Professional Documents

Culture Documents

FDC Net SPC 2014 Ssj.1

FDC Net SPC 2014 Ssj.1

Uploaded by

ArifihsanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FDC Net SPC 2014 Ssj.1

FDC Net SPC 2014 Ssj.1

Uploaded by

ArifihsanCopyright:

Available Formats

Production Data

Management

May 2014

PT. SCADA PRIMA CIPTA

System Integrator and Software Business Development

Jl. Kembar 1 No. 12 Bandung 40253

Telp : + 62 22 522 3648 Webmail : www.scada.co.id

Fax : + 62 22 520 6258 Support : support@scada.co.id

an integrated information system which generates production information

assembly, storage, transmission, statistics, analysis, and delivery

The on-site

production

state can be

viewed directly

by graphical

interface, and

it provides

powerful

decision

analysis for all

level

managers

plays an important

role in convenient

production

planning creation,

operation plan

adjustment and

optimization based

on practical

production,

transmission of

product instruction

and supervision of

planning

execution.

What is PDMS?

SYSTEM FUNCTION

Production planning management:

it is convenient and quick to establish various production

plans, and it automatically adjusts all plans according to

production instructions;

Real-time production data collection:

it automatically collects various real-time production data

and provides bottom data foundation for the whole system;

SYSTEM FUNCTION

Integrated information management of production process:

it implements data recording, arrangement, statistics, and

analysis timely and correctly. It provides the functions of input,

modification, and deletion of the data which cannot be

collected; and the system also provides various query functions

for statistical data analysis, report data, and production

technological processes for managing personal.

Production scheduling management:

the operator issues scheduling instruction information

according to the information via monitoring, requesting and

planning to establish a scheduling record, production

scheduling statistic report, and production scheduling account.

PDM Software Description

FDC .NET (Field Data Capture .NET)

Production data management and reporting system

mainly in oil and gas industry

Handles Automatic and Manual Data Entry

Integration of multiple data source: Automation and

Business Level Applications

Integrated reporting system

Virtual Metering

Customizable

PDM Software Characteristic

Production information is real-time, correct, comprehensive and

continuous;

It provides automatic production data collection, organization, and

statistics, and achieves real system data integration and system

integration.

It doesn't cost much, and it's convenient to operate and maintain.

It achieves production data sharing, transmission and issuance

which are required for enterprises;

The friendly user interface is simple and convenient to operate;

System maintenance is simple;

System expansibility provides an interface and a comprehensive

system that is reserved for continuous development.

Technologies

Microsoft .NET Framework

SOA (Services Oriented Architecture)

Smart client using Web Services

Automatic Email System

Oracle RDBMS

Crystal Reports

Automatic Data Interfacing:

Wonderware InSQL

Honeywell PHD

OSISoft PI

Yokogawa Exaquantum

OPC

Excel Spreadsheet

Text file

Features

Web Reporting

Customizable

Store and Forward

Data Validation

Range, Rate of change, rules

Interfacing with Historian Database, OPC, Excel

spreadsheet

INTEGRATE DATA FROM OLD TO LATEST TECHNOLOGY

Old Technology

New Technology Latest Technology

INTEGRATE DATA FROM VARIOUS TECHNOLOGY

INTEGRATE DATA FROM ANY EXISTING SYSTEM

Field Instrument Display PLC/RTU Software Application Database Automation

INTEGRATE DATA FROM VARIOUS DATA SOURCES

Allen-Bradley

Advantech

Adam

ABB

Modbus

DNP

Siemens

GE General Electric

Honeywell

Mitsubishi

Fisher

Triconect

BAC Net

Sixnet

LonWork

OPC / DDE

ODBC / OLE-DB

Etc

Omron

Toshiba

ScadaPack

Automation Direct

Analog Device

Yokogawa

Yaskawa

Cutler-Hammer

Fuji

INTEGRATE DATA FROM VARIOUS PRINCIPLE

OFFLINE CAPABILITY

DATA VALIDATION

Application flag and notification

Range: Minimum and Maximum value

Rate of Change: Value difference between time period

Rule: User formula

Reports:

User Validation: User/Management Approval

Experiences

Integrated Interfacing System

Integrated Interfacing System

Allocation/Material Balance/Mass Balance

Oil, Water, Gas, Condensate

LPG

Component e.g. Urea crystals, Urea, Biuret, CO2, NH3,

H2O, N2, H2, CH4, O2, Formaldehyde, etc

Neraca Bahan, Neraca Steam dan kondensat, Neraca

Cooling water

Polynomial

Custom

Function Builder

Integrated Reporting

Automation

System

Field Data Capture .NET

Historian

Database

FDC Application

- Mass Balance

- Calculation

- Modules

FDC

Internal Report:

- daily

- weekly

- monthly

- quarterly

- annually

- custom

External Report:

- daily

- weekly

- monthly

- quarterly

- annually

- custom

Integrated Reporting System

Operators

A

u

t

o

v

a

l

i

d

a

t

i

o

n

Automatic Printing

A

u

t

o

Web Reporting

Mobile FDC .NET

Software Configuration

Software Installation

Database Server

Database Installation

FDC Configuration

User Configuration

Reporting System

Web Server

Web Services Installation

Client

Client Installation

FDC.Net Prerequisite Development

Fields Configuration

Platforms/Stations Configuration

Wells Configuration

Existing Reporting system (Manual, Excel spreadsheet,

existing database, etc)

Allocation Calculation

Data Configuration e.g. Production parameters, Well

Properties, Equipments, etc

IT Infrastructures e.g. VSAT, LAN, Bandwidth, Server, IT

Policy

Software Package & Services

FDC.Net Suite

License unlimited (ever green)

Training for Administrator & User (2 days)

Engineering Services

Server Installation

Table configuration

Report development

User configuration

Technical Assistance

Custom development

Go Live in 4 months for 1 field

Products

Production Process

Amonia Production Process

Urea Production Process

PT. SCADA PRIMA CIPTA

System Integrator and Software Business Development

Jl. Kembar 1 No. 12 Bandung 40253

Telp : + 62 22 522 3648 Webmail : www.scada.co.id

Fax : + 62 22 520 6258 Support : support@scada.co.id

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shin Megami Tensei AmalaDocument21 pagesShin Megami Tensei AmalaDick DickersonNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Alan S. Kaufman, Nadeen L. Kaufman) Specific LearningDocument481 pagesAlan S. Kaufman, Nadeen L. Kaufman) Specific LearningArifihsanNo ratings yet

- PSIM TutorialDocument58 pagesPSIM TutorialArifihsanNo ratings yet

- Novas Presentation July 2013Document25 pagesNovas Presentation July 2013ArifihsanNo ratings yet

- PSIM TutorialDocument58 pagesPSIM TutorialArifihsanNo ratings yet

- Plasma Pulse TreatmentDocument13 pagesPlasma Pulse TreatmentArifihsanNo ratings yet

- Conditional Sentence (Ananda Firdaus, M. Aryo Fachrezi, Yehezkiel Imannuel XII-IPA1)Document6 pagesConditional Sentence (Ananda Firdaus, M. Aryo Fachrezi, Yehezkiel Imannuel XII-IPA1)Yehezkiel ImannuelNo ratings yet

- Thomas Hanna - Explorers of Humankind (1979)Document158 pagesThomas Hanna - Explorers of Humankind (1979)franco6araujo100% (1)

- ENGLISH 3 - Q1 - Mod2 - Writing A Short DescriptiveDocument19 pagesENGLISH 3 - Q1 - Mod2 - Writing A Short DescriptiveJinky NaguitNo ratings yet

- MCS052Document8 pagesMCS052AasNo ratings yet

- Introduction To Public International Law PDFDocument39 pagesIntroduction To Public International Law PDFsmriti royNo ratings yet

- 09 Maths Key Notes CH 02 PolynomialsDocument2 pages09 Maths Key Notes CH 02 PolynomialsAshutoshNo ratings yet

- Biodiversity ConventionDocument31 pagesBiodiversity Conventionaarzoo dadwalNo ratings yet

- MFH Edition PPT MUSIC-OF-THE-20TH-CENTURY-G10Document48 pagesMFH Edition PPT MUSIC-OF-THE-20TH-CENTURY-G10Hollman FrancisNo ratings yet

- Practice Test (D)Document5 pagesPractice Test (D)SORANo ratings yet

- (M3S3-POWERPOINT) Eva Is Inside Her CatDocument16 pages(M3S3-POWERPOINT) Eva Is Inside Her CatIGNACIO SALAS IINo ratings yet

- Think Python PDFDocument6 pagesThink Python PDF張耀文No ratings yet

- Watson Memorial Spiritual Temple of Christ v. Korban, No. 2023-CA-0293 (La. Ct. App. Dec. 13, 2023)Document17 pagesWatson Memorial Spiritual Temple of Christ v. Korban, No. 2023-CA-0293 (La. Ct. App. Dec. 13, 2023)RHTNo ratings yet

- Myths and Legends From Around The World - Banshee-Werewolf-Ghoul-ChupacabraDocument1 pageMyths and Legends From Around The World - Banshee-Werewolf-Ghoul-ChupacabraJuan Camilo Villada LoperaNo ratings yet

- History Class XDocument32 pagesHistory Class XavichalNo ratings yet

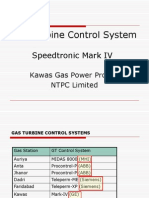

- Gas Turbine Control System1 - NemaDocument50 pagesGas Turbine Control System1 - Nemaveerclaire100% (1)

- Irc SP51 PDFDocument20 pagesIrc SP51 PDFSilambarasi Murugesan100% (1)

- Arabic Finger Ring From The Viking Age of Birka, Sweden PDFDocument7 pagesArabic Finger Ring From The Viking Age of Birka, Sweden PDFClaudia Patricia Arango100% (1)

- Practice Toolkit - Eric Silberger - Tonebase Violin WorkbookDocument15 pagesPractice Toolkit - Eric Silberger - Tonebase Violin WorkbookVít237 CzNo ratings yet

- RESEARCH Group4Document25 pagesRESEARCH Group4Kim Dela peña100% (2)

- Complete Rotational System Manual ME 8950A PDFDocument49 pagesComplete Rotational System Manual ME 8950A PDFSindi DayanaNo ratings yet

- Datuin and Zarco Ecoframe Landslides Sept2019Document49 pagesDatuin and Zarco Ecoframe Landslides Sept2019Isaiah Emmanuel SuguitanNo ratings yet

- 250+ Questions To Answer in EnglishDocument11 pages250+ Questions To Answer in EnglishOzheni A.100% (1)

- Y Varies Directly As X and Inversely As Z". Varies Directly As X and Inversely As Z"Document4 pagesY Varies Directly As X and Inversely As Z". Varies Directly As X and Inversely As Z"Rey Angelica Garcia TampusNo ratings yet

- Unsworth Basic MT, Skin Depth, TE, TMDocument8 pagesUnsworth Basic MT, Skin Depth, TE, TMFernando OktavianNo ratings yet

- Excuses PDFDocument5 pagesExcuses PDFUlisses PiassaNo ratings yet

- DG Reporting VFDocument2 pagesDG Reporting VFRamani DantuluriNo ratings yet

- Requisites of A Judicial InquiryDocument2 pagesRequisites of A Judicial InquiryMarvin Cabantac100% (1)

- Mezenin S M A History of English Life of Language PDFDocument123 pagesMezenin S M A History of English Life of Language PDFЕвгенийNo ratings yet

- Document (Answer)Document8 pagesDocument (Answer)SHELLE-MA HINDSNo ratings yet