Professional Documents

Culture Documents

Characterization Techniques and Epitaxy

Characterization Techniques and Epitaxy

Uploaded by

Ramakrishnan RamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Characterization Techniques and Epitaxy

Characterization Techniques and Epitaxy

Uploaded by

Ramakrishnan RamCopyright:

Available Formats

Carrier Mobility and Velocity

Mobility - the ease at which a carrier

(electron or hole) moves in a

semiconductor

Symbol:

n

for electrons and

p

for holes

Drift velocity the speed at which a

carrier moves in a crystal when an electric

field is present

For electrons: v

d

=

n

E

For holes: v

d

=

p

E

Drift Currents

( )

( )

( )E p n Aq I

L

V

E

p n Aq

L

V

I

p n q A

L

V

R

V

I

o p o n

a

o p o n

a

o p o n

a a

+ =

=

+ =

|

|

.

|

\

|

+

= =

1

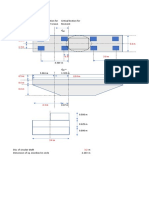

Four Point Probe

Probe tips must make

an Ohmic contact

Useful for Si

Not most compound

semiconductors

S when t

2 ln

S when t 2

<< =

>> =

I

V t

I

V

S

t

t

Diffusion

When there are changes in the

concentration of electrons and/or holes

along a piece of semiconductor

the Coulombic repulsion of the carriers force

the carriers to flow towards the region with a

lower concentration.

Diffusion Currents

( )

o p o n diff diff

diff

o

p o p diff

diff

o

n o n diff

diff

p D n D q J J

A

I

dx

dp

qD p qD J

A

I

dx

dn

qD n qD J

A

I

p n

p

p

n

n

V V = + =

= V = =

= V = =

Relationship between Diffusivity

and Mobility

q

kT

D

q

kT D

p

p

n

n

=

=

Mobility vs. Dopant Concentration

in Silicon

http://www.ioffe.ru/SVA/NSM/Semicond/Si/electric.html#Hall

Van der Pauw

Four equidistant Ohmic

contacts

Contacts are small in

area

Current is injected

across the diagonal

Voltage is measured

across the other

diagonal

Top view of Van der Pauw sample

http://www.eeel.nist.gov/812/meas.htm#geom

Calculation

Resistance is determined with and without a

magnetic field applied perpendicular to the

sample.

F

R R

t

R

B

t

H

2 2 ln

14 , 23 34 , 12

24 , 13

+

=

A

=

t

F is a correction factor that takes

into account the geometric shape

of the sample.

Hall Measurement

See http://www.eeel.nist.gov/812/hall.html for a

more complete explanation

http://www.sp.phy.cam.ac.uk/SPWeb/research/QHE.html

Calculation

Measurement of resistance is made while a

magnetic field is applied perpendicular to the

surface of the Hall sample.

The force applied causes a build-up of carriers along

the sidewall of the sample

The magnitude of this buildup is also a function of the

mobility of the carriers

where A is the cross-sectional area.

L

A

R

R R

L

H H

H

= =

N vs. P doping

The sign of the Hall voltage, V

H

, and on

A R

13,24

in the Van der Pauw measurement

provide information on doping.

Epitaxial Material Growth

Liquid Phase Epitaxy (LPE)

Vapor Phase Epitaxy (VPE)

Molecular Beam Epitaxy (MBE)

Atomic Layer Deposition (ALD) or Atomic

Layer Epitaxy (ALE)

Metal Organic Chemical Vapor Deposition

(MOCVD) or Organometallic Vapor Phase

Epitaxy (OMVPE)

MBE

Wafer is moved into the chamber using a

magnetically coupled transfer rod

Evaporation and sublimation of source material

under ultralow pressure conditions (10

-10

torr)

Shutters in front of evaporation ovens allow vapor to

enter chamber, temperature of oven determines

vapor pressure

Condensation of material on to a heated wafer

Heat allows the atoms to move to appropriate sites to

form a crystal

Schematic View

http://web.tiscali.it/decartes/phd_html/III-Vms-mbe.png

http://www.mse.engin.umich.edu/research/facilities/132/photo

http://ssel-front.eecs.umich.edu/Projects/proj00630002.jpg

Advantages

Slow growth rates

In-situ monitoring of growth

Extremely easy to prevent introduction of

impurities

Disadvantages

Slow growth rates

Difficult to evaporate/sublimate some

materials and hard to prevent the

evaporation/sublimation of others

Hard to scale up for multiple wafers

Expensive

MOCVD

Growths are performed at room pressure or low

pressure (10 mtorr-100 torr)

Wafers may rotate or be placed at a slant to the

direction of gas flow

Inductive heating (RF coil) or conductive heating

Reactants are gases carried by N

2

or H

2

into

chamber

If original source was a liquid, the carrier gas is

bubbled through it to pick up vapor

Flow rates determines ratio of gas at wafer surface

Schematic of MOCVD System

http://nsr.mij.mrs.org/1/24/figure1.gif

http://www.semiconductor-today.com/news_items/2008/FEB/VEECOe450.jpg

Advantages

Less expensive to operate

Growth rates are fast

Gas sources are inexpensive

Easy to scale up to multiple wafers

Disadvantages

Gas sources pose a potential health and

safety hazard

A number are pyrophoric and AsH

3

and PH

3

are highly toxic

Difficult to grow hyperabrupt layers

Residual gases in chamber

Higher background impurity

concentrations in grown layers

Misfit Dislocations

Occur when the difference between the

lattice constant of the substrate and the

epitaxial layers is larger than the critical

thickness.

http://www.iue.tuwien.ac.at/phd/smirnov/node68.html

Critical Thickness, t

C

where

b is the magnitude of the lattice distortion caused by a

dislocation (Burger vector)

f is the mismatch between the lattice constants of film

and the substrate

v is Poissons ratio (transverse strain divided by the axial

strain).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Critical Section For Moment Critical Section For Shear and TorsionDocument7 pagesCritical Section For Moment Critical Section For Shear and TorsionShashank Srivastava0% (1)

- SiC EpitaxyDocument48 pagesSiC EpitaxyRamakrishnan RamNo ratings yet

- SOP 2 KaustDocument3 pagesSOP 2 KaustAbu Suraisy100% (1)

- Application of Soft-Hard MagnetsDocument31 pagesApplication of Soft-Hard MagnetsRamakrishnan RamNo ratings yet

- Events That Shook The WorldDocument11 pagesEvents That Shook The WorldRamakrishnan RamNo ratings yet

- SuperconductorsDocument19 pagesSuperconductorsRamakrishnan Ram100% (1)

- 353 Xtal GrowthDocument5 pages353 Xtal GrowthRamakrishnan RamNo ratings yet

- MNW Lect Quant TunnelingDocument7 pagesMNW Lect Quant TunnelingRamakrishnan RamNo ratings yet

- Review of Shape Memory Alloy As Damping Material For Vibration ControlDocument9 pagesReview of Shape Memory Alloy As Damping Material For Vibration Controlletter_ashish4444No ratings yet

- Id 19Document13 pagesId 19Fernando SolisNo ratings yet

- Lec 11Document39 pagesLec 11renNo ratings yet

- Acta Materialia: T.C. Su, C. O'Sullivan, T. Nagira, H. Yasuda, C.M. GourlayDocument18 pagesActa Materialia: T.C. Su, C. O'Sullivan, T. Nagira, H. Yasuda, C.M. GourlayAT8iNo ratings yet

- Nanoelectronics: ECT292 Category L T P CreditDocument7 pagesNanoelectronics: ECT292 Category L T P CreditanoopegNo ratings yet

- Design Calculation of Pier Cap With 30.050 M Overall Length of Superstructure in Curved Alignment - R0 - DN-D07Document25 pagesDesign Calculation of Pier Cap With 30.050 M Overall Length of Superstructure in Curved Alignment - R0 - DN-D07Partha Gangopadhyay100% (1)

- Rak-43 3136 Prestressed Section Elastic ShorteningDocument2 pagesRak-43 3136 Prestressed Section Elastic ShorteningrammirisNo ratings yet

- Heat Transfer Short Notes PDFDocument35 pagesHeat Transfer Short Notes PDFBishal BortamulyNo ratings yet

- Sheep Wool ConcreteDocument10 pagesSheep Wool Concretesharin vargheseNo ratings yet

- JEE Main Polymers Revision Notes - Free PDF DownloadDocument8 pagesJEE Main Polymers Revision Notes - Free PDF Downloadpurple youNo ratings yet

- Steam Tables in Excel (By IIT, Mumbai)Document14 pagesSteam Tables in Excel (By IIT, Mumbai)myself_riteshNo ratings yet

- Ejercicio Resuelto de Tema Semana 4Document6 pagesEjercicio Resuelto de Tema Semana 4tomNo ratings yet

- International Society For Rock Mechanics Commission On Standardization of Laboratory and Field TestsDocument3 pagesInternational Society For Rock Mechanics Commission On Standardization of Laboratory and Field TestsJimmy AngelNo ratings yet

- Welding of Heat-Resisting Steels: Material For May 7th 2010Document43 pagesWelding of Heat-Resisting Steels: Material For May 7th 2010ABRAHAM SILVA HERNANDEZNo ratings yet

- AO204 Aircraft Structures - I PDFDocument2 pagesAO204 Aircraft Structures - I PDFVIGNESH RAJNo ratings yet

- Development and Application of Precast Concrete Double Wall System To Improve Productivity of Retaining Wall ConstructionDocument12 pagesDevelopment and Application of Precast Concrete Double Wall System To Improve Productivity of Retaining Wall ConstructionVasthy Jael Diaz GellNo ratings yet

- Metallurgical Features of NANOHITEN and Application To Warm StampingDocument6 pagesMetallurgical Features of NANOHITEN and Application To Warm Stampingdhafi keceNo ratings yet

- Method of Least Work: Swedish College of Engineering & Technology, Wah CanttDocument98 pagesMethod of Least Work: Swedish College of Engineering & Technology, Wah CanttpraveennagarajanNo ratings yet

- Martensitic Stainless SteelsDocument8 pagesMartensitic Stainless SteelsAdilmar E. NatãnyNo ratings yet

- China Steel PDFDocument38 pagesChina Steel PDFKalpeshNo ratings yet

- Failure Analysis of A Diesel Generator Connecting Rod PDFDocument8 pagesFailure Analysis of A Diesel Generator Connecting Rod PDFLeyner Ignacio CorreaNo ratings yet

- Experimental Research On The Behaviour of High Frequency Fatigue in ConcreteDocument10 pagesExperimental Research On The Behaviour of High Frequency Fatigue in Concreteming_zhu10No ratings yet

- Thermal Effects On MaterialsDocument37 pagesThermal Effects On MaterialsChockkalingam SubramanianNo ratings yet

- Part 1 CEAT - Post Installed Anchor - Design 2013revDocument79 pagesPart 1 CEAT - Post Installed Anchor - Design 2013revTanawat NuchNo ratings yet

- Padeye - SkidDocument16 pagesPadeye - SkidNaresh Kumar100% (1)

- Theory of Elasticity and PlasticityDocument3 pagesTheory of Elasticity and Plasticityrameshbabu_1979100% (1)

- Magnetic Materials PhyDocument18 pagesMagnetic Materials PhyMamidi Satya narayana100% (1)

- Embrittlement of Nylon in Arid EnvironmentsDocument78 pagesEmbrittlement of Nylon in Arid EnvironmentsSteven_Bolwing100% (1)