Professional Documents

Culture Documents

Concrete Casting: The Result Is Concrete Evidence of Workmanship

Concrete Casting: The Result Is Concrete Evidence of Workmanship

Uploaded by

jaffnaCopyright:

Available Formats

You might also like

- Cabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingFrom EverandCabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingNo ratings yet

- Week 4 - Renaissance Architecture Part 1 - Lecture NotesDocument48 pagesWeek 4 - Renaissance Architecture Part 1 - Lecture NotesShaina CruzNo ratings yet

- Making Test Cubes From Fresh ConcreteDocument4 pagesMaking Test Cubes From Fresh Concretesjpaul197367% (6)

- Sewage Treatment PlantDocument11 pagesSewage Treatment Plantjaffna86% (7)

- Building Management System - BMS 2Document44 pagesBuilding Management System - BMS 2jaffna100% (3)

- Concreting & FinshingDocument62 pagesConcreting & FinshingBijaya RaulaNo ratings yet

- Centering and Shuttering / Formwork:: BWP GradeDocument9 pagesCentering and Shuttering / Formwork:: BWP GradeAvish GunnuckNo ratings yet

- The Precautions To Be Taken While Constructing BeamsDocument7 pagesThe Precautions To Be Taken While Constructing BeamsMd MohibullahNo ratings yet

- Conc Centre Placing FINAL2Document1 pageConc Centre Placing FINAL2Sha RasonabeNo ratings yet

- Troubleshooting - Honeycomb and Voids - tcm45-589731Document1 pageTroubleshooting - Honeycomb and Voids - tcm45-589731Behdad_MNo ratings yet

- CHP 4Document24 pagesCHP 4M.IDREES KhanNo ratings yet

- Construction Joints:: Expansion JointDocument5 pagesConstruction Joints:: Expansion JointSathya MurthyNo ratings yet

- Concrete Formwork Checklist at SiteDocument5 pagesConcrete Formwork Checklist at SiteParthJainNo ratings yet

- Cracks in ConcreteDocument4 pagesCracks in ConcreteAhmed Daahir AdenNo ratings yet

- Strip Foudation ExcavationsDocument8 pagesStrip Foudation ExcavationsImperial OneNo ratings yet

- Joints in Concrete SlabsDocument2 pagesJoints in Concrete SlabsmutyokaNo ratings yet

- CIP 6 Joints in Concrete Slaabs On Grade PDFDocument2 pagesCIP 6 Joints in Concrete Slaabs On Grade PDFAli ParvezNo ratings yet

- Method ConstructionDocument5 pagesMethod ConstructionNurzulaikha SalimNo ratings yet

- See CHAPTER 9 FinishingDocument2 pagesSee CHAPTER 9 FinishingGloria Flores FloresNo ratings yet

- Concrete Formwork Checklist at SiteDocument6 pagesConcrete Formwork Checklist at Sitedineshkmr373100% (1)

- Pre Stressed BeamsDocument127 pagesPre Stressed BeamsjaffnaNo ratings yet

- Compaction of Concrete Methods, Defects & ImportaDocument12 pagesCompaction of Concrete Methods, Defects & ImportaHusnain Khan100% (1)

- Working With ConcreteDocument6 pagesWorking With ConcreteEng. victor kamau NjeriNo ratings yet

- 1.pile Foundation: Q1. Write Down Functions and Classification of Pile FoundationDocument9 pages1.pile Foundation: Q1. Write Down Functions and Classification of Pile FoundationSuhail AhmedNo ratings yet

- Cracking Joint No RestrictionDocument2 pagesCracking Joint No RestrictionThanh Khiet UngNo ratings yet

- Brick Masonry: Subhendu SamuiDocument31 pagesBrick Masonry: Subhendu SamuiRajniNo ratings yet

- Joints in SlabsDocument4 pagesJoints in Slabsتوان امتياس سامسدينNo ratings yet

- Site Supervision Group 9 PresentationDocument18 pagesSite Supervision Group 9 Presentationendalkachew gudetaNo ratings yet

- StripDocument8 pagesStripnawidrasoolyNo ratings yet

- Slump and VibrationDocument4 pagesSlump and VibrationMd. AamirNo ratings yet

- Your Guide To BricklayingDocument6 pagesYour Guide To BricklayingChristopher GeorgeNo ratings yet

- BRMCA TCC Placing Compacting and Curing Concrete May 2008Document1 pageBRMCA TCC Placing Compacting and Curing Concrete May 2008Ye PhoneNo ratings yet

- Non Engineered Reinforced Concrete BuildingDocument11 pagesNon Engineered Reinforced Concrete Buildingmath_0222No ratings yet

- Laying A Small Concrete Slab in Your GardenDocument6 pagesLaying A Small Concrete Slab in Your GardenLily ShubinaNo ratings yet

- Repairs of Concrete Roads: 1. Failure in Cement Concrete PavementsDocument10 pagesRepairs of Concrete Roads: 1. Failure in Cement Concrete PavementsPradeepLokhande100% (1)

- Slump Cone TestDocument7 pagesSlump Cone Teststephenhcc1No ratings yet

- Placing and Finishing of ConcreteDocument62 pagesPlacing and Finishing of ConcreteBharat Jhamnani100% (1)

- URBAN DESIGN unit-IVDocument16 pagesURBAN DESIGN unit-IVmrunalini KolaNo ratings yet

- Weekly Online Assignment: Concrete Technology LabDocument6 pagesWeekly Online Assignment: Concrete Technology LabAjmal KhanNo ratings yet

- Failures in Rigid PavementsDocument6 pagesFailures in Rigid PavementsRajesh KhadkaNo ratings yet

- Part 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary NotesDocument9 pagesPart 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary Notesmohannad eliassNo ratings yet

- Brick and Stone MasonryDocument36 pagesBrick and Stone Masonrym tahirNo ratings yet

- How To Do ConcreteDocument6 pagesHow To Do Concretemohannad eliassNo ratings yet

- Fresh ConcreteDocument34 pagesFresh Concreteahmedalkastawy19No ratings yet

- Types of Defects After and While ConsructionDocument10 pagesTypes of Defects After and While Consructionanon_831233388No ratings yet

- Questions in Building Technology IIIDocument3 pagesQuestions in Building Technology IIIImadeldein SalihNo ratings yet

- 02-Concrete P PDFDocument4 pages02-Concrete P PDFTharindu Sampath WeerasingheNo ratings yet

- 1.3 Defects in Building-1Document88 pages1.3 Defects in Building-1zodiackiller1960sNo ratings yet

- Finishing Concrete FlatworkDocument0 pagesFinishing Concrete Flatworkتوان امتياس سامسدينNo ratings yet

- Inverted Beams Not A Good ChoiceDocument4 pagesInverted Beams Not A Good ChoicefmalameerNo ratings yet

- Joints in Concrete Slabs On GradeDocument2 pagesJoints in Concrete Slabs On GradeaaNo ratings yet

- CIP14-Finishing Concrete FlatworkDocument2 pagesCIP14-Finishing Concrete Flatwork7774R105No ratings yet

- Constructing Concrete Forms Course 01421-6.5Document22 pagesConstructing Concrete Forms Course 01421-6.5virajNo ratings yet

- Block WorkDocument8 pagesBlock WorkOmugabe ReninNo ratings yet

- Concrete PavementDocument58 pagesConcrete PavementGieoden BuenNo ratings yet

- Concrete WorksDocument82 pagesConcrete WorksarnoldalejadoNo ratings yet

- DSR MicroprojectDocument7 pagesDSR Microprojectsgadekar634No ratings yet

- Do's and Dont'sDocument3 pagesDo's and Dont'sgoni TyagiNo ratings yet

- Foundry Practice - A Treatise On Moulding And Casting In Their Various DetailsFrom EverandFoundry Practice - A Treatise On Moulding And Casting In Their Various DetailsNo ratings yet

- The Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationFrom EverandThe Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationNo ratings yet

- Pre-Cast Girder ConstructionDocument19 pagesPre-Cast Girder ConstructionjaffnaNo ratings yet

- Introduction To Bridge EngineeringDocument125 pagesIntroduction To Bridge Engineeringjaffna100% (1)

- Basic Civil and Mechanical Engineering Unit 1Document60 pagesBasic Civil and Mechanical Engineering Unit 1A.R. Pradeep Kumar91% (11)

- Introduction To Surveying: Basics of TraversingDocument33 pagesIntroduction To Surveying: Basics of Traversingjaffna100% (1)

- Levelling ProceduresDocument58 pagesLevelling Proceduresjaffna100% (1)

- Multiview SketchesDocument28 pagesMultiview SketchesjaffnaNo ratings yet

- Traverse ComputationsDocument42 pagesTraverse Computationsjaffna100% (4)

- Management AccountingDocument21 pagesManagement AccountingbelladoNo ratings yet

- Hot Mix Plant Calibration, Laying & TestingDocument55 pagesHot Mix Plant Calibration, Laying & Testingjaffna88% (17)

- Leveling MethodsDocument33 pagesLeveling Methodsjaffna100% (2)

- Expansion JointsDocument35 pagesExpansion Jointsjaffna100% (2)

- Ingredients of Bituminous Mixes & Introduction To ModifiersDocument69 pagesIngredients of Bituminous Mixes & Introduction To ModifiersjaffnaNo ratings yet

- Fusion WeldingDocument31 pagesFusion WeldingjaffnaNo ratings yet

- Grillage Method of Superstructure Analysis: Dr. Shahzad Rahman NWFP University of Engg & Technology, PeshawarDocument59 pagesGrillage Method of Superstructure Analysis: Dr. Shahzad Rahman NWFP University of Engg & Technology, PeshawarpotharajudvnagaNo ratings yet

- Earthing HandoutDocument18 pagesEarthing Handoutjaffna100% (1)

- Engineering Product SpecificationDocument39 pagesEngineering Product SpecificationjaffnaNo ratings yet

- Chain SurveyDocument21 pagesChain SurveyjaffnaNo ratings yet

- Concrete Making MaterialsDocument55 pagesConcrete Making Materialsjaffna100% (1)

- Building Management System - BMS 1Document31 pagesBuilding Management System - BMS 1jaffna100% (2)

- Bituminous Mix Design & Superpave MixesDocument53 pagesBituminous Mix Design & Superpave Mixesjaffna100% (9)

- Natural Open Channel FlowDocument4 pagesNatural Open Channel FlowjaffnaNo ratings yet

- The Evolution of Management TheoryDocument25 pagesThe Evolution of Management TheoryjaffnaNo ratings yet

- Motivating EmployeesDocument21 pagesMotivating EmployeesjaffnaNo ratings yet

- Lecture 8 BearingsDocument53 pagesLecture 8 BearingsReemALMousawiNo ratings yet

- Managing Groups & TeamsDocument23 pagesManaging Groups & TeamsjaffnaNo ratings yet

- Organizational StructureDocument26 pagesOrganizational Structurejaffna100% (2)

- Pipeline DesignDocument12 pagesPipeline Designjaffna0% (1)

- Partially Full Pipe Flow CalculationsDocument17 pagesPartially Full Pipe Flow Calculationsjaffna0% (1)

- Section 05090 Metal FasteningDocument6 pagesSection 05090 Metal FasteningMØhãmmed ØwięsNo ratings yet

- Types of Foundation 1Document14 pagesTypes of Foundation 1Olawale AdebesinNo ratings yet

- The JSW Challenge 2021 Case Study: Case Study: Replacement of Asbestos Sheets With Colour Coated SheetsDocument2 pagesThe JSW Challenge 2021 Case Study: Case Study: Replacement of Asbestos Sheets With Colour Coated SheetsKrishna PrasadNo ratings yet

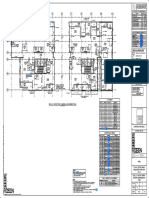

- S121 - LEVEL 2 - SOUTH TOWER - GENERAL ARRANGEMENT PLAN Rev.C4 MarkupDocument1 pageS121 - LEVEL 2 - SOUTH TOWER - GENERAL ARRANGEMENT PLAN Rev.C4 Markupxây dựng 123No ratings yet

- CBRIDocument15 pagesCBRIsonakshiNo ratings yet

- A Preliminary Report of The Archaeological Survey in The Potohar Plateau (Article in Indian Book)Document67 pagesA Preliminary Report of The Archaeological Survey in The Potohar Plateau (Article in Indian Book)Rukhsar AbroNo ratings yet

- HRD C Frame Anchor TDSDocument18 pagesHRD C Frame Anchor TDSronyNo ratings yet

- Basic DesignDocument75 pagesBasic DesignPhan AnhhNo ratings yet

- Method Statement For LEETSTEEL STIFFENER SYSTEM AAC 150mm & 200mmDocument2 pagesMethod Statement For LEETSTEEL STIFFENER SYSTEM AAC 150mm & 200mmpiakhong.cheongNo ratings yet

- Assa Abloy DS6060P Curtain Dock Shelter ParallelDocument2 pagesAssa Abloy DS6060P Curtain Dock Shelter ParallelmujahaddadNo ratings yet

- EGD ResurchDocument3 pagesEGD Resurchpreanca.govenderNo ratings yet

- Island Style Roof Fire Test ReportDocument29 pagesIsland Style Roof Fire Test ReportResearch DevelopmentNo ratings yet

- Timber and Timber ProductsDocument13 pagesTimber and Timber ProductsCollins Obari AdiyeNo ratings yet

- New 03 NBCC GREEN VIEWDocument3 pagesNew 03 NBCC GREEN VIEWsushil kumarNo ratings yet

- Working Drawing ReferenceDocument1 pageWorking Drawing ReferenceDexter LarawanNo ratings yet

- SolidWoodWeb Docs Report SST enDocument4 pagesSolidWoodWeb Docs Report SST ensantiago vallejoNo ratings yet

- Module 1 Introduction To Prestressed Concrete DesignDocument57 pagesModule 1 Introduction To Prestressed Concrete DesignVann AlfredNo ratings yet

- WSP Usor 2018Document36 pagesWSP Usor 2018Sonu VishwakarmaNo ratings yet

- CBLM Tile Setting IIDocument118 pagesCBLM Tile Setting IIrandy pumihicNo ratings yet

- MEP-P-ES-002-Standard Design Requirements For Piping SystemsDocument19 pagesMEP-P-ES-002-Standard Design Requirements For Piping SystemsElias EliasNo ratings yet

- Quotation # 01 - Revision # 03 (Real Ice Cream)Document15 pagesQuotation # 01 - Revision # 03 (Real Ice Cream)Umar AwaisNo ratings yet

- Estimate For Water Tank ConstructionDocument1 pageEstimate For Water Tank ConstructionAbhinav KumarNo ratings yet

- Sample Test On Philippine ArchitectureDocument10 pagesSample Test On Philippine ArchitecturesNo ratings yet

- Flood Zone BambooDocument20 pagesFlood Zone Bamboomansi sharmaNo ratings yet

- 12x8 Chicken Coop Plan FreeDocument21 pages12x8 Chicken Coop Plan Freegrawis18No ratings yet

- Field Quality Plan (FQP) : Appendix 1EDocument13 pagesField Quality Plan (FQP) : Appendix 1EGaurav PandeyNo ratings yet

- Chapter 1 BcoDocument15 pagesChapter 1 Bcoraman laychaNo ratings yet

- Sheat Metal ScrewsDocument39 pagesSheat Metal Screwsshaken56No ratings yet

- Methods of Enhancing and Decorating Finished Products: TLE 6 - Quarter 3Document24 pagesMethods of Enhancing and Decorating Finished Products: TLE 6 - Quarter 3Bethuel Pacasit AlquirozNo ratings yet

Concrete Casting: The Result Is Concrete Evidence of Workmanship

Concrete Casting: The Result Is Concrete Evidence of Workmanship

Uploaded by

jaffnaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Casting: The Result Is Concrete Evidence of Workmanship

Concrete Casting: The Result Is Concrete Evidence of Workmanship

Uploaded by

jaffnaCopyright:

Available Formats

1

Concrete Casting

The result is concrete evidence of

workmanship

2

Topics

Preparation

Securing props

Safety inspection

Casting columns

Casting beams

Casting slabs

Mixing

Curing

3

Preparation

Wash the joints

Remove dirt, soil

Wire brush bars

Check alignment

Secure props

4

Wire brush bars

If the bars are old and rusty wire brush

them. The cement cannot bond with the

steel if it is covered with a thick layer of

rust.

If the bars are factory new wait until they

start corroding. The black surface of new

bars does not bond with cement either.

5

Wash Joints and Formwork

6

Check Alignment

If the formwork is out

of alignment the

concrete will be too

and will have to be

demolished. Take care

that the formwork

cannot give way to the

heavy concrete.

7

Casting Columns

Large columns cannot be cast from the top.

The heavier aggregates would drop to the

lower section and the cement and water

would float on top. This would cause voids

which are called honey combs. These

weaken the structure and are unacceptable.

8

Cut a window into the Formwork of

Columns to cast the lower Part

Then close

the window

and cast the

upper part

9

Section Casting

Especially for fair face

concrete the

expensive formwork

is reduced in size and

used repeatedly. This

avoids also honey

combs since casting

and vibrating is easier

10

Pre-treat the joints

Treat the joint first with

some cement grout

before you cast the

concrete to ensure

better bonding

11

Check Verticality

While casting check verticality and

straightness. You may otherwise get a

terrible surprise since tilted columns cannot

be altered after casting

12

Evenness

Level the concrete along the upper edge of

the formwork after vibrating. Add some

grout and float the surface until it is even.

13

Casting Beams

Set up scaffolding for the entire

length to be able to work without

hindrance.

Column

Float The Top

To achieve

leveled beam

and edges

15

Check props and alignment

Draw a line and make sure that the beams are

aligned. There is nothing you can change

later. If props are not tightened do it

immediately when you feel they are giving

way. If the concrete starts setting you cant

do it any more.

16

Secure Props

Many sites crashed due to bad prop ups

Concrete weighs 2300kg / cu.M

Set a prop every 60cm and secure it on top

and bottom to prevent slippage

Base on

ground

Wedges

from both

sides

Base plate for

better adjustment

of wedges

Secure props

Steel Props

can be easily

adjusted and

secured with

cross braces

19

Casting Sections

Sometimes beams cannot be cast entirely.

They need to be cast in sections too. Do not

join them in the middle. This is the worst

point. Join them at 1/3 from the support.

1/3

2/3

20

Casting Slabs

It is better to cast the beams in the slab first

to put weight all around and then cast the

slab. Vibrating of the beams can be better

controlled to avoid honey combs.

21

Insert Marker Bars to control

evenness and equal thickness

Lay Planks on the reinforcement to

be able to walk, transport, vibrate,

and level the concrete

23

Concrete Mixing

Concrete Mixer

Timing

Handling

24

Concrete Mixer

Thilna Enterprises

25

Vibrate until air

bubbles popping

stops

Vibrate evenly along

the formwork

About Vibration..

26

Over vibration

Over vibration is dangerous to the concrete

Aggregates settle to a sediment at the

bottom, cement and sand collect at top

27

Over vibration

As a result aggregate would not bond and

remain weak and break

See that the aggregates remain visible on

the top!

28

Under Vibration

If the concrete is not sufficiently vibrated

air bubbles remain between the aggregates

and become later visible as honeycombs!

29

Under Vibration

These honeycombs are specially

unacceptable for fairface concrete.

Honeycombing is also the cause for water

leakage

30

Honey Combs

You might also like

- Cabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingFrom EverandCabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingNo ratings yet

- Week 4 - Renaissance Architecture Part 1 - Lecture NotesDocument48 pagesWeek 4 - Renaissance Architecture Part 1 - Lecture NotesShaina CruzNo ratings yet

- Making Test Cubes From Fresh ConcreteDocument4 pagesMaking Test Cubes From Fresh Concretesjpaul197367% (6)

- Sewage Treatment PlantDocument11 pagesSewage Treatment Plantjaffna86% (7)

- Building Management System - BMS 2Document44 pagesBuilding Management System - BMS 2jaffna100% (3)

- Concreting & FinshingDocument62 pagesConcreting & FinshingBijaya RaulaNo ratings yet

- Centering and Shuttering / Formwork:: BWP GradeDocument9 pagesCentering and Shuttering / Formwork:: BWP GradeAvish GunnuckNo ratings yet

- The Precautions To Be Taken While Constructing BeamsDocument7 pagesThe Precautions To Be Taken While Constructing BeamsMd MohibullahNo ratings yet

- Conc Centre Placing FINAL2Document1 pageConc Centre Placing FINAL2Sha RasonabeNo ratings yet

- Troubleshooting - Honeycomb and Voids - tcm45-589731Document1 pageTroubleshooting - Honeycomb and Voids - tcm45-589731Behdad_MNo ratings yet

- CHP 4Document24 pagesCHP 4M.IDREES KhanNo ratings yet

- Construction Joints:: Expansion JointDocument5 pagesConstruction Joints:: Expansion JointSathya MurthyNo ratings yet

- Concrete Formwork Checklist at SiteDocument5 pagesConcrete Formwork Checklist at SiteParthJainNo ratings yet

- Cracks in ConcreteDocument4 pagesCracks in ConcreteAhmed Daahir AdenNo ratings yet

- Strip Foudation ExcavationsDocument8 pagesStrip Foudation ExcavationsImperial OneNo ratings yet

- Joints in Concrete SlabsDocument2 pagesJoints in Concrete SlabsmutyokaNo ratings yet

- CIP 6 Joints in Concrete Slaabs On Grade PDFDocument2 pagesCIP 6 Joints in Concrete Slaabs On Grade PDFAli ParvezNo ratings yet

- Method ConstructionDocument5 pagesMethod ConstructionNurzulaikha SalimNo ratings yet

- See CHAPTER 9 FinishingDocument2 pagesSee CHAPTER 9 FinishingGloria Flores FloresNo ratings yet

- Concrete Formwork Checklist at SiteDocument6 pagesConcrete Formwork Checklist at Sitedineshkmr373100% (1)

- Pre Stressed BeamsDocument127 pagesPre Stressed BeamsjaffnaNo ratings yet

- Compaction of Concrete Methods, Defects & ImportaDocument12 pagesCompaction of Concrete Methods, Defects & ImportaHusnain Khan100% (1)

- Working With ConcreteDocument6 pagesWorking With ConcreteEng. victor kamau NjeriNo ratings yet

- 1.pile Foundation: Q1. Write Down Functions and Classification of Pile FoundationDocument9 pages1.pile Foundation: Q1. Write Down Functions and Classification of Pile FoundationSuhail AhmedNo ratings yet

- Cracking Joint No RestrictionDocument2 pagesCracking Joint No RestrictionThanh Khiet UngNo ratings yet

- Brick Masonry: Subhendu SamuiDocument31 pagesBrick Masonry: Subhendu SamuiRajniNo ratings yet

- Joints in SlabsDocument4 pagesJoints in Slabsتوان امتياس سامسدينNo ratings yet

- Site Supervision Group 9 PresentationDocument18 pagesSite Supervision Group 9 Presentationendalkachew gudetaNo ratings yet

- StripDocument8 pagesStripnawidrasoolyNo ratings yet

- Slump and VibrationDocument4 pagesSlump and VibrationMd. AamirNo ratings yet

- Your Guide To BricklayingDocument6 pagesYour Guide To BricklayingChristopher GeorgeNo ratings yet

- BRMCA TCC Placing Compacting and Curing Concrete May 2008Document1 pageBRMCA TCC Placing Compacting and Curing Concrete May 2008Ye PhoneNo ratings yet

- Non Engineered Reinforced Concrete BuildingDocument11 pagesNon Engineered Reinforced Concrete Buildingmath_0222No ratings yet

- Laying A Small Concrete Slab in Your GardenDocument6 pagesLaying A Small Concrete Slab in Your GardenLily ShubinaNo ratings yet

- Repairs of Concrete Roads: 1. Failure in Cement Concrete PavementsDocument10 pagesRepairs of Concrete Roads: 1. Failure in Cement Concrete PavementsPradeepLokhande100% (1)

- Slump Cone TestDocument7 pagesSlump Cone Teststephenhcc1No ratings yet

- Placing and Finishing of ConcreteDocument62 pagesPlacing and Finishing of ConcreteBharat Jhamnani100% (1)

- URBAN DESIGN unit-IVDocument16 pagesURBAN DESIGN unit-IVmrunalini KolaNo ratings yet

- Weekly Online Assignment: Concrete Technology LabDocument6 pagesWeekly Online Assignment: Concrete Technology LabAjmal KhanNo ratings yet

- Failures in Rigid PavementsDocument6 pagesFailures in Rigid PavementsRajesh KhadkaNo ratings yet

- Part 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary NotesDocument9 pagesPart 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary Notesmohannad eliassNo ratings yet

- Brick and Stone MasonryDocument36 pagesBrick and Stone Masonrym tahirNo ratings yet

- How To Do ConcreteDocument6 pagesHow To Do Concretemohannad eliassNo ratings yet

- Fresh ConcreteDocument34 pagesFresh Concreteahmedalkastawy19No ratings yet

- Types of Defects After and While ConsructionDocument10 pagesTypes of Defects After and While Consructionanon_831233388No ratings yet

- Questions in Building Technology IIIDocument3 pagesQuestions in Building Technology IIIImadeldein SalihNo ratings yet

- 02-Concrete P PDFDocument4 pages02-Concrete P PDFTharindu Sampath WeerasingheNo ratings yet

- 1.3 Defects in Building-1Document88 pages1.3 Defects in Building-1zodiackiller1960sNo ratings yet

- Finishing Concrete FlatworkDocument0 pagesFinishing Concrete Flatworkتوان امتياس سامسدينNo ratings yet

- Inverted Beams Not A Good ChoiceDocument4 pagesInverted Beams Not A Good ChoicefmalameerNo ratings yet

- Joints in Concrete Slabs On GradeDocument2 pagesJoints in Concrete Slabs On GradeaaNo ratings yet

- CIP14-Finishing Concrete FlatworkDocument2 pagesCIP14-Finishing Concrete Flatwork7774R105No ratings yet

- Constructing Concrete Forms Course 01421-6.5Document22 pagesConstructing Concrete Forms Course 01421-6.5virajNo ratings yet

- Block WorkDocument8 pagesBlock WorkOmugabe ReninNo ratings yet

- Concrete PavementDocument58 pagesConcrete PavementGieoden BuenNo ratings yet

- Concrete WorksDocument82 pagesConcrete WorksarnoldalejadoNo ratings yet

- DSR MicroprojectDocument7 pagesDSR Microprojectsgadekar634No ratings yet

- Do's and Dont'sDocument3 pagesDo's and Dont'sgoni TyagiNo ratings yet

- Foundry Practice - A Treatise On Moulding And Casting In Their Various DetailsFrom EverandFoundry Practice - A Treatise On Moulding And Casting In Their Various DetailsNo ratings yet

- The Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationFrom EverandThe Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationNo ratings yet

- Pre-Cast Girder ConstructionDocument19 pagesPre-Cast Girder ConstructionjaffnaNo ratings yet

- Introduction To Bridge EngineeringDocument125 pagesIntroduction To Bridge Engineeringjaffna100% (1)

- Basic Civil and Mechanical Engineering Unit 1Document60 pagesBasic Civil and Mechanical Engineering Unit 1A.R. Pradeep Kumar91% (11)

- Introduction To Surveying: Basics of TraversingDocument33 pagesIntroduction To Surveying: Basics of Traversingjaffna100% (1)

- Levelling ProceduresDocument58 pagesLevelling Proceduresjaffna100% (1)

- Multiview SketchesDocument28 pagesMultiview SketchesjaffnaNo ratings yet

- Traverse ComputationsDocument42 pagesTraverse Computationsjaffna100% (4)

- Management AccountingDocument21 pagesManagement AccountingbelladoNo ratings yet

- Hot Mix Plant Calibration, Laying & TestingDocument55 pagesHot Mix Plant Calibration, Laying & Testingjaffna88% (17)

- Leveling MethodsDocument33 pagesLeveling Methodsjaffna100% (2)

- Expansion JointsDocument35 pagesExpansion Jointsjaffna100% (2)

- Ingredients of Bituminous Mixes & Introduction To ModifiersDocument69 pagesIngredients of Bituminous Mixes & Introduction To ModifiersjaffnaNo ratings yet

- Fusion WeldingDocument31 pagesFusion WeldingjaffnaNo ratings yet

- Grillage Method of Superstructure Analysis: Dr. Shahzad Rahman NWFP University of Engg & Technology, PeshawarDocument59 pagesGrillage Method of Superstructure Analysis: Dr. Shahzad Rahman NWFP University of Engg & Technology, PeshawarpotharajudvnagaNo ratings yet

- Earthing HandoutDocument18 pagesEarthing Handoutjaffna100% (1)

- Engineering Product SpecificationDocument39 pagesEngineering Product SpecificationjaffnaNo ratings yet

- Chain SurveyDocument21 pagesChain SurveyjaffnaNo ratings yet

- Concrete Making MaterialsDocument55 pagesConcrete Making Materialsjaffna100% (1)

- Building Management System - BMS 1Document31 pagesBuilding Management System - BMS 1jaffna100% (2)

- Bituminous Mix Design & Superpave MixesDocument53 pagesBituminous Mix Design & Superpave Mixesjaffna100% (9)

- Natural Open Channel FlowDocument4 pagesNatural Open Channel FlowjaffnaNo ratings yet

- The Evolution of Management TheoryDocument25 pagesThe Evolution of Management TheoryjaffnaNo ratings yet

- Motivating EmployeesDocument21 pagesMotivating EmployeesjaffnaNo ratings yet

- Lecture 8 BearingsDocument53 pagesLecture 8 BearingsReemALMousawiNo ratings yet

- Managing Groups & TeamsDocument23 pagesManaging Groups & TeamsjaffnaNo ratings yet

- Organizational StructureDocument26 pagesOrganizational Structurejaffna100% (2)

- Pipeline DesignDocument12 pagesPipeline Designjaffna0% (1)

- Partially Full Pipe Flow CalculationsDocument17 pagesPartially Full Pipe Flow Calculationsjaffna0% (1)

- Section 05090 Metal FasteningDocument6 pagesSection 05090 Metal FasteningMØhãmmed ØwięsNo ratings yet

- Types of Foundation 1Document14 pagesTypes of Foundation 1Olawale AdebesinNo ratings yet

- The JSW Challenge 2021 Case Study: Case Study: Replacement of Asbestos Sheets With Colour Coated SheetsDocument2 pagesThe JSW Challenge 2021 Case Study: Case Study: Replacement of Asbestos Sheets With Colour Coated SheetsKrishna PrasadNo ratings yet

- S121 - LEVEL 2 - SOUTH TOWER - GENERAL ARRANGEMENT PLAN Rev.C4 MarkupDocument1 pageS121 - LEVEL 2 - SOUTH TOWER - GENERAL ARRANGEMENT PLAN Rev.C4 Markupxây dựng 123No ratings yet

- CBRIDocument15 pagesCBRIsonakshiNo ratings yet

- A Preliminary Report of The Archaeological Survey in The Potohar Plateau (Article in Indian Book)Document67 pagesA Preliminary Report of The Archaeological Survey in The Potohar Plateau (Article in Indian Book)Rukhsar AbroNo ratings yet

- HRD C Frame Anchor TDSDocument18 pagesHRD C Frame Anchor TDSronyNo ratings yet

- Basic DesignDocument75 pagesBasic DesignPhan AnhhNo ratings yet

- Method Statement For LEETSTEEL STIFFENER SYSTEM AAC 150mm & 200mmDocument2 pagesMethod Statement For LEETSTEEL STIFFENER SYSTEM AAC 150mm & 200mmpiakhong.cheongNo ratings yet

- Assa Abloy DS6060P Curtain Dock Shelter ParallelDocument2 pagesAssa Abloy DS6060P Curtain Dock Shelter ParallelmujahaddadNo ratings yet

- EGD ResurchDocument3 pagesEGD Resurchpreanca.govenderNo ratings yet

- Island Style Roof Fire Test ReportDocument29 pagesIsland Style Roof Fire Test ReportResearch DevelopmentNo ratings yet

- Timber and Timber ProductsDocument13 pagesTimber and Timber ProductsCollins Obari AdiyeNo ratings yet

- New 03 NBCC GREEN VIEWDocument3 pagesNew 03 NBCC GREEN VIEWsushil kumarNo ratings yet

- Working Drawing ReferenceDocument1 pageWorking Drawing ReferenceDexter LarawanNo ratings yet

- SolidWoodWeb Docs Report SST enDocument4 pagesSolidWoodWeb Docs Report SST ensantiago vallejoNo ratings yet

- Module 1 Introduction To Prestressed Concrete DesignDocument57 pagesModule 1 Introduction To Prestressed Concrete DesignVann AlfredNo ratings yet

- WSP Usor 2018Document36 pagesWSP Usor 2018Sonu VishwakarmaNo ratings yet

- CBLM Tile Setting IIDocument118 pagesCBLM Tile Setting IIrandy pumihicNo ratings yet

- MEP-P-ES-002-Standard Design Requirements For Piping SystemsDocument19 pagesMEP-P-ES-002-Standard Design Requirements For Piping SystemsElias EliasNo ratings yet

- Quotation # 01 - Revision # 03 (Real Ice Cream)Document15 pagesQuotation # 01 - Revision # 03 (Real Ice Cream)Umar AwaisNo ratings yet

- Estimate For Water Tank ConstructionDocument1 pageEstimate For Water Tank ConstructionAbhinav KumarNo ratings yet

- Sample Test On Philippine ArchitectureDocument10 pagesSample Test On Philippine ArchitecturesNo ratings yet

- Flood Zone BambooDocument20 pagesFlood Zone Bamboomansi sharmaNo ratings yet

- 12x8 Chicken Coop Plan FreeDocument21 pages12x8 Chicken Coop Plan Freegrawis18No ratings yet

- Field Quality Plan (FQP) : Appendix 1EDocument13 pagesField Quality Plan (FQP) : Appendix 1EGaurav PandeyNo ratings yet

- Chapter 1 BcoDocument15 pagesChapter 1 Bcoraman laychaNo ratings yet

- Sheat Metal ScrewsDocument39 pagesSheat Metal Screwsshaken56No ratings yet

- Methods of Enhancing and Decorating Finished Products: TLE 6 - Quarter 3Document24 pagesMethods of Enhancing and Decorating Finished Products: TLE 6 - Quarter 3Bethuel Pacasit AlquirozNo ratings yet