Professional Documents

Culture Documents

Well Control Equipment1 FHFZ

Well Control Equipment1 FHFZ

Uploaded by

rery1985Copyright:

Available Formats

You might also like

- Koomey S&s ManualDocument0 pagesKoomey S&s Manualborregocr91% (11)

- Well Control Equipment PDFDocument48 pagesWell Control Equipment PDFHoan Hoan100% (8)

- Tally Book OngcDocument44 pagesTally Book OngcCamron Gomes100% (2)

- Lifting Plan OverviewDocument10 pagesLifting Plan Overviewrery1985100% (2)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Diverter SystemDocument46 pagesDiverter Systemjairaso2950100% (1)

- 12 - WellSharp Subsea Study GuideDocument2 pages12 - WellSharp Subsea Study GuideAdolfo AnguloNo ratings yet

- Well Intervention Pressure Control Syllabus - Level 2Document28 pagesWell Intervention Pressure Control Syllabus - Level 2Richard ReiersenNo ratings yet

- Equipment Questions.Document137 pagesEquipment Questions.rajgogoi85% (20)

- Bop Test 1Document1 pageBop Test 1asiraza100% (2)

- Formulas Well ControlDocument6 pagesFormulas Well ControlJosue FishNo ratings yet

- Drilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsFrom EverandDrilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsRating: 5 out of 5 stars5/5 (1)

- Oil Based Mud or Fluids (OBM)Document7 pagesOil Based Mud or Fluids (OBM)mmohsinaliawanNo ratings yet

- Deutz 226b Euro II Engine ManualDocument46 pagesDeutz 226b Euro II Engine Manualmarcosluna6871% (7)

- WEll ControlDocument60 pagesWEll Controlbennimitz100% (1)

- Surface Well Control Exercise No. 11 - Equipment - GeneralDocument27 pagesSurface Well Control Exercise No. 11 - Equipment - GeneralKaleem UllahNo ratings yet

- Well Control EquiptDocument115 pagesWell Control EquiptGhavban David100% (3)

- Preventive Maintenance Program For Ram Type Blowout PreventesDocument24 pagesPreventive Maintenance Program For Ram Type Blowout Preventesnjava1978100% (1)

- BOP Equipments Use and TestingDocument17 pagesBOP Equipments Use and TestingAjay Kumar100% (3)

- Well Control OpenDocument311 pagesWell Control OpenRobert Verret100% (1)

- Well ControlDocument40 pagesWell ControlNoumanIhsanNo ratings yet

- Preventive Maintenance Program For Spherical Blowout PreventerDocument19 pagesPreventive Maintenance Program For Spherical Blowout Preventernjava1978100% (1)

- Accumulator and BOP Control Unit5 - Aly2Document65 pagesAccumulator and BOP Control Unit5 - Aly2Khaled Yazid100% (1)

- Well ControlDocument70 pagesWell ControlAbd EnnacerNo ratings yet

- API Rp53 RecommendationsDocument2 pagesAPI Rp53 Recommendationseight minutes100% (1)

- Diverter Drilling System For Well Control Full GuideDocument19 pagesDiverter Drilling System For Well Control Full GuiderahulNo ratings yet

- Iwcf Exercise STC 1Document149 pagesIwcf Exercise STC 1ali jabbar100% (1)

- Bit HydraulicsDocument1 pageBit HydraulicsstevebeardsleyNo ratings yet

- 2016.06.20 GNZYQ Poor Boy Degasser ManualDocument14 pages2016.06.20 GNZYQ Poor Boy Degasser ManualGeorge100% (2)

- (Equip (Accumulator)Document34 pages(Equip (Accumulator)Nagendra Singh Ranawat100% (4)

- Iwcf Equipment: - Prepared by - Assistant Chief Engineer - Ahmed Qassim JaberDocument12 pagesIwcf Equipment: - Prepared by - Assistant Chief Engineer - Ahmed Qassim Jaberahmed qassimNo ratings yet

- Secondary Well Control - Well Control EquipmentDocument43 pagesSecondary Well Control - Well Control EquipmentalizareiforoushNo ratings yet

- ANNEX VIII BOP Testing, Inspection, Training and MaintenanceDocument5 pagesANNEX VIII BOP Testing, Inspection, Training and MaintenanceMohsen Shk100% (1)

- Drilling Formulas Calculation Sheet Verson 1.5Document199 pagesDrilling Formulas Calculation Sheet Verson 1.5Vidit GuptaNo ratings yet

- BOP CLOSING UNITS (Koomey)Document1 pageBOP CLOSING UNITS (Koomey)SHRINIVAS100% (2)

- Well Control BPDocument498 pagesWell Control BPcristianoclem100% (1)

- BOP Control UnitDocument102 pagesBOP Control UnitDrilling Engineering ChannelNo ratings yet

- 37 Drill Stem Tools 1 PDFDocument2 pages37 Drill Stem Tools 1 PDFRizwan FaridNo ratings yet

- BOP HandbookDocument51 pagesBOP HandbookJacob Keemink100% (3)

- Ton Miles Calculator User ManualDocument19 pagesTon Miles Calculator User Manualibrh42No ratings yet

- Well Barriers ConceptsDocument13 pagesWell Barriers ConceptsOSCAR BUSTOSNo ratings yet

- Calculate Bottles Required For Koomey UnitDocument3 pagesCalculate Bottles Required For Koomey Unitmsm.ele2009No ratings yet

- Well Control Questions and Answers Part 2Document8 pagesWell Control Questions and Answers Part 2Rizwan FaridNo ratings yet

- Control Unit - Day3 - Test IntroDocument46 pagesControl Unit - Day3 - Test IntroMrityunjay Dhanraj100% (1)

- Falcon Latest Well Intrevention With GlosoryDocument440 pagesFalcon Latest Well Intrevention With GlosorySachin SahooNo ratings yet

- Esp Running ProceduresDocument12 pagesEsp Running ProceduresAhmedMohsenNo ratings yet

- Combined Surface & Subsea, Equipment - Exercise 1Document16 pagesCombined Surface & Subsea, Equipment - Exercise 1tonyNo ratings yet

- Blocks Drilling Line 3rd Ed PreviewwtrmrkDocument28 pagesBlocks Drilling Line 3rd Ed PreviewwtrmrkAmbrish Rai100% (1)

- BOPs and Their ControlDocument59 pagesBOPs and Their Controlelflaco79No ratings yet

- Koomey AccumulatorDocument7 pagesKoomey AccumulatorQadriNo ratings yet

- Bop RepairDocument13 pagesBop Repairnjava1978100% (1)

- Operator'S Manual: Bop Control System With Air Remote ControlDocument12 pagesOperator'S Manual: Bop Control System With Air Remote ControlagusNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!From EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Rating: 5 out of 5 stars5/5 (1)

- Presentation On BOPDocument27 pagesPresentation On BOPRatnakar Patil100% (2)

- Presentation: Reliability of Hydrogen Area Diaphragm CompressorDocument43 pagesPresentation: Reliability of Hydrogen Area Diaphragm CompressorBiju_Pottayil100% (1)

- ZB Scroll Compressors ManualDocument70 pagesZB Scroll Compressors ManualJavier AffifNo ratings yet

- Lidan Autodriller SystemsDocument24 pagesLidan Autodriller Systemsrery1985100% (1)

- HBeamTechnicalData PDFDocument1 pageHBeamTechnicalData PDFDidit AndiatmokoNo ratings yet

- Part Book Manual 3 NB 1300Document9 pagesPart Book Manual 3 NB 1300rery1985100% (2)

- 200 Design BackgroundDocument43 pages200 Design BackgroundALI YILMAZNo ratings yet

- Measurement of Crushing Strength of Coal AgglomeraDocument5 pagesMeasurement of Crushing Strength of Coal AgglomeraAnonymous 4PuFzARNo ratings yet

- Speciality Performance Packings PDFDocument16 pagesSpeciality Performance Packings PDFHEMANTKHERANo ratings yet

- Part 1-LubeDocument133 pagesPart 1-LubeHưng Luca100% (1)

- Safety Sign Schedule - ZAUDocument19 pagesSafety Sign Schedule - ZAUAlok KumarNo ratings yet

- Chapter 4 - Thermochemistry and FuelsDocument25 pagesChapter 4 - Thermochemistry and FuelsZaidan AlsallalNo ratings yet

- Bunsen Burner LabDocument2 pagesBunsen Burner LabFarikha UlyNo ratings yet

- Lubrication Schematic PDFDocument1 pageLubrication Schematic PDFjoimir rafael perezNo ratings yet

- Cara Kerja Mesin Diesel 4 TakDocument12 pagesCara Kerja Mesin Diesel 4 TakKhairulNo ratings yet

- Olefin Plastic Presentation (CMT - Final.02) 2Document29 pagesOlefin Plastic Presentation (CMT - Final.02) 2Noor HasanahNo ratings yet

- Well ControlDocument56 pagesWell Controlmohhom50% (2)

- Company Profile Alternative Energy New PDFDocument8 pagesCompany Profile Alternative Energy New PDFIqra AngelsNo ratings yet

- Farm TankDocument39 pagesFarm TankLawal Idris AdesholaNo ratings yet

- Anhydrous Ammonia: Production CapacityDocument2 pagesAnhydrous Ammonia: Production CapacityM A JADOONNo ratings yet

- Experiment 11: Saponification and Transesterification: Making Soap and BiodieselDocument5 pagesExperiment 11: Saponification and Transesterification: Making Soap and BiodieselSriArthiNo ratings yet

- Crude Oil Distillation and Petrochemicals: Chemical TechnologyDocument41 pagesCrude Oil Distillation and Petrochemicals: Chemical TechnologyMansi SinghNo ratings yet

- Ongc Report AhmedabadDocument35 pagesOngc Report AhmedabadSwetabh SahayNo ratings yet

- BS 598-104-1989Document18 pagesBS 598-104-1989hibonardo100% (1)

- Chemsep Tutorial: Absorber Case Study: Tutorial 1: Absorption of Propane by N-DodecaneDocument9 pagesChemsep Tutorial: Absorber Case Study: Tutorial 1: Absorption of Propane by N-DodecanemichypaoNo ratings yet

- Chapter 10: Gases: Section B: Answer All The Questions in This SectionDocument2 pagesChapter 10: Gases: Section B: Answer All The Questions in This SectionFaizanAusNo ratings yet

- Oil Tankers: A.A. B. Dinariyana Jurusan Teknik Sistem Perkapalan Fakultas Teknologi Kelautan - ITS Surabaya 2013Document28 pagesOil Tankers: A.A. B. Dinariyana Jurusan Teknik Sistem Perkapalan Fakultas Teknologi Kelautan - ITS Surabaya 2013Annisa Maya Shabrina100% (2)

- Refining Processes Handbook 2006Document222 pagesRefining Processes Handbook 2006Neagu Mihaela100% (1)

- 5-mp Separator PDFDocument1 page5-mp Separator PDFquangNo ratings yet

- Troubleshooting - Engine Cranks But Will Not StartDocument5 pagesTroubleshooting - Engine Cranks But Will Not Startcarlos_ku2061100% (5)

- Ethylene BalanceDocument29 pagesEthylene BalanceCraigUnderwood100% (2)

- IP - 15 - Calculations in Support of IP15-The Area Classification Code For Petroleum Installations - November 2001 PDFDocument63 pagesIP - 15 - Calculations in Support of IP15-The Area Classification Code For Petroleum Installations - November 2001 PDFmpica100% (6)

- Alternative Fuel Requirements SolutionsDocument3 pagesAlternative Fuel Requirements SolutionsIrfan AhmedNo ratings yet

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaDocument3 pagesRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesNo ratings yet

Well Control Equipment1 FHFZ

Well Control Equipment1 FHFZ

Uploaded by

rery1985Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Well Control Equipment1 FHFZ

Well Control Equipment1 FHFZ

Uploaded by

rery1985Copyright:

Available Formats

ZPEB

Chapter 1 Summarization

1. Conception & function of WCE

2. Compositions of WCE

3. Characteristic of hydraulic BOP

4. Parameters of hydraulic BOP

5. BOP stacks

ZPEB

ZPEB

What is WCE?

A complete set of equipment, instruments and tools

for operations of oil/gas well control.

1-1 Conception & functions of WCE

Functions of WCE

Blowout prevention

Kick detection

Control blowout promptly

Treating complications

ZPEB

ZPEB

To shaker

To mud pit

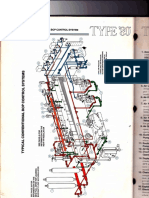

1-2 Compositions of WCE

Accumulator

Auxiliary

control panel

Air control

lines

BOP Stack

Kill line

Control

lines

Choke

manifold

Mud pump & tank

Remote control panel

Mud tank & accessories

Degasser

Vacuum degasser

Drillers control

panel

Upper Kelly cock

ZPEB

To flare pit

Remote control unit

ZPEB

1-2 Compositions of WCE

ZPEB

1-2 Compositions of WCE

ZPEB

1-2 Compositions of WCE

ZPEB

1-2 Compositions of WCE

ZPEB

1-2 Compositions of WCE

ZPEB

1-2 Compositions of WCE

ZPEB

1-3 Characteristic of hydraulic BOP

ZPEB

1.Fast action

Shut in time:Ram BOP3~8SAnnular BOP: 30S & Gate valve: 3 s

2. Convenient operation

Easy operated with air & hydraulic controlled

equipment

3. Reliable & safe

Several control points of remote control, drillers control, auxiliary

control and manual control

4. Quick site maintenance

Easy to change parts

ZPEB

1-4 Parameters of hydraulic BOP

ZPEB

Nominal

diameter

Rated

working

pressure

Definition: Inner fullhole diameter mm

180mm230mm280mm

Types: 346mm426mm476mm

528mm540mm680mm

Definition: Maximum rating pressure MPa

Types: 14MPa21MPa35MPa70MPa

105MPa

Notes: yellow being available in ZPEB area

ZPEB

1-5 Model number of hydraulic BOP

ZPEB

Before 1985

KPY -

Maximum working

pressure, kgf/cm

2

Nominal inner diameter, cm

Exploration, WC & hydraulic

Note: No mentioned BOP type

ZPEB

1-4 Parameters of hydraulic BOP

ZPEB

Nominal

diameter

Rated

working

pressure

Definition: Inner fullhole diameter mm

7 inch,9 inch,11 inch,

Types: 13 5/8 inch,16 inch,18 inch,

20 inch,21 inch,26 inch

Definition: Maximum rating pressure MPa

Types: 1 M,2 M,3 M, 5 M,10M,

15M

Notes: yellow being available in ZPEB area

ZPEB

1-5 Model number of hydraulic BOP

ZPEB

After 1985

-

Max. working

pressure, MPa

Nominal inner diameter, cm

Type code

FZ Single ram BOP

2FZ Double ram BOP

3FZ Three ram BOP

FH Annular BOP

API code

R -Ram

Rd -Double Rams

Rt -Three Rams

A -Annular

S -Spool

ZPEB

1-5 Model number of hydraulic BOP

ZPEB

ZPEB

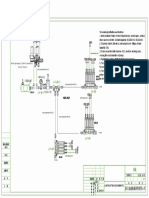

1-6 BOP Stacks

ZPEB

Take consideration of:

1. Size

Match with wellhead and casing size

2. Rated working pressure

Must be higher than predicted maximum

wellhead pressure

3. Type & numbers

Be suitable for sealing in different

borehole condition

ZPEB

1-6 BOP Stacks

ZPEB

14 MPA BOP Stacks

1S+A

2S+SR+SR

3SR+S+SR S+SR+A

ZPEB

1-6 BOP Stacks

ZPEB

21MPa 35MPa BOP Stacks

S+SR+SR+A 4SR+S+SR+A

ZPEB

1-6 BOP Stacks

ZPEB

70MPa 105MPa BOP Stacks

5CH+SR+S

+SR+SR+A

6CH+S

+SR+SR+SR+A

CH+SR+S+SR

+SR+SR+RBOP

ZPEB

1-6 BOP Stacks

ZPEB

4 types of Wellhead of ZPEB

CH+SR+S

+SR+SR+A

CH+S+SR

+SR+A

Type 1 Type 2

ZPEB

1-6 BOP Stacks

ZPEB

4 types of Wellhead of ZPEB

CH+S+SR+A

Type 3

CH+S+SR+SR

ZPEB

1-6 BOP Stacks

ZPEB

4 types of Wellhead of ZPEB

CH+S+A

Type 4

CH+S+SR

ZPEB ZPEB

Conception and composition of WCE

Which pressure grades and sizes of BOP are

often used in China

Point out the parameter of each as follows

KPY28-210 FZ23-21 FH28-35

2FZ35-21 KPY35-350 FZ54-14

Types of BOP Stacks

Questions

ZPEB ZPEB

2 Annular BOP

1. Functions of annular BOP

2. Types of annular BOP

3. Taper rubber

4. Ball rubber

5. Compound rubber

6. Comparison of rubbers

7. Technical specification

8. Cautions

9. Maintenance & repairs

Well Control Equipment

ZPEB ZPEB

2-1 Functions of annular BOP

1. Open hole sealing

No any tubular in borehole

2 .Annulus sealingTubular

exists in borehole

3 Stripping in/outWith 18

o

tapered drill pipe, reducing

control pressure

ZPEB ZPEB

2-2 Types of annular BOP

Ball rubber

Compound

rubber

Tapered rubber

ZPEB

ZPEB

ZPEB ZPEB

2-3 Taper rubber annular BOP

Structure

Scout Rubber

Dustproof

ring

Oil outlet

Piston

Open cavity

Close cavity

Support

cylinder

Body

Coping

Oil outlet

ZPEB ZPEB

2-3 Taper rubber annular BOP

Scout

Rubber

Dustproof

ring

Oil outlet

Open cavity

Piston

Close cavity

Support

cylinder

Body

Coping

Oil outlet

Close:

OilClose

cavityPiston

upRubber up

confined by

coping,

contracting and

being squeezed to

the center and

close BOP

Principle

Open:

OilOpen cavity

Piston down

Release squeezing

forceRubber

recover by

elasticity and open

BOP

ZPEB

1. Rubber

Taper rubber

Large rubber store

Auto-recover

Easy to change rubber

Change rubber directly in

open hole

Change rubber by cutting

with tubular in borehole

ZPEB

2-3 Taper rubber annular BOP

Characteristic:

ZPEB

2-3 Taper rubber annular BOP

ZPEB

2-3 Taper rubber annular BOP

ZPEB

2-3 Taper rubber annular BOP

ZPEB ZPEB

2-3 Taper rubber annular BOP

2. Piston

Long sealing

section

centralizing

Anti-wearing

High dimension

3. Auto-sealing

Borehole pressure

push piston up so as to

squeeze rubber tight

ZPEB ZPEB

2-3 Taper rubber annular BOP

4 Sealing

position

ZPEB ZPEB

2-4 Ball rubber annular BOP

Structure

Coping

Dustproof

ring

Rubber

Piston

Body

ZPEB ZPEB

2-4 Ball rubber annular BOP

Principle

Close cavity outlet

Open cavity outlet

Close:

OilClose cavity

Piston upRubber

up,confined by

coping, contracting

and being squeezed to

the center and close

BOP

Open:

OilOpen cavityPiston

down Release

squeezing forceRubber

recover by elasticity and

open BOP

ZPEB ZPEB

2-4 Ball rubber annular BOP

Characteristic

1.Rubber

Ball type

Large rubber store

Auto-recover

Funnel efficiency

Easy to change rubber

Less friction, large

quantity of oil

for control

ZPEB

Funnel efficiency

When closing, rubber

moved up near coping so

as to make rubbers

collection looks like a

reversed funnel.

Borehole pressure push

bottom of rubber as a

auxiliary power for

sealing.

This help to let tubular

joints pass through

rubber and reduce rubber

wearing.

ZPEB ZPEB

2-4 Ball rubber annular BOP

2. Characteristic

Short sealing

section

Bad

centralizing

Easy for

wearing

Lower dimension

ZPEB ZPEB

2-4 Ball rubber annular BOP

3. Sealing

positions

4. Auxiliary sealing

source

Borehole

pressure push

bottom of

rubber as a

auxiliary power

for sealing.

ZPEB

Structure of

compound rubber

ZPEB

2-5 Compound rubber annular BOP

Structure

Full

open

With tubular Full close

Distortion of inner

rubber

ZPEB ZPEB

2-5 Compound rubber annular BOP

Principle

Close

OilClose cavityPiston

move-upPusher plate

pushing outer rubber

Outer rubber move to

centerInner rubber

furling Packer insert turn

and move to centerClose

borehole

ZPEB ZPEB

2-5 Compound rubber annular BOP

Principle

Open

OilOpen cavity

Piston move-down

Pusher plate return

back-Squeezing force

removedInner & outer

rubbers turn back by

elasticity Open

borehole

ZPEB ZPEB

2-5 Compound rubber annular BOP

Characteristic

Inner & outer rubbers

Complicated structure

Improperly close with new rubber

Less dimension & weight

unavailable with cutting rubber change

Less deformation with inner rubber, less

oil for

control

Less rubber wearing, long rubber life

ZPEB ZPEB

2-6 Comparison of annular BOP

Structure Simple Simple Complex

Totally close OK OK

Worse with

new one

Rubber

change at site

Directly or by

cutting

Directly or by

cutting

Only directly but

no way by cutting

Rubber life Short Long Long

Oil quantity

of operation

2

Medium

3

More

1

less

Dimension Thin, high Thick, short Thin, short

Weight Medium Heavy Light

Annular BOP Type

ZPEB ZPEB

2-7 Specification of annular BOP

Model

Nominal

diameter

mm (in)

Max.

work

pressure

M pa

Shut-in

time

S

Control

pressure

MPa

Dimension mm

Outer

diameter

Height

FH23-35 230(9) 35 < 30 10.5 900 1090

FH28-35 280(11) 35 < 30 10.5 1000 1205

FH35-21 346(13) 21 < 30 10.5 1050 1117

Specification of taper rubber annular BOP

ZPEB ZPEB

2-7 Specification of annular BOP

Model

Nominal

diameter

mm (in)

Max.

work

pressure

MPa

Shut-in

time

S

Control

pressure

MPa

Dimension mm

Outer

diameter

Height

FH28-35 280(11) 35 < 30 10.5 1138 1056

FH35-35 346(13) 35 < 30 10.5 1270 1165

Specification of ball rubber annular BOP

ZPEB ZPEB

2-8 Cautions

No totally close test at site

Close with tubular regular only

Oil pressure range8.5~10.5MPa

Max. pressure: 15MPa

No totally close annular BOP for long period

ZPEB ZPEB

2-8 Cautions

For snub in/out operation, only use 18

o

shoulder drill pipe,

meanwhile, adjusting regulate valve to release fluctuation

pressure as to postpone rubber life

ZPEB ZPEB

2-8 Cautions

In closing status, tubular could be moved

up/down slowly only. No rotating drill string. No

releasing pressure through annular BOP.

Rubber parts must be stored in a lower

temperature of 27 and dry house. Keep away

from electric-arc equipment. No using after

expiration date.

ZPEB ZPEB

2-8 Cautions

Daily maintenance

After rig-up at site, test BOP as per standard.

After entering production zone, test BOP at

each tripping time.

Test annular BOP with

70% of rated working pressure

After each opening, check if BOP is fully

opened to avoid damaging rubber by tubular.

After special operation, wash & clean rubber

chamber.

ZPEB ZPEB

2-9 Troubleshooting

Improperly sealing of annular BOP

With new rubber,close & open several times. If

it is a used rubber, and support frame closed

properly, that means rubber consumed too much.

Change rubber core.

Used rubber worn out and some rubber block

dropped off , cause sealing improperly. Change

rubber core.

Keeping open long term without moving,

impurity deposited in rubber chamber. Clean &

move rubber timely.

ZPEB ZPEB

2-9 Troubleshooting

Fail to open BOP

Long term closing caused rubber deformation. Or

cement deposited in rubber chamber after cementing

job. Need to be thoroughly cleaning.

BOP operating slowly

Before connecting hydraulic control lines,

blow lines with compressed air and clean

connections.

Oil leaking in control lines. Or control

lines were blocked by impurities.

ZPEB ZPEB

2 Ram BOP

1. Functions of ram BOP

2. Types of ram BOP

3. Structure of ram BOP

4. Job principle of ram BOP

5. Structure specialty of ram BOP

6. Side door of ram BOP

7. Lock device of ram BOP

8. Specifications of ram BOP

9. Properly using of ram BOP

10. Troubleshooting

Well Control Equipment

ZPEB

4 Replacing spoolSide flange

of BOP to be used as spool for

connecting choke line and kill line

ZPEB

3-1 Functions of ram BOP

2 Sealing annulus Seal annulus

with available pipe ram

1 Totally sealingSeal open hole with

blind ram

3 Shearing pipeDrill pipe to be

cut off in case of emergency

ZPEB

S

i

n

g

l

e

D

o

u

b

l

e

T

h

r

i

b

b

l

e

ZPEB

3-2 Types of ram BOP

As per ram numbers

As per ram shape

Type

B

l

i

n

d

P

i

p

e

S

h

e

a

r

i

n

g

V

a

r

i

a

b

l

e

ZPEB ZPEB

3-3 Structure of ram BOP

Structure figure

Side flange

Up hinge

Down hinge

Side cover

Body

Side door

Locking axle

Cylinder

Piston & rod

Rams

Injecting outlet

ZPEB ZPEB

3-4 Job principle of ram BOP

Close

Oil in close inletOil path in shellHinge

seatOil path in side doorOil path in

cylinderOil path in cylinder cover

Closing port

Open

Oil in open inletOil path in shellHinge

seatOil path in side doorOpening port

ZPEB ZPEB

3-5 Structure specialty of ram BOPBOP

4. Sidedoor cavity & rod

3. Side door & shell

2. Top ram & shell

1. Front ram & tubular

4 sealing areas

2nd sealing device

ZPEB

3-5 Structure specialty of ram BOPBOP

ZPEB ZPEB

3-5 Structure specialty of ram BOP

Auxiliary source from borehole

1. Rams to be pushed

by downhole pressure to

strengthen contact versus

shell

2. Even high pressure exist

in closing process, as surface

area of piston is larger than rod,

with lower system pressure easy

to control borehole higher

pressure

Note: Area ratio of piston versus rod is called pressure ratio

ZPEB ZPEB

3-5 Structure specialty of ram BOP

Auto cleaning

2 ditches on bottom of

ram cavity to be cleaned by

ram as soon as moving to

prevent blocking of sand

Auto centering

Front bulge of rams to fit

opposite groove, triangle bulge

help to push unlined tubular to

center of borehole

ZPEB

2. Hinge move

ZPEB

3-6 Side door of ram BOP

Functions 1. To seal ram port 2. To transfer oil 3. To

install two way seals

1. Straight move Type

ZPEB

Side door of ram BOP

ZPEB

ZPEB ZPEB

3-6 Side door of ram BOP

Rules of side door operation

1. Two sidedoors cant be opened at same time

2. Only using hydraulic control when side door fully

opened or tightened to shell

3. Releasing pressure when rotating side door

4. After opening side door, tight it when using

hydraulic control to prevent moving

ZPEB ZPEB

3-6 Side door of ram BOP

Sequence of changing ram

1. Release pressureSwitch to be in center in accumulator

2. Open side doorTake off fixing bolts, rotate door open

3. Hydraulic closing ramMake ram extrude out of cavity

4. Take off old & fix a newInstall properly

5. Hydraulic opening ramMake ram shrink to cavity

6. Close side doorRotate sidedoor to close then tighten up bolts

7. Pressure testTest BOP as per rated pressure

ZPEB ZPEB

3-7 Lock device of ram BOP

Auto. lock device

Lock device

Handle lock device

ZPEB ZPEB

3-7 Lock device of ram BOP

Auto. lock deviceHydraulic

controlled lock device, locate in place

where is unavailable for men working

Operation specialtyAfter closing rams,

system complete locking automatically,

before opening rams, system unlock

device automatically

Disadvantage: Unavailable closing by

hand if hydraulic system is out of

control

ZPEB ZPEB

3-7 Lock device of ram BOP

Functions of handle lock device

2. Closing BOP by manpower In the

case of system failure, ram BOP

could be closed by turning lock

device

1. Ensure long term closing After closing

ram BOP, by using lock device, control

pressure could be released to prevent

control lines leaking and misoperation

ZPEB

3-7 Lock device of ram BOP

Thread bar

Types of manual lock device

ZPEB

ZPEB

Simplicity

Spl i ne bar

ZPEB

3-7 Lock device of ram BOP

ZPEB

Makeup of manual lock device

Ro d L o c k s h a f t Oi l c y l i n d e r

Gimbal

Handwheel

ZPEB

3-7 Lock device of ram BOP

ZPEB

Thread bar structure

ZPEB

3-7 Lock device of ram BOP

ZPEB

3-7 Lock device of ram BOP

ZPEB

3-7 Lock device of ram BOP

Ram

Shell

Rod

Side

door

V seal ring

Piston

Fixing nuts

Spline bar case

Spline axis

Cover

Seal ring

Rubber

bowl

Cylinder

Spring clip ring

Plate

Bolts

Thrust

bearing

sdek

Spline bar structure

ZPEB

weep hole

[](

,

)

[]

(

)

ZPEB

3-7 Lock device of ram BOP

ZPEB

Simplicity structure

ZPEB

3-7 Lock device of ram BOP

ZPEB

Manual lock

Turn

clockwise in

place then

~ round

back

Manual unlock

Turn counter

clockwise in

place then

~ round

back

Main points of operation

ZPEB

3-7 Lock device of ram BOP

ZPEB

Closing steps of ram BOP

1. Closing BOP with hydraulic system

Normal practice

2. Using manual lock device

3. Releasing hydraulic pressure

ZPEB

3-7 Lock device of ram BOP

ZPEB

Closing steps of ram BOP

1. Handle of switch to be in closing position

Special practice(Failure of hydraulic control)

2. Manual closing ram BOP

3. Handle of switch to be in central position

ZPEB

3-7 Lock device of ram BOP

ZPEB

Opening steps of ram BOP

1. Manually unlock device

2. Open rams with hydraulic control

3. Releasing hydraulic pressure

ZPEB

3-7 Lock device of ram BOP

ZPEB

Status judgement of lock mechanism

Status figure of Thread bar structure

ZPEB

3-7 Lock device of ram BOP

ZPEB

Status judgement of lock mechanism

Status figure of Spline bar structure

ZPEB

3-7 Lock device of ram BOP

ZPEB

Status judgement of lock mechanism

Status figure of Simplicity structure

ZPEB

3-8 Specifications of ram BOP

ZPEB

Size

9 11 13 5/8 21

28

Rated pressure

1000 psi

2000 psi

3000 psi

5000 psi

10000 psi

15000 psi

ZPEB

3-9 Properly using of ram BOP

ZPEB

Cautions

Size of rams to be applied to tubular

Blind rams to be used in open hole condition only

Manual lock device to be used for long term closing,

leave rams control switch in central position

ZPEB

3-9 Properly using of ram BOP

ZPEB

Before releasing lock device, dont open rams with

hydraulic system, dont move tubular

Dont rotate tubular before opening rams

Manual lock device cant open rams, only

way to open rams is to release lock device firstly

and then open rams with hydraulic system

ZPEB

3-9 Properly using of ram BOP

ZPEB

Daily maintenance

After entering production zone,

function test rams each trip

Use lock device for long term closing, hanging up

warning sign in control panel

Test ram BOP with full rated work

pressure

Cleaning inside BOP thoroughly after cementing job

Never release borehole pressure by opening ram

BOP

ZPEB

1.Change seal ring

2.Tighten all nuts

3.Cleaning seal area

3-10 Troubleshooting

ZPEB

1. Downhole fluid

flows out from

connection

between shell and

sidedoor

1. Sealing damage

between shell and

sidedoor

2. Loose bolts

connection between

shell and sidedoor

3. Impurities exist in

seal ring

ZPEB

Rearrange BOP control lines

3-10 Troubleshooting

ZPEB

2. Ram

moving

doesnt fit to

switch plate

Control lines

being connected

wrong

ZPEB

Clean rams and sidedoor

3-10 Troubleshooting

ZPEB

3. Rams

couldnt be in

place even

control system

seems ok

Sand, muddy silt

or impurities

exist in ram

contacting area

ZPEB

Change rod O ring,

repair damaged rod

3-10 Troubleshooting

ZPEB

4.Downhole

fluid flows to

cylinder mixing

with hydraulic

oil

Rod O ring

damaged, rod

deformed or rod

surface damaged

ZPEB

Change O ring or new

parts, repair sealing

surface

3-10 Troubleshooting

ZPEB

5. Unstable

hydraulic system of

BOP control

Damage of

cylinder, rod,

rod O ring or

sealing surface

ZPEB

Repair sealing surface,

Or change O ring

3-10 Troubleshooting

ZPEB

6. Oil leaking in

hinge area

Damage of

sealing surface

or O ring

ZPEB

Change rubber seal,

repair sealing area

3-10 Troubleshooting

ZPEB

7.Improper

sealing after

closing BOP

Rubber seal

damage, or sealing

area failure of ram

chamber

ZPEB

Clean silt/sand,

raise control pressure

3-10 Troubleshooting

ZPEB

8.Fail to open

BOP even

control system

seems ok

Ram stuck by

silt and sand

You might also like

- Koomey S&s ManualDocument0 pagesKoomey S&s Manualborregocr91% (11)

- Well Control Equipment PDFDocument48 pagesWell Control Equipment PDFHoan Hoan100% (8)

- Tally Book OngcDocument44 pagesTally Book OngcCamron Gomes100% (2)

- Lifting Plan OverviewDocument10 pagesLifting Plan Overviewrery1985100% (2)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Diverter SystemDocument46 pagesDiverter Systemjairaso2950100% (1)

- 12 - WellSharp Subsea Study GuideDocument2 pages12 - WellSharp Subsea Study GuideAdolfo AnguloNo ratings yet

- Well Intervention Pressure Control Syllabus - Level 2Document28 pagesWell Intervention Pressure Control Syllabus - Level 2Richard ReiersenNo ratings yet

- Equipment Questions.Document137 pagesEquipment Questions.rajgogoi85% (20)

- Bop Test 1Document1 pageBop Test 1asiraza100% (2)

- Formulas Well ControlDocument6 pagesFormulas Well ControlJosue FishNo ratings yet

- Drilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsFrom EverandDrilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsRating: 5 out of 5 stars5/5 (1)

- Oil Based Mud or Fluids (OBM)Document7 pagesOil Based Mud or Fluids (OBM)mmohsinaliawanNo ratings yet

- Deutz 226b Euro II Engine ManualDocument46 pagesDeutz 226b Euro II Engine Manualmarcosluna6871% (7)

- WEll ControlDocument60 pagesWEll Controlbennimitz100% (1)

- Surface Well Control Exercise No. 11 - Equipment - GeneralDocument27 pagesSurface Well Control Exercise No. 11 - Equipment - GeneralKaleem UllahNo ratings yet

- Well Control EquiptDocument115 pagesWell Control EquiptGhavban David100% (3)

- Preventive Maintenance Program For Ram Type Blowout PreventesDocument24 pagesPreventive Maintenance Program For Ram Type Blowout Preventesnjava1978100% (1)

- BOP Equipments Use and TestingDocument17 pagesBOP Equipments Use and TestingAjay Kumar100% (3)

- Well Control OpenDocument311 pagesWell Control OpenRobert Verret100% (1)

- Well ControlDocument40 pagesWell ControlNoumanIhsanNo ratings yet

- Preventive Maintenance Program For Spherical Blowout PreventerDocument19 pagesPreventive Maintenance Program For Spherical Blowout Preventernjava1978100% (1)

- Accumulator and BOP Control Unit5 - Aly2Document65 pagesAccumulator and BOP Control Unit5 - Aly2Khaled Yazid100% (1)

- Well ControlDocument70 pagesWell ControlAbd EnnacerNo ratings yet

- API Rp53 RecommendationsDocument2 pagesAPI Rp53 Recommendationseight minutes100% (1)

- Diverter Drilling System For Well Control Full GuideDocument19 pagesDiverter Drilling System For Well Control Full GuiderahulNo ratings yet

- Iwcf Exercise STC 1Document149 pagesIwcf Exercise STC 1ali jabbar100% (1)

- Bit HydraulicsDocument1 pageBit HydraulicsstevebeardsleyNo ratings yet

- 2016.06.20 GNZYQ Poor Boy Degasser ManualDocument14 pages2016.06.20 GNZYQ Poor Boy Degasser ManualGeorge100% (2)

- (Equip (Accumulator)Document34 pages(Equip (Accumulator)Nagendra Singh Ranawat100% (4)

- Iwcf Equipment: - Prepared by - Assistant Chief Engineer - Ahmed Qassim JaberDocument12 pagesIwcf Equipment: - Prepared by - Assistant Chief Engineer - Ahmed Qassim Jaberahmed qassimNo ratings yet

- Secondary Well Control - Well Control EquipmentDocument43 pagesSecondary Well Control - Well Control EquipmentalizareiforoushNo ratings yet

- ANNEX VIII BOP Testing, Inspection, Training and MaintenanceDocument5 pagesANNEX VIII BOP Testing, Inspection, Training and MaintenanceMohsen Shk100% (1)

- Drilling Formulas Calculation Sheet Verson 1.5Document199 pagesDrilling Formulas Calculation Sheet Verson 1.5Vidit GuptaNo ratings yet

- BOP CLOSING UNITS (Koomey)Document1 pageBOP CLOSING UNITS (Koomey)SHRINIVAS100% (2)

- Well Control BPDocument498 pagesWell Control BPcristianoclem100% (1)

- BOP Control UnitDocument102 pagesBOP Control UnitDrilling Engineering ChannelNo ratings yet

- 37 Drill Stem Tools 1 PDFDocument2 pages37 Drill Stem Tools 1 PDFRizwan FaridNo ratings yet

- BOP HandbookDocument51 pagesBOP HandbookJacob Keemink100% (3)

- Ton Miles Calculator User ManualDocument19 pagesTon Miles Calculator User Manualibrh42No ratings yet

- Well Barriers ConceptsDocument13 pagesWell Barriers ConceptsOSCAR BUSTOSNo ratings yet

- Calculate Bottles Required For Koomey UnitDocument3 pagesCalculate Bottles Required For Koomey Unitmsm.ele2009No ratings yet

- Well Control Questions and Answers Part 2Document8 pagesWell Control Questions and Answers Part 2Rizwan FaridNo ratings yet

- Control Unit - Day3 - Test IntroDocument46 pagesControl Unit - Day3 - Test IntroMrityunjay Dhanraj100% (1)

- Falcon Latest Well Intrevention With GlosoryDocument440 pagesFalcon Latest Well Intrevention With GlosorySachin SahooNo ratings yet

- Esp Running ProceduresDocument12 pagesEsp Running ProceduresAhmedMohsenNo ratings yet

- Combined Surface & Subsea, Equipment - Exercise 1Document16 pagesCombined Surface & Subsea, Equipment - Exercise 1tonyNo ratings yet

- Blocks Drilling Line 3rd Ed PreviewwtrmrkDocument28 pagesBlocks Drilling Line 3rd Ed PreviewwtrmrkAmbrish Rai100% (1)

- BOPs and Their ControlDocument59 pagesBOPs and Their Controlelflaco79No ratings yet

- Koomey AccumulatorDocument7 pagesKoomey AccumulatorQadriNo ratings yet

- Bop RepairDocument13 pagesBop Repairnjava1978100% (1)

- Operator'S Manual: Bop Control System With Air Remote ControlDocument12 pagesOperator'S Manual: Bop Control System With Air Remote ControlagusNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!From EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Rating: 5 out of 5 stars5/5 (1)

- Presentation On BOPDocument27 pagesPresentation On BOPRatnakar Patil100% (2)

- Presentation: Reliability of Hydrogen Area Diaphragm CompressorDocument43 pagesPresentation: Reliability of Hydrogen Area Diaphragm CompressorBiju_Pottayil100% (1)

- ZB Scroll Compressors ManualDocument70 pagesZB Scroll Compressors ManualJavier AffifNo ratings yet

- Lidan Autodriller SystemsDocument24 pagesLidan Autodriller Systemsrery1985100% (1)

- HBeamTechnicalData PDFDocument1 pageHBeamTechnicalData PDFDidit AndiatmokoNo ratings yet

- Part Book Manual 3 NB 1300Document9 pagesPart Book Manual 3 NB 1300rery1985100% (2)

- 200 Design BackgroundDocument43 pages200 Design BackgroundALI YILMAZNo ratings yet

- Measurement of Crushing Strength of Coal AgglomeraDocument5 pagesMeasurement of Crushing Strength of Coal AgglomeraAnonymous 4PuFzARNo ratings yet

- Speciality Performance Packings PDFDocument16 pagesSpeciality Performance Packings PDFHEMANTKHERANo ratings yet

- Part 1-LubeDocument133 pagesPart 1-LubeHưng Luca100% (1)

- Safety Sign Schedule - ZAUDocument19 pagesSafety Sign Schedule - ZAUAlok KumarNo ratings yet

- Chapter 4 - Thermochemistry and FuelsDocument25 pagesChapter 4 - Thermochemistry and FuelsZaidan AlsallalNo ratings yet

- Bunsen Burner LabDocument2 pagesBunsen Burner LabFarikha UlyNo ratings yet

- Lubrication Schematic PDFDocument1 pageLubrication Schematic PDFjoimir rafael perezNo ratings yet

- Cara Kerja Mesin Diesel 4 TakDocument12 pagesCara Kerja Mesin Diesel 4 TakKhairulNo ratings yet

- Olefin Plastic Presentation (CMT - Final.02) 2Document29 pagesOlefin Plastic Presentation (CMT - Final.02) 2Noor HasanahNo ratings yet

- Well ControlDocument56 pagesWell Controlmohhom50% (2)

- Company Profile Alternative Energy New PDFDocument8 pagesCompany Profile Alternative Energy New PDFIqra AngelsNo ratings yet

- Farm TankDocument39 pagesFarm TankLawal Idris AdesholaNo ratings yet

- Anhydrous Ammonia: Production CapacityDocument2 pagesAnhydrous Ammonia: Production CapacityM A JADOONNo ratings yet

- Experiment 11: Saponification and Transesterification: Making Soap and BiodieselDocument5 pagesExperiment 11: Saponification and Transesterification: Making Soap and BiodieselSriArthiNo ratings yet

- Crude Oil Distillation and Petrochemicals: Chemical TechnologyDocument41 pagesCrude Oil Distillation and Petrochemicals: Chemical TechnologyMansi SinghNo ratings yet

- Ongc Report AhmedabadDocument35 pagesOngc Report AhmedabadSwetabh SahayNo ratings yet

- BS 598-104-1989Document18 pagesBS 598-104-1989hibonardo100% (1)

- Chemsep Tutorial: Absorber Case Study: Tutorial 1: Absorption of Propane by N-DodecaneDocument9 pagesChemsep Tutorial: Absorber Case Study: Tutorial 1: Absorption of Propane by N-DodecanemichypaoNo ratings yet

- Chapter 10: Gases: Section B: Answer All The Questions in This SectionDocument2 pagesChapter 10: Gases: Section B: Answer All The Questions in This SectionFaizanAusNo ratings yet

- Oil Tankers: A.A. B. Dinariyana Jurusan Teknik Sistem Perkapalan Fakultas Teknologi Kelautan - ITS Surabaya 2013Document28 pagesOil Tankers: A.A. B. Dinariyana Jurusan Teknik Sistem Perkapalan Fakultas Teknologi Kelautan - ITS Surabaya 2013Annisa Maya Shabrina100% (2)

- Refining Processes Handbook 2006Document222 pagesRefining Processes Handbook 2006Neagu Mihaela100% (1)

- 5-mp Separator PDFDocument1 page5-mp Separator PDFquangNo ratings yet

- Troubleshooting - Engine Cranks But Will Not StartDocument5 pagesTroubleshooting - Engine Cranks But Will Not Startcarlos_ku2061100% (5)

- Ethylene BalanceDocument29 pagesEthylene BalanceCraigUnderwood100% (2)

- IP - 15 - Calculations in Support of IP15-The Area Classification Code For Petroleum Installations - November 2001 PDFDocument63 pagesIP - 15 - Calculations in Support of IP15-The Area Classification Code For Petroleum Installations - November 2001 PDFmpica100% (6)

- Alternative Fuel Requirements SolutionsDocument3 pagesAlternative Fuel Requirements SolutionsIrfan AhmedNo ratings yet

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaDocument3 pagesRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesNo ratings yet