Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

54 viewsEdat Steel Works Div.

Edat Steel Works Div.

Uploaded by

Syed IrfanuddinEDAT Industrial Solutions provides engineering, procurement, fabrication, painting, and erection services for structural steel works in industrial plants. It has expertise in designing, fabricating, and erecting steel structures for thermal power plants up to 500 MW. The company procures steel materials, fabricates structures in its workshop according to standards and client specifications, paints the pieces, and then transports and erects them on site. It has the necessary equipment, manpower, and safety policies to handle structural steel projects.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Scienceclinic Smartprep Gr12 Dbe Eng v3.0Document69 pagesScienceclinic Smartprep Gr12 Dbe Eng v3.0Ridwaan SalieNo ratings yet

- Rigging & Lifting Operations - 150305 (EB)Document30 pagesRigging & Lifting Operations - 150305 (EB)S RNo ratings yet

- Horse Pony GuideDocument12 pagesHorse Pony Guidebeowolf12No ratings yet

- Inventory PolicyDocument10 pagesInventory Policydeepak aNo ratings yet

- Program 3pDocument12 pagesProgram 3pInternal AuditNo ratings yet

- Managing Safely v5 Course SyllabusDocument5 pagesManaging Safely v5 Course SyllabusYuri Dias SobrinhoNo ratings yet

- Descon Corporate IntroductionDocument23 pagesDescon Corporate IntroductionAdnan AhmedNo ratings yet

- QP-11.0 Culture Survey-EnglishDocument2 pagesQP-11.0 Culture Survey-EnglishKamonrat PangareanNo ratings yet

- 07 LSR Pack Road Safety Seat BeltsDocument6 pages07 LSR Pack Road Safety Seat Beltspreventing becejNo ratings yet

- Protecting Your Investment With Refractory Inspection Jim AllenDocument33 pagesProtecting Your Investment With Refractory Inspection Jim AllenFränk HäyfördNo ratings yet

- Safety AttitudeDocument15 pagesSafety AttitudeJhon SihalohoNo ratings yet

- Inventory Stock Control TemplateDocument31 pagesInventory Stock Control TemplateAnonymous XQ41RokjNo ratings yet

- Drilling SpillsDocument396 pagesDrilling SpillsToxics TargetingNo ratings yet

- Improving Safety Communication SkillsDocument25 pagesImproving Safety Communication SkillsMalahayati ZamzamNo ratings yet

- Anti Bribery Trainer Profile PDFDocument8 pagesAnti Bribery Trainer Profile PDFSutharthanMariyappanNo ratings yet

- FM 03-03 Management Review Minutes of Meeting - Issue 3Document3 pagesFM 03-03 Management Review Minutes of Meeting - Issue 3MohamedNo ratings yet

- Leadership Is Driving Home Safe Till The Destination. There Is Nothing Like "Almost Reached."Document21 pagesLeadership Is Driving Home Safe Till The Destination. There Is Nothing Like "Almost Reached."hr_darshanNo ratings yet

- Vocational Training ReportDocument56 pagesVocational Training ReportSaksham jainNo ratings yet

- Working at HeightDocument33 pagesWorking at HeightWaquar AhmadNo ratings yet

- H010ARDocument22 pagesH010ARMohammed ChaabateNo ratings yet

- Form 105, Internal Quality Audit RecordDocument2 pagesForm 105, Internal Quality Audit RecordadiqualityconsultNo ratings yet

- Feasibility of Expanding The Use of Steel Slag As A Concrete Pavement AggregateDocument204 pagesFeasibility of Expanding The Use of Steel Slag As A Concrete Pavement Aggregatepma1motorsport motorsportNo ratings yet

- Dalmia Catalogue - 2014.compressedDocument44 pagesDalmia Catalogue - 2014.compressedAlok RanjanNo ratings yet

- Causes of Failure and Repairing Options PDFDocument17 pagesCauses of Failure and Repairing Options PDFSubhash AhujaNo ratings yet

- Quality Management System: Understanding Our QMS For The Achievement of Organization and Business SuccessDocument56 pagesQuality Management System: Understanding Our QMS For The Achievement of Organization and Business SuccessNoor AhmedNo ratings yet

- Aic Steels Saudi ArabiaDocument1 pageAic Steels Saudi ArabiaTradiyo ForexNo ratings yet

- Presented by Mohammed Fajis Mahesh M Narmatha Devi V.PDocument20 pagesPresented by Mohammed Fajis Mahesh M Narmatha Devi V.Pmahy_1986No ratings yet

- Sty MatDocument7 pagesSty Matsonalisabir100% (1)

- Prepared By:-Sumant Sahu Metallurgy 3203808302Document21 pagesPrepared By:-Sumant Sahu Metallurgy 3203808302Rahul PandeyNo ratings yet

- DissertationDocument179 pagesDissertationLionel YdeNo ratings yet

- Case Materials Tanzania 09 07Document19 pagesCase Materials Tanzania 09 07Ali YudiNo ratings yet

- Lean KaizenDocument55 pagesLean KaizenNadeem NaseemNo ratings yet

- M.rigaud Aluminaandmagnesia BasedcastablescontaininggraphiteDocument15 pagesM.rigaud Aluminaandmagnesia BasedcastablescontaininggraphiteBagas Prasetyawan Adi NugrohoNo ratings yet

- Study On Supply Chain Management at Visakhapatnam Steelplant (Rinl), VizagDocument76 pagesStudy On Supply Chain Management at Visakhapatnam Steelplant (Rinl), VizagSahil GouthamNo ratings yet

- Management Practices: Institute of Information Technology, Lahore Institute of Information Technology, LahoreDocument46 pagesManagement Practices: Institute of Information Technology, Lahore Institute of Information Technology, LahoreNaveed AkbarNo ratings yet

- Scaffolding ChecklistDocument2 pagesScaffolding ChecklistPrajnay ShettyNo ratings yet

- A Comprehensive Review of Recent Advances in Magnesia Carbon RefractoryDocument9 pagesA Comprehensive Review of Recent Advances in Magnesia Carbon RefractorySoumya MukherjeeNo ratings yet

- SHP Safety Walk Arounds For ManagersDocument2 pagesSHP Safety Walk Arounds For ManagersIoana UrsanNo ratings yet

- Technology Paper Report CSI 31-03-09Document98 pagesTechnology Paper Report CSI 31-03-09jmpbarrosNo ratings yet

- Jimma Institute of Technology: Product Design: Introduction Lecture-IDocument35 pagesJimma Institute of Technology: Product Design: Introduction Lecture-IfayzaNo ratings yet

- Project (Final) NEW - OriginalDocument26 pagesProject (Final) NEW - OriginalNagesh BhadoleNo ratings yet

- Thermal Conductivity of Refractory MaterialsDocument108 pagesThermal Conductivity of Refractory MaterialsKhaled BOUALINo ratings yet

- Heavy Equitment Monitoring May 2019Document4 pagesHeavy Equitment Monitoring May 2019Febry TribrataNo ratings yet

- RSP ReportDocument26 pagesRSP ReportSwastik MohapatraNo ratings yet

- Kaizen 01Document15 pagesKaizen 01jesusmemNo ratings yet

- As 1774.1-2000 Refractories and Refractory Materials - Physical Test Methods Determination of Cold CompressivDocument2 pagesAs 1774.1-2000 Refractories and Refractory Materials - Physical Test Methods Determination of Cold CompressivSAI Global - APACNo ratings yet

- Responsibilities - ForemanDocument1 pageResponsibilities - ForemanjaffrinNo ratings yet

- Chapter 5 Structural Imperfections 1Document52 pagesChapter 5 Structural Imperfections 1耀慶No ratings yet

- RefractoriesDocument24 pagesRefractoriesArnulfo PerezNo ratings yet

- Competency & Training Masterlist 2017. Rev2Document65 pagesCompetency & Training Masterlist 2017. Rev2Azmi FauziNo ratings yet

- HM Furnaces en Ver1Document4 pagesHM Furnaces en Ver1Mohamed Diaa MortadaNo ratings yet

- Traditional Versus Advanced Ceramics: Sanitary Ware, Tiles, EtcDocument26 pagesTraditional Versus Advanced Ceramics: Sanitary Ware, Tiles, EtcfayzaNo ratings yet

- Bessemer FurnaceDocument4 pagesBessemer FurnaceHariman El EmirNo ratings yet

- Uis ReportDocument41 pagesUis ReportVikas SandhuNo ratings yet

- Fdocuments - in Presentation Steel MakingDocument26 pagesFdocuments - in Presentation Steel MakingShimaa ElhadadNo ratings yet

- Chapter 1Document12 pagesChapter 1Oscar Espinosa BonillaNo ratings yet

- An Overview of Iso: Envirotech Quality Management 1Document30 pagesAn Overview of Iso: Envirotech Quality Management 1bubun007No ratings yet

- 663 Chemical TechnologyDocument28 pages663 Chemical TechnologyAnonymous okVyZFmqqXNo ratings yet

- SOP For Unloading, Storage, Handling and Use of Compressed Gas CylindersDocument3 pagesSOP For Unloading, Storage, Handling and Use of Compressed Gas CylindersSolomonNo ratings yet

- Carpentry Forming Framing or Wood WorkingDocument1 pageCarpentry Forming Framing or Wood WorkingPrakash PavuralaNo ratings yet

- MS008 Steel Tank MSDocument9 pagesMS008 Steel Tank MSMhando IgnasNo ratings yet

- 3D Piping Model Reviews ProcedureDocument7 pages3D Piping Model Reviews ProcedureSyed IrfanuddinNo ratings yet

- Schedule of Fees As Per Societies Registration Act (G.O.Ms - No. 475 Revenue (Regn-II) Dept, DT 25.7.12Document1 pageSchedule of Fees As Per Societies Registration Act (G.O.Ms - No. 475 Revenue (Regn-II) Dept, DT 25.7.12Syed IrfanuddinNo ratings yet

- Structural SteelDocument4 pagesStructural SteelSyed IrfanuddinNo ratings yet

- RT340Document2 pagesRT340Syed IrfanuddinNo ratings yet

- Hyderabad:: - Self Employment Programme - Name of The DistrictDocument4 pagesHyderabad:: - Self Employment Programme - Name of The DistrictSyed IrfanuddinNo ratings yet

- Trenchless Portions in Contract Packages # 6 & 7Document2 pagesTrenchless Portions in Contract Packages # 6 & 7Syed IrfanuddinNo ratings yet

- 5.piping Dynamic Stress AnalysisDocument3 pages5.piping Dynamic Stress AnalysisSyed IrfanuddinNo ratings yet

- Frequently Asked Questions-Trust DeedsDocument1 pageFrequently Asked Questions-Trust DeedsSyed IrfanuddinNo ratings yet

- Process Piping Design & Engineering Per ASME B 31.3Document16 pagesProcess Piping Design & Engineering Per ASME B 31.3naveenbaskaran1989No ratings yet

- AP Executive SummaryDocument6 pagesAP Executive SummarySyed IrfanuddinNo ratings yet

- Pre-Qualifying Requirements 10Document2 pagesPre-Qualifying Requirements 10Syed IrfanuddinNo ratings yet

- Rapport Egypte enDocument50 pagesRapport Egypte enSyed IrfanuddinNo ratings yet

- Business Opportunity Profile: Metal Fabrication WorkshopDocument16 pagesBusiness Opportunity Profile: Metal Fabrication WorkshopSyed IrfanuddinNo ratings yet

- Improved Hybrid Switched Inductor Switched Capacitor DC-DC ConvertersDocument10 pagesImproved Hybrid Switched Inductor Switched Capacitor DC-DC ConvertersMasoom AhmedNo ratings yet

- Two-Stage Gas Turbine: C K C KDocument3 pagesTwo-Stage Gas Turbine: C K C KgowthamAG07No ratings yet

- Training Couses CatalogueDocument99 pagesTraining Couses CatalogueZ Babar KhanNo ratings yet

- Unit 3 Grade 9 Sept 09Document28 pagesUnit 3 Grade 9 Sept 09girmaamanNo ratings yet

- March 17, 2016 Strathmore TimesDocument24 pagesMarch 17, 2016 Strathmore TimesStrathmore TimesNo ratings yet

- THE AWAKENING - Quantum Mechanics of The Human Brain and ConsciousnessDocument38 pagesTHE AWAKENING - Quantum Mechanics of The Human Brain and ConsciousnessMokhtar MohdNo ratings yet

- Astm D4462-90Document2 pagesAstm D4462-90Priyadarshini KrishnaswamyNo ratings yet

- Manual PSAT PDFDocument260 pagesManual PSAT PDFCan Mert KalaycıNo ratings yet

- Smockb Assignment1Document5 pagesSmockb Assignment1api-317462017No ratings yet

- Rotating Machinery Rotor BalancingDocument15 pagesRotating Machinery Rotor BalancingGunjanNo ratings yet

- Jot CompositeDocument12 pagesJot CompositeabdulsmithNo ratings yet

- Chapter No. 5 (Theory Notes)Document23 pagesChapter No. 5 (Theory Notes)Kashif MahmoodNo ratings yet

- Reliability Evaluation of Distribution Systems Arellano Lapie RelleveDocument8 pagesReliability Evaluation of Distribution Systems Arellano Lapie RelleveKevin RelleveNo ratings yet

- Rajnidhi Project WorkDocument35 pagesRajnidhi Project WorkRAJ NIDHINo ratings yet

- 01 Rotor Turning Gear SSS Rev13 en PDFDocument10 pages01 Rotor Turning Gear SSS Rev13 en PDFVinod Varadan SNo ratings yet

- Elna (Radial Thru-Hole) RLB SeriesDocument1 pageElna (Radial Thru-Hole) RLB Seriesjghjkhgkh87No ratings yet

- Ameren Service DropDocument12 pagesAmeren Service DropZoe WheeleyNo ratings yet

- A Fan For All Seasons A Fan For All Seasons: CirculationDocument84 pagesA Fan For All Seasons A Fan For All Seasons: CirculationshaikhbwcNo ratings yet

- Internal Combustion Engines: MET 101 Basic Mechanical EngineeringDocument30 pagesInternal Combustion Engines: MET 101 Basic Mechanical EngineeringAnish RulesNo ratings yet

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- CRC Airco Cleen PDFDocument2 pagesCRC Airco Cleen PDFpirata_elmejor0% (1)

- Motion and Forces Test Review With AnswersDocument3 pagesMotion and Forces Test Review With AnswersMary Love Juanico33% (3)

- Capacitance - JEE Main 2024 January Question Bank - MathonGoDocument7 pagesCapacitance - JEE Main 2024 January Question Bank - MathonGopediredla.ajithkumarNo ratings yet

- Litrature Review PresentationDocument15 pagesLitrature Review PresentationMuzafar AhmadNo ratings yet

- In - Abb - LTB 245e1 - 2012 PDFDocument231 pagesIn - Abb - LTB 245e1 - 2012 PDFkienNo ratings yet

- Nptel: Basic Electrical Technology - Video CourseDocument3 pagesNptel: Basic Electrical Technology - Video Courseavv456No ratings yet

- R & Ac 1Document38 pagesR & Ac 1ahsanNo ratings yet

- Service 3121852 04-20-07 CE EnglishDocument136 pagesService 3121852 04-20-07 CE EnglishWere WolfNo ratings yet

- Site Assesment Pump ReportDocument1 pageSite Assesment Pump ReportThebe HanyaneNo ratings yet

Edat Steel Works Div.

Edat Steel Works Div.

Uploaded by

Syed Irfanuddin0 ratings0% found this document useful (0 votes)

54 views14 pagesEDAT Industrial Solutions provides engineering, procurement, fabrication, painting, and erection services for structural steel works in industrial plants. It has expertise in designing, fabricating, and erecting steel structures for thermal power plants up to 500 MW. The company procures steel materials, fabricates structures in its workshop according to standards and client specifications, paints the pieces, and then transports and erects them on site. It has the necessary equipment, manpower, and safety policies to handle structural steel projects.

Original Description:

Steel Structure works

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEDAT Industrial Solutions provides engineering, procurement, fabrication, painting, and erection services for structural steel works in industrial plants. It has expertise in designing, fabricating, and erecting steel structures for thermal power plants up to 500 MW. The company procures steel materials, fabricates structures in its workshop according to standards and client specifications, paints the pieces, and then transports and erects them on site. It has the necessary equipment, manpower, and safety policies to handle structural steel projects.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

0 ratings0% found this document useful (0 votes)

54 views14 pagesEdat Steel Works Div.

Edat Steel Works Div.

Uploaded by

Syed IrfanuddinEDAT Industrial Solutions provides engineering, procurement, fabrication, painting, and erection services for structural steel works in industrial plants. It has expertise in designing, fabricating, and erecting steel structures for thermal power plants up to 500 MW. The company procures steel materials, fabricates structures in its workshop according to standards and client specifications, paints the pieces, and then transports and erects them on site. It has the necessary equipment, manpower, and safety policies to handle structural steel projects.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 14

Structural Steel works Div.

EDAT INDUSTRIAL SOLUTIONS

EPC CONTRACTOR

DESIGN, ENGINEERING & PROCUREMENT

FABRICATION, PAINTING &

ERECTION

GENERAL INFORMATION

EDAT has as engineering execution and technical

expertise in the fabrication & erection of all kinds of

Steel structures.

EDAT undertakes the erection of piping, and structural

work in main plant building, bunker bay and

miscellaneous structures.

EDAT has steel fabrication capacity and specializes in

building steel structures for thermal power plants. The

company takes up civil works for power plants of up to

500 MW. EDAT undertakes manufacture, supply, and

commissioning of super-heater Eco, reheater coils

and equipment for thermal power stations.

DESIGN & ENGINEERING

Recognizing the customer requirement

for a one stop solution, we offer the

complete Design and Build package for

steelwork. Our design capability draws

on the expertise of structural

steel Engineers who each have 8 years

of experience in the trade. Couple that

with the 10 years service of our

Construction team.

DESIGN & ENGINEERING

EDAT can meet, and often exceed, our clients

requirements, utilizing the wealth of

experience available from key personnel. We

offer a complete service, from Design,

Fabrication, through to Installation within the

Structural Steel Industry. In addition to the

structural steel service EDAT. have the in-

house ability to undertake cladding design,

supply and installation packages as required.

PROCUREMENT

Procurement of steel material as per

the specification and standards

mentioned.

Procurement from certified suppliers.

Obtain the complete test certificates

& Mill certificates with the certificate

of origin.

The material supplied must be in

accordance to IS 8910.

FABRICATION & PAINTING

As the material is inspected and

approved by the Quality Control

Dept. and the fabrication drawings

are approved by the client, the

fabrication team start its process.

Complete fabrication is done in

accordance with the relevant

standards, the project specifications

and approved drawings.

Periodically the QC will be checking

the fabrication works

After the completion of the fabrication

works, the member is sent for

cleaning and blasting (if required).

After the member is cleaned and free

from all the debris and corrosion, all the

welding points are inspected by the QC.

Then the member is sent for painting as

per the required specification and client

requirement.

Special type of paints and painting

procedure is followed for Offshore

structure, Oil & Gas plants, Power

Plants etc

As per the requirement the steel is also

fire proofed by painting Intumesent

Paints and cementitious coatings.

FABRICATION & PAINTING

ERECTION

1. After the complete fabrication

is done in the workshop, after

the cleaning and painting is

done the members are then

transported to site on trailers.

2. On arrival of the complete

members on site the erection

team and the site QC inspector

check the material on the basis

of the project specification and

the approved drawings for

construction.

3. Then daily erection activity is

planed and the erection of the

structure begins with the help of

cranes.

4. Erection of a structure is done by

qualified erectors and helpers.

5. The site engineer and the

supervisor ensures all the material

and all the required tools, safety

tools are on site for the erection.

6. A site safety officer and a QC is

always present on site for regular

inspections and audits.

ERECTION

ORGANIZATION CHART

BOD

GM DESIGN &

DEVELOPME

NT

DESIGN

ENGINEERS

CAD

OPERATORS/

DRAFTMAN

GM

PROJECTS &

PRODUCTION

PROJECT

MANAGER

PROJECT

ENGINEER

PRODUCTION

ENGINEER

WORKSHOP

SUPERVISOR

FABRICATORS

WELDERS TACK WELDERS HELPERS

SITE ENGINEER

SITE

SUPERVISOR

SITE FOREMAN

ERRECTORS

SEMI SKILLED

HELPERS

LIST OF EQUIPMENT

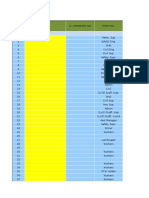

N0.T LIST OF MACHINES/EQUIPMENT N0.T LIST OF MACHINES/EQUIPMENT

1 BAND SAWING MACHINE KBS 1301 DG 15 AIR DRYER

2 HYDRAULIC BENDING MACHINE 6mm THICK 16 DRILL AND END MILL GRINDING MACHINE

3 HYDRAULIC SHEARING MACHINE FOR 16mm THICK 17 UNIVERSAL IRON WORKER

4 SIX WHEEL AUTOMATIC SHOT BLASTING MACHINE 18 RADIAL DRILL

5 INFEED AND OUT FEED CONVEYORS FOR 18mm EACH 19 CUT OFF MACHINE

6 9000 CFM DUST COLLECTOR FOR BLASTING MACHINE 20 PIPE BENDER WITH DIE

7 AIRLESS SPRAY PAINTING SYSTEM 21 FORK LIFT 5 TONNER

8 WELDING MACHINE 600 Amp FCAW 22 PORTABLE AUTOMATIC GAS CUTTING MACHINE

9 WELDING MACHINE SMAW 23 PLASMA CUTTING MACHINE

10 WELDING MACHINE 400 Amp FCAW 24 FORKLIFT 3 TONS

11 OVERHEAD CRANE 10 MT CAPACITY

12 SEMI GANTRY CRANE 10 MT CAPACITY

13 AIR COMPRESSOR 7.5 HP

14 AIR STORAGE TANK

LIST OF MANPOWER

Sr.n. LIST OF MAPOWER Nos.

1 General Manager Design & Development 1

2 General Manager Projects & Production 1

3 Projects Managers 2

4 Project Engineers 2

5 Design Engineers 2

6 Site Engineers 4

7 CAD Operators/ Draftman 4

8 Site Supervisors 4

9 Site Foremans 4

10 Production Engineer 1

11 Workshop Supervisors 2

12 Fabricators 6

13 Welders 6

14 Tack Welders 2

15 Errectors 15

16 Helpers 25

HSE

All the staff and workers have to comply

with the safety rules and regulations of the

company.

No person is allowed on site without the

PPE (Personal Protective Equipments)

The PPE general requirement is as

follows,

Safety shoes (i.e., with steel toe)

Safety helmet,

Hand gloves (normal)

Leather hand gloves for the erection team

and welders.

Safety Glasses.

Dust mask.

Work safe - live safe.

Safety Policy:

You might also like

- Scienceclinic Smartprep Gr12 Dbe Eng v3.0Document69 pagesScienceclinic Smartprep Gr12 Dbe Eng v3.0Ridwaan SalieNo ratings yet

- Rigging & Lifting Operations - 150305 (EB)Document30 pagesRigging & Lifting Operations - 150305 (EB)S RNo ratings yet

- Horse Pony GuideDocument12 pagesHorse Pony Guidebeowolf12No ratings yet

- Inventory PolicyDocument10 pagesInventory Policydeepak aNo ratings yet

- Program 3pDocument12 pagesProgram 3pInternal AuditNo ratings yet

- Managing Safely v5 Course SyllabusDocument5 pagesManaging Safely v5 Course SyllabusYuri Dias SobrinhoNo ratings yet

- Descon Corporate IntroductionDocument23 pagesDescon Corporate IntroductionAdnan AhmedNo ratings yet

- QP-11.0 Culture Survey-EnglishDocument2 pagesQP-11.0 Culture Survey-EnglishKamonrat PangareanNo ratings yet

- 07 LSR Pack Road Safety Seat BeltsDocument6 pages07 LSR Pack Road Safety Seat Beltspreventing becejNo ratings yet

- Protecting Your Investment With Refractory Inspection Jim AllenDocument33 pagesProtecting Your Investment With Refractory Inspection Jim AllenFränk HäyfördNo ratings yet

- Safety AttitudeDocument15 pagesSafety AttitudeJhon SihalohoNo ratings yet

- Inventory Stock Control TemplateDocument31 pagesInventory Stock Control TemplateAnonymous XQ41RokjNo ratings yet

- Drilling SpillsDocument396 pagesDrilling SpillsToxics TargetingNo ratings yet

- Improving Safety Communication SkillsDocument25 pagesImproving Safety Communication SkillsMalahayati ZamzamNo ratings yet

- Anti Bribery Trainer Profile PDFDocument8 pagesAnti Bribery Trainer Profile PDFSutharthanMariyappanNo ratings yet

- FM 03-03 Management Review Minutes of Meeting - Issue 3Document3 pagesFM 03-03 Management Review Minutes of Meeting - Issue 3MohamedNo ratings yet

- Leadership Is Driving Home Safe Till The Destination. There Is Nothing Like "Almost Reached."Document21 pagesLeadership Is Driving Home Safe Till The Destination. There Is Nothing Like "Almost Reached."hr_darshanNo ratings yet

- Vocational Training ReportDocument56 pagesVocational Training ReportSaksham jainNo ratings yet

- Working at HeightDocument33 pagesWorking at HeightWaquar AhmadNo ratings yet

- H010ARDocument22 pagesH010ARMohammed ChaabateNo ratings yet

- Form 105, Internal Quality Audit RecordDocument2 pagesForm 105, Internal Quality Audit RecordadiqualityconsultNo ratings yet

- Feasibility of Expanding The Use of Steel Slag As A Concrete Pavement AggregateDocument204 pagesFeasibility of Expanding The Use of Steel Slag As A Concrete Pavement Aggregatepma1motorsport motorsportNo ratings yet

- Dalmia Catalogue - 2014.compressedDocument44 pagesDalmia Catalogue - 2014.compressedAlok RanjanNo ratings yet

- Causes of Failure and Repairing Options PDFDocument17 pagesCauses of Failure and Repairing Options PDFSubhash AhujaNo ratings yet

- Quality Management System: Understanding Our QMS For The Achievement of Organization and Business SuccessDocument56 pagesQuality Management System: Understanding Our QMS For The Achievement of Organization and Business SuccessNoor AhmedNo ratings yet

- Aic Steels Saudi ArabiaDocument1 pageAic Steels Saudi ArabiaTradiyo ForexNo ratings yet

- Presented by Mohammed Fajis Mahesh M Narmatha Devi V.PDocument20 pagesPresented by Mohammed Fajis Mahesh M Narmatha Devi V.Pmahy_1986No ratings yet

- Sty MatDocument7 pagesSty Matsonalisabir100% (1)

- Prepared By:-Sumant Sahu Metallurgy 3203808302Document21 pagesPrepared By:-Sumant Sahu Metallurgy 3203808302Rahul PandeyNo ratings yet

- DissertationDocument179 pagesDissertationLionel YdeNo ratings yet

- Case Materials Tanzania 09 07Document19 pagesCase Materials Tanzania 09 07Ali YudiNo ratings yet

- Lean KaizenDocument55 pagesLean KaizenNadeem NaseemNo ratings yet

- M.rigaud Aluminaandmagnesia BasedcastablescontaininggraphiteDocument15 pagesM.rigaud Aluminaandmagnesia BasedcastablescontaininggraphiteBagas Prasetyawan Adi NugrohoNo ratings yet

- Study On Supply Chain Management at Visakhapatnam Steelplant (Rinl), VizagDocument76 pagesStudy On Supply Chain Management at Visakhapatnam Steelplant (Rinl), VizagSahil GouthamNo ratings yet

- Management Practices: Institute of Information Technology, Lahore Institute of Information Technology, LahoreDocument46 pagesManagement Practices: Institute of Information Technology, Lahore Institute of Information Technology, LahoreNaveed AkbarNo ratings yet

- Scaffolding ChecklistDocument2 pagesScaffolding ChecklistPrajnay ShettyNo ratings yet

- A Comprehensive Review of Recent Advances in Magnesia Carbon RefractoryDocument9 pagesA Comprehensive Review of Recent Advances in Magnesia Carbon RefractorySoumya MukherjeeNo ratings yet

- SHP Safety Walk Arounds For ManagersDocument2 pagesSHP Safety Walk Arounds For ManagersIoana UrsanNo ratings yet

- Technology Paper Report CSI 31-03-09Document98 pagesTechnology Paper Report CSI 31-03-09jmpbarrosNo ratings yet

- Jimma Institute of Technology: Product Design: Introduction Lecture-IDocument35 pagesJimma Institute of Technology: Product Design: Introduction Lecture-IfayzaNo ratings yet

- Project (Final) NEW - OriginalDocument26 pagesProject (Final) NEW - OriginalNagesh BhadoleNo ratings yet

- Thermal Conductivity of Refractory MaterialsDocument108 pagesThermal Conductivity of Refractory MaterialsKhaled BOUALINo ratings yet

- Heavy Equitment Monitoring May 2019Document4 pagesHeavy Equitment Monitoring May 2019Febry TribrataNo ratings yet

- RSP ReportDocument26 pagesRSP ReportSwastik MohapatraNo ratings yet

- Kaizen 01Document15 pagesKaizen 01jesusmemNo ratings yet

- As 1774.1-2000 Refractories and Refractory Materials - Physical Test Methods Determination of Cold CompressivDocument2 pagesAs 1774.1-2000 Refractories and Refractory Materials - Physical Test Methods Determination of Cold CompressivSAI Global - APACNo ratings yet

- Responsibilities - ForemanDocument1 pageResponsibilities - ForemanjaffrinNo ratings yet

- Chapter 5 Structural Imperfections 1Document52 pagesChapter 5 Structural Imperfections 1耀慶No ratings yet

- RefractoriesDocument24 pagesRefractoriesArnulfo PerezNo ratings yet

- Competency & Training Masterlist 2017. Rev2Document65 pagesCompetency & Training Masterlist 2017. Rev2Azmi FauziNo ratings yet

- HM Furnaces en Ver1Document4 pagesHM Furnaces en Ver1Mohamed Diaa MortadaNo ratings yet

- Traditional Versus Advanced Ceramics: Sanitary Ware, Tiles, EtcDocument26 pagesTraditional Versus Advanced Ceramics: Sanitary Ware, Tiles, EtcfayzaNo ratings yet

- Bessemer FurnaceDocument4 pagesBessemer FurnaceHariman El EmirNo ratings yet

- Uis ReportDocument41 pagesUis ReportVikas SandhuNo ratings yet

- Fdocuments - in Presentation Steel MakingDocument26 pagesFdocuments - in Presentation Steel MakingShimaa ElhadadNo ratings yet

- Chapter 1Document12 pagesChapter 1Oscar Espinosa BonillaNo ratings yet

- An Overview of Iso: Envirotech Quality Management 1Document30 pagesAn Overview of Iso: Envirotech Quality Management 1bubun007No ratings yet

- 663 Chemical TechnologyDocument28 pages663 Chemical TechnologyAnonymous okVyZFmqqXNo ratings yet

- SOP For Unloading, Storage, Handling and Use of Compressed Gas CylindersDocument3 pagesSOP For Unloading, Storage, Handling and Use of Compressed Gas CylindersSolomonNo ratings yet

- Carpentry Forming Framing or Wood WorkingDocument1 pageCarpentry Forming Framing or Wood WorkingPrakash PavuralaNo ratings yet

- MS008 Steel Tank MSDocument9 pagesMS008 Steel Tank MSMhando IgnasNo ratings yet

- 3D Piping Model Reviews ProcedureDocument7 pages3D Piping Model Reviews ProcedureSyed IrfanuddinNo ratings yet

- Schedule of Fees As Per Societies Registration Act (G.O.Ms - No. 475 Revenue (Regn-II) Dept, DT 25.7.12Document1 pageSchedule of Fees As Per Societies Registration Act (G.O.Ms - No. 475 Revenue (Regn-II) Dept, DT 25.7.12Syed IrfanuddinNo ratings yet

- Structural SteelDocument4 pagesStructural SteelSyed IrfanuddinNo ratings yet

- RT340Document2 pagesRT340Syed IrfanuddinNo ratings yet

- Hyderabad:: - Self Employment Programme - Name of The DistrictDocument4 pagesHyderabad:: - Self Employment Programme - Name of The DistrictSyed IrfanuddinNo ratings yet

- Trenchless Portions in Contract Packages # 6 & 7Document2 pagesTrenchless Portions in Contract Packages # 6 & 7Syed IrfanuddinNo ratings yet

- 5.piping Dynamic Stress AnalysisDocument3 pages5.piping Dynamic Stress AnalysisSyed IrfanuddinNo ratings yet

- Frequently Asked Questions-Trust DeedsDocument1 pageFrequently Asked Questions-Trust DeedsSyed IrfanuddinNo ratings yet

- Process Piping Design & Engineering Per ASME B 31.3Document16 pagesProcess Piping Design & Engineering Per ASME B 31.3naveenbaskaran1989No ratings yet

- AP Executive SummaryDocument6 pagesAP Executive SummarySyed IrfanuddinNo ratings yet

- Pre-Qualifying Requirements 10Document2 pagesPre-Qualifying Requirements 10Syed IrfanuddinNo ratings yet

- Rapport Egypte enDocument50 pagesRapport Egypte enSyed IrfanuddinNo ratings yet

- Business Opportunity Profile: Metal Fabrication WorkshopDocument16 pagesBusiness Opportunity Profile: Metal Fabrication WorkshopSyed IrfanuddinNo ratings yet

- Improved Hybrid Switched Inductor Switched Capacitor DC-DC ConvertersDocument10 pagesImproved Hybrid Switched Inductor Switched Capacitor DC-DC ConvertersMasoom AhmedNo ratings yet

- Two-Stage Gas Turbine: C K C KDocument3 pagesTwo-Stage Gas Turbine: C K C KgowthamAG07No ratings yet

- Training Couses CatalogueDocument99 pagesTraining Couses CatalogueZ Babar KhanNo ratings yet

- Unit 3 Grade 9 Sept 09Document28 pagesUnit 3 Grade 9 Sept 09girmaamanNo ratings yet

- March 17, 2016 Strathmore TimesDocument24 pagesMarch 17, 2016 Strathmore TimesStrathmore TimesNo ratings yet

- THE AWAKENING - Quantum Mechanics of The Human Brain and ConsciousnessDocument38 pagesTHE AWAKENING - Quantum Mechanics of The Human Brain and ConsciousnessMokhtar MohdNo ratings yet

- Astm D4462-90Document2 pagesAstm D4462-90Priyadarshini KrishnaswamyNo ratings yet

- Manual PSAT PDFDocument260 pagesManual PSAT PDFCan Mert KalaycıNo ratings yet

- Smockb Assignment1Document5 pagesSmockb Assignment1api-317462017No ratings yet

- Rotating Machinery Rotor BalancingDocument15 pagesRotating Machinery Rotor BalancingGunjanNo ratings yet

- Jot CompositeDocument12 pagesJot CompositeabdulsmithNo ratings yet

- Chapter No. 5 (Theory Notes)Document23 pagesChapter No. 5 (Theory Notes)Kashif MahmoodNo ratings yet

- Reliability Evaluation of Distribution Systems Arellano Lapie RelleveDocument8 pagesReliability Evaluation of Distribution Systems Arellano Lapie RelleveKevin RelleveNo ratings yet

- Rajnidhi Project WorkDocument35 pagesRajnidhi Project WorkRAJ NIDHINo ratings yet

- 01 Rotor Turning Gear SSS Rev13 en PDFDocument10 pages01 Rotor Turning Gear SSS Rev13 en PDFVinod Varadan SNo ratings yet

- Elna (Radial Thru-Hole) RLB SeriesDocument1 pageElna (Radial Thru-Hole) RLB Seriesjghjkhgkh87No ratings yet

- Ameren Service DropDocument12 pagesAmeren Service DropZoe WheeleyNo ratings yet

- A Fan For All Seasons A Fan For All Seasons: CirculationDocument84 pagesA Fan For All Seasons A Fan For All Seasons: CirculationshaikhbwcNo ratings yet

- Internal Combustion Engines: MET 101 Basic Mechanical EngineeringDocument30 pagesInternal Combustion Engines: MET 101 Basic Mechanical EngineeringAnish RulesNo ratings yet

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- CRC Airco Cleen PDFDocument2 pagesCRC Airco Cleen PDFpirata_elmejor0% (1)

- Motion and Forces Test Review With AnswersDocument3 pagesMotion and Forces Test Review With AnswersMary Love Juanico33% (3)

- Capacitance - JEE Main 2024 January Question Bank - MathonGoDocument7 pagesCapacitance - JEE Main 2024 January Question Bank - MathonGopediredla.ajithkumarNo ratings yet

- Litrature Review PresentationDocument15 pagesLitrature Review PresentationMuzafar AhmadNo ratings yet

- In - Abb - LTB 245e1 - 2012 PDFDocument231 pagesIn - Abb - LTB 245e1 - 2012 PDFkienNo ratings yet

- Nptel: Basic Electrical Technology - Video CourseDocument3 pagesNptel: Basic Electrical Technology - Video Courseavv456No ratings yet

- R & Ac 1Document38 pagesR & Ac 1ahsanNo ratings yet

- Service 3121852 04-20-07 CE EnglishDocument136 pagesService 3121852 04-20-07 CE EnglishWere WolfNo ratings yet

- Site Assesment Pump ReportDocument1 pageSite Assesment Pump ReportThebe HanyaneNo ratings yet