Professional Documents

Culture Documents

01 Dedusting Equipment

01 Dedusting Equipment

Uploaded by

rudye kardunOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 Dedusting Equipment

01 Dedusting Equipment

Uploaded by

rudye kardunCopyright:

Available Formats

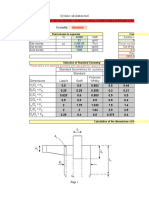

Dedusting Equipment

2

Dedusting Equipment

Bag filter

Electrostatic precipitator

Electrostatic Precipitators

4

The electrode system

Gasflow

Gap width

250400 mm

Max. field

height

12,5 m

Discharge electrodes

5

3 steps for particle collection

Charging precipitation rapping

mA

kV

Migration

velocity

(~6-14 cm/s and

thus ~60% of dust

collected within first 3 m

~84% in 6 m,

~94% in 9 m,

~98% in 12 m)

6

Charging Precipitation - Rapping

Charging you need mA

7

More power input improves the dust emission

Dust

Emission

kW

Potential for improvement

kW ~ kV

avg

x

mA

avg

Curve from test

8

Charging Precipitation - Rapping

Precipitation

you need kV

9

Conditioning with water improves EP efficiency

0

20

40

60

80

100

120

140

160

180

45 47 49 51 53 55 57 59 61

Dew point

[C]

C

l

e

a

n

g

a

s

d

u

s

t

c

o

n

t

e

n

t

r

[

m

g

/

N

m

3

d

r

y

]

design point

Potential for improvement

Example

e.g.: 38 g/Nm

3

more water

(5.4 m

3

/h for a 2000 tpd kiln)

or 63C lower CT exit temp.

10

How to increase Moisture?

Improve conditioning tower efficiency with better water

evaporation and lower the EP inlet temperature

Flow distribution optimization (new CT inlet?)

If Spillback nozzles:

Higher water pressure (new pumps?)

Optimize control loops (new control valve?)

Change to Dual fluid nozzles (only if flow distribution is OK)

If Dual fluid nozzles:

Higher atomizing air throughput (add compressor?)

11

Exponential impact of flow on dust emission

0

10

20

30

40

50

60

70

80

90

100

80 85 90 95 100 105 110 115 120

Relative gas flow Q [%]

C

l

e

a

n

g

a

s

d

u

s

t

c

o

n

t

e

n

t

r

[

m

g

/

N

m

3

d

r

y

]

design point

12% more gas can double dust emissions

Example

12

Local condensation when false air enters

13

Charging Precipitation - Rapping

Rapping

14

The rapping system

15

Without grounding still 3000 Volt in a shut off filter

Remove fuses from controller

Local grounding of T/R-set and EP roof isolator

Local grounding of each electrical field directly at

inspection door

T/R-set

Almost good

Discharge electrodes

16

CO Trip

17

Zero Dust Clouds

If above 6% O

2

, then

explosion risk already at low

CO concentrations

In presence of H

2

or CH

4

from incomplete combustion

the critical CO limit is very

low

H

2

/CO ratio up to 2

[normal: 0.1 1.0]

Explosion limit in any case

around 2.0 vol-% CO

Explosive

Range (200C)

O

2

[vol-%]

C

O

[

v

o

l

-

%

]

0 vol-% H

2

1 vol-% H

2

2 vol-% H

2

3 vol-% H

2

18

An EP is a selective dust collector

Dust that is easy to collect is mainly in the first zones,

while difficult dust is concentrated in the last zones

Difficult dust:

Very fine dust <1mm (having a high specific surface an thus

enriched in absorbed substances e.g. Hg)

Salts (KCl, NaCl, K

2

SO

4

, Na

2

SO

4

)

Dust extraction from last fields to open the outer cycles

is state of the art and highly recommended

Effect can be used for CKD minimization

19

Changed conditions due to AFR can have

an impact on EP performance

More CO peaks due to instable combustion (fuel feed,

net calorific value)

Higher gas flow rate (due to higher heat consumption or

additional water)

More Cl, SO

3

, NH

3

can lower the EP performance:

sublimates bypassing the electrical zones

space charge suppressing the filter current

sticky material builds-up and lowers the field strength

Organic matter can lower the conductivity of dust and

cause effects that look like back corona

Dedusting: Bag Filters

21

Bag Filter Technologies

Reverse Gas Bag Filter

Pulse Jet Bag Filter

High or Low pressure online cleaning

Offline cleaning

Quasi offline cleaning

Hybrid Filters

Serial EP/BF-part

Parallel EP/BF-part

(advanced hybrid from Elex, discontinued)

22

Velocities have main impact on function

1. Filtration

(Formation of dust cake)

2. Cleaning

(Moving cake into hopper)

Critical parameters

air-to-cloth ratio (~1 m/min) can(yon)-velocity (~1 m/s)

= gas flow rate / fabric area = gas flow rate / tubesheet area w/o bag area

Critical for pressure difference Critical for dust accumulation

23

Cleaning Principles of Bag Filters

a, b: manual or mechanical, by rapping or shaking

c: mechanical, by vibrating

d: pneumatic, by reverse air flow (often combined with shaking or vibrating)

e: pneumatic, by compressed air (pulse jet)

Vibrator

24

Reverse Gas Bag Filter: The Vacuum Cleaner

Dust emission <10-30

mg/Nm

3

Typically 12-15 mbar at

air-to-cloth ratio 0.6

m

3

/m

2

min

Large footprint

(n-1) chamber operation

requires many chambers

Dp

Filtration Cleaning

25

Cleaning Cycles Reverse Gas Bag Filter

Purge Air

Valve

Deflation Valve Outlet Valve

Clean Gas

Outlet

Purge Air

Shaking

Mechanism

Tubesheet

Dust Extraction

Purging

Maintenance

Bypass

Valve

Dirty

Flue

Gas Inlet

Filtering

Inlet

Valve

Null Deflation Cleaning

(Shake)

Thimble

Deflation Gas

26

Pulse Jet

Holcim State of the art

Dust emission <10-20 mg/Nm

3

Typically: 10-12 mbar at air-to-

cloth ratio 1.0 m

3

/m

2

min

Small footprint and ideal for

EP conversion

n-chambers nice to have

Clean gas side

compartmentalized is

recommended

Dp

Filtration Cleaning

27

Pulse Jet Cleaning

Compressed Air

Inlet Valve

Tube

sheet

Clean Gas

outlet

Cage

Compressor

or Blower

Outlet Valve

Dust Disposal

Bypass

Valve

Gas Inlet

Filtering Maintenance Pulse-Jet

Cleaning

Filtering

28

Pulse Jet Cleaning Mode: Online

Standard mode (the most

common filter and cleaning type)

No compartmentalization

required

No division walls required and

thus dust transport from

converted EPs can be reused

Can velocity is limiting the filter

geometry

29

Pulse Jet Cleaning Mode: Offline

Unusual mode, but good when

intensive cleaning required (helps only

for a short time, if root cause not

solved)

Can velocity has no impact on cleaning

operation

On-line maintenance possible (seldom

used in kiln filters; safety issue)

Requires new dust transport when

converting EPs

Requires additional inlet dampers

Allows to shut-off compartment with

broken bag

30

Pulse Jet Cleaning Mode: Quasi Offline

No can velocity impact

Low air consumption and low

cleaning pressure

Allows to shut-off compartment

with broken bag

No division walls required and

thus dust transport from

converted EPs can be reused

31

Hybrid Filter

Up to 90% pre-collection of

dust in EP part, thus lower

bag load

Electrically charged residual

dust forms permeable dust

layer resulting in low diff.

pressure

Possibly better for PM2.5

High investment, low

operating costs

Attractive if system fan and

EP parts can be reused

Short CO shut-down of EP

part has no big impact on

operation

Both filter parts need

maintenance (two systems)

33

Needle Felt

Penetration of fine dust

particles into fabric and thus

continuously increasing diff.

pressure during bag life

Cleaning pulse dust peaks

Average: <20 mg/Nm

3

dust

emission

Enhancement with PTFE-

coating possible

Life guarantee between 2 y

and 4 y

34

Woven glass fiber with PTFE Membrane

Slightly higher fabric

resistance during first few

month

Negligible dust penetration

and negligible dust peaks from

cleaning pulses

Average: < 10 mg/Nm

3

Careful installation required

High gas velocities can cause

bag damage more easily

Life guarantee from 4 y to

4 y + 2 y pro rata

35

Bag Life

Differential Pressure over Filter fabric

0

2

4

6

8

10

12

14

16

18

1 10 100 1000 10000 100000

Operating time [hr]

F

a

b

r

i

c

d

i

f

f

e

r

e

n

t

i

a

l

p

r

e

s

s

u

r

e

[

m

b

a

r

]

Early clogging phase Bag midlife phase End

Logarithmic time scale

36

Differential Pressure Reaction

Bag filter reaction to gas flow increase

0

5

10

15

20

25

0 20 40 60 80 100 120 140 160 180 200

Gas flow [% from design]

F

i

l

t

e

r

d

i

f

f

e

r

e

n

t

i

a

l

p

r

e

s

s

u

r

e

[

m

b

a

r

]

0

2

4

6

8

10

C

l

e

a

n

i

n

g

c

y

c

l

e

s

p

e

r

h

o

u

r

[

1

/

h

]

Sufficient dust cake for bag protection

(Distance arrow proportional to cake thickness)

Continuous cleaning,

no bag protection

High can-velocity

hinders dust settling,

filter out of control

Cleaning cycle

Diff. pressure

Design

37

Filter Protection

Chemical attack

Acid or water condensation (bag blinding)

respect dew points (water & acid) and do pre-coating

Mechanical attack

Erosion (holes, rips, high emissions)

respect velocity guidelines

Penetration of finest dust (high Dp, high emissions))

do pre-coating

Thermal attack

respect fabric temperature range

and use emergency cooling

38

Pre-coating

First Filter Start-up:

Do Pre-coating with approx. 200 g/m

2

inert material

(e.g. CaCO

3

, Ca(OH)

2

)

e.g. bag filter with 5000 m

2

bag surface 1 ton raw meal being

injected upstream of the bag filter into the gas duct by a rented

silo truck equipped with an on-board compressor

Short Stop (hours up to max. a few days):

deactivate cleaning cycle before stopping the filter

Long Stop (several days to weeks):

clean down the filter as much as possible and do pre-coating before

restarting the filter

39

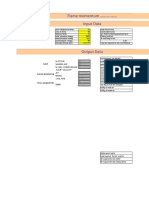

Guide Values for Bag Filters (Pulse Jet)

Inlet velocities (central duct): < 10 m/s

Can velocities: < 1.2 m/s

A/C ratios: < 1.0 m/min

Experience with bag length up to 7m

State of art cleaning: <3.5 bar compressed air

Fabric:

PE (140C) or Nomex (250C) for cooler filter

Glass fiber/membrane (260C), P84 (220C) or Ryton (180C) for

kiln/mill filter

PAN (120C) or PEAC siliconized (140C, lower moisture) for coal mill

filters

PAN (120C) or P84 (250C) for cement mill filters

Safety on system fan: +10% flow, +10 mbar pressure

40

Impact of not meeting the guidelines

41

Corrosion Protection

Filter for combustion gas dedusting

Minimum 30C above acid dew point

Gas temperature <150C:

Epoxy resins

Gas temperature >150C:

Flue Guard 225

Avoid using stainless steel in

presence of Cl and not required if

gas temperature always >180C

Filter for air dedusting

Minimum 20C above water dew

point

FlueGuard 225

Prerequisite

Good insulation (100 mm, rain water

tight) when combustion gas

Avoid cold spots/bridges

You might also like

- 6) Fläkts FansSystem StagECC 2009Document82 pages6) Fläkts FansSystem StagECC 2009hmaza shakeelNo ratings yet

- Welcome To All: Basics of Dedusting (Nuisance) FilterDocument109 pagesWelcome To All: Basics of Dedusting (Nuisance) Filterm_verma21100% (2)

- Bag HouseDocument23 pagesBag HouseTarak A Positive100% (1)

- Bag HouseDocument55 pagesBag HousegovardhanNo ratings yet

- 6 Bag House BasicsDocument27 pages6 Bag House BasicsPANKAJ AGRAHARI100% (1)

- Main Fans: by Daniel Brassel (Cts - TPT)Document41 pagesMain Fans: by Daniel Brassel (Cts - TPT)Mahmoud MohammadNo ratings yet

- The Cement Grinding Office: Home About Us Services Mining AreaDocument3 pagesThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarNo ratings yet

- Company Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Document2 pagesCompany Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Kumaran GopalNo ratings yet

- 10 BagHouseDocument32 pages10 BagHouseSrikant Ch100% (1)

- Cyclone Design Calculation Tool SimplifiedDocument6 pagesCyclone Design Calculation Tool SimplifiedKevin WilliamNo ratings yet

- Belt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldDocument1 pageBelt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldManoj ThakurNo ratings yet

- (Cyclone Separator) PDFDocument11 pages(Cyclone Separator) PDFهاجر صالح جبارNo ratings yet

- Bag FilterDocument27 pagesBag FiltermkpqNo ratings yet

- Bag FiltersDocument18 pagesBag FiltersMehmet C100% (2)

- Bag FilterDocument64 pagesBag FilterAtul Jain100% (1)

- Design Recommendations For Process FiltersDocument8 pagesDesign Recommendations For Process FiltersKenny RuizNo ratings yet

- Data Bag Filter Narogong 2: Polyster Antistatis Polyster Antistatis Polyster Antistatis Polyster AntistatisDocument7 pagesData Bag Filter Narogong 2: Polyster Antistatis Polyster Antistatis Polyster Antistatis Polyster AntistatisSafrin SangiaNo ratings yet

- WHRS and PP For Cement Plants - Todays Boiler Spring 2014Document2 pagesWHRS and PP For Cement Plants - Todays Boiler Spring 2014ash22202No ratings yet

- FIMSUP Double Rows Graphite Sealing For Rotary KilnDocument4 pagesFIMSUP Double Rows Graphite Sealing For Rotary KilnFurqan ShabbirNo ratings yet

- Rotary FurnaceDocument10 pagesRotary Furnaceagbajelola idrisNo ratings yet

- Rotary Kiln SimulatorDocument10 pagesRotary Kiln SimulatorPassmore DubeNo ratings yet

- Can VelocityDocument4 pagesCan VelocityRawatNo ratings yet

- False AirDocument665 pagesFalse AirSantanu PachhalNo ratings yet

- Draft of Chimney CalculationDocument7 pagesDraft of Chimney Calculationshani5573No ratings yet

- Reverse Air Bag House PDFDocument4 pagesReverse Air Bag House PDFRanga VamshiNo ratings yet

- Flowsheet& Theoretical HeatDocument35 pagesFlowsheet& Theoretical HeatRamachandrarao MaddaliNo ratings yet

- KilnDocument2 pagesKilnSSAC PVT.LTD.100% (1)

- MEBCO - Bag Filter (SHC) - enDocument27 pagesMEBCO - Bag Filter (SHC) - enhcqwert trewqNo ratings yet

- Bag Filter CalculationDocument4 pagesBag Filter CalculationJag Khadse100% (1)

- Data and Result Calculation Bag FilterDocument2 pagesData and Result Calculation Bag FilterUmmiey SyahirahNo ratings yet

- 2 - Fan Assessment - PresentationDocument15 pages2 - Fan Assessment - PresentationSundara SubramaniyanNo ratings yet

- Fan Efficiency CalculatorDocument109 pagesFan Efficiency CalculatorSantanu PachhalNo ratings yet

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocument9 pagesEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- Data Sheet Jet Pulse Bag FilterDocument1 pageData Sheet Jet Pulse Bag FilterHassan SleemNo ratings yet

- Fabric Filter Design VariablesDocument14 pagesFabric Filter Design VariablesElumalai Srinivasan100% (2)

- Bag Filter Calculation1234567 IPDocument24 pagesBag Filter Calculation1234567 IPsujith kumarNo ratings yet

- Esp PresentationDocument19 pagesEsp PresentationRocky JonesNo ratings yet

- RABH-sugest by SatputeDocument1 pageRABH-sugest by Satputegvrr1954No ratings yet

- Esp eDocument40 pagesEsp eVijayakumarVageesanNo ratings yet

- Excel Sheet For Fuel UsageDocument7 pagesExcel Sheet For Fuel UsageAnonymous Xi0MsWMpNo ratings yet

- Fans & BlowersDocument7 pagesFans & BlowersSanjoy Kr. DeyNo ratings yet

- Bag Filter CalculationDocument2 pagesBag Filter Calculationjenifferrayen75% (8)

- High Air To Cloth Ratio Bag FilterDocument2 pagesHigh Air To Cloth Ratio Bag Filterayaskant751001No ratings yet

- Combustion Air Fan CalculationDocument2 pagesCombustion Air Fan CalculationVijay BhanNo ratings yet

- Screw Conveyor Example - Engineering GuideDocument12 pagesScrew Conveyor Example - Engineering GuideskylineshareNo ratings yet

- Benchmarks IndiaDocument78 pagesBenchmarks IndialafecapoNo ratings yet

- Flame Momentum CalculationDocument7 pagesFlame Momentum CalculationMohamed ZayedNo ratings yet

- Interstitial Velocity GuidelinesDocument6 pagesInterstitial Velocity GuidelinesnaushadNo ratings yet

- Ceramic Ball in Cement IndustryDocument6 pagesCeramic Ball in Cement IndustryMauricio PortillaNo ratings yet

- Static Separator Design CalculationDocument9 pagesStatic Separator Design CalculationbipinagarwalNo ratings yet

- Twin Flue MEPL ReferenceDocument3 pagesTwin Flue MEPL ReferenceDurjoy ChakrabortyNo ratings yet

- From Wikipedia, The Free Encyclopedia: Process Duct WorkDocument17 pagesFrom Wikipedia, The Free Encyclopedia: Process Duct WorkB DASNo ratings yet

- Kiln Shell CoolingDocument4 pagesKiln Shell CoolingjmpbarrosNo ratings yet

- Air Pollution Treatment MethodsDocument64 pagesAir Pollution Treatment Methodssagbvn100% (1)

- Latest Fabric Filter Technology For Power IndustryDocument47 pagesLatest Fabric Filter Technology For Power IndustrysimplyammarNo ratings yet

- Bag Filter PrincipleDocument3 pagesBag Filter PrincipleZahoor Ahmed75% (8)

- Fabric Dust Collector SystemsDocument50 pagesFabric Dust Collector Systemsbreyes25100% (3)

- Environmental Pollution Control: - K.PRAVEEN B.Tech (Under Graduate)Document24 pagesEnvironmental Pollution Control: - K.PRAVEEN B.Tech (Under Graduate)saiganeshmadasuNo ratings yet

- Air Cooler Cleaning TechniqueDocument4 pagesAir Cooler Cleaning Techniquedinakaranpatel100% (1)

- Gravitational Settling ChambersDocument6 pagesGravitational Settling ChambersVinod KumarNo ratings yet

- Ball Mill - Finish Mill Ball Charge CalculationDocument4 pagesBall Mill - Finish Mill Ball Charge Calculationrudye kardunNo ratings yet

- Cooler Bed DepthDocument3 pagesCooler Bed Depthrudye kardunNo ratings yet

- Laboratory Test Report Quality Assurance Department Qard Incoming Raw Coal StorageDocument2 pagesLaboratory Test Report Quality Assurance Department Qard Incoming Raw Coal Storagerudye kardunNo ratings yet

- Lucie MillDocument50 pagesLucie Millrudye kardunNo ratings yet

- Evaporation CalculationDocument2 pagesEvaporation Calculationrudye kardunNo ratings yet

- ABB Raw Mix Preparation PDFDocument8 pagesABB Raw Mix Preparation PDFrudye kardun100% (1)

- A Comparative Analysis of The Recent Cement Grinding Systems With Particle-Based Influences On Cement Properties PDFDocument109 pagesA Comparative Analysis of The Recent Cement Grinding Systems With Particle-Based Influences On Cement Properties PDFrudye kardunNo ratings yet

- Mining Division: Pt. Indocement Tunggal Prakarsa, TBKDocument19 pagesMining Division: Pt. Indocement Tunggal Prakarsa, TBKrudye kardunNo ratings yet

- Livro Química Analítica Qualitativa - VogelDocument617 pagesLivro Química Analítica Qualitativa - VogelDaniel PrettiNo ratings yet

- CESA Projects PDFDocument15 pagesCESA Projects PDFrudye kardunNo ratings yet

- Architecture Specifications For W - FDocument12 pagesArchitecture Specifications For W - FDileepa DissanayakeNo ratings yet

- Imp 4Document38 pagesImp 4nikhilNo ratings yet

- An Assessment of Small-Scale STP Technologies: India: Examples, Performance, and Cost For Three Common STP TypesDocument35 pagesAn Assessment of Small-Scale STP Technologies: India: Examples, Performance, and Cost For Three Common STP TypesRabindra SinghNo ratings yet

- Making A Topponcino: Material: For Front of ShamDocument3 pagesMaking A Topponcino: Material: For Front of Shamjeanete1234No ratings yet

- K 5Document44 pagesK 5Ricardo Rincon Vega100% (1)

- Gas Turbine IntroductionDocument84 pagesGas Turbine IntroductionMohammad Akram100% (3)

- HTCR Vs HTERDocument7 pagesHTCR Vs HTERlaquetengoNo ratings yet

- Workshop Manual: Book ID: 4-P08273CU - ENDocument192 pagesWorkshop Manual: Book ID: 4-P08273CU - ENJulio Ortega100% (4)

- t275 PDFDocument1 paget275 PDFAnonymous PCsoNCt0mFNo ratings yet

- Hdpe MSDSDocument2 pagesHdpe MSDSAhmad Matin RifaldiNo ratings yet

- Flowcrete Uk Tds Deckshield Rapide Ed3 August 2021Document2 pagesFlowcrete Uk Tds Deckshield Rapide Ed3 August 2021nblinoNo ratings yet

- Yale Cadance OrCAD Layout TutorialDocument32 pagesYale Cadance OrCAD Layout TutorialIon IonutNo ratings yet

- Declaration of ConformityDocument10 pagesDeclaration of ConformityLol RatNo ratings yet

- 08-08-2019Document18 pages08-08-2019KBR GADAGNo ratings yet

- Sewage TreatmentDocument99 pagesSewage Treatmentfatkhan fatahillahNo ratings yet

- Stainless Steel in The Pharmaceutical Food and Beverages Industries PDFDocument2 pagesStainless Steel in The Pharmaceutical Food and Beverages Industries PDFEng.sh1994shhotmail.com EngNo ratings yet

- SpecsCASE 621E SeriesDocument6 pagesSpecsCASE 621E SeriesDian SikumbangNo ratings yet

- Daf English 2009 PDFDocument2 pagesDaf English 2009 PDFAquasoul CoNo ratings yet

- Introducing Cold Pilger Mill Technology - Tube and Pipe ProductionDocument4 pagesIntroducing Cold Pilger Mill Technology - Tube and Pipe Productionribeiro30No ratings yet

- Final PPT LITRACONDocument15 pagesFinal PPT LITRACONRAmyaNo ratings yet

- Different Types of Floor CoveringsDocument18 pagesDifferent Types of Floor Coveringssurya rajputNo ratings yet

- FPA 5000 Quick Selection Guide EnUS 1218515979Document2 pagesFPA 5000 Quick Selection Guide EnUS 1218515979kao sophearakNo ratings yet

- Comparison of Mineral Wool Vs Calcium Silicate Pipe SectionsDocument9 pagesComparison of Mineral Wool Vs Calcium Silicate Pipe SectionsPhan Công ChiếnNo ratings yet

- Cofran Marathon Premium 15w40 enDocument1 pageCofran Marathon Premium 15w40 enAhmed KabbajNo ratings yet

- Update Terbaru PFD FixDocument1 pageUpdate Terbaru PFD FixaulianwNo ratings yet

- Experiment 6 DrillingDocument17 pagesExperiment 6 DrillingAnusha Anu100% (1)

- Production and Materials Management (Study Material) : Sri Vidya Mandir Arts and Science College (Autonomous)Document87 pagesProduction and Materials Management (Study Material) : Sri Vidya Mandir Arts and Science College (Autonomous)Anonymous 1ClGHbiT0JNo ratings yet

- Challenges With Using Ethyl Silicate Inorganic Zinc-Rich PrimerDocument43 pagesChallenges With Using Ethyl Silicate Inorganic Zinc-Rich PrimerMOHAMEDNo ratings yet

- MultitecDocument96 pagesMultitecarietilang100% (1)

- Flowserve, Rotary Valve & Actuation CatalogueDocument27 pagesFlowserve, Rotary Valve & Actuation CatalogueJunaidi Santoso100% (1)