Professional Documents

Culture Documents

Three Phase Induction Motor

Three Phase Induction Motor

Uploaded by

Pushan Kumar Datta0 ratings0% found this document useful (0 votes)

164 views16 pagesThis document provides an overview of induction motors, including:

- How induction motors work by inducing current in the rotor via the rotating magnetic field in the stator.

- The main components of an induction motor are the stator, which produces the rotating magnetic field, and the rotor, which is induced to rotate by the stator field.

- Induction motors have advantages over synchronous motors in their simpler design, lower cost, higher power-to-weight ratio, and ability to directly connect to AC power sources.

Original Description:

Design of Induction Motor

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview of induction motors, including:

- How induction motors work by inducing current in the rotor via the rotating magnetic field in the stator.

- The main components of an induction motor are the stator, which produces the rotating magnetic field, and the rotor, which is induced to rotate by the stator field.

- Induction motors have advantages over synchronous motors in their simpler design, lower cost, higher power-to-weight ratio, and ability to directly connect to AC power sources.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

164 views16 pagesThree Phase Induction Motor

Three Phase Induction Motor

Uploaded by

Pushan Kumar DattaThis document provides an overview of induction motors, including:

- How induction motors work by inducing current in the rotor via the rotating magnetic field in the stator.

- The main components of an induction motor are the stator, which produces the rotating magnetic field, and the rotor, which is induced to rotate by the stator field.

- Induction motors have advantages over synchronous motors in their simpler design, lower cost, higher power-to-weight ratio, and ability to directly connect to AC power sources.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 16

1 What are motors

2 Principle of operation and comparison

to synchronous motors

3 Formulas

4 Construction

5 Speed control

6 Starting of induction motor

7 Types of starters

An electric motor is an electromechanical

device that converts electrical energy to

mechanical energy. The mechanical

energy can be used to perform work

such as rotating a pump impeller, fan,

blower, driving a compressor, lifting

materials etc.

Advantages:

Simple design

Inexpensive

High power to weight ratio

Easy to maintain

Direct connection to AC power source

An induction motor works on

transforming action. The stator works

as the primary while the rotor works as

the secondary. It is also called

asynchronous motor.

It consists of two parts: 1. Stator - It is

the stationary part of the motor. 2. Rotor It is the rotating part of the motor.

Stator has three main parts:

Outer Frame It is the outer body of the

of the motor. It protects the inner part of

the machine. Stator Core Built up of

high grade silicon steel. Carries the

alternating magnetic field. Stator winding

Has a three phase winding.

The basic difference between an induction

motor and a synchronous AC motor is that

in the latter a currentis supplied onto the

rotor. This then creates amagnetic field

which, through magnetic interaction,links

to the rotating magnetic field in the

statorwhich in turn causes the rotor to

turn. It is calledsynchronous because at

steady state the speed of therotor is the

same as the speed of the

rotatingmagnetic field in the stator.

A 3 phase induction motor derives its

name from the fact that the rotor current

is induced by the magnetic field, instead

of electrical connections.

The operating principle of a 3 phase

induction motor is based on the

production of r.m.f.

According to Faradays law an emf induced in any

circuit is due to the rate of change of

magnetic flux linkage through the circuit. As the

rotor winding in an induction motor are either

closed through an external resistance or directly

shorted by end ring, and cut the stator rotating

magnetic field, an emf is induced in the rotor

copper bar and due to this emf a current flows

through the rotor conductor.

Here the relative velocity between the rotating

flux and static rotor conductor is the cause of

current generation; hence as per Lenzs law the

rotor will rotate in the same direction to reduce

the cause i.e. the relative velocity.

In a three phase induction motor, the induced emf in

the rotorcircuit depends on the slip of the induction

motor and themagnitude of the rotor current depends

upon this induced emf(electromotive force). When the

motor is started, the slip is equalto 1 as the rotor

speed is zero, so the induced emf in the rotor islarge.

As a result, a very high current flows through the rotor.

Thisis similar to a transformer with the secondary coil

short circuited,which causes the primary coil to draw a

high current from themains. Similarly, when an

induction motor starts, a very highcurrent is drawn by

the stator, on the order of 5 to 9 times the fullload

current. This high current can damage the motor

windingsand because it causes heavy line voltage

drop, other appliancesconnected to the same line may

be affected by the voltagefluctuation. To avoid such

effects, the starting current should belimited

it may observed that the rotor speed should

not reach the synchronous speed produced by

the stator. If the speeds equals, there would

be no such relative velocity, so no emf

induction in the rotor, & no current would be

flowing, and therefore no torque would be

generated. Consequently the rotor can not

reach at the synchronous speed. The

difference between the stator (synchronous

speed) and rotor speeds is called the slip. The

rotation of the magnetic field in an induction

motor has the advantage that no electrical

connections need to be made to the rotor.

The induction motor does not have any

directsupply onto the rotor; instead, a

secondarycurrent is induced in the rotor. To

achievethis, stator windings are arranged around

therotor so that when energised with a

polyphasesupply they create a rotating magnetic

fieldpattern which sweeps past the rotor

At the moment illustrated, the current in the

statorcoil is in the direction shown and increasing.

Theinduced voltage in the coil shown drives

current andresults in a clockwise torque. Note that

this simplified motor will turn once it isstarted in

motion, but has no starting torque.Various

techniques are used to produce someasymmetry

in the fields to give the motor a startingtorque.

In a DC machine, the stator winding is

excited by DCcurrent and hence the field

produced by thiswinding is time invariant

in nature. In this machine theconversion

of energy from electrical to mechanical

form orvice versa is possible by one of

the following ways:1.rotating the rotor in

the field produced by the stator2.feeding

external dc current through carbon

brushes tothe rotor

Electric motors convert electrical power to

mechanicalpower in its rotor (rotating

part).There are several ways to supply power

to the rotor.AC motor this power is induced in

the rotating device. An induction motor can

be called a rotatingtransformer because the

stator(stationary part) is essentially the

primary side of the transformer and the rotor

(rotating part) is the secondary side.Induction

motors are widely used, especially

polyphaseinduction motors, which are

frequently used in industrialdrives.

The relationship between the supply

frequency, f, thenumber of pole pairs, p,

and the synchronous speed, n,is given by

f = p*n.From this relationship:Speed of

rotating field (n) = f/P (revs.s-1)Speed of

rotor = n(1-S) (rev.s-1)where S is the

slip.Slip is calculated using:% slip = (n - r)

/ n * 100where r is the rotor speed. In

contrast, a synchronous motor always

runs at either a constant speed

N=(120f)/P or zero.

You might also like

- Service Manual: S4S Diesel EngineDocument178 pagesService Manual: S4S Diesel EngineRAJESH RAMDAS100% (1)

- JD 9965 PDFDocument625 pagesJD 9965 PDFJosé Roberto VircentsNo ratings yet

- T/SP/PIP/1: Specification ForDocument31 pagesT/SP/PIP/1: Specification Formichael7michlovsky100% (1)

- Synchronous MotorsDocument27 pagesSynchronous MotorsSyed Muhammad Munavvar Hussain50% (2)

- Group 2 Ac Motors Technical ReportDocument12 pagesGroup 2 Ac Motors Technical Reporttristan jeff bautistaNo ratings yet

- SL030 PDFDocument2 pagesSL030 PDFCesar VillegasNo ratings yet

- Unit VDocument7 pagesUnit VMonte CarloNo ratings yet

- IM (1) NotesDocument4 pagesIM (1) NotesHarshitNo ratings yet

- Induction Motor: From Wikipedia, The Free EncyclopediaDocument6 pagesInduction Motor: From Wikipedia, The Free EncyclopediaJose EvonneNo ratings yet

- Electrical Machine II: EEEEC11 (3 - 0 - 2) Semester 4Document250 pagesElectrical Machine II: EEEEC11 (3 - 0 - 2) Semester 4sanjoni.jainNo ratings yet

- #5 Module 5Document52 pages#5 Module 5anishdeshmukh108No ratings yet

- 3phase Induction Motor (Sukhpreet)Document17 pages3phase Induction Motor (Sukhpreet)Ankesh KunwarNo ratings yet

- Syncronous MotorDocument22 pagesSyncronous MotorSambhav JainNo ratings yet

- Three Phase Induction MotorDocument2 pagesThree Phase Induction MotorsamyramuNo ratings yet

- 2:induction Motor Action: Torque Induced Magnetic FieldDocument3 pages2:induction Motor Action: Torque Induced Magnetic Fieldapi-19880840No ratings yet

- Magnetic Field Faraday's Law Magnetic Flux Induction Motor Resistance Magnetic Field CurrentDocument2 pagesMagnetic Field Faraday's Law Magnetic Flux Induction Motor Resistance Magnetic Field CurrentyokeshNo ratings yet

- Skip To ContentDocument17 pagesSkip To Contentkidanemariam teseraNo ratings yet

- Induction MotorDocument12 pagesInduction MotorsacchashuddhoNo ratings yet

- 3-Phase IMDocument16 pages3-Phase IMk rajendraNo ratings yet

- Induction Motor: Working Principle, Types, &Document6 pagesInduction Motor: Working Principle, Types, &0409piyushNo ratings yet

- Induction Motor Working Principle Types PDFDocument6 pagesInduction Motor Working Principle Types PDFdumpyNo ratings yet

- Induction MotorDocument43 pagesInduction MotorJanine Jade SetiasNo ratings yet

- EES (Lec20)Document16 pagesEES (Lec20)Muhammad SagheerNo ratings yet

- AC Synchronous GeneratorDocument8 pagesAC Synchronous Generatoraswardi8756No ratings yet

- Induction Synchronous MotorsDocument35 pagesInduction Synchronous MotorsDeandre LaingNo ratings yet

- Ac Motors: (A) Synchronous Motors. (B) Asynchronous MotorsDocument18 pagesAc Motors: (A) Synchronous Motors. (B) Asynchronous MotorsStudy portalNo ratings yet

- Induction Machine TrainerDocument29 pagesInduction Machine TrainerBabyNo ratings yet

- Mechatronics Ktu Module 6Document36 pagesMechatronics Ktu Module 6Adarsh s nairNo ratings yet

- The Difference Between Asynchronous and Synchronous MotorsDocument6 pagesThe Difference Between Asynchronous and Synchronous MotorsShiva Kumar ReddyNo ratings yet

- Induction Motors Unit 3Document26 pagesInduction Motors Unit 3babu KaroliNo ratings yet

- Induction Motor ReportDocument13 pagesInduction Motor ReportShivani SinghNo ratings yet

- Unit 1 Three Phase Induction MotorDocument87 pagesUnit 1 Three Phase Induction Motormahato741No ratings yet

- Induction Motor CharacteristicsDocument14 pagesInduction Motor CharacteristicsAnnaRajNo ratings yet

- Induction and Synchronous Motor FundamentalsDocument9 pagesInduction and Synchronous Motor FundamentalsfitxvNo ratings yet

- Induction Motor: Principle of OperationDocument7 pagesInduction Motor: Principle of OperationAbhishek ChibNo ratings yet

- UNIT-III Three Phase & Single Phase Induction MotorsDocument8 pagesUNIT-III Three Phase & Single Phase Induction MotorsRahulRamamoorthyNo ratings yet

- Microsoft Word - 4 - Induction Machines PDFDocument16 pagesMicrosoft Word - 4 - Induction Machines PDFMegat Ahmad FaizNo ratings yet

- Chapter 1 - Introduction To AC MotorDocument13 pagesChapter 1 - Introduction To AC MotorJiachyi YeohNo ratings yet

- AC MotorsDocument48 pagesAC MotorsBrandon SookdeoNo ratings yet

- Induction MotorDocument2 pagesInduction MotorStephen CooperNo ratings yet

- Synchronous Motor & Its Applications & Power Factor ImprovementDocument4 pagesSynchronous Motor & Its Applications & Power Factor ImprovementYash BansalNo ratings yet

- Three Phase Induction Motor Interview Questions 2 1Document24 pagesThree Phase Induction Motor Interview Questions 2 1Kulshresth Joshi100% (1)

- 1-EM Section 1 Motor OperationDocument38 pages1-EM Section 1 Motor Operationmhafidz49No ratings yet

- Synchronous MotorDocument33 pagesSynchronous Motorvnyshreyas100% (2)

- MotorsDocument7 pagesMotorsVikramNo ratings yet

- 3.18 Ac MotorsDocument25 pages3.18 Ac Motorsdeleted Yt acc.No ratings yet

- 3 Phase Induction Motors PDFDocument11 pages3 Phase Induction Motors PDFFauzan Dimas KusyonoNo ratings yet

- 3 Phase Induction MotorsDocument10 pages3 Phase Induction MotorsSTIP Teknik BravoNo ratings yet

- Three Phase MotorsDocument24 pagesThree Phase MotorsRobert MarcoliniNo ratings yet

- Slip Ring Induction MotorsDocument9 pagesSlip Ring Induction MotorsTuhin ShahNo ratings yet

- A.C. Motor and Its TypesDocument10 pagesA.C. Motor and Its TypessasidaranNo ratings yet

- A.C. Motor and Its TypesDocument10 pagesA.C. Motor and Its Typesandi yusufNo ratings yet

- Synchronous Motor Working PrincipleDocument6 pagesSynchronous Motor Working PrincipleHemraj Singh RautelaNo ratings yet

- AC Machines Stepper, BLCD MotorDocument22 pagesAC Machines Stepper, BLCD MotorMaadheshNo ratings yet

- Synchronous Machines and SCDocument6 pagesSynchronous Machines and SCivancho04mNo ratings yet

- Electrical Motor (1) DDocument20 pagesElectrical Motor (1) Drksamy0102No ratings yet

- Reaction PaperDocument6 pagesReaction PaperAngelo Escoro Dante100% (1)

- Synchronous MotorDocument26 pagesSynchronous MotorSyed Muhammad Munavvar HussainNo ratings yet

- Ac Motors: An AC Motor Is An Driven by AnDocument18 pagesAc Motors: An AC Motor Is An Driven by AnBalamuni PsaNo ratings yet

- Speed Control of Induction Motor Using AnnDocument67 pagesSpeed Control of Induction Motor Using AnnBnr Goud50% (6)

- Induction Motor: by WiresDocument3 pagesInduction Motor: by Wireswajeeh shahNo ratings yet

- Ac MotorDocument17 pagesAc Motorthebeast.suazoNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- Electrical Machines: Lecture Notes for Electrical Machines CourseFrom EverandElectrical Machines: Lecture Notes for Electrical Machines CourseNo ratings yet

- It Encompasses Three Principles: Design Out Toxins, Waste and Pollution Keep Products and Materials in Use Regenerate Natural SystemsDocument12 pagesIt Encompasses Three Principles: Design Out Toxins, Waste and Pollution Keep Products and Materials in Use Regenerate Natural SystemsPushan Kumar DattaNo ratings yet

- CountersDocument36 pagesCountersPushan Kumar DattaNo ratings yet

- Success Starts With IeltsDocument43 pagesSuccess Starts With IeltsPushan Kumar DattaNo ratings yet

- Box 9.7: Modal Symbols: © Cambridge University Press 2009Document1 pageBox 9.7: Modal Symbols: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 11.2.3c: Shopping: © Cambridge University Press 2009Document1 pageBox 11.2.3c: Shopping: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 14.1.5b: Pictures Into Story: © Cambridge University Press 2009Document1 pageBox 14.1.5b: Pictures Into Story: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 14.1.6c: Putting Stories in Order: © Cambridge University Press 2009Document1 pageBox 14.1.6c: Putting Stories in Order: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 11.2.3a: Shopping: © Cambridge University Press 2009Document1 pageBox 11.2.3a: Shopping: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 11.2.4b: Finding Investment Partners: © Cambridge University Press 2009Document1 pageBox 11.2.4b: Finding Investment Partners: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 11.1.3: Occupations: © Cambridge University Press 2009Document1 pageBox 11.1.3: Occupations: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 11.3.2a: Similarities: © Cambridge University Press 2009Document1 pageBox 11.3.2a: Similarities: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

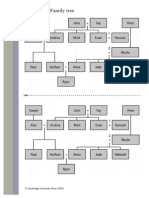

- Box 15.3a: Family Tree: © Cambridge University Press 2009Document1 pageBox 15.3a: Family Tree: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 19.4a: Extending A Story: © Cambridge University Press 2009Document1 pageBox 19.4a: Extending A Story: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 15.3b: Family Tree: © Cambridge University Press 2009Document1 pageBox 15.3b: Family Tree: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 10.3a PDFDocument1 pageBox 10.3a PDFPushan Kumar DattaNo ratings yet

- Box 16.8b: Who's She Talking To?: © Cambridge University Press 2009Document1 pageBox 16.8b: Who's She Talking To?: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Describe The Courses You Have Taught by Summarizing The Course Content and Assignments Required. Subjects I Will Be Comfortable To TeachDocument15 pagesDescribe The Courses You Have Taught by Summarizing The Course Content and Assignments Required. Subjects I Will Be Comfortable To TeachPushan Kumar DattaNo ratings yet

- RSVP Protocol Operation in MPLSDocument2 pagesRSVP Protocol Operation in MPLSPushan Kumar DattaNo ratings yet

- Box 19.2: Relative Quizzes: © Cambridge University Press 2009Document1 pageBox 19.2: Relative Quizzes: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Box 16.5b: Describe and Arrange: © Cambridge University Press 2009Document1 pageBox 16.5b: Describe and Arrange: © Cambridge University Press 2009Pushan Kumar DattaNo ratings yet

- Assignment Applied ElectronicsDocument6 pagesAssignment Applied ElectronicsPushan Kumar DattaNo ratings yet

- Welcome To IndiaDocument7 pagesWelcome To IndiaPushan Kumar DattaNo ratings yet

- Systems and Applications, Mecs Publishers, 2014 (Under Review)Document3 pagesSystems and Applications, Mecs Publishers, 2014 (Under Review)Pushan Kumar DattaNo ratings yet

- Manuals - G200 Series Back Check Valves Instruction Manual, Fisher-ENDocument4 pagesManuals - G200 Series Back Check Valves Instruction Manual, Fisher-ENrey sarNo ratings yet

- NISTIR 5634 Prediction of Cracking in Reinforced Concrete StructuresDocument51 pagesNISTIR 5634 Prediction of Cracking in Reinforced Concrete Structurespmc_lbm4440No ratings yet

- FPT PG Brochure NE ENG 02 2023 WebDocument23 pagesFPT PG Brochure NE ENG 02 2023 WebMohammad ShaatNo ratings yet

- BALLUFF-KT Mechanik Gesamt enDocument135 pagesBALLUFF-KT Mechanik Gesamt enJarosław Polske ZbawNo ratings yet

- KSB Sewabloc Sewatec CharakterystykiDocument112 pagesKSB Sewabloc Sewatec Charakterystykilouis etienneNo ratings yet

- PIEZOMETER (Pressure Tube)Document7 pagesPIEZOMETER (Pressure Tube)Devendra Kumar VishwakarmaNo ratings yet

- Exergetic Analysis of A Gas Turbine With Inlet Air Cooling System PDFDocument28 pagesExergetic Analysis of A Gas Turbine With Inlet Air Cooling System PDFWashoo HasooNo ratings yet

- Bodybuilder Guidelines: Update: 2011-22Document438 pagesBodybuilder Guidelines: Update: 2011-22thkimzone73100% (12)

- Flying Cart Hovercraft PlansDocument8 pagesFlying Cart Hovercraft PlansJimNo ratings yet

- Seminar Report VACCUM BRAKING SYSTEM (1sb16me042)Document22 pagesSeminar Report VACCUM BRAKING SYSTEM (1sb16me042)Manasa100% (1)

- A Review Study On Seismic Response of Steel Building Frames With Different Beam - Column ConnectionsDocument8 pagesA Review Study On Seismic Response of Steel Building Frames With Different Beam - Column ConnectionsIJRASETPublicationsNo ratings yet

- Lift ManualDocument24 pagesLift Manualnaik_shreyNo ratings yet

- SUMMARY - Oscillations and WavesDocument19 pagesSUMMARY - Oscillations and Wavessethupanic macanic gamedzeNo ratings yet

- Workshopmanual - vf750 - Sabre Magna - 1982 1988 19022021 1225Document248 pagesWorkshopmanual - vf750 - Sabre Magna - 1982 1988 19022021 1225Grupo GatroNo ratings yet

- RTA-29 Improved Oil Supply To The Integrated Axial DetunerDocument3 pagesRTA-29 Improved Oil Supply To The Integrated Axial DetunerCatalin CataNo ratings yet

- Reclaimer ChainDocument4 pagesReclaimer ChainAmeer Ahmad RazaNo ratings yet

- Wagner Apprentice Program Offers Tools For SuccessDocument4 pagesWagner Apprentice Program Offers Tools For Successabduallah muhammadNo ratings yet

- Embrague Freno Manual ResorteDocument100 pagesEmbrague Freno Manual ResorteÁlvaro José Abaunza GómezNo ratings yet

- Atlas Copco Gas & Process and Vericor Power Systems Sign A Strategic Alliance To Power Integrally Geared Centrifugal Compressors and Companders™ With Vericor Gas TurbinesDocument2 pagesAtlas Copco Gas & Process and Vericor Power Systems Sign A Strategic Alliance To Power Integrally Geared Centrifugal Compressors and Companders™ With Vericor Gas TurbinesPR.comNo ratings yet

- 2 Phase Stepper CatalogDocument6 pages2 Phase Stepper CatalogShenna Kim CasinilloNo ratings yet

- R PT Instruction PlanDocument6 pagesR PT Instruction PlanVipin KumarNo ratings yet

- Five-Speed Automatic Gearbox With Tiptronic (01V)Document6 pagesFive-Speed Automatic Gearbox With Tiptronic (01V)FSR1407No ratings yet

- Snap-Fit OPTIMIZATIONDocument9 pagesSnap-Fit OPTIMIZATIONManish RajNo ratings yet

- EPS - 10K1 - Solution - Wood Based Panel - Press - 97.ENDocument1 pageEPS - 10K1 - Solution - Wood Based Panel - Press - 97.ENhufuents-1No ratings yet

- MM204 Assn3 2017Document5 pagesMM204 Assn3 2017jayNo ratings yet

- AC MachinesDocument41 pagesAC Machineskr_abhijeet72356587No ratings yet