Professional Documents

Culture Documents

Tunneling & Rock Drilling Equipment

Tunneling & Rock Drilling Equipment

Uploaded by

Rasu RawatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tunneling & Rock Drilling Equipment

Tunneling & Rock Drilling Equipment

Uploaded by

Rasu RawatCopyright:

Available Formats

TUNNELING & ROCK DRILLING EQUIPMENT

JACK HAMMER AND DRIFTING

MEER UZAIR

1

PILE DRIVING EQUIPMENT

INTRODUCTION

A tunnel machine used to excavate the tunnels.

They can bore through anything from hard rock to sand.

The rock drilling equipment or rock tools are breaks and demolished, drilling loading. Crushing or handling bulk materials.

WHAT IS JACK HAMMER ?

a jack hammer is phenomatic or electro-mechanical tool that combines a hammer directly

with a chisel. its using in drilling a blast hole with a jack hammer.

hydraulic jack hammer, is widely used for roadwork ,quarrying and general demolition or

construction ground work

such tools also used for mines.

USES

A full sized portable jack hammer is impractical for use against-walls and steep slopes.

Used on construction machinery.

TYPES

phenomatic - its also known as pneumatic drill or phenomatic.

this type of hammer compressed air as the power source.

furthermore ,air compressors typically incorporate moisture into the

compressed air leading to freeze-ups of the jack hammer or air hammer

in cold weather.

Electromechanical - electro pneumatic tools use a variety of chucks for

attaching chisels, but the most common are sds-max,7/8and te-s

and 1-1/8hex.

WHAT IS DRIFTER HAMMER ?

Rock drill or drifter is usually a machines, the consists of perceive system and rotating system.

USES

The use of underground, for mining as well as for civil engineering projects.

Requires the driving of drifts and tunnels.

JACK HAMMER

TUNNELING & ROCK DRILLING EQUIPMENT

ROTARY TYPE ,TRUCK MOUNTED

DRILLING EQUIPMENT

ROTARY TYPE ,TRUCK MOUNTED DRILLING EQUIPMENT

INTRODUCTION

A machine or device for drilling a hole in rock so that it may be blasted; usually driven by compressed air, but also may be driven by

electricity or by steam.

A drilling control system automatically adjusts the impact, feed, rotation and dampening pressures to match the rock conditions.

Rock Drills are used for quarry, mining in ores, trenching & general excavation involving short holes. It is the everyday tool for the

small job. Rock drills are also used for marble-granites industries.

Rock Drills can be used for the holes up to 20 feet or over but are most efficient when confined to holes of not over 10 to 12 feet.

Rock drills are designed to fight the hardest materials created by nature-rock & ore.

High Performance-Low Maintenance

High drilling capacity and low maintenance cost are two of the distinctive features of Drill man handheld rock drills. Used in

combination with portable compressors or tractor mounted compressors & drill steel, they guarantee low operation cost.

Power that's easy to handle

The high power-to-weight ratios and compact, versatile designs of Drillman rock drills enable simple positioning and easy handling.

Their high penetration means you get the job done quickly for maximum productivity.

You might also like

- DrillingDocument4 pagesDrillingHardik KarkarNo ratings yet

- Drilling and Blasting As A Tunnel Excavation Method PP TDocument29 pagesDrilling and Blasting As A Tunnel Excavation Method PP TAnonymous USbc7XzsA6No ratings yet

- BSR 2021Document223 pagesBSR 2021Hasitha KarunanayakaNo ratings yet

- Schedule of Rates: Public Works DepartmentDocument75 pagesSchedule of Rates: Public Works Departmentsanju_mahapatraNo ratings yet

- Use of Pu Grout in Himalayan Tunnel ConstructionDocument15 pagesUse of Pu Grout in Himalayan Tunnel Constructionअभितेश्वर ज्सरोटिया100% (1)

- Tunnel BlastingDocument27 pagesTunnel BlastingAiman Bashir100% (1)

- Geo StructureDocument13 pagesGeo StructuregchakroNo ratings yet

- Methods of New Construction: Design Manual Chapter 14 - Trenchless Construction 14B - New ConstructionDocument16 pagesMethods of New Construction: Design Manual Chapter 14 - Trenchless Construction 14B - New Constructionroronoa_zorro11No ratings yet

- IS 4880-1 (1987) Code of Practice For Design of Tunnels Conveying Water, General DesignDocument7 pagesIS 4880-1 (1987) Code of Practice For Design of Tunnels Conveying Water, General DesignAlok Kumar0% (1)

- Conventional Shaft Sinking by Manual MeansDocument26 pagesConventional Shaft Sinking by Manual Meansmechanical0% (1)

- Rohtang Tunnel Under Border Road Organization: Industrial Training Report ONDocument38 pagesRohtang Tunnel Under Border Road Organization: Industrial Training Report ONakNo ratings yet

- Challenges and Strategies For Tunnelling in The Himalyan RegionDocument4 pagesChallenges and Strategies For Tunnelling in The Himalyan RegionPremnath YadavNo ratings yet

- Tunnel CollapseDocument6 pagesTunnel CollapseGaddam Padmaja ReddyNo ratings yet

- Tunnel FailureDocument4 pagesTunnel FailurekzxeNo ratings yet

- Diaphragm Wall JointsDocument10 pagesDiaphragm Wall JointsAtaa AssaadNo ratings yet

- GroutingDocument8 pagesGroutingSajid Iqbal0% (1)

- Conventional Tunneling: Drill and Blast MethodDocument6 pagesConventional Tunneling: Drill and Blast MethodGodfrey EmilioNo ratings yet

- Heritage Infraspace Private LimitedDocument10 pagesHeritage Infraspace Private LimitedGagan GoswamiNo ratings yet

- DocumentDocument9 pagesDocumentea_she3415No ratings yet

- 04-1 Site InvestigationDocument146 pages04-1 Site InvestigationRohit BudhwaniNo ratings yet

- Bhopal Itarsi 5 Tunnel - Site Visit Report by SRDocument11 pagesBhopal Itarsi 5 Tunnel - Site Visit Report by SRsubhashNo ratings yet

- Types of Rock Supports in Design of Underground StructuresDocument36 pagesTypes of Rock Supports in Design of Underground StructuresShanul Saxena75% (8)

- Basic Road Statistics of IndiaDocument109 pagesBasic Road Statistics of IndiaSuryaprakash Reddy Eesari100% (1)

- Aftes - Construction Time and Use of TBMDocument15 pagesAftes - Construction Time and Use of TBMBrianNo ratings yet

- Shotcrete Mix DesignDocument8 pagesShotcrete Mix DesignMalak HindiNo ratings yet

- TBM BrochureDocument20 pagesTBM BrochurePablo Martínez BerenguerNo ratings yet

- Foundation Manual: State of California Department of Transportation Engineering Service Center Division of StructuresDocument529 pagesFoundation Manual: State of California Department of Transportation Engineering Service Center Division of Structureszambrilleco100% (1)

- 93 Palmstrom&Broch On Design Unlined Hydropower Tunnels PDFDocument9 pages93 Palmstrom&Broch On Design Unlined Hydropower Tunnels PDFpggopal_85No ratings yet

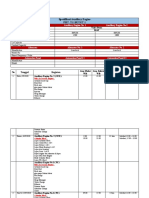

- Part 1 Bidding ProcedureDocument329 pagesPart 1 Bidding ProcedurevetrismanikkamNo ratings yet

- Robit Forepoling Catalogue ENG 03-2015Document36 pagesRobit Forepoling Catalogue ENG 03-2015Purwadi Eko SaputroNo ratings yet

- Geo 249 PDFDocument60 pagesGeo 249 PDFリムスィギャン瑞娴No ratings yet

- Sandvik SS GradesDocument3 pagesSandvik SS Gradespipedown456No ratings yet

- Soil Nailing TestingDocument122 pagesSoil Nailing TestingParvatha Vardhan GandrakotaNo ratings yet

- Bill of Quantity For Drilling of Twenty BoreholesDocument1 pageBill of Quantity For Drilling of Twenty BoreholesAnonymous OeoeVBmwNo ratings yet

- DGMS Circular No7 (1997) - IndiaDocument4 pagesDGMS Circular No7 (1997) - IndiaAntónio Nôro0% (1)

- New Austrian Method Used Design of Soft-Ground Tunnels For Washington MetroDocument4 pagesNew Austrian Method Used Design of Soft-Ground Tunnels For Washington MetroJothimanikkam SomasundaramNo ratings yet

- Importance of Engineering Geology in Civil EngineeringDocument7 pagesImportance of Engineering Geology in Civil EngineeringNishant MeenaNo ratings yet

- Strength Measurement of Shotcrete: Method StatementDocument16 pagesStrength Measurement of Shotcrete: Method StatementSarath Chandran SNo ratings yet

- Lec11-Soft Ground TunnelingDocument28 pagesLec11-Soft Ground TunnelingAmraha NoorNo ratings yet

- SLS-T Allgemein VMT - JMDocument65 pagesSLS-T Allgemein VMT - JMjmtexla680% (1)

- Diaphragm Walls - GGU SoftwareDocument5 pagesDiaphragm Walls - GGU Softwareindrajit sodhaNo ratings yet

- Geotechnical Investigation: (Drilling Tools)Document17 pagesGeotechnical Investigation: (Drilling Tools)A Bashir AsalaiNo ratings yet

- Lecture 17Document15 pagesLecture 17Rehman AbbasiNo ratings yet

- NATM PPT Gall-Natm-Design-Construction PDFDocument63 pagesNATM PPT Gall-Natm-Design-Construction PDFRakesh KapoorNo ratings yet

- Daily Progress Report Tunnel Heading Excavation in : NoteDocument1 pageDaily Progress Report Tunnel Heading Excavation in : NoteSanjeev Kr. ThakurNo ratings yet

- Casing Advancements 2014Document62 pagesCasing Advancements 2014Elgi Zacky ZachryNo ratings yet

- TERRATEC Microtunnelling Brochure PDFDocument5 pagesTERRATEC Microtunnelling Brochure PDFKhaled MaddallahNo ratings yet

- MZ460Y-2 Drilling Accessories Quotation ListDocument13 pagesMZ460Y-2 Drilling Accessories Quotation ListLUIS GABRIEL ESCOBAR COTENo ratings yet

- Chapter 6-1Document33 pagesChapter 6-1Punitha PaulNo ratings yet

- Tunnel Boring Machine 1Document6 pagesTunnel Boring Machine 1Omkar GordeNo ratings yet

- Tunnel Excavation MethodsDocument16 pagesTunnel Excavation Methodsharikrishna007No ratings yet

- Is .5529.1.1985-Permeability TestsDocument30 pagesIs .5529.1.1985-Permeability TestsGEOMAHESHNo ratings yet

- Tunnels Lecture NotesDocument105 pagesTunnels Lecture NotesTamra100% (1)

- Preene - Pumping Tests in Chalk 2018 PDFDocument7 pagesPreene - Pumping Tests in Chalk 2018 PDFmaribo2005No ratings yet

- Geotechnical Instrumentation and MonitoringDocument2 pagesGeotechnical Instrumentation and MonitoringLuiz SilvaNo ratings yet

- Rock Excavation Tests For Drill-Blast & TBM Tunnels-Predicting Cutter WearDocument41 pagesRock Excavation Tests For Drill-Blast & TBM Tunnels-Predicting Cutter WearLipsa MahapatraNo ratings yet

- Maharashtra SSRDocument253 pagesMaharashtra SSRvijayunityNo ratings yet

- Forpoling Tunnel PDFDocument12 pagesForpoling Tunnel PDFDilipNo ratings yet

- Rock Excavation Machines - Surface Mining: Sr. Under Manager Singareni Collieries Company LTDDocument50 pagesRock Excavation Machines - Surface Mining: Sr. Under Manager Singareni Collieries Company LTDjorgedavid31No ratings yet

- Cte Unit-5 NotesDocument34 pagesCte Unit-5 NotesLokesh MeenaNo ratings yet

- Related Literature and Studies of AntennaDocument4 pagesRelated Literature and Studies of AntennaStephen Joy ArellanoNo ratings yet

- 1.vol. I - FDPR A-42 - Lower Narmada - Revision-I - UpdatedDocument60 pages1.vol. I - FDPR A-42 - Lower Narmada - Revision-I - UpdatedDipesh JoshiNo ratings yet

- Manual de Servicio Dodge Jeep Chrysler 3.7l PDFDocument82 pagesManual de Servicio Dodge Jeep Chrysler 3.7l PDFvmanuel23No ratings yet

- 1.6KVA 12V MultiPlus 230 Volt System Example 4 PIN VE Bus BMS Lithium Orion TRDocument1 page1.6KVA 12V MultiPlus 230 Volt System Example 4 PIN VE Bus BMS Lithium Orion TRAlba Car MarNo ratings yet

- Pilot A2, CE2 Service Manual PDFDocument138 pagesPilot A2, CE2 Service Manual PDFKittiwat WongsuwanNo ratings yet

- Plasma Arc Machining (Pam)Document13 pagesPlasma Arc Machining (Pam)Abhishek Kumar0% (1)

- TI ApN EnCal 3000 Biogas enDocument2 pagesTI ApN EnCal 3000 Biogas enAndrew LingsNo ratings yet

- TT Electronics Capacitor Discharge CalculatorDocument7 pagesTT Electronics Capacitor Discharge CalculatorAnonymous ga5pyLmMCWNo ratings yet

- CX75 225SRDocument28 pagesCX75 225SREng Ahmed ABasNo ratings yet

- AboutDocument1 pageAboutMartynov MedinaNo ratings yet

- Laporan Kerja Harian TJ - BUYUT 1-1Document6 pagesLaporan Kerja Harian TJ - BUYUT 1-1Agustinus Leonardo SijabatNo ratings yet

- Building and Construction Sector in Kuwait - 2014Document27 pagesBuilding and Construction Sector in Kuwait - 2014Long Dong MidoNo ratings yet

- Heating Circuit and D H W Controller 17588 HQ enDocument94 pagesHeating Circuit and D H W Controller 17588 HQ enRuben WalshNo ratings yet

- ENG0011 DB DE Mechanical EngineDocument44 pagesENG0011 DB DE Mechanical Enginefrezgi birhanuNo ratings yet

- D1078-11 Standard Test Method For Distillation Range of Volatile Organic Liquids - IP 195-98Document9 pagesD1078-11 Standard Test Method For Distillation Range of Volatile Organic Liquids - IP 195-98Anbuchelvan CNo ratings yet

- F510 Instruction ManualDocument438 pagesF510 Instruction ManualMitzi Coleene BuezaNo ratings yet

- Chiller Plant 1Document20 pagesChiller Plant 1Krishna Kanchi100% (1)

- C 035 RW Vibrator12 Rev.1Document1 pageC 035 RW Vibrator12 Rev.1slamet4riadiNo ratings yet

- Light Is Technology PDFDocument84 pagesLight Is Technology PDFGopi KrishnaNo ratings yet

- 7.7-Hydraulic and Energy Grade ..Document6 pages7.7-Hydraulic and Energy Grade ..moussa66No ratings yet

- CV - Faracitra A SEP 2021-2Document2 pagesCV - Faracitra A SEP 2021-2Faracitra Akuwalifah KusumadewiNo ratings yet

- IEM Question PaperDocument1 pageIEM Question PaperGunabalan SellanNo ratings yet

- ATD Module 4Document23 pagesATD Module 4kannanNo ratings yet

- RC Infant Flow Sipap Operator Manual UG enDocument80 pagesRC Infant Flow Sipap Operator Manual UG enpericopepeNo ratings yet

- CastañedaLopez YuryAndrea 2016Document79 pagesCastañedaLopez YuryAndrea 2016danielNo ratings yet

- MC34063AMDocument16 pagesMC34063AMSajjad4434No ratings yet

- Taner Industrial Technology (M) Sdn. BHDDocument1 pageTaner Industrial Technology (M) Sdn. BHDHaris Munandar NasutionNo ratings yet

- Wiring Diagram Outdoor Emergency Lighting Units: Installation Instructions Model: Wgc42FeDocument2 pagesWiring Diagram Outdoor Emergency Lighting Units: Installation Instructions Model: Wgc42FeMario WiryaNo ratings yet

- 1 s2.0 S1755008421000387 MainDocument13 pages1 s2.0 S1755008421000387 MainZhipeng HOUNo ratings yet

- PPTC Operating Principle 11 04 2016 RaychemDocument20 pagesPPTC Operating Principle 11 04 2016 Raychemsvgl123No ratings yet