extractables/leachables Various <0.1-10 mg/l

UF/

Chromatography

Purification reagents Various <0.1-10mg/l UF

Common Process Compounds and Methods of Removal or Purification

Biopharmaceutical Production Overview

Typical Process Flow

(Feed 2)

(Feed 3)

(Feed 4)

Chrom 1

Chrom 3

Cryo-preservation

Concentration /

Diafiltration

Centrifuge

Viral Removal

Filtration

(Feed1)

Inoculum Expansion

Ampoule Thaw

Chrom 2

What Will Change During Scale-up?

Process Development Considerations

Utility requirements

Water requirement

Cleaning/Sanitizing solution requirements

Buffer prep

Number of steps in cell culture scale up

Harvest techniques

Column packing; distribution of introduced liquid at

large columns

Equipment bubble trap

Automation of process

Data collection

Sample load

How to survive when scale up process?

Understanding the physics, chemistry and biology of the

chromatographic system and the binding of the protein of

interest to the chromatographic matrix or beads (Science)

Understanding the design and operation of chromatography

components and of the chromatographic process (Technology

and Engineering).

Understanding the calculations needed to run the

chromatographic system (column volume) and the

measurements on chromatograms needed to calculate the

HETP, number of theoretical plates, retention time, and

resolution (Mathematics).

Actual BioLogic System

Complex System

Not easy to see

interaction of components

Students use virtual

system to prepare to use

actual system

Use virtual system for

BIOMANonline

System same as industrial

chromatography skid

Further reading

G Rao.2007. Introduction to Biochemical

Engineering , Chapter 17

39

Terima kasih

You might also like

- Actualizacion ElmDuinoDocument42 pagesActualizacion ElmDuinoLauraNo ratings yet

- MeraDocument11 pagesMeraShikhar Virmani100% (1)

- By: Miss Thida ChanyachukulDocument29 pagesBy: Miss Thida ChanyachukulDnd LiyanageNo ratings yet

- Downstream ProcessingDocument33 pagesDownstream ProcessingSampath Yadav GaddamNo ratings yet

- Upstream and DownstDocument21 pagesUpstream and Downstbiotech181985No ratings yet

- How To Isolate Proteins FinalDocument9 pagesHow To Isolate Proteins Finalmukeshsriwastva14No ratings yet

- Mohsin Downstream ProcessingDocument20 pagesMohsin Downstream Processingchintan kapadiaNo ratings yet

- Mohsin My New Down Stream ProcessingDocument56 pagesMohsin My New Down Stream Processingchintan kapadiaNo ratings yet

- Thesis Protein PurificationDocument6 pagesThesis Protein Purificationauroratuckernewyork100% (2)

- Fast Protein Liquid Chromatography) or (Fast Performance Liquid Chromatography)Document17 pagesFast Protein Liquid Chromatography) or (Fast Performance Liquid Chromatography)Resna N K ResiNo ratings yet

- Down Stream ProcessingDocument44 pagesDown Stream ProcessingShifa ChoudharyNo ratings yet

- High Performance Liquid Chromatography (HPLC)Document16 pagesHigh Performance Liquid Chromatography (HPLC)Jojo ChanNo ratings yet

- 500L MLaDocument50 pages500L MLaPrecious IJNo ratings yet

- Biopharmaceuticals 20jan09 - 2 - Ian Marison DCUDocument28 pagesBiopharmaceuticals 20jan09 - 2 - Ian Marison DCUFiqa SuccessNo ratings yet

- Bios Era Part Ion 2Document10 pagesBios Era Part Ion 2Pooja Singh JainNo ratings yet

- Biotech Chapter 9Document28 pagesBiotech Chapter 9Hana HamidNo ratings yet

- BTH 401 AssignmentDocument15 pagesBTH 401 AssignmentMelissa lhingnunhoi SimteNo ratings yet

- Presentation1 22Document24 pagesPresentation1 22Hadia ShahidNo ratings yet

- Proteomics Full LecturesDocument107 pagesProteomics Full LecturesPUBG Hacker100% (1)

- History of Nano FiltrationDocument42 pagesHistory of Nano FiltrationKieran Sexton100% (2)

- Protein Purification: What Is The Table Below and Where Have You Seen It Before?Document45 pagesProtein Purification: What Is The Table Below and Where Have You Seen It Before?Aaditya Vignyan VellalaNo ratings yet

- Recovery and Purification of Intracellular and Extra Cellular ProductsDocument25 pagesRecovery and Purification of Intracellular and Extra Cellular ProductsGanesh V GaonkarNo ratings yet

- Chapter - IV - B Fermenter - Design and ConstructionDocument25 pagesChapter - IV - B Fermenter - Design and ConstructionYohannes AfeworkNo ratings yet

- Protein PurificationDocument78 pagesProtein Purificationduverney.gaviria100% (1)

- Upstream and Downstream Processing UpdatedDocument20 pagesUpstream and Downstream Processing UpdatedSara AsgharNo ratings yet

- Fernandes 2013 April 16 Miniaturization Speeding-Up Bioprocess DevelopmentDocument36 pagesFernandes 2013 April 16 Miniaturization Speeding-Up Bioprocess DevelopmentpedroefeNo ratings yet

- Proteins BIOC2069 #1Document36 pagesProteins BIOC2069 #1erica williamsNo ratings yet

- Lec3 PurificationDocument55 pagesLec3 PurificationDawlat SlamaNo ratings yet

- Product Isolation in FermentationDocument18 pagesProduct Isolation in FermentationdeltaoperativNo ratings yet

- GROUP 10 HPLC PresentationDocument26 pagesGROUP 10 HPLC PresentationdesidivamyNo ratings yet

- Downstream ProcessingDocument72 pagesDownstream ProcessingTrainer NIANo ratings yet

- Biopharmaceuticals Chapter 3-2023Document75 pagesBiopharmaceuticals Chapter 3-2023Anh NguyễnNo ratings yet

- Downstream ProcessingDocument53 pagesDownstream ProcessingNaevisweloveuNo ratings yet

- P 1 1 Leung DDocument10 pagesP 1 1 Leung DMasha NikolovaNo ratings yet

- Unit Vi Downstream ProcessingDocument49 pagesUnit Vi Downstream ProcessingSavitaNo ratings yet

- HPLCDocument7 pagesHPLCmeprabhatmishra99No ratings yet

- What Is The Purpose of Coagulation and FlocculationDocument5 pagesWhat Is The Purpose of Coagulation and FlocculationMpumeleloNo ratings yet

- Design and Specifications of BioreactorsDocument57 pagesDesign and Specifications of BioreactorsBalu GbkNo ratings yet

- Protease EnzymeDocument22 pagesProtease Enzymeامنة احمد زيدNo ratings yet

- Chapter 2c Jan2010Document47 pagesChapter 2c Jan2010KumaranNo ratings yet

- Lecture 6Document32 pagesLecture 6Neywa RasliNo ratings yet

- Downstream ProcessingDocument36 pagesDownstream Processingjeevalakshmanan29No ratings yet

- Deep FreezerDocument15 pagesDeep FreezerAbhishek MahajanNo ratings yet

- Bio-Chemical Engineering: CHE-422 Date: 10/05/2018Document18 pagesBio-Chemical Engineering: CHE-422 Date: 10/05/2018Atif MehfoozNo ratings yet

- Ultra FiltrationDocument17 pagesUltra FiltrationNagwa MansyNo ratings yet

- Modern Separation ProcessDocument14 pagesModern Separation ProcesswinkiNo ratings yet

- Membrane FiltrationDocument36 pagesMembrane FiltrationRinika ArdinaNo ratings yet

- Ge Healthcare Mab PurificationDocument8 pagesGe Healthcare Mab PurificationravarNo ratings yet

- Downstream ProcessingDocument30 pagesDownstream ProcessingResa100% (1)

- Bioprocess - Pharmaceutical ProteinDocument41 pagesBioprocess - Pharmaceutical ProteinSirsha PattanayakNo ratings yet

- VOC Expts - PTDocument8 pagesVOC Expts - PTdjmooloba.99No ratings yet

- ULTA Normal Ow Filters Extend Our Filtration Offering: Cross Flow FiltrationDocument4 pagesULTA Normal Ow Filters Extend Our Filtration Offering: Cross Flow Filtrationcrjacob20075482No ratings yet

- Factors For Deciding The Extraction MethodDocument50 pagesFactors For Deciding The Extraction MethodRouf AhmadNo ratings yet

- EXP004b Isolation of GFPDocument9 pagesEXP004b Isolation of GFPNariopolusNo ratings yet

- Upstream & DownstreamDocument20 pagesUpstream & DownstreamLamtiarma PanjaitanNo ratings yet

- Final SampleDocument28 pagesFinal SampleJoshua ArrojoNo ratings yet

- Aspergillus Niger Citric Acid Lactobacillus Delbruckii Lactic Acid Lactobacillus Shirota Strain YakultDocument6 pagesAspergillus Niger Citric Acid Lactobacillus Delbruckii Lactic Acid Lactobacillus Shirota Strain YakultRoxan Bueno MoraNo ratings yet

- Ultra-High Performance Liquid Chromatography and Its ApplicationsFrom EverandUltra-High Performance Liquid Chromatography and Its ApplicationsNo ratings yet

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.From EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Rating: 4 out of 5 stars4/5 (1)

- Microbial Transport SystemsFrom EverandMicrobial Transport SystemsGünther WinkelmannNo ratings yet

- Form Permintaan BarangDocument66 pagesForm Permintaan BarangNaela RizqiNo ratings yet

- Appropriate Use of Benzathine Penicillin G For Treatment of SyphilisDocument2 pagesAppropriate Use of Benzathine Penicillin G For Treatment of SyphilisNaela RizqiNo ratings yet

- 1398943904MS Ijbpas 2014 1756Document10 pages1398943904MS Ijbpas 2014 1756Naela RizqiNo ratings yet

- Antiepilepsy Drugs: Pharmacodynamics and Principles of Drug SelectionDocument22 pagesAntiepilepsy Drugs: Pharmacodynamics and Principles of Drug SelectionNaela RizqiNo ratings yet

- Phytochemicals From Phyllanthus Niruri Linn. and Their Pharmacological Properties: A ReviewDocument12 pagesPhytochemicals From Phyllanthus Niruri Linn. and Their Pharmacological Properties: A ReviewNaela RizqiNo ratings yet

- Data Mining: A Prediction For Performance Improvement Using ClassificationDocument5 pagesData Mining: A Prediction For Performance Improvement Using ClassificationNaela RizqiNo ratings yet

- ASPECDocument7 pagesASPECMickaela Kassandra P. ParanNo ratings yet

- Readme Digsi 5 Tea-X-PluginDocument15 pagesReadme Digsi 5 Tea-X-PluginadbNo ratings yet

- Practical File Part-1Document136 pagesPractical File Part-1soniya tewatiaNo ratings yet

- Literature Review Essay-2Document4 pagesLiterature Review Essay-2api-548944132No ratings yet

- SnsjvuDocument112 pagesSnsjvudocwavy9481No ratings yet

- Release NoteDocument10 pagesRelease NoteyusufNo ratings yet

- SOP For Fenil - Bachelor's Degree in Science (Biology)Document2 pagesSOP For Fenil - Bachelor's Degree in Science (Biology)Ahmed100% (1)

- Synthesis and Characterization of Cadmium Sulphide NanoparticlesDocument17 pagesSynthesis and Characterization of Cadmium Sulphide NanoparticlesHoneylyn IgnacioNo ratings yet

- Smart Attendance System Using Raspberry PiDocument5 pagesSmart Attendance System Using Raspberry PiEditor IJTSRDNo ratings yet

- SSC Maths Quiz 15Document10 pagesSSC Maths Quiz 15Tarun PandeyNo ratings yet

- Training Evaluation Form: To Be Completed by UserDocument2 pagesTraining Evaluation Form: To Be Completed by Usersatish dhimanNo ratings yet

- 4 Ship Handling Tricks To Handle Ships in Better WayDocument18 pages4 Ship Handling Tricks To Handle Ships in Better WayKunal Singh100% (1)

- Addiction of Gadgets and Its Impact On Health of YouthDocument6 pagesAddiction of Gadgets and Its Impact On Health of YouthRonald Dela Cruz IINo ratings yet

- Green Book NCCDocument181 pagesGreen Book NCCChittaranjan satapathyNo ratings yet

- Economic and Political Weekly Economic and Political WeeklyDocument3 pagesEconomic and Political Weekly Economic and Political WeeklyMoon MishraNo ratings yet

- An Epic Post Breakup Glow Up GuideDocument1 pageAn Epic Post Breakup Glow Up GuideMichelle Yvonne ClerigoNo ratings yet

- st3.8 76292 ManualDocument332 pagesst3.8 76292 Manualanon_828943220100% (1)

- VX150 VX2 FMB T: 3: Troubleshooting ManualDocument105 pagesVX150 VX2 FMB T: 3: Troubleshooting ManualragiNo ratings yet

- WSPD Pursuit PolicyDocument7 pagesWSPD Pursuit PolicyCBS 11 NewsNo ratings yet

- SHRM HandbookDocument72 pagesSHRM HandbookVineeth Radhakrishnan100% (1)

- Iptables - F (Or) Iptables - Flush: 1. Delete Existing RulesDocument5 pagesIptables - F (Or) Iptables - Flush: 1. Delete Existing RulesZumaro QoirulNo ratings yet

- Sub-Project Proposal: Municipality of Kabayan Barangay TAWANGANDocument6 pagesSub-Project Proposal: Municipality of Kabayan Barangay TAWANGANpres carap60% (5)

- Valid Dealer ListingDocument33 pagesValid Dealer ListingKristy MayNo ratings yet

- Vayu Issue Vayu Issue III May Jun 2016Document136 pagesVayu Issue Vayu Issue III May Jun 2016Manjunath GangadharNo ratings yet

- 593c0be3230b5002a4a21249 Daniel Guillot Ortiz PDFDocument80 pages593c0be3230b5002a4a21249 Daniel Guillot Ortiz PDFElisa MartinezNo ratings yet

- Design of Engine Stand For Inline Type Engines. Final Year ProjectDocument71 pagesDesign of Engine Stand For Inline Type Engines. Final Year ProjectTolasa NamomsaNo ratings yet

- Light Emitting Diode PresentationDocument22 pagesLight Emitting Diode PresentationRetro GamerNo ratings yet

- Asphalt Surfacing To Bridge DecksDocument44 pagesAsphalt Surfacing To Bridge DecksNguyễn Văn MinhNo ratings yet