Professional Documents

Culture Documents

Machine Tools: Dept. of Mech & Mfg. Engg

Machine Tools: Dept. of Mech & Mfg. Engg

Uploaded by

GoldySamadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Tools: Dept. of Mech & Mfg. Engg

Machine Tools: Dept. of Mech & Mfg. Engg

Uploaded by

GoldySamadCopyright:

Available Formats

Dept. of Mech & Mfg. Engg.

1

MACHINE TOOLS

Dept. of Mech & Mfg. Engg.

2

Dept. of Mech & Mfg. Engg.

3

Bed:

Foundation part of a

lathe

Supports all its other

parts.

Two guide ways on top

of the bed

outer guide ways

inner guide ways.

Dept. of Mech & Mfg. Engg.

4

Working principle of lathe

Direction of cutting tool

Cutting tool

Work piece

Direction of rotation

of work piece

Chuck

Dept. of Mech & Mfg. Engg.

5

Cutting tool can remove material

in the form of chips from rotating

work pieces to produce circular

objects

Work piece held rigidly by one of

the work holding devices known

as chuck

Uses V shaped cutting tool

Working principle of a lathe

Chuck

Direction of

cutting tool

Cutting

tool

Direction of

rotation of

work piece

Dept. of Mech & Mfg. Engg.

6

Principle of cutting operation

Dept. of Mech & Mfg. Engg.

7

Explain with neat diagram the principal parts of

an engine lathe.

Dept. of Mech & Mfg. Engg.

8

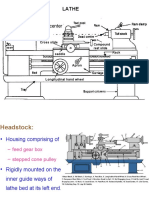

LATHE

Live center

Dept. of Mech & Mfg. Engg.

9

Headstock:

Housing comprising of

feed gear box

stepped cone pulley

Rigidly mounted on the

inner guide ways of

lathe bed at its left end.

Dept. of Mech & Mfg. Engg.

10

Tailstock:

Movable part of the

lathe that carries the

dead centre in it.

Used to clamp tools

like: Twist drills

Reamers

For making holes.

Mounted loosely on

the inner guide ways

of a lathe bed

Moved and locked in

any position.

Dept. of Mech & Mfg. Engg.

11

Carriage assembly:

To support the tool

Moves over the outer

guide ways longitudinally

between headstock

and tailstock.

It is composed of 5 main parts:

1. Saddle

2. Cross slide

3. Compound Rest

4. Apron

5. Tool post

Dept. of Mech & Mfg. Engg.

12

Saddle

H shaped casting that

slides over set of guide

ways

Serves as the base for the

cross slide.

Cross slide

Mounted on the saddle

Enables the movement

of the cutting tool laterally

across the lathe bed by

means of cross feed hand

wheel.

Dept. of Mech & Mfg. Engg.

13

Compound Rest

Mounted on the top of the

cross slide

Supports the tool post.

Swiveled to any angle in

the horizontal plane

To facilitate following

operations:

Taper turning

Threading operations

Moved manually by the

compound rest feed

handle independent of the

lathe cross feed.

Dept. of Mech & Mfg. Engg.

14

Apron

Mounted on the front of the saddle

Consists of,

- Carriage

- Cross slide mechanisms

Apron hand wheel moves the carriage manually by

means of the rack and pinion gears.

Dept. of Mech & Mfg. Engg.

15

Tool post

Mounted on the T slot of the compound rest.

Clamps the tool holder in the proper position for

machining operations.

Dept. of Mech & Mfg. Engg.

16

Lead Screw:

A screw rod which runs longitudinally in front of the

lathe bed.

Rotation of the lead screw moves the carriage to and

fro longitudinally during thread cutting operation.

Dept. of Mech & Mfg. Engg.

17

Feed rod:

A stationary rod mounted in front of the lathe

bed

Facilitates longitudinal movement of carriage

during turning and facing operations.

Dept. of Mech & Mfg. Engg.

18

Cone pulley and back gear:

Cone pulley which drives the main spindle is

driven by the motor.

Various spindle speeds can be obtained by shifting the

belt on different steps of the cone pulley.

Spindle speeds can be further varied using a back gear

arrangement.

You might also like

- Caterpillar Generator Data C15Document12 pagesCaterpillar Generator Data C15Aditya PratamaNo ratings yet

- Machine Tools: Dept. of Mech & Mfg. EnggDocument18 pagesMachine Tools: Dept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- Dept. of Mech & Mfg. EnggDocument24 pagesDept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- LatheClass1 3dupDocument20 pagesLatheClass1 3dupomkardashetwarNo ratings yet

- Machine Tools: Dept. of Mech & Mfg. EnggDocument20 pagesMachine Tools: Dept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- Machine Tools: Dept. of Mech & Mfg. EnggDocument21 pagesMachine Tools: Dept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- 05 Machine ToolsDocument39 pages05 Machine ToolsomkardashetwarNo ratings yet

- Workshop Practice II (MEng4191)Document35 pagesWorkshop Practice II (MEng4191)Tesema TeshomeNo ratings yet

- L3 Lathe SlideDocument36 pagesL3 Lathe SlideSajen PokharelNo ratings yet

- Project PresentationDocument26 pagesProject PresentationRishav RakeshNo ratings yet

- Lathe MachineDocument36 pagesLathe MachinePrem100% (4)

- Taper Turning Operation in LatheDocument20 pagesTaper Turning Operation in LatheomkardashetwarNo ratings yet

- Lathe Machine Unit 4Document43 pagesLathe Machine Unit 4AshirwadNo ratings yet

- LatheDocument130 pagesLatheAjay Sharma86% (7)

- Machine Tool SDocument14 pagesMachine Tool Ssiri.pogulaNo ratings yet

- Machining Operations: Lathe Machine Parts and Mechanisms Dr. Dalia NabilDocument52 pagesMachining Operations: Lathe Machine Parts and Mechanisms Dr. Dalia NabilMr makladNo ratings yet

- Lathe-1Document26 pagesLathe-1Meer Umar100% (2)

- 1-11 Lathe-Machine/machine ShopDocument11 pages1-11 Lathe-Machine/machine ShopAyushman Gohain100% (1)

- Unit #5Document29 pagesUnit #5vigneshk7697No ratings yet

- Lathe and Drilling MachineDocument99 pagesLathe and Drilling Machinesagar0% (1)

- Shaper and Types of Shaper MachinesDocument26 pagesShaper and Types of Shaper MachinesAli ArsalanNo ratings yet

- Me 6402 Manufacturing Technology-Ii Unit IiDocument15 pagesMe 6402 Manufacturing Technology-Ii Unit Iiananda narayananNo ratings yet

- Lab 7 Workshop Teacher VersionDocument4 pagesLab 7 Workshop Teacher Versionumar272No ratings yet

- s6 Machining Operations-1Document94 pagess6 Machining Operations-1Libin AbrahamNo ratings yet

- Module 5 PDFDocument28 pagesModule 5 PDFkaushal shivaprakashNo ratings yet

- Manufacturing ProcessDocument11 pagesManufacturing ProcessRimti BhowmikNo ratings yet

- Dept. of Mech & Mfg. EnggDocument13 pagesDept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- 04-04 Milling Operations PDFDocument57 pages04-04 Milling Operations PDFRafiaNo ratings yet

- Chapter 7 (Turning - Lathe Work)Document58 pagesChapter 7 (Turning - Lathe Work)Munashe ZharareNo ratings yet

- Machining and Machine Tools Lab ManualDocument33 pagesMachining and Machine Tools Lab ManualMail Bot100% (1)

- Lathe Machine and OperationsDocument54 pagesLathe Machine and OperationsVeda SrutiNo ratings yet

- Lathe, Milling Machine, Computer Numerical Control (CNC) and RobotsDocument25 pagesLathe, Milling Machine, Computer Numerical Control (CNC) and RobotsLAKSH RAMASWAMYNo ratings yet

- Lathe MachineDocument34 pagesLathe MachineVaibhav Vithoba Naik100% (1)

- Unit-II The LatheDocument14 pagesUnit-II The LatheThulasi RamNo ratings yet

- Parts of Lathe Machine:: Take Protecting It SeriouslyDocument1 pageParts of Lathe Machine:: Take Protecting It SeriouslyKlucifer XinNo ratings yet

- AMPT (3140204) LAB MANUAL 2022 LNJDocument100 pagesAMPT (3140204) LAB MANUAL 2022 LNJShubham JadavNo ratings yet

- Lecture On Workshops in Industry Rev 1Document60 pagesLecture On Workshops in Industry Rev 1Anoop SharmaNo ratings yet

- Unit 2 Machine ToolsDocument11 pagesUnit 2 Machine ToolsMemes TechnicalNo ratings yet

- EnginelatheDocument125 pagesEnginelatheChandra NurikoNo ratings yet

- Machine ToolsDocument22 pagesMachine ToolsSankalpRaiNo ratings yet

- Report 3 200301032Document18 pagesReport 3 200301032Muhammad AbtaheeNo ratings yet

- Lab Manual - Manufacturing TechnologyDocument79 pagesLab Manual - Manufacturing Technologyvelumani2003No ratings yet

- BME Unit IV Machine ToolsDocument41 pagesBME Unit IV Machine ToolsArvind BhosaleNo ratings yet

- Capstan & Turret LatheDocument18 pagesCapstan & Turret LatheNIKHIL CHIKATE50% (2)

- Machining Process - I: Lathe MachineDocument48 pagesMachining Process - I: Lathe MachineNajshhsNo ratings yet

- Lathe Machine Ex. No. 4Document3 pagesLathe Machine Ex. No. 4Rodgie Christian CruzNo ratings yet

- LatheDocument16 pagesLathepokalNo ratings yet

- Unit-4 Machine ToolsDocument77 pagesUnit-4 Machine ToolsSOURABH GANGWARNo ratings yet

- Making of Lathe DogDocument18 pagesMaking of Lathe DogAashi RoseNo ratings yet

- Lathe PDNDocument108 pagesLathe PDNSagar ShindeNo ratings yet

- Unit 2 Me1203Document20 pagesUnit 2 Me1203Muthuvel MNo ratings yet

- Milling Machine (Group 7)Document52 pagesMilling Machine (Group 7)Faisal Maqsood100% (1)

- LatheDocument2 pagesLathesule1989No ratings yet

- Lathe Machine PDFDocument17 pagesLathe Machine PDFharshbodkhe2002No ratings yet

- LATHE - WriteupDocument21 pagesLATHE - WriteupMERISH GURU100% (1)

- Chapter 2Document49 pagesChapter 2zelalemmekonnen823No ratings yet

- Department of Petrochemical Engineering College of Technical Engineering University of Polytechnic-DuhokDocument21 pagesDepartment of Petrochemical Engineering College of Technical Engineering University of Polytechnic-DuhokWalid AdnanNo ratings yet

- EME Module 2Document46 pagesEME Module 2vishnubabannaNo ratings yet

- Prodn CH02-2 PDFDocument36 pagesProdn CH02-2 PDFadigoNo ratings yet

- Machine Tools Lab Manual (13-14)Document39 pagesMachine Tools Lab Manual (13-14)Krishna Murthy100% (1)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- MCQs PPEDocument10 pagesMCQs PPEfrieda20093835100% (1)

- Assessment-2: Sithind002 Source and Use Information On The Hospitality IndustryDocument19 pagesAssessment-2: Sithind002 Source and Use Information On The Hospitality IndustryNidhi GuptaNo ratings yet

- 03-737-800 Ramp & Transit Electrical PowerDocument92 pages03-737-800 Ramp & Transit Electrical PowerNicolas Sal100% (2)

- Vedic Astrolgy Paet - 4Document64 pagesVedic Astrolgy Paet - 4krumiaaNo ratings yet

- Essential Kanban Condensed Guide v0.9.3Document27 pagesEssential Kanban Condensed Guide v0.9.3Gaurav SharmaNo ratings yet

- SfdfdsDocument4 pagesSfdfdsDominikCampanellaNo ratings yet

- Spoken English PPT 1Document147 pagesSpoken English PPT 1Sindhu Manja100% (3)

- CESTARO - Plan-Tonificacion Inicial MujerDocument14 pagesCESTARO - Plan-Tonificacion Inicial MujerLucas Javier VidalNo ratings yet

- Generator Manual 1Document392 pagesGenerator Manual 1Gopal Radhakrishnan100% (5)

- SPM Linear LawDocument5 pagesSPM Linear LawNg YieviaNo ratings yet

- MBA Global Management Technische Hochschule Ingolstadt - IngolstadtDocument7 pagesMBA Global Management Technische Hochschule Ingolstadt - IngolstadtHieu NguyenNo ratings yet

- Test Initial EnglezaDocument4 pagesTest Initial EnglezaPop CameliaNo ratings yet

- Active Directory GP Programming and Registry ReferenceDocument99 pagesActive Directory GP Programming and Registry ReferenceHarmandeep Singh SagguNo ratings yet

- India To Open Up Cowin For The World: PM: Bourses, Top Executives To Pay For Technical GlitchesDocument20 pagesIndia To Open Up Cowin For The World: PM: Bourses, Top Executives To Pay For Technical GlitchesSatish WadawadagiNo ratings yet

- 2020a1t182 Assgn1Document9 pages2020a1t182 Assgn1Aahib NazirNo ratings yet

- Salami Attacks and Their Mitigation - AnDocument4 pagesSalami Attacks and Their Mitigation - AnParmalik KumarNo ratings yet

- Contextualized Online and Research SkillsDocument16 pagesContextualized Online and Research SkillsAubrey Castillo BrionesNo ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger DesignCharito Sollera AlbaricoNo ratings yet

- Bermundo Task 3 Iii-20Document2 pagesBermundo Task 3 Iii-20Jakeson Ranit BermundoNo ratings yet

- Gloss 1Document8 pagesGloss 1api-3723109No ratings yet

- 66 - Series Singer 66 Sewing Machine ManualDocument16 pages66 - Series Singer 66 Sewing Machine ManualCynthia PorterNo ratings yet

- NoSleep Ebook - 2014, Issue 2 - NoSleep PDFDocument76 pagesNoSleep Ebook - 2014, Issue 2 - NoSleep PDFSofiiBaudeanNo ratings yet

- Clinical and Diagnostic Imaging Findings in Police Working Dogs Referred For Hip OsteoarthritisDocument11 pagesClinical and Diagnostic Imaging Findings in Police Working Dogs Referred For Hip OsteoarthritisEquilibrium EduardoNo ratings yet

- The Impact of Food Branding On Children's Eating Behaviour and ObesityDocument8 pagesThe Impact of Food Branding On Children's Eating Behaviour and ObesityAlessandraBattagliaNo ratings yet

- Asimakopulos, A. (1975) - A Kaleckian Theory of Income Distribution. Canadian Journal of Economics, 313-333.Document22 pagesAsimakopulos, A. (1975) - A Kaleckian Theory of Income Distribution. Canadian Journal of Economics, 313-333.lcr89No ratings yet

- BS en 1713 - UtDocument20 pagesBS en 1713 - UtBoranAlouaneNo ratings yet

- Ifgtb List Lds Mts 03feb15Document11 pagesIfgtb List Lds Mts 03feb15kaifiahmedNo ratings yet

- Moduflex Power Core (12kW) Rev01Document2 pagesModuflex Power Core (12kW) Rev01Steven SeNo ratings yet

- © The Institute of Chartered Accountants of IndiaDocument154 pages© The Institute of Chartered Accountants of IndiaJattu TatiNo ratings yet