Professional Documents

Culture Documents

LNG Liquification Processes

LNG Liquification Processes

Uploaded by

Mani EarnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LNG Liquification Processes

LNG Liquification Processes

Uploaded by

Mani EarnCopyright:

Available Formats

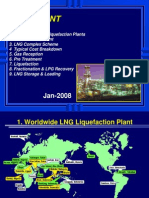

LNG PLANT

1. World-wide LNG Liquefaction Plants

2. Baseload LNG Plant

3. LNG Complex Scheme

4 Typical Cost Breakdown

5. Gas Reception

6. Pre Treatment

7. Liquefaction

8. Fractionation & LPG Recovery

9. LNG Storage & Loading

Jan-2008

1. Worldwide LNG Liquefaction Plant

Snohvit, Norway

Skikda, Algeria

Arzew, Algeria

Qatargas, Qatar

RasLaffan, QatarTombak, Iran

Kenai

Sakhalin, Russia

Das Island, Abu Dhabi

Bintulu, Malaysia

Damietta, Egypt

Brunei

Oman

Yemen

Bonny, Nigeria

Arun, Indonesia

Tangguh, Indonesia

Bontang, Indonesia

Angola

Woodside, Australia

Namibia

Libya

Existing

Existing

Planned or Construction

Jose, Venezuela

Atlantic, Trinidad

Camisea, Peru

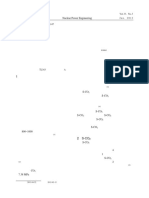

2. Baseload LNG Plant

2.1 General Profile

Project

Country

Year

Start

mtpa

Capacity

Nos.

Trains Liquefaction

Process Media

Driver

Media

Cooling

Heating

EPC Contractor

Camel

Kenai

Libya

Brunei

Skikda,Ph1

Adgas,Tr1&2

Bontang,A/B

Arun,No1-3

Arzew,No1

Arzew,No2

Skikda,Ph2

Buntulu,Satu

Bontang,C/D

Arun,No4&5

Arun,No6

Woodside,Tr1-3

Bontang,E

Bontang,F

Adgas,Tr3

Buntulu,Dua

QatarGas,Tr1&2

Bontang,G

Atlantic,Tr1

Bontang,H

Nigeria,Tr1& 2

RasLaffan,Tr1&2

Oman,Tr1&2

Atlantic,Tr2&3

Nigeria,Tr3

Buntulu,Tiga

QatarGas,Tr3

RasLaffan,Tr3

SEGas,Tr1

Woodside,Tr4

Atlantic,Tr4

Idku,Tr1&2

Nigeria,Tr4

RasLaffan,Tr4

Darwin

Algeria

USA

Libya

Brunei

Algeria

UAE

Indonesia

Indonesia

Algeria

Algeria

Algeria

Malaysia

Indonesia

Indonesia

Indonesia

Australia

Indonesia

Indonesia

UAE

Malaysia

Qatar

Indonesia

Trinidad T

Indonesia

Nigeria

Qatar

Oman

Trinidad T

Nigeria

Malaysia

Qatar

Qatar

Egypt

Australia

Trinidad T

Egypt

Nigeria

Qatar

Australia

1964

1969

1970

1972

1972

1977

1977

1978

1978

1980

1980

1983

1983

1984

1987

1988

1990

1993

1994

1995

1997

1998

1999

1999

1999

1999

2000

2002

2002

2003

2003

2004

2004

2004

2005

2005

2005

2005

2006

0.44

0.95

0.64

1.44

1.0

1.23

1.67

1.67

1.22

1.22

1.21

2.53

1.67

1.67

1.67

2.43

2.3

2.3

2.3

2.65

2.2

2.6

3.0

2.95

2.95

2.9

3.3

3.3

2.95

3.87

4.7

4.7

5.0

4.2

5.2

3.6

4.0

4.7

3.5

3

2

4

5

1

2

2

3

6

6

2

3

2

2

1

3

1

1

1

3

2

1

1

1

2

2

2

2

1

2

1

1

1

1

1

2

1

1

1

Stm/T

G/T

Stm/T

Stm/T

Stm/T

Stm/T

Stm/T

F5x3

Stm/T

Stm/T

Stm/T

Stm/T

Stm/T

F5x3

F5x3

F5x4

Stm/T

Stm/T

Stm/T

F6+F7

F5x4

Stm/T

F5x6

Stm/T

F6+F7

F7x2

F6+F7

F5x6

F6+F7

F7+F7

F5x5

F7x2

Fr7x2

F7x2

F5x8

F5x5

F7x2

F7x2

LM2500x6

SW

CW

SW

CW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

SW

Air

SW

SW

SW

SW+Air

SW

SW

Air

SW

CW

SW+CW

SW

Air

CW

Air

SW

SW+CW

Air

Air

Air

Air

Air

SW+CW

Air

Steam

?

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Steam

Steam

HotWater

Steam

Steam

Steam

Steam

Steam

Steam

HotOil

Steam

HotOil

Steam

HTF

HotOil

HTF

HotOil

Steam

Steam

HotOil

HotWater

HotOil

?

HTF

Steam

?

Technip/Prichard

Phillips/Bechtel/SW

Esso R&E/Snam/Bechtel

JGC/Procon

Technip

CCEC/Bechtel

Bechtel

Bechtel

Bechtel

Pullman Kellogg

Prichard/ Pullman kellogg

JGC/Kellogg

Bechtel

CCEC

JGC

JGC/Kellogg/Kaiser

CCEC

CCEC/IKPT

CCEC

JGC/Kellogg

CCEC

CCEC/IKPT

Bechtel

Kellogg/IKPT

JGC/Kellogg/Technip/Snam

JGC/Kellogg

CCEC/FW

Bechtel

JGC/Kellogg/Technip/Snam

JGC/Kellogg

CCEC

CCEC

JGC/Kellogg/Technicas

Kellogg/JGC/Hatch/Clough

Bechtel

Bechtel

JGC/Kellogg/Technip/Snam

CCEC

Bechtel

TEAL,Cascade

Phillips,Cascade

APCI,MR

APCI,PP+MR

TEAL,2Pressure

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

Prichard,PRICO

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

Phillips,Cascade

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

Phillips,Cascade

APCI,PP+MR

Shell,PP+MR

APCI,PP+MR

APCI,PP+MR

APCI,PP+MR

Shell,PP+MR

Phillips,Cascade

Phillips,Cascade

APCI,PP+MR

APCI,PP+MR

Phillips,Cascade

2. Baseload LNG Plant

2.1 General Profile (update)

Project

Country

Start

Year

Capacity

mtpa

Trains

Nos.

Liquefaction

Process

Driver

Cooling

Media

Heating

Media

EPC Contractor

Nigeria,Tr5

RasLaffan,Tr5

Equatorial Guinea

Snohvit

Nigeria

Qatar

Guinea

Norway

2006

2007

2007

2007

4.1

4.7

3.4

4.1

1

1

1

1

APCI,PP+MR

APCI,PP+MR

Phillips,Cascade

Linde MFC

F7x2

F7x2

F5x6

Motor

Air

SW+CW

?

SW

HTF

Steam

?

HTF

JGC/Kellogg/Technip/Snam

CCEC

Bechtel

Linde

Sakhalin

Qatar Gas II

Nigeria,Tr6

Tangguh

Woodside, Tr5

Yemen

RasGas II

Russia

Qatar

Nigeria

Indonesia

Australia

Yemen

Qatar

2008

2008

2008

2008

2009

2009

2009

4.8

7.8

4.1

3.8

4.2

3.4

7.8

2

2

1

2

1

2

2

Shell DMR

APCI,APX

APCI,PP+MR

APCI,PP+MR

Shell,PP+MR

APCI,PP+MR

APCI,APX

F7x2

F9x3

F7x2

F7x2

F7x2

F7x2

F9x3

2. Baseload LNG Plant

2.2 Evolution of LNG Train Capacity

8

QGII

GE Fr.9

Gas Turbine Driven

Egypt SEGAS

GE Fr.5

Brunei

0

1960

Kenai

1970

Qatargas

Tangguh

Woodside Exp

Oman

Atlantic

Ras

Laffan

Arun 6

Badak

Lybia

Camel

Australia

Malaysia

Snohvit

Egypt Idku

Ras Laffan Exp

Malaysia Tiga

Malaysia Dua Nigeria

Arun

GE Fr. 6&7

Helper Motor

Motor Drive

Elec Motor Driven

Power Export

Million Ton/Yr

Steam Turbine Driven

Arzew

Abu Dhabi

Abu Dhabi

Skikda

1980

1990

2000

2010

3. LNG Complex Scheme

End Flash gas

LNG TRAIN

ACID

GAS

REMOVAL

BOG

HANDLING

LNG

DEHYDRATION

MERCURY

REMOVAL

SCRUB

COLUMN

LIQUEFACTION

TANK

REFRIG. STORAGE

FUEL GAS

SYSTEM

NG

FRACTIONATION

C3 & MR

REFRIGE-RANT

RECIEVING

&

METERING

TANK

LP

G

TANK

CONDENSATE

RECOVERY

CONDENSATE

RAW

WATER

WATER

TREATMENT

STEAM

GENERATION

COOLING

WATER

INERT GAS

ELECT.

GENERATOR

INSTRUMENT

& SERVICE AIR

FIRE

PROTECTION

FLARE &

LIQ.DISPOSAL

WET /COLD/ OPERATIONAL/

LIQUID /TANK/ SPARE FLARES

4. Plant Cost

4.1 Typical Cost Breakdown

LNG Train 48%

Liquefaction

36%

Dehydration

3%

Gas

Treating

7%

Fractionation

2%

Jetty

3%

Offsite

Facility

Utility

14%

G/T, Air Cooled LNG Plant

13%

Storage

& Loading

22%

4. Plant Cost

4.2 Historical Cost of LNG Plant

100

90

80

70

60

50

40

30

20

10

0

1960

Brunei

Malaysia

Australia

Nigeria

Ras Laffan

Trinidad

Oman

1970

1980

1990

2000

Design Year

Robert G. Ryan et.al., Special Report LNG Evolution, Oil&Gas J July 16,2001

4. Plant Cost

4.3 Historical Cost of LNG Plant (update)

5. LNG Plant Projects

5.1 Particulars of LNG Plant Projects

High Quality & Reliability Required

LNG Chain (Long term contract between

Seller and Buyer, LNG Ship)

Large CAPEX

High Grade Material for HP /LT conditions

Merit of Scale

Finance

Completion Reliability

Long-term PJ Schedule

Phased Development Required

Remote Sites

5. LNG Plant Projects

5.2 Technologies

Particular Aspects of LNG Technology

Process Licensers Limited

LNG Equipment

Long Delivery

Large Size

Technical Complexity

- Main Cryogenic

Exchangers

- Gas Turbines &

Compressors

- Liquid Expanders

- LNG Tanks

5. LNG Plant Projects

5.3 Current Requirements

Lower Investment & Operation Costs

Shorter Completion Schedules

Higher Availability

More Environmentally Friendly

5. LNG Plant Projects

5.4 Typical Schedule

1st year

DEFINITION

BOD/BDP

BCE

FRONT END DESIGN

LICENSORS DESIGN

FEED PACKAGE

EPC COST ESTIMATE(10%)

EPC BIDDING

PROPOSAL

EVALUATION

IMPLEMENTATION

PROC. CRITICAL ITEMS

SITE PREPARATION

EPC

START UP

2nd year

3rd year

4th year

5th year

6th year

7th year

6. Gas Reception & Pre Treatment

6.1 Slug Catcher & Stabilizer

Feed Gas

&

Condensate

(Two Phase)

Feed Gas

Separator

Feed Gas

Recovery

Compressor

Pig

Receiver

Slug

Catcher

Stabilizer

Condensate

6. Gas Reception & Pre Treatment

6.2 Metering & Feed Gas Compression

F

Metering Skid

Inlet Separator

After

Cooler

Booster

Compressor

To LNG

Train

F

Feed Gas

Metering Skid

Inlet Separator

After

Cooler

Booster

Compressor

F

After

Cooler

Metering Skid

Inlet Separator

Booster

Compressor

6. Gas Reception & Pre Treatment

6.3 Acid Gas Removal Scheme

Sweet

Gas

Lean

Amine

Absorber

Acid Gas to

Downstream

Regenerator

Feed Gas

Rich

Amine

6. Gas Reception & Pre Treatment

6.4 Comparison of Solvents

MEA

MDEA Sulfinol

(Benfield)

H2S

CO2

Mercaptans Partial Partial

Degradation COS No

CO2 No

CO2

CS2

CS2

H2S select

X

Q duty large large small

small

Adsorption chem. chem.

chem. chem.

physic.

6. Gas Reception & Pre Treatment

6.5 Dehydrator

Recycle Gas

Compressor

Water

Regeneration

Gas Heater

Propane

Refrigerant

Wet Gas

Dehydrator

Dry

Gas

7. Liquefaction

7.1 Process Classification

External Refrigerant type

Cascade

Mixed Refrigerant Process (MR Process)

- Single MR

- Dual MR

- C3 Pre-cooled

Self-refrigerant Process

Expander Process

Nitrogen Cycle (Peak-shaving & On-board)

7. Liquefaction

7.2 Existing Process

Single MR Process (PRICO)

TEALARC Dual MR (Technip)

CASCADE Process (Phillips)

C3 Pre-cooled MR Process (APCI, Shell)

7.2.1 Single MR (PRICO)

Low Pressure Refrigerant

Treated Feed Gas

High Pressure Refrigerant

Inter

Cooler

Refrigerant

Heat Exchanger

Inter Stage

Scrubber

Inter Stage

Pump

Heavy Liquid

Separator

Refrigerant

Condenser

Refrigerant

Compressor

Heavy Liquid

to Processing

LNG

Refrigerant

Pump

To Storage

GASTECH 1998

7.2.2 TEALARC Dual MR (Technip)

Treated Feed Gas

Mixed Refrigerant

Refrigerant

Heat Exchanger

Pre-refrigeration

Cycle

Fractionators

Mixed

Refrigerant

C2+

Refrigerant

Heat Exchanger

Liquefaction Cycle

LNG

to Storage

by LNG9 1989

7.2.3 Cascade Process (Phillips)

C3 Surge Drum

Treated Feed Gas

Refrigerant Heat

Exchanger

After

Cooler

C3

Compressor

C2= Surge Drum

After Cooler

C2+

to Fractionation

C2=

Compressor

After Cooler

Fuel Gas

Refrigerant Heat

Exchanger

C1

Compressor

LNG to Storage

Ship and Tank Vapor

by GASTECH 1996

7.2.4 Propane Pre-cooled MR (APCI)

Fuel Gas

N2

Reject

LNG

C3

Pre-cooling

to Storage

C3

Compressor

LP

C3

MR

Compressor

Scrub Column

MP C3

Mixed

Refrigerant

Refrigerant

Heat

Exchanger

HHP HP

C3 C3

MP

C3

LP

C3

LPG Fractionation

HP C3

Treated

Feed Gas

LPG

Condensate

7.2.5 Cooling Curve of Cascade Process

20

0

Natural Gas

-20

Temperature (C)

-40

Propane

-60

-80

-100

Ethylene

-120

-140

Methane

-160

1000

2000

Enthalpy difference (kcal/mol)

3000

7.2.6 Cooling Curve of C3 Pre-cooled MR

20

0

Natural Gas

Temperature (C)

-20

-40

C3 Cycle

-60

-80

-100

MR Cycle

-120

-140

-160

1000

2000

3000

Enthalpy difference (kcal/mol)

7. Liquefaction

7.3 New Process

Dual MR Process (Shell)

Liqeufin Process (Axens)

MFC Process (Linde)

AP-X Process (APCI)

7.3.1 Dual MR Process (Shell)

Fuel Gas

LNG

N2

Reject

to Storage

Mixed

Refrigerant

Spool wound

Heat Exchangers

MR Compressor

Compressor

Scrub Column

Mixed

Refrigerant

Refrigerant

Heat

Exchanger

LPG Fractionation

Treated

Feed Gas

LPG

Condensate

by LNG12 1998

7.3.2 Liquefin Dual MR (IFP-Axens)

Treated Feed Gas

After

Cooler

Refrigerant

Heat Exchanger

Fuel Gas

After

Cooler

MR 1

Compressors

Inter

Cooler

LNG

to Storage

MR2

Compressors

Expander

by GASTECH 1998

7.3.3 Mixed Fluid Cascade (LINDE)

Treated Feed Gas

Refrigerant

Heat Exchanger

Fuel Gas

Pre-cooling Cycle

Liquefaction

Cycle

Refrigerant

Heat Exchanger

Refrigerant

Heat

Exchanger

End Flash

LNG

to Storage

Sub-cooling Cycle

7.3.4 AP-XTM Process (APCI)

Coil Wound

Sub-cool Heat Exchanger

Propane Pre-cool Compressor

Feed

Gas

Propane Pre-cool

Heat Exchangers

MR Compressor

Nitrogen Gas Expander

Coil Wound

MCHE

Nitrogen Cold-box

Nitrogen Compressor

7. Liquefaction

7.4 Evolution of LNG Train Capacity

8

QGII

GE Fr.9

Gas Turbine Driven

Egypt SEGAS

GE Fr.5

Brunei

0

1960

Kenai

1970

Qatargas

Tangguh

Woodside Exp

Oman

Atlantic

Ras

Laffan

Arun 6

Badak

Lybia

Camel

Australia

Malaysia

Snohvit

Egypt Idku

Ras Laffan Exp

Malaysia Tiga

Malaysia Dua Nigeria

Arun

GE Fr. 6&7

Helper Motor

Motor Drive

Elec Motor Driven

Power Export

Million Ton/Yr

Steam Turbine Driven

Arzew

Abu Dhabi

Abu Dhabi

Skikda

1980

1990

2000

2010

7. Liquefaction

7.5 Driver for Refrigerant Compressor

Plant Capacity (MTPA)

25.00

20.00

15.00

First Single Shaft

GT Application

10.00

5.00

19

64

19

70

19

77

19

80

19

84

19

89

19

93

19

95

19

98

20

00

20

03

0.00

Gas Turbine

Steam Turbine

7. Liquefaction

7.6 Compressor & Driver Configuration

Large Size Gas Turbine

Application of Three Frame 7s or Frame 9s

Combined Cycle

Increase Plant Efficiency

Large Size Compressor

Limitation of Suction Volume

Parallel Configuration of Refrigerant Compressor

Train in Liquefaction Train

Relaxed by New Liquefaction Process

Motor Drive

Future Possible Option

7. Liquefaction

7.7 Train Size & Driver Configuration

G/T

Configuration

Plant

Capacity

Before 1990

1990 - 1999

2000 - 2005

(3 or 4) x F5

F7 + F6

2 x F7

1.6 - 2.5

3.0

3.9 - 4.8

Near Future

3 x F7

or 2 x F9

or 3 x F9

or Motor Drive

6.0 7.8

7. Liquefaction

7.8 Driver Type vs. Efficiency

Type

Steam Turbine 60 kg/cm2G 440 deg. C

Steam Turbine 105 kg/cm2G 510 deg. C

Gas Turbine for Industrial Use

Combined Cycle (G/T for Industrial Use)

Gas Turbine for Aircraft

Combined Cycle (G/T for Aircraft)

Efficiency %

25.3

28.5

27 31

33.5

33.4

39

7. Liquefaction

7.9 Cooling Medium

Air Cooling

Sea Water Cooling

Cheap

Expensive

(sea water intake &

required high

quality material)

Corrosion

Problem

No

Yes

(lower availability)

Temperature

High

(larger refrig.

compressor

power)

Low

(smaller refrig.

compressor

power)

Investment

cost

8. Fractionation and LPG Recovery

8.1 Simple LPG Re-injection System

Liquefaction

MCHE Section

Treated

Feed Gas

Scrub

Column

C1

LNG

Refrigerant

Storage

C2

C4

C3

C5+

To Condensate

Storage

Demethanizer

Deethanizer

Depropanizer

Debutanizer

8. Fractionation and LPG Recovery

8.2 Associated LPG Recovery

Liquefaction

MCHE Section

Treated

Feed Gas

C1

LNG

Refrigerant

Storage

C2

LPG Storage

C4

C3

Scrub

Column

Deeper

Sub-cooling

C5+

To Condensate

Storage

Increase LPG

Recovery

Demethanizer

Deethanizer

Depropanizer

Debutanizer

8. Fractionation and LPG Recovery

Pre-Cooling

LNG

Residue Gas

Stabilization

& Treating

Scrub Column Ovhd

8.3 Combined LPG Extraction

Liquefaction

LNG

MCHE Section

Gas

Re-injection

LPG Extraction Unit

NGL Extraction

LPG

LPG

Extraction

Fractionation

C3, C4 and Heavier

Maximize LPG Recovery

Sweet Feed Gas

C3

C4

Condensate

9. LNG Storage and Loading

9.1 Configuration

Suction

Drum

TC

To Fuel

BOG Compressor

PC

BOG

From Loading

Jetty

LNG Tank

LNG Rundown

LNG

To Loading

Jetty

9. LNG Storage and Loading

9.2 LNG Tank

One of Critical Equipment in Cost and Schedule

Recent Technological Trend

Type : Full Containment

Size : Greater than 140,000 m3

Number : Minimized

Possible Application of Single Containment

Site location : Sufficient Safe distance

Risk Assessment : Allowable Option

You might also like

- 生質能簡報Document31 pages生質能簡報Simon ChangNo ratings yet

- 你,是自己的鑰匙:靈媒媽媽的心靈解答書 by Ruowen Huang zDocument198 pages你,是自己的鑰匙:靈媒媽媽的心靈解答書 by Ruowen Huang zJunlin YinNo ratings yet

- LNG ConversionDocument6 pagesLNG Conversionagusrendiw100% (1)

- BS en 1532 LNG Ship To Shore Interface PDFDocument20 pagesBS en 1532 LNG Ship To Shore Interface PDFsnamprogNo ratings yet

- 基于Aspen Plus建立喷流床煤气化炉模型Document4 pages基于Aspen Plus建立喷流床煤气化炉模型qqqNo ratings yet

- Chapter V LNG TransportationDocument144 pagesChapter V LNG TransportationPutu Indra Mahatrisna100% (1)

- Secl - 2. LNG Plant BDocument42 pagesSecl - 2. LNG Plant Bsunilkumar5078100% (1)

- LNG Transport and StorageDocument10 pagesLNG Transport and Storageiran josueNo ratings yet

- LNG Industry 2016-12Document68 pagesLNG Industry 2016-12crystalmanNo ratings yet

- RC443.DS.000.2542.0001 Rev2 - LNG Storage TankDocument12 pagesRC443.DS.000.2542.0001 Rev2 - LNG Storage TankLong Nguyễn HoàngNo ratings yet

- 2006 LNG Fleet p40-44Document5 pages2006 LNG Fleet p40-44Euclid1No ratings yet

- EMSA-Guidance On LNG BunkeringDocument430 pagesEMSA-Guidance On LNG BunkeringyoungfpNo ratings yet

- LNG Conversion SheetDocument9 pagesLNG Conversion SheetAnkit Kumar Ankur100% (1)

- C09001987Document20 pagesC09001987Jonathan WuNo ratings yet

- 液氦储罐发展现状及关键技术 李均方Document4 pages液氦储罐发展现状及关键技术 李均方钱哥No ratings yet

- 低碳烷烃脱氢技术评述 赵万恒Document4 pages低碳烷烃脱氢技术评述 赵万恒Forcus onNo ratings yet

- 精细化工中催化加氢技术的运用Document2 pages精细化工中催化加氢技术的运用董芳儒No ratings yet

- India Nagarjuna JVDocument18 pagesIndia Nagarjuna JVusig881803No ratings yet

- 煤制烯烃项目的煤气化技术对比分析 PDFDocument7 pages煤制烯烃项目的煤气化技术对比分析 PDFSebastian ShengNo ratings yet

- 液化天然气运行和操作.pdf (液化天然气运行和操作.pdf) (Z-Library)Document245 pages液化天然气运行和操作.pdf (液化天然气运行和操作.pdf) (Z-Library)李文毅No ratings yet

- 2.4 文献总结报告Document17 pages2.4 文献总结报告殷迪No ratings yet

- Duvernay FieldDocument11 pagesDuvernay Fieldjesf_2014No ratings yet

- 2017 Directory of China's LNG Plants PDFDocument2 pages2017 Directory of China's LNG Plants PDFarapublicationNo ratings yet

- 20&Times;10 Sup 4 Sup +m Sup 3 Sup +LNG+储罐的设计与建造Document4 pages20&Times;10 Sup 4 Sup +m Sup 3 Sup +LNG+储罐的设计与建造won choiNo ratings yet

- Recirculating Process of Pellet Exhaust Gas From Grate-Kiln and Numerical SimulationDocument7 pagesRecirculating Process of Pellet Exhaust Gas From Grate-Kiln and Numerical SimulationCésar Noriega MendozaNo ratings yet

- 固体储热技术现状及挑战Document35 pages固体储热技术现状及挑战Alien liuNo ratings yet

- QSY 06014.1-2016 油气田地面工程给排水设计规范 第1部分:通则Document6 pagesQSY 06014.1-2016 油气田地面工程给排水设计规范 第1部分:通则叶芊No ratings yet

- Nb/t 1001-2011 液化天然气 (Lng) 汽车加气站技术规范 (正式版)Document72 pagesNb/t 1001-2011 液化天然气 (Lng) 汽车加气站技术规范 (正式版)ccq0707No ratings yet

- 加氢裂化装置换热网络优化Document11 pages加氢裂化装置换热网络优化董芳儒No ratings yet

- 纯电动汽车CO2 热泵空调及整车热管理概述Document12 pages纯电动汽车CO2 热泵空调及整车热管理概述董豪豪No ratings yet

- 2017 Directory of China's LNG Terminals PDFDocument1 page2017 Directory of China's LNG Terminals PDFarapublicationNo ratings yet

- 2011 丙烷脱氢生产丙烯技术进展Document4 pages2011 丙烷脱氢生产丙烯技术进展gpcshfNo ratings yet

- 2.1 实施总结报告Document14 pages2.1 实施总结报告殷迪No ratings yet

- DOC与DPF结合在柴油机后处理上的应用研究 梁曦 PDFDocument1 pageDOC与DPF结合在柴油机后处理上的应用研究 梁曦 PDFzhenguo Dong0% (1)

- PDH丙烷脱氢工艺流程介绍Document37 pagesPDH丙烷脱氢工艺流程介绍yuxiulieNo ratings yet

- 实现裂解焦油制丁辛醇生产110天不停车 国产气化炉烧嘴使用寿命延长Document1 page实现裂解焦油制丁辛醇生产110天不停车 国产气化炉烧嘴使用寿命延长董芳儒No ratings yet

- Absorption ChillersDocument46 pagesAbsorption ChillersHonda WuNo ratings yet

- Microsoft Word - 台電訓練教材-吸收式Document46 pagesMicrosoft Word - 台電訓練教材-吸收式Honda WuNo ratings yet

- 2023:郑州市天然气储运有限公司豫中LNG应急储备中心项目竣工环境保护验收监测报告表Document82 pages2023:郑州市天然气储运有限公司豫中LNG应急储备中心项目竣工环境保护验收监测报告表arapublicationsNo ratings yet

- 二氧化碳储能技术研究现状与发展前景Document12 pages二氧化碳储能技术研究现状与发展前景mike.tangNo ratings yet

- 锂离子电池用氧化亚硅负极材料表面碳包覆技术研究 陈怀德Document83 pages锂离子电池用氧化亚硅负极材料表面碳包覆技术研究 陈怀德James ChengNo ratings yet

- (42) 小型天然气转化制氢装置长周期运行总结Document4 pages(42) 小型天然气转化制氢装置长周期运行总结Cary zhNo ratings yet

- 【培训】液氮泵车产品推介 【讲师傅连松】 (副本)Document41 pages【培训】液氮泵车产品推介 【讲师傅连松】 (副本)WEI SHANGNo ratings yet

- 风电制氢 3Document7 pages风电制氢 3Bingfei HeNo ratings yet

- ùÓÚAspen EDR Ä Ü¿ÇÊ ÈÈÆ÷ ÄÉè ÆDocument3 pagesùÓÚAspen EDR Ä Ü¿ÇÊ ÈÈÆ÷ ÄÉè ÆMogahid OsmanNo ratings yet

- 相变储热技术研究进展Document21 pages相变储热技术研究进展ywain86No ratings yet

- 核废料玻璃固化国际研究进展Document8 pages核废料玻璃固化国际研究进展Lejing ZhangNo ratings yet

- (11) 第參篇 我國重點能源科技研發動向及策略 (第二章第二節)Document17 pages(11) 第參篇 我國重點能源科技研發動向及策略 (第二章第二節)21 522No ratings yet

- 量子节能器的设计及节油降耗应用Document3 pages量子节能器的设计及节油降耗应用shexinyejianNo ratings yet

- UntitledDocument40 pagesUntitled21412林詣臻No ratings yet

- 1 博迈科技术标书v7.12.15Document144 pages1 博迈科技术标书v7.12.15Tao QuNo ratings yet

- World LNG Plant & TerminalsDocument4 pagesWorld LNG Plant & TerminalsChin Boon WoiNo ratings yet

- 二氧化碳捕捉、封存、再利用技術的產業應用現況Document7 pages二氧化碳捕捉、封存、再利用技術的產業應用現況tsrcNo ratings yet

- 01 清華大學 鄭西顯教授Document27 pages01 清華大學 鄭西顯教授YuuNo ratings yet

- 超临界二氧化碳在核反应堆系统中的应用 黄彦平Document7 pages超临界二氧化碳在核反应堆系统中的应用 黄彦平jing qiangNo ratings yet

- 蒸汽鍋爐高效率作業技術手冊Document67 pages蒸汽鍋爐高效率作業技術手冊呂仲書No ratings yet

- 煤基燃料油品特性与煤制油产业发展分析Document9 pages煤基燃料油品特性与煤制油产业发展分析Zhen YuanNo ratings yet

- 16788692623281nDocument8 pages16788692623281nhailin wangNo ratings yet

- 台中發電廠新建燃氣機組計畫說明 第三次專案小組初審會議Document112 pages台中發電廠新建燃氣機組計畫說明 第三次專案小組初審會議環境資訊中心公共檔案區100% (1)

- 加氢工艺技术生产变压器油的研究 王海军Document5 pages加氢工艺技术生产变压器油的研究 王海军Jicheng PiaoNo ratings yet

- 112.06.20【報告案2簡報】氫能關鍵戰略行動計畫辦理情形 經濟部Document16 pages112.06.20【報告案2簡報】氫能關鍵戰略行動計畫辦理情形 經濟部tap.jackson6255No ratings yet

- 光纤通信原理与技术Document75 pages光纤通信原理与技术c12345No ratings yet

- IM DECS100 ChineseDocument98 pagesIM DECS100 ChineseTran SangNo ratings yet

- 100025 图书 电磁类 特斯拉类 特斯拉的"增加人类能量的问题"Document22 pages100025 图书 电磁类 特斯拉类 特斯拉的"增加人类能量的问题"自由星光No ratings yet

- 能源效率評估︰ 概念與實務Document94 pages能源效率評估︰ 概念與實務billNo ratings yet

- GB 1094.3 绝缘水平、绝缘试验和外绝缘空气间隙Document41 pagesGB 1094.3 绝缘水平、绝缘试验和外绝缘空气间隙Huang HanNo ratings yet