Professional Documents

Culture Documents

100%(1)100% found this document useful (1 vote)

449 viewsBunker Fuel Analysis

Bunker Fuel Analysis

Uploaded by

Medha Jog Katdare1. Fuel oils are numbered 1 through 6 based on their boiling point, with 1 being the lightest and 6 the heaviest and most viscous, requiring preheating to flow.

2. Numbers 1-3 are distillate fuels like kerosene and diesel, while 4-6 are residual fuels from heavier crude oil components.

3. Regulations limit sulfur content in fuel oils within Emission Control Areas to reduce air pollution, with limits outside the areas also getting progressively lower.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You might also like

- Pipeline Arrangement in Oil TankersDocument11 pagesPipeline Arrangement in Oil TankersManpreet SinghNo ratings yet

- Marine Fuel Oil Bunker IngDocument85 pagesMarine Fuel Oil Bunker IngJuan Ramón Fuentes67% (3)

- LPG Co-MinglingDocument17 pagesLPG Co-Minglingderhgawenrahul100% (1)

- Bunker Delivery NoteDocument3 pagesBunker Delivery NoteMugilrajan Devarajan100% (2)

- Remediation Proposal For The Fukushima Daiichi Nuclear Power7dec2015 r9Document40 pagesRemediation Proposal For The Fukushima Daiichi Nuclear Power7dec2015 r9api-313099740100% (1)

- Emergency Engine Operation PDFDocument4 pagesEmergency Engine Operation PDFAnakin SkywalkerNo ratings yet

- Norwegian Training Center Bilge Water Waste Oil Operation Management PDFDocument141 pagesNorwegian Training Center Bilge Water Waste Oil Operation Management PDFLuis100% (3)

- Bunkering Code of Practice PDFDocument62 pagesBunkering Code of Practice PDFsijuwolaoluranti100% (3)

- Wall Wash TestDocument5 pagesWall Wash Testutkarshgahtori100% (1)

- Bilge Water Instructions & Requirements - ENDocument5 pagesBilge Water Instructions & Requirements - ENclaudioNo ratings yet

- Purifier OverhaulDocument27 pagesPurifier OverhaulMedha Jog KatdareNo ratings yet

- Astm F496Document8 pagesAstm F496Aditya ManNo ratings yet

- Study On The Stoichiometry and Reaction Products of Extra Virgin Olive Oil OzonationDocument5 pagesStudy On The Stoichiometry and Reaction Products of Extra Virgin Olive Oil OzonationAlexiss Chavez-De la Mora100% (1)

- 11 Marine Fuel Properties.Document7 pages11 Marine Fuel Properties.Kevin LeysonNo ratings yet

- A Masters Guide To Using Fuel Oil Onboard ShipsDocument74 pagesA Masters Guide To Using Fuel Oil Onboard ShipsPatetico Pianto LupoNo ratings yet

- Tier III SCR For Large 2-Stroke MAN B&W Diesel EnginesDocument6 pagesTier III SCR For Large 2-Stroke MAN B&W Diesel EnginesWon-young SeoNo ratings yet

- Fuel Oil Analysis: Know The Condition of The Fuel Oils You Use!Document6 pagesFuel Oil Analysis: Know The Condition of The Fuel Oils You Use!lolo100% (1)

- Tricks of Bunker SupplyDocument5 pagesTricks of Bunker SupplyrubinoestelaNo ratings yet

- Lloyds FOBAS Guidance On CominglingDocument11 pagesLloyds FOBAS Guidance On CominglingBruno KosNo ratings yet

- CH 0 Cleaning Cross Refference Table DREW AMEROIDDocument36 pagesCH 0 Cleaning Cross Refference Table DREW AMEROIDPavel ViktorNo ratings yet

- Bunker EbookDocument76 pagesBunker EbookNatalia Moskvitina100% (1)

- Inert Gas OverviewDocument6 pagesInert Gas OverviewRahulChoudharyNo ratings yet

- MSC 1 Circ 1511 - Unified Interpretations of SOLAS Regulations II-2 - 9 & II-2 - 13Document9 pagesMSC 1 Circ 1511 - Unified Interpretations of SOLAS Regulations II-2 - 9 & II-2 - 13Goh Boon TiongNo ratings yet

- Fuel Oil AnalysisDocument6 pagesFuel Oil AnalysisPawan BeniwalNo ratings yet

- Khaksar KhanDocument36 pagesKhaksar KhanAlsamad Borkar100% (1)

- BunkeringDocument26 pagesBunkeringPaul Abonita100% (2)

- Properties of Fuel Oil and Bunkering Pro PDFDocument34 pagesProperties of Fuel Oil and Bunkering Pro PDFRajeev Valunjkar100% (1)

- Amspec Techtalk Hydrogen Sulfide - h2s 4Document3 pagesAmspec Techtalk Hydrogen Sulfide - h2s 4Javier Gomez TorregrosaNo ratings yet

- 3 Fuel Properties and EffectsDocument28 pages3 Fuel Properties and EffectsZohaib AhmedNo ratings yet

- 9 Oil Pollution Act of 1990Document6 pages9 Oil Pollution Act of 1990Ur Loafer MarinerNo ratings yet

- Marpol Annex VDocument3 pagesMarpol Annex VJulio Chavez DiazNo ratings yet

- Man B W Two Stroke Engine Operating On AmmoniaDocument18 pagesMan B W Two Stroke Engine Operating On Ammoniasimhadri sanganiNo ratings yet

- Oral-Preparation-Guide (Rifat Azad-Bma 49) PDFDocument105 pagesOral-Preparation-Guide (Rifat Azad-Bma 49) PDFTarek Aziz100% (2)

- MEO Class 2 Misc Info PDFDocument17 pagesMEO Class 2 Misc Info PDFrajishrrrNo ratings yet

- Bilge Water Management & PollutionDocument12 pagesBilge Water Management & PollutionGeorgios PapakostasNo ratings yet

- Gas CargoesDocument56 pagesGas CargoesTom AlexNo ratings yet

- Marpol Regulations and AnnexesDocument5 pagesMarpol Regulations and AnnexesUtkarsh MathurNo ratings yet

- Amspec Techtalk - Pona PianoDocument4 pagesAmspec Techtalk - Pona PianoUmarFidaNo ratings yet

- Oil Record Book Cum Se Completeaza Corect 15.10.2018Document29 pagesOil Record Book Cum Se Completeaza Corect 15.10.2018Popa VasileNo ratings yet

- Watchkeeping and TroubleshootingDocument16 pagesWatchkeeping and TroubleshootingAditya Joglekar100% (1)

- Marpol Annex 6Document11 pagesMarpol Annex 6tripuraridheerajNo ratings yet

- Pentane Msds Praxair p6229Document8 pagesPentane Msds Praxair p6229Michael SchreiberNo ratings yet

- Oil Record 15.10.2018Document18 pagesOil Record 15.10.2018Popa VasileNo ratings yet

- Measuring Propeller Drop With The Help of Poker GaugeDocument2 pagesMeasuring Propeller Drop With The Help of Poker Gaugeas100% (1)

- VLSFO FUEL CharacterDocument5 pagesVLSFO FUEL CharacterDad’s Adventures LanderoNo ratings yet

- Disposal For Spilled Oil and Prevention For Secondary DisasterDocument4 pagesDisposal For Spilled Oil and Prevention For Secondary DisasterIonescu EdaNo ratings yet

- Revised MARPOL Annex VDocument6 pagesRevised MARPOL Annex VDiana MoralesNo ratings yet

- Objective and Purpose of Boiler Water TestDocument3 pagesObjective and Purpose of Boiler Water TestAayush AgrawalNo ratings yet

- Amspec Techtalk A Stands For API Gravity 4Document5 pagesAmspec Techtalk A Stands For API Gravity 4Sudea CadabaNo ratings yet

- M2 Pipe Identification Tape To ISO14726Document1 pageM2 Pipe Identification Tape To ISO14726chrisNo ratings yet

- Bunkering ProcedureDocument4 pagesBunkering ProcedureVinay Gupta100% (2)

- Oral Question and AnswerDocument179 pagesOral Question and AnswerMariyath Muraleedharan Kiran100% (1)

- Gasoline FAQ 1Document9 pagesGasoline FAQ 1Claudia MmsNo ratings yet

- 010 Marine Fuel Handling and Pre-TreatmentDocument2 pages010 Marine Fuel Handling and Pre-TreatmentKhasy Jeans P. Tampos100% (1)

- Simplified VOC Management Plan, RevDocument11 pagesSimplified VOC Management Plan, RevSumeet SawantNo ratings yet

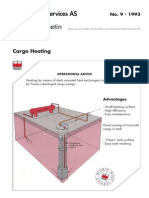

- 09 - Cargo Heating - Operational Advice PDFDocument4 pages09 - Cargo Heating - Operational Advice PDFrpichoNo ratings yet

- E23a ISGOTT Bunker ChklistDocument4 pagesE23a ISGOTT Bunker Chklistvic.barca2012100% (1)

- Inventory of Hazardous Materials (IHM) - A Brief Explanation - Ship TechnologyDocument5 pagesInventory of Hazardous Materials (IHM) - A Brief Explanation - Ship Technologyanand raoNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- OILDocument4 pagesOILJoão LucasNo ratings yet

- Marine FuelDocument17 pagesMarine FuelviviwulanNo ratings yet

- Marine Fuels - SpecificationDocument13 pagesMarine Fuels - SpecificationMetehan İlbayNo ratings yet

- OM - Marine Fuel Oil - 2 - Standards & HandlingDocument103 pagesOM - Marine Fuel Oil - 2 - Standards & Handlingroberto luckyNo ratings yet

- Gear Oil: Function of A Gear LubricantDocument2 pagesGear Oil: Function of A Gear LubricantMedha Jog KatdareNo ratings yet

- Ac and DC Solenoid ValvesDocument3 pagesAc and DC Solenoid ValvesMedha Jog KatdareNo ratings yet

- Housekeeping: Storage On DeckDocument3 pagesHousekeeping: Storage On DeckMedha Jog KatdareNo ratings yet

- What Is Grease?Document5 pagesWhat Is Grease?Medha Jog KatdareNo ratings yet

- Scavenge FireDocument4 pagesScavenge FireMedha Jog KatdareNo ratings yet

- Classification of PumpsDocument22 pagesClassification of PumpsMedha Jog KatdareNo ratings yet

- Dismantling of Horizontal ShaftDocument2 pagesDismantling of Horizontal ShaftMedha Jog KatdareNo ratings yet

- Scavenge FireDocument4 pagesScavenge FireMedha Jog KatdareNo ratings yet

- Dynamics of RotationDocument32 pagesDynamics of RotationMedha Jog KatdareNo ratings yet

- Cargo Pumping SystemDocument24 pagesCargo Pumping SystemMedha Jog Katdare100% (2)

- Ship-Shore Safety Check List For TankersDocument6 pagesShip-Shore Safety Check List For TankersMedha Jog Katdare67% (3)

- Formulae and Definitions in MathematicsDocument71 pagesFormulae and Definitions in MathematicsMedha Jog Katdare100% (1)

- Mitsubishi Hiden SystemsDocument3 pagesMitsubishi Hiden SystemsMedha Jog KatdareNo ratings yet

- Stern Tube BoringDocument2 pagesStern Tube BoringMedha Jog KatdareNo ratings yet

- Typical Engine Room CraneDocument12 pagesTypical Engine Room CraneMedha Jog Katdare100% (3)

- Propeller RemovalDocument10 pagesPropeller RemovalMedha Jog Katdare100% (1)

- Lifesaving EquipmentDocument31 pagesLifesaving EquipmentMedha Jog KatdareNo ratings yet

- STPM Biology Past Year QuestionDocument8 pagesSTPM Biology Past Year QuestionMc Donalds Ohl Ohlsen100% (2)

- FDA PresentationDocument27 pagesFDA PresentationTimothy William C. Laurence100% (1)

- DownloadDocument174 pagesDownloadyattsudrajatNo ratings yet

- Feinguss in India - Sumangal CastingDocument2 pagesFeinguss in India - Sumangal Castingsumangal castingNo ratings yet

- Electron Transfer at Different Electrode MatDocument13 pagesElectron Transfer at Different Electrode MatAbeerNo ratings yet

- Inspire Cast Final 2021 TreinamentoDocument197 pagesInspire Cast Final 2021 TreinamentoDave DaveNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- A Pre-Concentration and Online Solid Phase Extraction Setup For The LC-MS Analysis of Therapeutic Protein MixturesDocument8 pagesA Pre-Concentration and Online Solid Phase Extraction Setup For The LC-MS Analysis of Therapeutic Protein MixturesReactivos Para-AnalisisNo ratings yet

- Muhammad Quthbil Irsyad 4311419042 Chemistry-2Document2 pagesMuhammad Quthbil Irsyad 4311419042 Chemistry-2Muhammad Quthbil IrsyadNo ratings yet

- Certificate No. 273 Technical Methanol Grade A: No. Indicator Name Test Method Actual ValueDocument2 pagesCertificate No. 273 Technical Methanol Grade A: No. Indicator Name Test Method Actual Valueذياب الكايدNo ratings yet

- Mid Static Pressure-DUCTEDDocument29 pagesMid Static Pressure-DUCTEDsyed mustafa aliNo ratings yet

- Atom WorksheetsDocument4 pagesAtom Worksheetsapi-271960049100% (1)

- MigDocument6 pagesMigPensel KoNtotNo ratings yet

- Aaac 1120Document1 pageAaac 1120TriSanNo ratings yet

- PSD200912 Meter PG 46 PDFDocument84 pagesPSD200912 Meter PG 46 PDFosamamae100% (1)

- Research Project Data e LogbookDocument8 pagesResearch Project Data e LogbookEl John CalicaNo ratings yet

- TDS Celvolit 1326 (SG)Document2 pagesTDS Celvolit 1326 (SG)Duc Nguyen100% (1)

- Manual For Making TEM Samples Using FIBDocument8 pagesManual For Making TEM Samples Using FIBfgsgdNo ratings yet

- Long Test As Level Nucleic AcidDocument9 pagesLong Test As Level Nucleic AcidPrisky Jofan SimbarNo ratings yet

- MSDS - DK PGT Paste R27Document4 pagesMSDS - DK PGT Paste R27RND PT SIPNo ratings yet

- Branching and Control Manual With Dupont Engineering PolymersDocument24 pagesBranching and Control Manual With Dupont Engineering PolymersKaman LoNo ratings yet

- Models Relating Mixture Composition To The Density and Strength of Foam Concrete Using Response Surface Methodology - Nambiar & Ramamurthy 2006 PDFDocument9 pagesModels Relating Mixture Composition To The Density and Strength of Foam Concrete Using Response Surface Methodology - Nambiar & Ramamurthy 2006 PDFalexnlima852No ratings yet

- General GrindingDocument28 pagesGeneral GrindingRavi Arjun Kumar100% (1)

- Hair Care Tips For High Porosity HairDocument10 pagesHair Care Tips For High Porosity HairJuanGuillermoCarmonaOcampo0% (1)

- Vigogrease Re0 Msds 07-750 1Document5 pagesVigogrease Re0 Msds 07-750 1FlintLockwoodNo ratings yet

- Major Paper On Development of Novel Self Healing Concrete Using Carbon NanotubesDocument7 pagesMajor Paper On Development of Novel Self Healing Concrete Using Carbon NanotubesVujjini RaghuNo ratings yet

- Soundness of Aggregates by Use of Sodium Sulfate or Magnesium SulfateDocument5 pagesSoundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfatekordef zeminNo ratings yet

- Why Is Rigor Mortis Absent in AnthraxDocument25 pagesWhy Is Rigor Mortis Absent in Anthraxravigg100% (2)

Bunker Fuel Analysis

Bunker Fuel Analysis

Uploaded by

Medha Jog Katdare100%(1)100% found this document useful (1 vote)

449 views18 pages1. Fuel oils are numbered 1 through 6 based on their boiling point, with 1 being the lightest and 6 the heaviest and most viscous, requiring preheating to flow.

2. Numbers 1-3 are distillate fuels like kerosene and diesel, while 4-6 are residual fuels from heavier crude oil components.

3. Regulations limit sulfur content in fuel oils within Emission Control Areas to reduce air pollution, with limits outside the areas also getting progressively lower.

Original Description:

Bunkering requirements and fuel analysis

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Fuel oils are numbered 1 through 6 based on their boiling point, with 1 being the lightest and 6 the heaviest and most viscous, requiring preheating to flow.

2. Numbers 1-3 are distillate fuels like kerosene and diesel, while 4-6 are residual fuels from heavier crude oil components.

3. Regulations limit sulfur content in fuel oils within Emission Control Areas to reduce air pollution, with limits outside the areas also getting progressively lower.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

100%(1)100% found this document useful (1 vote)

449 views18 pagesBunker Fuel Analysis

Bunker Fuel Analysis

Uploaded by

Medha Jog Katdare1. Fuel oils are numbered 1 through 6 based on their boiling point, with 1 being the lightest and 6 the heaviest and most viscous, requiring preheating to flow.

2. Numbers 1-3 are distillate fuels like kerosene and diesel, while 4-6 are residual fuels from heavier crude oil components.

3. Regulations limit sulfur content in fuel oils within Emission Control Areas to reduce air pollution, with limits outside the areas also getting progressively lower.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 18

Classes

Generally six fuel grades numerical specifications.

The boiling point and carbon chain length of the fuel increases with fuel oil number.

Viscosity also increases with number, and the heaviest oil has to be heated to get it to flow.

Price usually decreases as the fuel number increases.

Number 1 fuel oil is a volatile distillate oil - kerosene, gasoline

Number 2 fuel oil distillate - diesel fuel with a cetane number limit describing the ignition quality of the

fuel.

Number 3 fuel oil distillate oil for burners requiring low-viscosity fuel. ASTM merged this grade into the

number 2 specification, and the term has been rarely used

Number 4 fuel oil is a commercial heating oil for burner installations not equipped with preheaters.

Number 5 fuel oil is a residual-type industrial heating oil requiring preheating to 170 220 F (77 104

C) for proper atomization at the burners. This fuel is sometimes known as Bunker B. It may be obtained

from the heavy gas oil cut, or it may be a blend of residual oil with enough number 2 oil to adjust viscosity

until it can be pumped without preheating.

Number 6 fuel oil is a high-viscosity residual oil requiring preheating to 220 260 F (104 127 C).

Residual means the material remaining after the more valuable cuts of crude oil have boiled off. The

residue may contain various undesirable impurities including 2 percent water and one-half percent

mineral soil. This fuel may be known as residual fuel oil (RFO)

Mazut is a residual fuel oil often derived from Russian petroleum sources and is either blended with

lighter petroleum fractions or burned directly in specialized boilers and furnaces.

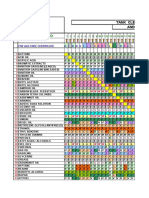

Table of fuel oils

Name Alias Alias Type Chain Length

No. 1 fuel oil No. 1 distillate No. 1 diesel fuel Distillate 9-16

No. 2 fuel oil No. 2 distillate No. 2 diesel fuel Distillate 10-20

No. 3 fuel oil No. 3 distillate No. 3 diesel fuel Distillate

No. 4 fuel oil No. 4 distillate

No. 4 residual

fuel oil

Distillate/Residua

l

12-70

No. 5 fuel oil

No. 5 residual

fuel oil

Heavy fuel oil Residual 12-70

No. 6 fuel oil

No. 6 residual

fuel oil

Heavy fuel oil Residual 20-70

Small molecules like those in propane, naphtha, gasoline for cars, and jet fuel have

relatively low boiling points, and they are removed at the start of the fractional

distillation process.

Heavier petroleum products like diesel and lubricating oil are much less volatile

and distill out more slowly, while bunker oil is literally the bottom of the barrel;

The only things more dense than bunker fuel are carbon black feedstock and

bituminous residue which is used for paving roads (asphalt) and sealing roofs.

Bunker fuel or bunker crude is technically any type of fuel oil used aboard ships. It

gets its name from the containers on ships and in ports that it is stored in; in the

early days of steam they were coal bunkers but now they are bunker fuel tanks.

Bunker A is No. 2 fuel oil, Bunker B is No. 4 or No. 5 and bunker C is No. 6.

No. 5 or 6 are also commonly called heavy fuel oil (HFO) or furnace fuel oil (FFO);

the high viscosity requires heating, usually by a re-circulated low pressure steam

system, before the oil can be pumped from a bunker tank. Bunkers are rarely

labeled this way in modern maritime practice.

International Organization for Standardization (ISO) has been the accepted

standard for marine fuels (bunkers). The standard is listed under number 8217,

with recent updates in 2005 and 2010.

They have broken it down to Residual and Distillate fuels.

The most common residual fuels in the shipping industry are RMG and RMK. The

differences between the two are mainly the density and viscosity, with RMG

generally being delivered at 380 centistokes or less, and RMK at 700 centistokes or

less.

Ships with more advanced engines can process heavier, more viscous, and thus

cheaper, fuel.

Governing bodies (i.e., California, European Union) around the world have

established Emission Control Areas (ECA) which limit the maximum sulfur of fuels

burned in their ports to limit pollution, reducing the percentage of sulfur and

other particulates from 4.5% m/m to as little as .10% as of 2015 inside an ECA.

As of 2013; 3.5% is continued to be permitted outside an ECA.

They have similar properties to Diesel #2 which is used as road Diesel around the

world. The most common grades used in shipping are DMA and DMB.

Greenhouse gas emissions resulting from the use of international bunker fuels are

currently included in national inventories

MGO (Marine gas oil) - roughly equivalent to No. 2 fuel oil, made from

distillate only

MDO (Marine diesel oil) - A blend of heavy gasoil that may contain very

small amounts of black refinery feed stocks, but has a low viscosity up to

12 cSt so it need not be heated for use in internal combustion engines

IFO (Intermediate fuel oil) A blend of gasoil and heavy fuel oil, with less

gasoil than marine diesel oil

MFO (Marine fuel oil) - same as HDO (just another "naming")

HFO (Heavy fuel oil) - Pure or nearly pure residual oil, roughly equivalent

to No. 6 fuel oil

Standards and classification

CCAI and CII are two indexes which describe the ignition quality of residual fuel oil, and

CCAI is especially often calculated for marine fuels. Despite this, marine fuels are still

quoted on the international bunker markets with their maximum viscosity (which is set

by the ISO 8217 standard ) due to the fact that marine engines are designed to use

different viscosities of fuel. The unit of viscosity used is the Centistokes and the fuels

most frequently quoted are listed below in order of cost, the least expensive first-

IFO 380 - Intermediate fuel oil with a maximum viscosity of 380 Centistokes (<3.5%

sulphur)

IFO 180 - Intermediate fuel oil with a maximum viscosity of 180 Centistokes (<3.5%

sulphur)

LS 380 - Low-sulphur (<1.0%) intermediate fuel oil with a maximum viscosity of 380

Centistokes

LS 180 - Low-sulphur (<1.0%) intermediate fuel oil with a maximum viscosity of 180

Centistokes

MDO - Marine diesel oil.

MGO - Marine gasoil.

LSMGO - Low-sulphur (<0.1%) Marine Gas Oil - The fuel is to be used in EU community

Ports and Anchorages. EU Sulphur directive 2005/33/EC

ULSMGO - Ultra Low Sulphur Marine Gas Oil - referred to as Ultra Low Sulfur Diesel

(sulphur 0.0015% max) in the US and Auto Gas Oil (sulphur 0.001% max) in the EU.

Maximum sulphur allowable in US territories and territorial waters (inland, marine and

automotive) and in the EU for inland use.

$/mt FUEL GRADE

564 IFO380 (RMG380 RMH380)

589 IFO180 (RME180 RMF180)

847 MGO (DMA DMX)

570 LS380 (1.00% Sulphur)

594 LS180 (1.00% Sulphur)

847 LSMGO (0.1% Sulphur)

BUNKER PRICES

Sulphur oxides (SOx) Regulation 14

SOx and particulate matter emission controls apply to all fuel oil, as defined in regulation 2.9,

combustion equipment and devices onboard and therefore include both main and all

auxiliary engines together with items such boilers and inert gas generators.

These controls divide between those applicable inside Emission Control Areas (ECA) established

to limit the emission of SOx and particulate matter and those applicable outside such areas

and are primarily achieved by limiting the maximum sulphur content of the fuel oils as

loaded, bunkered, and subsequently used onboard.

These fuel oil sulphur limits (expressed in terms of % m/m that is by weight) are subject to a

series of step changes over the years, regulations 14.1 and 14.4:

* depending on the outcome of a review, to be concluded in 2018, as to the availability of the

required fuel oil, this date could be deferred to 1 January 2025.

Outside an ECA established to limit SOx

and particulate matter emissions

Inside an ECA established to limit SOx and

particulate matter emissions

4.50% m/m prior to 1 January 2012

1.50% m/m prior to 1 July 2010

3.50% m/m on and after 1 January 2012

1.00% m/m on and after 1 July 2010

0.50% m/m on and after 1 January 2020*

0.10% m/m on and after 1 January 2015

The ECA established are:

Baltic Sea area as defined in Annex I of MARPOL (SOx only);

North Sea area as defined in Annex V of MARPOL (SOx only);

North American area (entered into effect 1 August 2012) as defined in Appendix VII of Annex

VI of MARPOL (SOx, NOx and PM); and

United States Caribbean Sea area (entered into effect 1 January 2014) as defined in Appendix

VII of Annex VI of MARPOL (SOx, NOx and PM).

Most ships which operate both outside and inside these ECA will therefore operate on

different fuel oils in order to comply with the respective limits. In such cases, prior to entry

into the ECA, it is required to have fully changed-over to using the ECA compliant fuel oil,

regulation 14.6, and to have onboard implemented written procedures as to how this is to be

undertaken. Similarly change-over from using the ECA compliant fuel oil is not to commence

until after exiting the ECA. At each change-over it is required that the quantities of the ECA

compliant fuel oils onboard are recorded, together with the date, time and position of the ship

when either completing the change-over prior to entry or commencing change-over after exit

from such areas. These records are to be made in a logbook as prescribed by the ships flag

State, in the absence of any specific requirement in this regard the record could be made, for

example, in the ships Annex I Oil Record Book.

The first level of control in this respect is therefore on the actual sulphur content of the fuel

oils as bunkered. This value is to be stated by the fuel oil supplier on the bunker delivery note

and hence this, together with other related aspects, is directly linked to the fuel oil quality

requirements as covered under regulation 18 . Thereafter it is for the ships crew to ensure, in

respect of the ECA compliant fuel oils, that through avoiding loading into otherwise part filled

storage, settling or service tanks, or in the course of transfer operations, that such fuel oils do

not become mixed with other, higher sulphur content fuel oils, so that the fuel oil as actually

used within an ECA exceeds the applicable limit.

Consequently, regulation 14 provides both the limit values and the means to comply.

However, there are other means by which equivalent levels of SOx and particulate matter

emission control, both outside and inside ECA, could be achieved. These may be divided into

methods termed primary (in which the formation of the pollutant is avoided) or secondary (in

which the pollutant is formed but subsequently removed to some degree prior to discharge of

the exhaust gas stream to the atmosphere). Regulation 4.1 allows for the application of such

methods subject to approval by the Administration.

As of October 2010 there are no guidelines in respect of any primary methods (which could

encompass, for example, onboard blending of liquid fuel oils or dual fuel (gas / liquid) use).

In terms of secondary control methods, guidelines (MEPC.184(59)) have been adopted for

exhaust gas cleaning systems which operate by water washing the exhaust gas stream prior to

discharge to the atmosphere, in using such arrangements there would be no constraint on the

sulphur content of the fuel oils as bunkered other than that given the systems certification.

Bunker Fuel Analysis

ensures marine fuel oil quality.

helps prevent costly ship engine failure, downtime, and repairs.

Analyzing marine bunker fuel also helps ship owners meet marine fuel

environmental regulatory compliance.

Bunker analysis labs analyze to ISO 8217, Marpol Annex VI and other

industry specifications.

Bunker fuel testing and inspection capabilities are located in major

shipping centers around the world, including Singapore, Rotterdam,

Shanghai, Panama, UK, UAE, and the USA.

Bunker fuel oil analysis and inspection:

Asphaltenes

Carbon Residue

Density at 15 C,

Flashpoint

Hydrogen Sulfide IP 570

Microbes Contamination

Pour Point

Stability

Sulfur content,

Total Sediment Potential (TSP)

Kinematic Viscosity

Water Content

Bunker Fuel Chemical Contamination Screening

Cetane index,

Acid number

Oxidation stability

Cloud point

Lubricity

Appearance

ISO 8217 bunker fuel oil testing capabilities:

ISO 2719: Flash Point, Pensky-Martens

ISO 3679: Flash point, rapid equilibrium

ISO 3015: Cloud Point

ISO 3016: Pour Point

ISO 3104: Kinematic viscosity

ISO 3675: Density, Hydrometer method

ISO 12185: Density, Oscillating U-tube

ISO 3733:Water Content

ISO 4264: Cetane index

ISO 6245: Ash content

ISO 8754: Sulfur content, energy-dispersive x-ray (XRF)

ISO 14596: Sulfur content, wavelength-dispersive x-ray (XRD)

ISO 103071: Total sediment

ISO 10307-2: Total sediment

ISO 10370: Carbon residue

ISO 10478: Aluminium and silicon in fuel oils (ICP, AA)

ISO 12156-1: Lubricity (HFRR)

ISO 12205: Oxidation stability

ISO 8217 bunker fuel oil testing capabilities:

ISO 12937: Water content, Karl Fischer titration

ISO 14597: Vanadium and Nickel content

EN 14078: Fatty acid methyl ester (FAME) content

EN 14214: Fatty acid methyl esters (FAME) for diesel

IP 470: Aluminium, Silicon, Vanadium, Nickel, Iron, Calcium, zinc and Sodium in residual fuel

oil

IP 500: Phosphorus content of residual fuels by ultra-violet spectrometry

IP 501: Aluminium, Silicon, Vanadium, Nickel, Iron, Sodium, Calcium, Zinc and Phosphorus in

residual fuel oil

IP 570: H2S Testing for Bunker Fuels (Hydrogen Sulfide in bunker fuel oils)

ASTM D664-09: Acid Number

ASTM D6751: Biodiesel fuel blend stock (B100)

Bunker Fuel Adulterant Testing ISO 8217

Marine bunker fuel testing detects and identifies adulterants which can harm ship engines

and violate emission regulations.

Marine bunker fuels should not contain added substances or chemical waste products, per

section 5 of ISO-8217.

Adulterated Bunker Fuel jeopardizes the safety of ships, adversely affects the performance

of machinery, and may prove harmful to personnel and the environment.

Adulterated bunker fuel incidents occur when marine bunker fuels are blended with

chemical waste products such as styrene, chlorinated solvents, and other volatile solvents.

Bunker Fuel Chemical Contamination Screening

GC/MS (Gas chromatography/Mass Spectrometry) analysis for detecting volatile

contaminants in bunker fuel - A small amount of fuel oil is heated in a sealed vial for one

hour, after which time a portion of the vapour above the sample is taken for GC/MS

analysis. Solvents, such as chlorinated compounds, dry cleaning fluids, and chemical

wastes such as styrene, are easily detectable down to low ppm levels.

additional tests

ISO-8217 bunker fuel oil tests:

Kinematic Viscosity

Density at 15 C, ISO-3675 or ISO-12185

Cetane index, ISO-4264

Sulfur content, ISO-8754, ISO-14596

Flash Point Test, ISO-2719

Hydrogen sulfide, IP570

Acid number, ASTM D664

Total sediment by hot filtration, ISO-103071

Oxidation stability, ISO-12205

Carbon residue, ISO-10370

Cloud point, ISO-3015

Pour point, ISO-3016

Appearance

Water volume, ISO-3733

Ash, ISO-6245

Lubricity, ISO-121561

additional tests

You might also like

- Pipeline Arrangement in Oil TankersDocument11 pagesPipeline Arrangement in Oil TankersManpreet SinghNo ratings yet

- Marine Fuel Oil Bunker IngDocument85 pagesMarine Fuel Oil Bunker IngJuan Ramón Fuentes67% (3)

- LPG Co-MinglingDocument17 pagesLPG Co-Minglingderhgawenrahul100% (1)

- Bunker Delivery NoteDocument3 pagesBunker Delivery NoteMugilrajan Devarajan100% (2)

- Remediation Proposal For The Fukushima Daiichi Nuclear Power7dec2015 r9Document40 pagesRemediation Proposal For The Fukushima Daiichi Nuclear Power7dec2015 r9api-313099740100% (1)

- Emergency Engine Operation PDFDocument4 pagesEmergency Engine Operation PDFAnakin SkywalkerNo ratings yet

- Norwegian Training Center Bilge Water Waste Oil Operation Management PDFDocument141 pagesNorwegian Training Center Bilge Water Waste Oil Operation Management PDFLuis100% (3)

- Bunkering Code of Practice PDFDocument62 pagesBunkering Code of Practice PDFsijuwolaoluranti100% (3)

- Wall Wash TestDocument5 pagesWall Wash Testutkarshgahtori100% (1)

- Bilge Water Instructions & Requirements - ENDocument5 pagesBilge Water Instructions & Requirements - ENclaudioNo ratings yet

- Purifier OverhaulDocument27 pagesPurifier OverhaulMedha Jog KatdareNo ratings yet

- Astm F496Document8 pagesAstm F496Aditya ManNo ratings yet

- Study On The Stoichiometry and Reaction Products of Extra Virgin Olive Oil OzonationDocument5 pagesStudy On The Stoichiometry and Reaction Products of Extra Virgin Olive Oil OzonationAlexiss Chavez-De la Mora100% (1)

- 11 Marine Fuel Properties.Document7 pages11 Marine Fuel Properties.Kevin LeysonNo ratings yet

- A Masters Guide To Using Fuel Oil Onboard ShipsDocument74 pagesA Masters Guide To Using Fuel Oil Onboard ShipsPatetico Pianto LupoNo ratings yet

- Tier III SCR For Large 2-Stroke MAN B&W Diesel EnginesDocument6 pagesTier III SCR For Large 2-Stroke MAN B&W Diesel EnginesWon-young SeoNo ratings yet

- Fuel Oil Analysis: Know The Condition of The Fuel Oils You Use!Document6 pagesFuel Oil Analysis: Know The Condition of The Fuel Oils You Use!lolo100% (1)

- Tricks of Bunker SupplyDocument5 pagesTricks of Bunker SupplyrubinoestelaNo ratings yet

- Lloyds FOBAS Guidance On CominglingDocument11 pagesLloyds FOBAS Guidance On CominglingBruno KosNo ratings yet

- CH 0 Cleaning Cross Refference Table DREW AMEROIDDocument36 pagesCH 0 Cleaning Cross Refference Table DREW AMEROIDPavel ViktorNo ratings yet

- Bunker EbookDocument76 pagesBunker EbookNatalia Moskvitina100% (1)

- Inert Gas OverviewDocument6 pagesInert Gas OverviewRahulChoudharyNo ratings yet

- MSC 1 Circ 1511 - Unified Interpretations of SOLAS Regulations II-2 - 9 & II-2 - 13Document9 pagesMSC 1 Circ 1511 - Unified Interpretations of SOLAS Regulations II-2 - 9 & II-2 - 13Goh Boon TiongNo ratings yet

- Fuel Oil AnalysisDocument6 pagesFuel Oil AnalysisPawan BeniwalNo ratings yet

- Khaksar KhanDocument36 pagesKhaksar KhanAlsamad Borkar100% (1)

- BunkeringDocument26 pagesBunkeringPaul Abonita100% (2)

- Properties of Fuel Oil and Bunkering Pro PDFDocument34 pagesProperties of Fuel Oil and Bunkering Pro PDFRajeev Valunjkar100% (1)

- Amspec Techtalk Hydrogen Sulfide - h2s 4Document3 pagesAmspec Techtalk Hydrogen Sulfide - h2s 4Javier Gomez TorregrosaNo ratings yet

- 3 Fuel Properties and EffectsDocument28 pages3 Fuel Properties and EffectsZohaib AhmedNo ratings yet

- 9 Oil Pollution Act of 1990Document6 pages9 Oil Pollution Act of 1990Ur Loafer MarinerNo ratings yet

- Marpol Annex VDocument3 pagesMarpol Annex VJulio Chavez DiazNo ratings yet

- Man B W Two Stroke Engine Operating On AmmoniaDocument18 pagesMan B W Two Stroke Engine Operating On Ammoniasimhadri sanganiNo ratings yet

- Oral-Preparation-Guide (Rifat Azad-Bma 49) PDFDocument105 pagesOral-Preparation-Guide (Rifat Azad-Bma 49) PDFTarek Aziz100% (2)

- MEO Class 2 Misc Info PDFDocument17 pagesMEO Class 2 Misc Info PDFrajishrrrNo ratings yet

- Bilge Water Management & PollutionDocument12 pagesBilge Water Management & PollutionGeorgios PapakostasNo ratings yet

- Gas CargoesDocument56 pagesGas CargoesTom AlexNo ratings yet

- Marpol Regulations and AnnexesDocument5 pagesMarpol Regulations and AnnexesUtkarsh MathurNo ratings yet

- Amspec Techtalk - Pona PianoDocument4 pagesAmspec Techtalk - Pona PianoUmarFidaNo ratings yet

- Oil Record Book Cum Se Completeaza Corect 15.10.2018Document29 pagesOil Record Book Cum Se Completeaza Corect 15.10.2018Popa VasileNo ratings yet

- Watchkeeping and TroubleshootingDocument16 pagesWatchkeeping and TroubleshootingAditya Joglekar100% (1)

- Marpol Annex 6Document11 pagesMarpol Annex 6tripuraridheerajNo ratings yet

- Pentane Msds Praxair p6229Document8 pagesPentane Msds Praxair p6229Michael SchreiberNo ratings yet

- Oil Record 15.10.2018Document18 pagesOil Record 15.10.2018Popa VasileNo ratings yet

- Measuring Propeller Drop With The Help of Poker GaugeDocument2 pagesMeasuring Propeller Drop With The Help of Poker Gaugeas100% (1)

- VLSFO FUEL CharacterDocument5 pagesVLSFO FUEL CharacterDad’s Adventures LanderoNo ratings yet

- Disposal For Spilled Oil and Prevention For Secondary DisasterDocument4 pagesDisposal For Spilled Oil and Prevention For Secondary DisasterIonescu EdaNo ratings yet

- Revised MARPOL Annex VDocument6 pagesRevised MARPOL Annex VDiana MoralesNo ratings yet

- Objective and Purpose of Boiler Water TestDocument3 pagesObjective and Purpose of Boiler Water TestAayush AgrawalNo ratings yet

- Amspec Techtalk A Stands For API Gravity 4Document5 pagesAmspec Techtalk A Stands For API Gravity 4Sudea CadabaNo ratings yet

- M2 Pipe Identification Tape To ISO14726Document1 pageM2 Pipe Identification Tape To ISO14726chrisNo ratings yet

- Bunkering ProcedureDocument4 pagesBunkering ProcedureVinay Gupta100% (2)

- Oral Question and AnswerDocument179 pagesOral Question and AnswerMariyath Muraleedharan Kiran100% (1)

- Gasoline FAQ 1Document9 pagesGasoline FAQ 1Claudia MmsNo ratings yet

- 010 Marine Fuel Handling and Pre-TreatmentDocument2 pages010 Marine Fuel Handling and Pre-TreatmentKhasy Jeans P. Tampos100% (1)

- Simplified VOC Management Plan, RevDocument11 pagesSimplified VOC Management Plan, RevSumeet SawantNo ratings yet

- 09 - Cargo Heating - Operational Advice PDFDocument4 pages09 - Cargo Heating - Operational Advice PDFrpichoNo ratings yet

- E23a ISGOTT Bunker ChklistDocument4 pagesE23a ISGOTT Bunker Chklistvic.barca2012100% (1)

- Inventory of Hazardous Materials (IHM) - A Brief Explanation - Ship TechnologyDocument5 pagesInventory of Hazardous Materials (IHM) - A Brief Explanation - Ship Technologyanand raoNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- OILDocument4 pagesOILJoão LucasNo ratings yet

- Marine FuelDocument17 pagesMarine FuelviviwulanNo ratings yet

- Marine Fuels - SpecificationDocument13 pagesMarine Fuels - SpecificationMetehan İlbayNo ratings yet

- OM - Marine Fuel Oil - 2 - Standards & HandlingDocument103 pagesOM - Marine Fuel Oil - 2 - Standards & Handlingroberto luckyNo ratings yet

- Gear Oil: Function of A Gear LubricantDocument2 pagesGear Oil: Function of A Gear LubricantMedha Jog KatdareNo ratings yet

- Ac and DC Solenoid ValvesDocument3 pagesAc and DC Solenoid ValvesMedha Jog KatdareNo ratings yet

- Housekeeping: Storage On DeckDocument3 pagesHousekeeping: Storage On DeckMedha Jog KatdareNo ratings yet

- What Is Grease?Document5 pagesWhat Is Grease?Medha Jog KatdareNo ratings yet

- Scavenge FireDocument4 pagesScavenge FireMedha Jog KatdareNo ratings yet

- Classification of PumpsDocument22 pagesClassification of PumpsMedha Jog KatdareNo ratings yet

- Dismantling of Horizontal ShaftDocument2 pagesDismantling of Horizontal ShaftMedha Jog KatdareNo ratings yet

- Scavenge FireDocument4 pagesScavenge FireMedha Jog KatdareNo ratings yet

- Dynamics of RotationDocument32 pagesDynamics of RotationMedha Jog KatdareNo ratings yet

- Cargo Pumping SystemDocument24 pagesCargo Pumping SystemMedha Jog Katdare100% (2)

- Ship-Shore Safety Check List For TankersDocument6 pagesShip-Shore Safety Check List For TankersMedha Jog Katdare67% (3)

- Formulae and Definitions in MathematicsDocument71 pagesFormulae and Definitions in MathematicsMedha Jog Katdare100% (1)

- Mitsubishi Hiden SystemsDocument3 pagesMitsubishi Hiden SystemsMedha Jog KatdareNo ratings yet

- Stern Tube BoringDocument2 pagesStern Tube BoringMedha Jog KatdareNo ratings yet

- Typical Engine Room CraneDocument12 pagesTypical Engine Room CraneMedha Jog Katdare100% (3)

- Propeller RemovalDocument10 pagesPropeller RemovalMedha Jog Katdare100% (1)

- Lifesaving EquipmentDocument31 pagesLifesaving EquipmentMedha Jog KatdareNo ratings yet

- STPM Biology Past Year QuestionDocument8 pagesSTPM Biology Past Year QuestionMc Donalds Ohl Ohlsen100% (2)

- FDA PresentationDocument27 pagesFDA PresentationTimothy William C. Laurence100% (1)

- DownloadDocument174 pagesDownloadyattsudrajatNo ratings yet

- Feinguss in India - Sumangal CastingDocument2 pagesFeinguss in India - Sumangal Castingsumangal castingNo ratings yet

- Electron Transfer at Different Electrode MatDocument13 pagesElectron Transfer at Different Electrode MatAbeerNo ratings yet

- Inspire Cast Final 2021 TreinamentoDocument197 pagesInspire Cast Final 2021 TreinamentoDave DaveNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- A Pre-Concentration and Online Solid Phase Extraction Setup For The LC-MS Analysis of Therapeutic Protein MixturesDocument8 pagesA Pre-Concentration and Online Solid Phase Extraction Setup For The LC-MS Analysis of Therapeutic Protein MixturesReactivos Para-AnalisisNo ratings yet

- Muhammad Quthbil Irsyad 4311419042 Chemistry-2Document2 pagesMuhammad Quthbil Irsyad 4311419042 Chemistry-2Muhammad Quthbil IrsyadNo ratings yet

- Certificate No. 273 Technical Methanol Grade A: No. Indicator Name Test Method Actual ValueDocument2 pagesCertificate No. 273 Technical Methanol Grade A: No. Indicator Name Test Method Actual Valueذياب الكايدNo ratings yet

- Mid Static Pressure-DUCTEDDocument29 pagesMid Static Pressure-DUCTEDsyed mustafa aliNo ratings yet

- Atom WorksheetsDocument4 pagesAtom Worksheetsapi-271960049100% (1)

- MigDocument6 pagesMigPensel KoNtotNo ratings yet

- Aaac 1120Document1 pageAaac 1120TriSanNo ratings yet

- PSD200912 Meter PG 46 PDFDocument84 pagesPSD200912 Meter PG 46 PDFosamamae100% (1)

- Research Project Data e LogbookDocument8 pagesResearch Project Data e LogbookEl John CalicaNo ratings yet

- TDS Celvolit 1326 (SG)Document2 pagesTDS Celvolit 1326 (SG)Duc Nguyen100% (1)

- Manual For Making TEM Samples Using FIBDocument8 pagesManual For Making TEM Samples Using FIBfgsgdNo ratings yet

- Long Test As Level Nucleic AcidDocument9 pagesLong Test As Level Nucleic AcidPrisky Jofan SimbarNo ratings yet

- MSDS - DK PGT Paste R27Document4 pagesMSDS - DK PGT Paste R27RND PT SIPNo ratings yet

- Branching and Control Manual With Dupont Engineering PolymersDocument24 pagesBranching and Control Manual With Dupont Engineering PolymersKaman LoNo ratings yet

- Models Relating Mixture Composition To The Density and Strength of Foam Concrete Using Response Surface Methodology - Nambiar & Ramamurthy 2006 PDFDocument9 pagesModels Relating Mixture Composition To The Density and Strength of Foam Concrete Using Response Surface Methodology - Nambiar & Ramamurthy 2006 PDFalexnlima852No ratings yet

- General GrindingDocument28 pagesGeneral GrindingRavi Arjun Kumar100% (1)

- Hair Care Tips For High Porosity HairDocument10 pagesHair Care Tips For High Porosity HairJuanGuillermoCarmonaOcampo0% (1)

- Vigogrease Re0 Msds 07-750 1Document5 pagesVigogrease Re0 Msds 07-750 1FlintLockwoodNo ratings yet

- Major Paper On Development of Novel Self Healing Concrete Using Carbon NanotubesDocument7 pagesMajor Paper On Development of Novel Self Healing Concrete Using Carbon NanotubesVujjini RaghuNo ratings yet

- Soundness of Aggregates by Use of Sodium Sulfate or Magnesium SulfateDocument5 pagesSoundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfatekordef zeminNo ratings yet

- Why Is Rigor Mortis Absent in AnthraxDocument25 pagesWhy Is Rigor Mortis Absent in Anthraxravigg100% (2)